Preparation method of instant-dissolving type effervescent salt tablet

An instant, effervescent technology, applied in skin care preparations, pharmaceutical formulations, cosmetic preparations, etc., can solve problems such as inappropriateness, foot soaking effect and feeling discount, slow dissolution rate, etc., to achieve comprehensive effect improvement , The dissolution speed is fast, and the effect of accelerating the dissolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

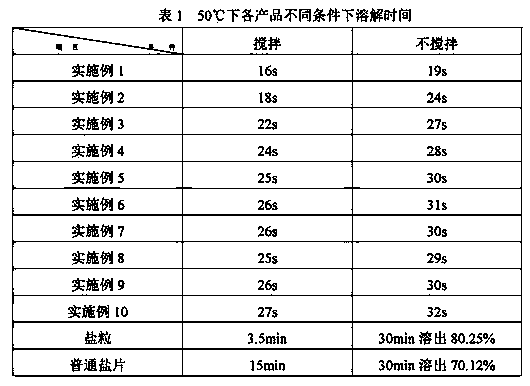

Examples

Example Embodiment

[0034] Example 1:

[0035] The preparation method of instant effervescent salt tablet of the present invention, the detailed steps of the preparation method are as follows:

[0036] a. Using sodium chloride as the basic raw material, citric acid as the acid source, sodium bicarbonate as the alkali source, 10% polyvinylpyrrolidone-ethanol solution as the binder, polyethylene glycol 4000 as the lubricant, and lactose and The mixture of polyvinylpyrrolidone and PVP (the weight mixing ratio between the two is 1:1); the basic raw material sodium chloride is food grade, and its mass percentage is ≥91%; the sodium chloride is used before use The pulverizer pulverizes and passes through a 60-mesh sieve after pulverization to obtain sodium chloride powder;

[0037] Expressed in parts by weight, the raw material composition of the instant effervescent salt tablet is: 35 parts of sodium chloride powder, 1.0 part of 10% polyvinylpyrrolidone-ethanol solution, 1 part of a mixture of lactose and p...

Example Embodiment

[0044] Embodiment 2: It is basically the same as Embodiment 1, except that:

[0045] In step a: using sodium chloride particles (with a particle size of 0.1 to 3.5 mm) as the basic raw material, using malic acid as the acid source, sodium carbonate as the alkali source, and polyethylene glycol 6000 as the lubricant;

[0046] Expressed in parts by weight, the raw material composition of the instant effervescent salt tablet is: 35 parts of sodium chloride particles, 1.5 parts of 10% polyvinylpyrrolidone-ethanol solution, 0.2 parts of a mixture of lactose and polyvinylpyrrolidone PVP, apple 7 parts of acid, 7 parts of sodium carbonate and 1 part of polyethylene glycol 6000;

[0047] In step b: the mixture of part of lactose and polyvinylpyrrolidone PVP is 45% of the total mixture weight;

[0048] In step c: the drying temperature is 50°C, and the drying time is 80 min;

[0049] In step d: the drying temperature is 50°C, and the drying time is 80min;

[0050] In step e: the pressure during ...

Example Embodiment

[0051] Embodiment 3: It is basically the same as Embodiment 1, except that:

[0052] In step a: using sodium chloride particles (with a particle size of 0.1 to 3.5 mm) as the basic raw material, using tartaric acid as the acid source, potassium bicarbonate as the alkali source, and polyethylene glycol 4000 as the lubricant;

[0053] Expressed in parts by weight, the raw material composition of the instant effervescent salt tablet is: 40 parts of sodium chloride particles, 1.5 parts of 10% polyvinylpyrrolidone-ethanol solution, 0.8 parts of a mixture of lactose and polyvinylpyrrolidone PVP, tartaric acid 8 parts, 8 parts potassium bicarbonate and 1.5 parts polyethylene glycol 4000;

[0054] In step b: the mixture of part of lactose and polyvinylpyrrolidone PVP is 30% of the total mixture weight;

[0055] In step c: the drying temperature is 45°C, and the time is 90 minutes;

[0056] In step d: the drying temperature is 45°C, and the time is 90 minutes;

[0057] In step e: the pressure du...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com