Afterheat recovery method and special appts for silcon ore furnace fume purification and nano si02 micro powder

A special equipment and flue gas purification technology, applied in chemical instruments and methods, lighting and heating equipment, separation methods, etc., can solve the problems of large equipment structure, increased dust removal fan power and operating costs, difficulty in improving the grade of silicon products, etc. , to achieve a good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

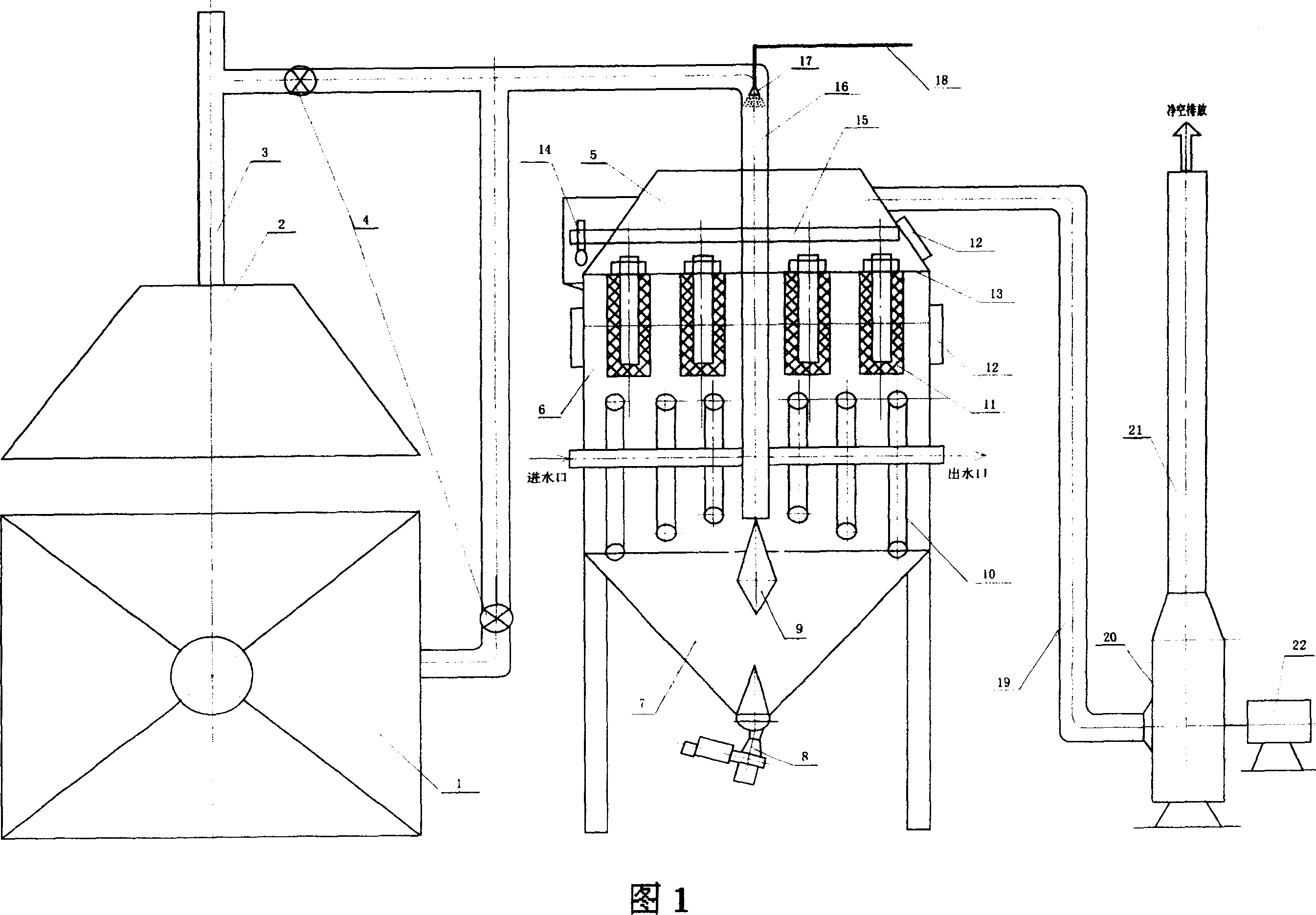

[0021] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0022] In Fig. 1, the dust generation mechanism of silicon submerged arc furnace 1: the production of industrial silicon, ferrosilicon, silicon manganese, silicon calcium is in the high temperature reducing atmosphere of submerged arc furnace, high-purity SiO 2 It is prepared by reacting CaO with coke. In SiO 2 During the reduction reaction with CaO, a large amount of SiO and CO gas escape from the material surface, and gaseous SiO and O in the air 2 The reaction produces free SiO 2 Micronized powder, namely:

[0023] SiO 2 +C=SiO+CO

[0024] CaO+3C=CaC 2 +CO

[0025] 5SiO 2 +2CaC 2 =3Si+2CaSiO 3 +4CO

[0026] SiO+1 / 2O 2 = SiO 2

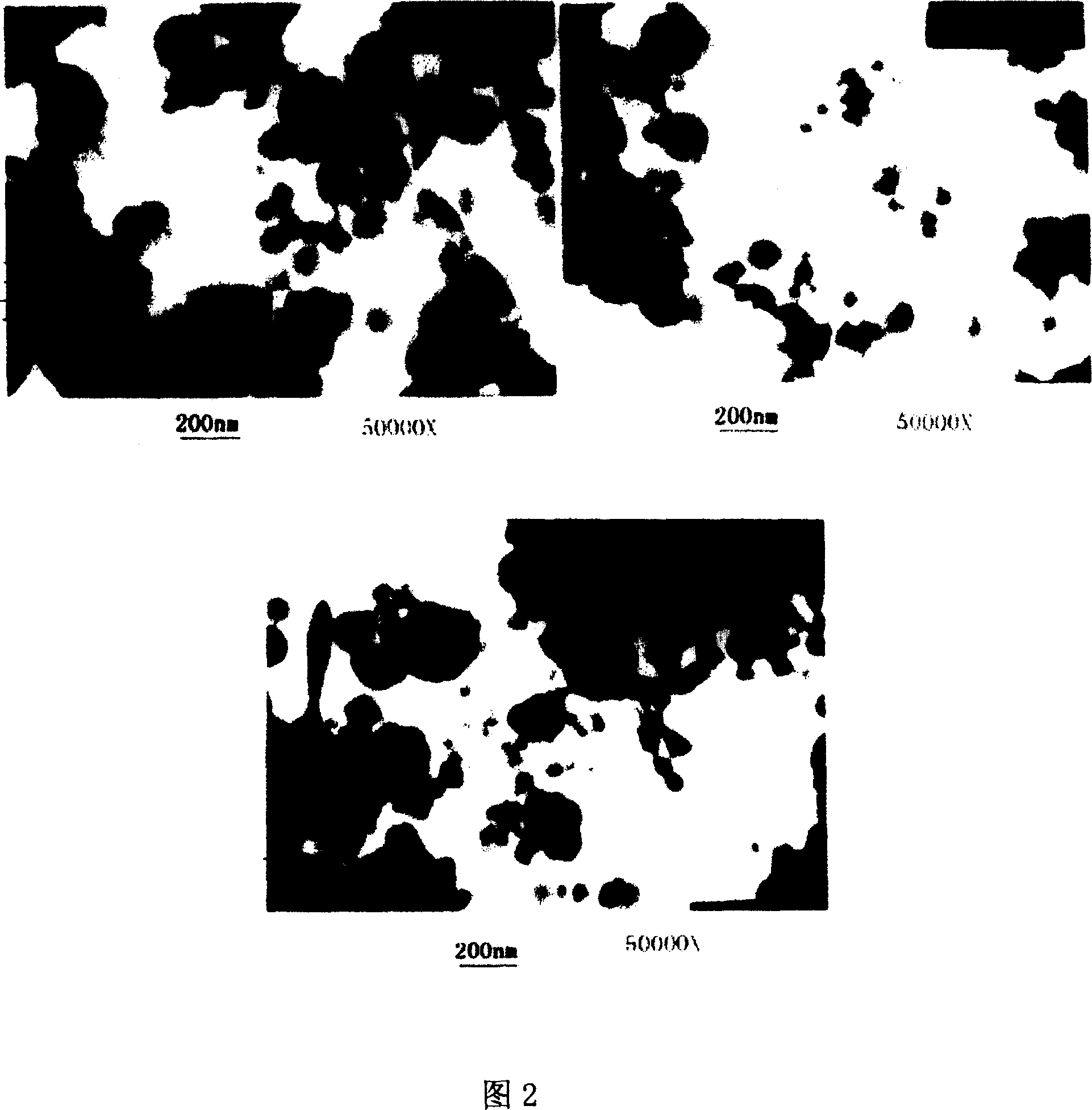

[0027] The inventor shows through sampling test that industrial silicon submerged arc furn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com