Planted roof root-resistance waterproof roll and production process thereof

A waterproofing membrane, root puncture-resistant technology, applied in the direction of roofing, roof covering, roofing using flexible materials, etc. The effect of good effect, strong impact resistance and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

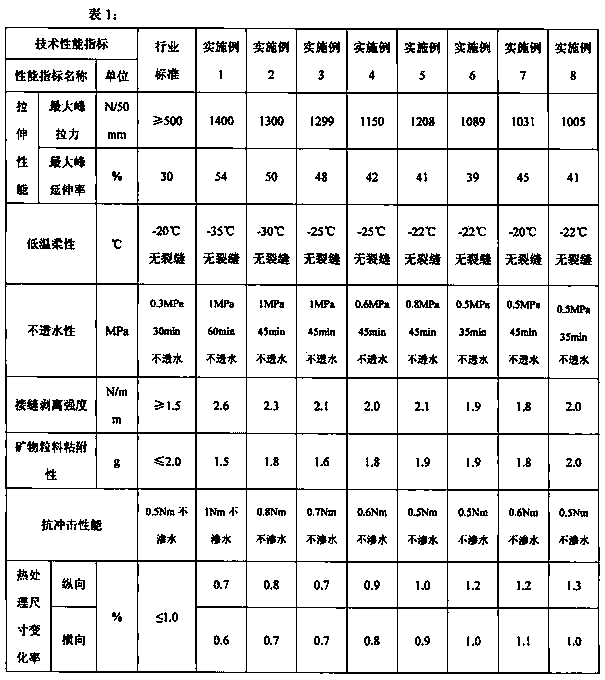

Examples

Embodiment 1

[0030] The invention relates to a root puncture-resistant waterproof membrane for planting roofs, which comprises a copper foil layer, an asphalt layer and a composite layer.

[0031] A planting roof root-penetration-resistant feng shui coiled material, calculated by weight, comprising 29 parts in total of 90# road asphalt, 70# road asphalt and 100# road asphalt in a mixing ratio of 3:2:1, 4 parts of SBS, 4 parts of SBR, 5 parts of APP, 20 parts of biodiesel, second-line oil and epoxidized soybean oil with a ratio of 4:3:2, 4 parts of aluminum hydroxide with a purity of 98.5%, 11 parts of anti-migration plasticizer, polyvinyl chloride resin 23.5 parts, 9 parts of Portland cement powder, 1.1 parts of nano-zinc oxide, 3 parts of dibasic lead phosphite, 5 parts of ternary vinyl chloride resin, 3 parts of ABS resin, 19 parts of 909 antifreeze adhesive glue, length 11 parts of polypropylene fiber filaments with a diameter of 2 cm and a diameter of 0.05 mm and 1.0 parts of a chemica...

Embodiment 2

[0044] On the basis of Example 1, under the condition that the components of the composition remain unchanged, the mixing ratio of each component in the waterproof membrane is changed as follows: 90# road asphalt and 70# road asphalt with a mixing ratio of 3:2:1 28 parts of 100# road asphalt, 2 parts of SBS, 3 parts of SBR, 1.6 parts of APP, 15 parts of biodiesel, second line oil and epoxidized soybean oil with a ratio of 4:3:2, hydrogen with a purity of 98.5% 3 parts of alumina, 10 parts of anti-migration plasticizer, 23 parts of polyvinyl chloride resin, 8 parts of Portland cement powder, 1.0 part of nano zinc oxide, 1 part of dibasic lead phosphite, 2 parts of tertiary vinyl chloride resin , 1 part of ABS resin, 15 parts of 909 antifreeze adhesive glue, 10 parts of polypropylene fiber filaments with a length of 2 cm and a diameter of 0.05 mm, and 0.8 parts of chemical root inhibitor; The copper base is copper foil, and the thickness of the copper foil is 2OZ type of 0.07mm....

Embodiment 3

[0046] On the basis of Example 1, under the condition that the components of the composition remain unchanged, the mixing ratio of each component in the waterproof membrane is changed as follows: 90# road asphalt and 70# road asphalt with a mixing ratio of 3:2:1 A total of 30 parts of 100# road asphalt, 6 parts of SBS, 6 parts of SBR, 7 parts of APP, a total of 23 parts of biodiesel, second-line oil and epoxy soybean oil with a ratio of 4:3:2, aluminum hydroxide with a purity of 98.5% 6 parts, 13 parts of anti-migration plasticizer, 24 parts of polyvinyl chloride resin, 10 parts of Portland cement powder, 1.2 parts of nano-zinc oxide, 5 parts of dibasic lead phosphite, 8 parts of ternary vinyl chloride resin, ABS 5 parts of resin, 22 parts of 909 anti-freezing adhesive glue, 12 parts of polypropylene fiber filaments with a length of 2 cm and a diameter of 0.05 mm, and 1.2 parts of chemical root-blocking agent; The base is copper foil, and the thickness of the copper foil is 2O...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com