Anti-aging polypropylene material based on fiber reinforcement and preparation method thereof

A polypropylene material and fiber-reinforced technology, applied in the field of polypropylene, can solve the problems of short service life, poor aging resistance and anti-ultraviolet performance of polypropylene materials, and affect compatibility, so as to ensure service life and improve anti-aging Performance, the effect of improving dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

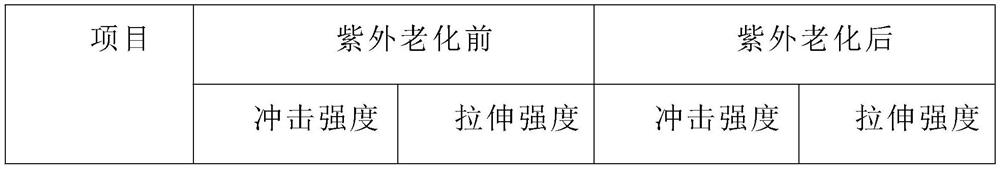

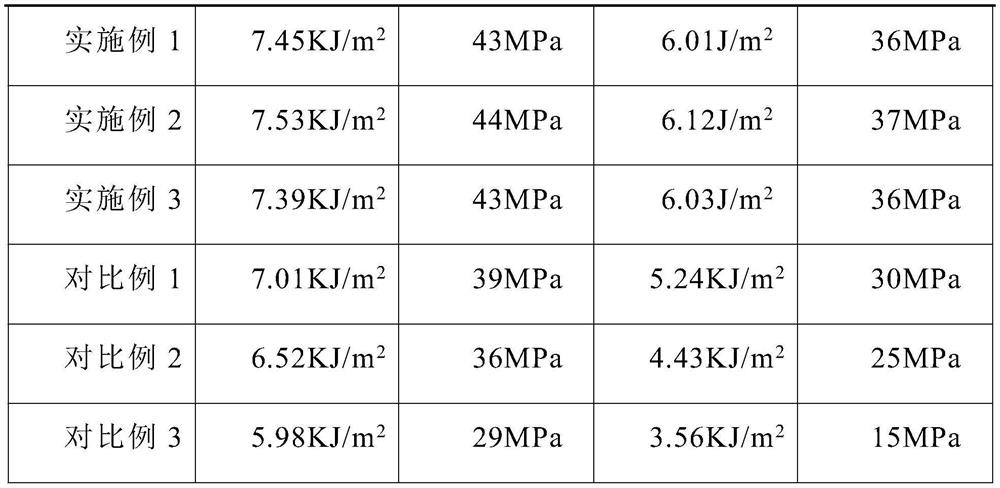

Examples

Embodiment 1

[0047] S1: Prepare materials;

[0048] S2: Preparation of modified zinc oxide:

[0049] Take zinc acetate, sodium hydroxide, and deionized water to dissolve, stir for 10 minutes, add glycerol, continue stirring for 10 minutes, heat up to 180°C in a closed environment, react for 24 hours, cool, wash and dry, and obtain nano-zinc oxide;

[0050] Take nanometer zinc oxide, dissolve it in ethanol, stir for 5 minutes, add tetraethyl orthosilicate at 25°C, ultrasonically disperse for 20 minutes, stir for 6 hours, add n-hexane after stirring, centrifuge, wash with ethanol, and dry at 60°C to obtain modified zinc oxide ;

[0051] S3: Preparation of anti-aging agent:

[0052] Take 1 / 2 amount of wood fiber, soak it in silane coupling agent, mix and stir for 10min, dry for 10h to get wood fiber A; take 1 / 2 amount of wood fiber, soak it in sodium hydroxide solution for 24h, wash with deionized water When the pH is 7, wood fiber B is obtained; carbon fiber is placed in acetone solution,...

Embodiment 2

[0062] S1: Prepare materials;

[0063] S2: Preparation of modified zinc oxide:

[0064] Take zinc acetate, sodium hydroxide, and deionized water to dissolve, stir for 12 minutes, add glycerol, continue stirring for 11 minutes, heat up to 182°C in a closed environment, react for 26 hours, cool, wash and dry, and obtain nano-zinc oxide;

[0065] Take nano-zinc oxide, dissolve it in ethanol, stir for 8 minutes, add tetraethyl orthosilicate at 27°C, ultrasonically disperse for 23 minutes, stir for 6.5 hours, add n-hexane after stirring, centrifuge, wash with ethanol, and dry at 60°C to obtain modified oxide Zinc;

[0066] S3: Preparation of anti-aging agent:

[0067] Take 1 / 2 of the wood fiber, soak it in the silane coupling agent, mix and stir for 12 minutes, and dry it for 11 hours to obtain wood fiber A; take 1 / 2 of the wood fiber, soak it in sodium hydroxide solution for 25 hours, wash it with deionized water When the pH was 7, wood fiber B was obtained; carbon fiber was pl...

Embodiment 3

[0077] S1: Prepare materials;

[0078] S2: Preparation of modified zinc oxide:

[0079] Take zinc acetate, sodium hydroxide, and deionized water to dissolve, stir for 15 minutes, add glycerol, continue stirring for 12 minutes, heat up to 185°C in a closed environment, react for 28 hours, cool, wash and dry, and obtain nano-zinc oxide;

[0080] Take nanometer zinc oxide, dissolve it in ethanol, stir for 10 minutes, add tetraethyl orthosilicate at 28°C, ultrasonically disperse for 25 minutes, stir for 7 hours, add n-hexane after stirring, centrifuge, wash with ethanol, and dry at 60°C to obtain modified zinc oxide ;

[0081] S3: Preparation of anti-aging agent:

[0082] Take 1 / 2 amount of wood fiber, soak it in silane coupling agent, mix and stir for 15 minutes, dry for 12 hours to obtain wood fiber A; take 1 / 2 amount of wood fiber, soak it in sodium hydroxide solution for 26 hours, wash with deionized water When the pH is 7, wood fiber B is obtained; carbon fiber is taken, p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com