Oil-solubility carbon quantum dots (OCDs), PMMA-coated OOCDs, and preparation method and application thereof

A carbon quantum dot, oil-soluble technology, applied in chemical instruments and methods, nanotechnology for materials and surface science, nanotechnology, etc., can solve problems such as no further development and application, and achieve excellent optical transparency, good dispersion Sexual and luminous performance, small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

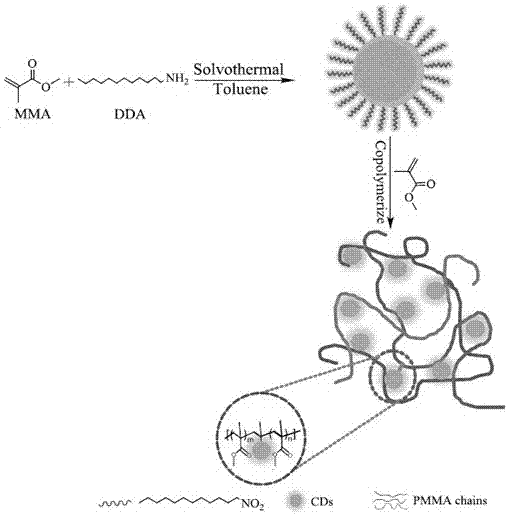

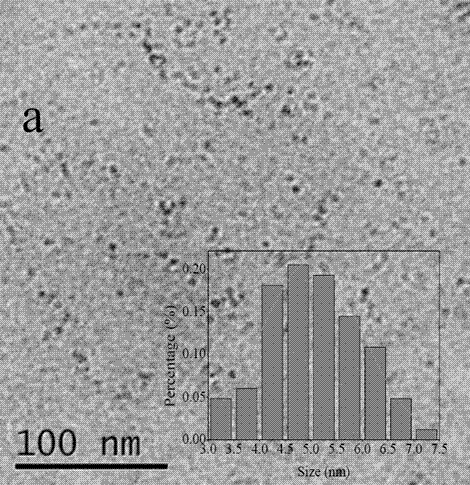

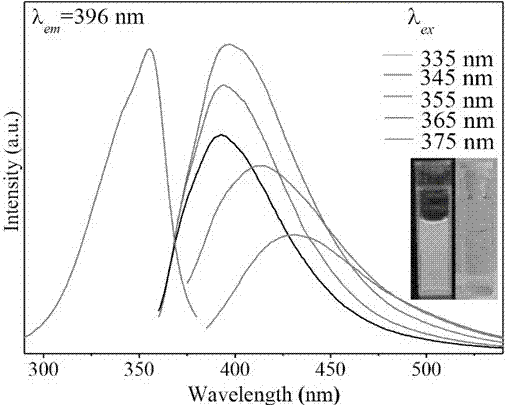

[0031] 1. Synthesis of OOCDs

[0032] As shown below, methyl methacrylate (MMA) was used as a single precursor to synthesize oil-soluble carbon quantum dots (OOCDs) in one step: 5.30 ml of methyl methacrylate (MMA) and 2.97 ml of dodecylamine (DDA ), and 2ml of NH 3 ·H 2 O was added to 20ml of toluene respectively, sealed in a 100ml stainless steel autoclave with a polytetrafluoroethylene liner, and reacted at 180°C for 2 hours respectively. From the appearance of the final reaction, there are oil-soluble nanoparticles and oil-soluble residues.

[0033] The product was purified to remove dodecylamine (DDA) and methyl methacrylate (MMA) residues. Therefore, each product was washed with 20ml of water and 20ml of ethanol, and the obtained emulsion was centrifuged at 10000r / min with a centrifuge to separate and remove the lower layer solution. This process was repeated twice. Then add 20ml of pure water to wash twice, and the obtained organic product is further dialyzed in dia...

Embodiment 2

[0037] 1. Synthesis of OOCDs

[0038]Oil-soluble carbon quantum dots (OOCDs) were synthesized in one step using methyl methacrylate (MMA) as a single precursor as follows: 5.30 ml of methyl methacrylate (MMA) and 5.94 ml of dodecylamine (DDA ), and 2 ml of NH 3 ·H 2 O was added to 20 ml of toluene, sealed in a 100 ml stainless steel autoclave lined with polytetrafluoroethylene, and then reacted at 200 °C for 4 hours. From the appearance of the final reaction, there are oil-soluble nanoparticles and oil-soluble residues.

[0039] The product was purified to remove dodecylamine (DDA) and methyl methacrylate (MMA) residues. Therefore, each product was washed with 20 ml of water and 20 ml of ethanol, and the obtained emulsion was centrifuged with a centrifuge at 10,000 r / min to separate and remove the lower layer solution. This process was repeated twice. 20 ml of pure water was added to wash twice, and the obtained organic product was further dialyzed in a dialysis tube for 2...

Embodiment 3

[0043] 1. Synthesis of OOCDs

[0044] Oil-soluble carbon quantum dots (OOCDs) were synthesized in one step using methyl methacrylate (MMA) as a single precursor as follows: 5.30 ml of methyl methacrylate (MMA) and 11.88 ml of dodecylamine (DDA ), and 4 ml of NH 3 ·H 2 O was added to 20 ml of toluene, sealed in a 100 ml stainless steel autoclave lined with polytetrafluoroethylene, and then reacted at 220 °C for 6 hours. From the appearance of the final reaction, there are oil-soluble nanoparticles and oil-soluble residues.

[0045] The product was purified to remove dodecylamine (DDA) and methyl methacrylate (MMA) residues. Therefore, each product was washed with 20 ml of water and 20 ml of ethanol, and the obtained emulsion was centrifuged with a centrifuge at 10,000 r / min to separate and remove the lower layer solution. This process was repeated twice. 20 ml of pure water was added to wash twice, and the obtained organic product was further dialyzed in a dialysis tube for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com