Stainless steel based metal fiber porous material with high specific surface area and preparation method thereof

A technology of high specific surface area and porous materials, which is applied in the field of preparation of stainless steel-based metal fiber porous materials, can solve the problems of inapplicability of high specific surface SMFM and damage to fiber surface microstructure, etc., and achieve good mechanical properties, high specific surface area, high The effect of surface energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

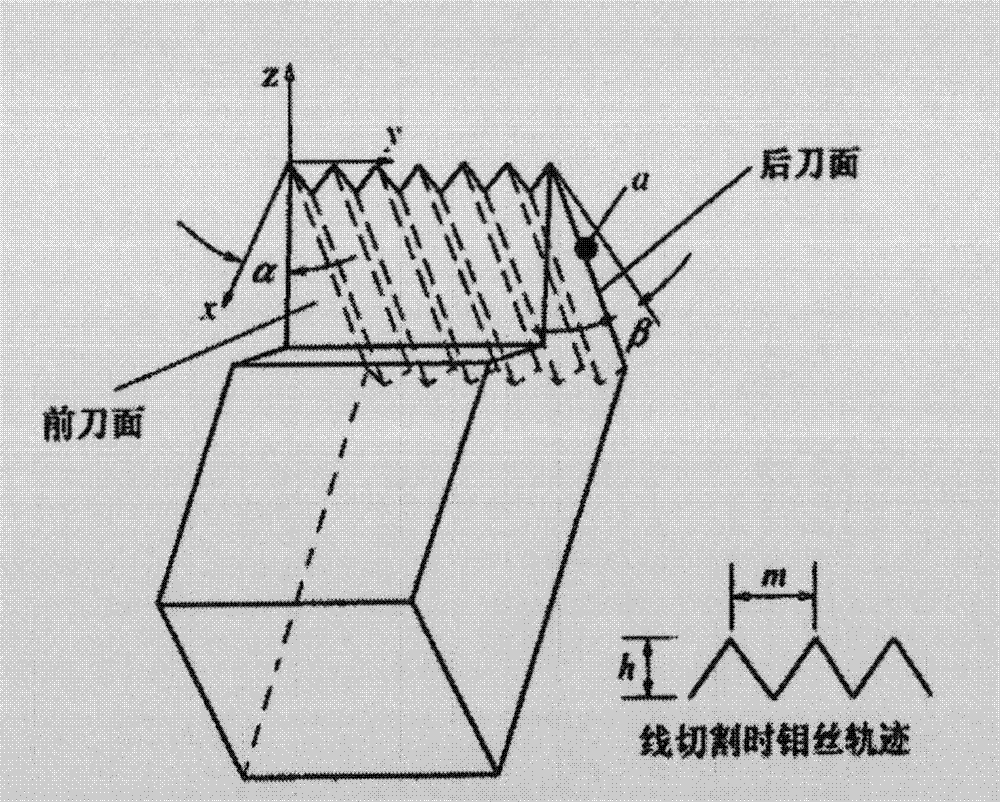

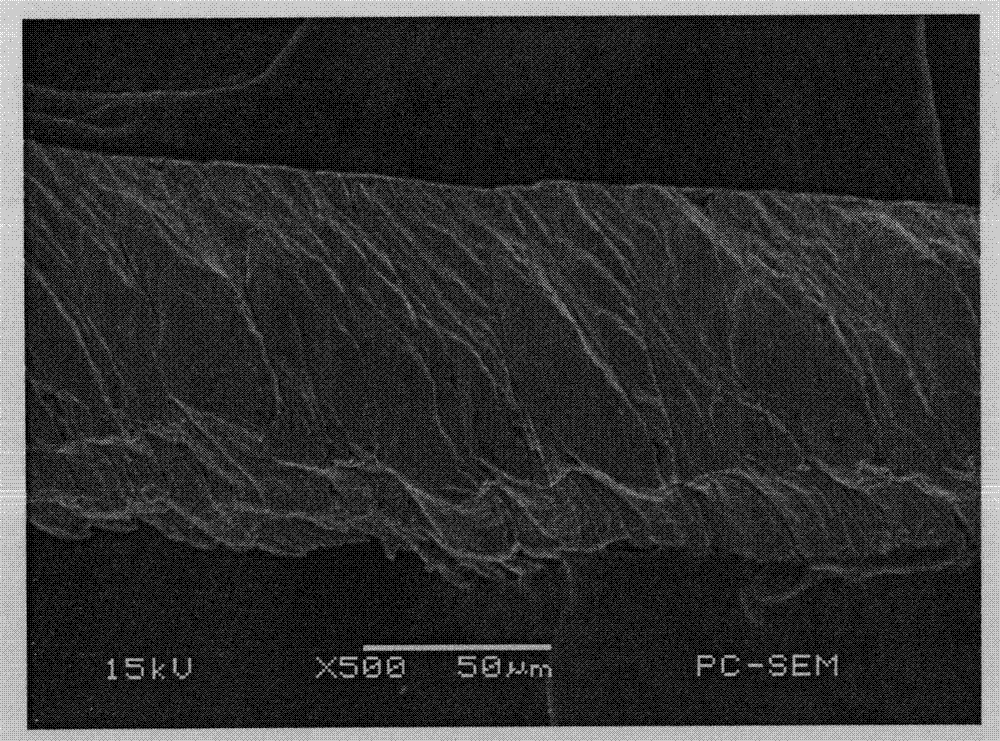

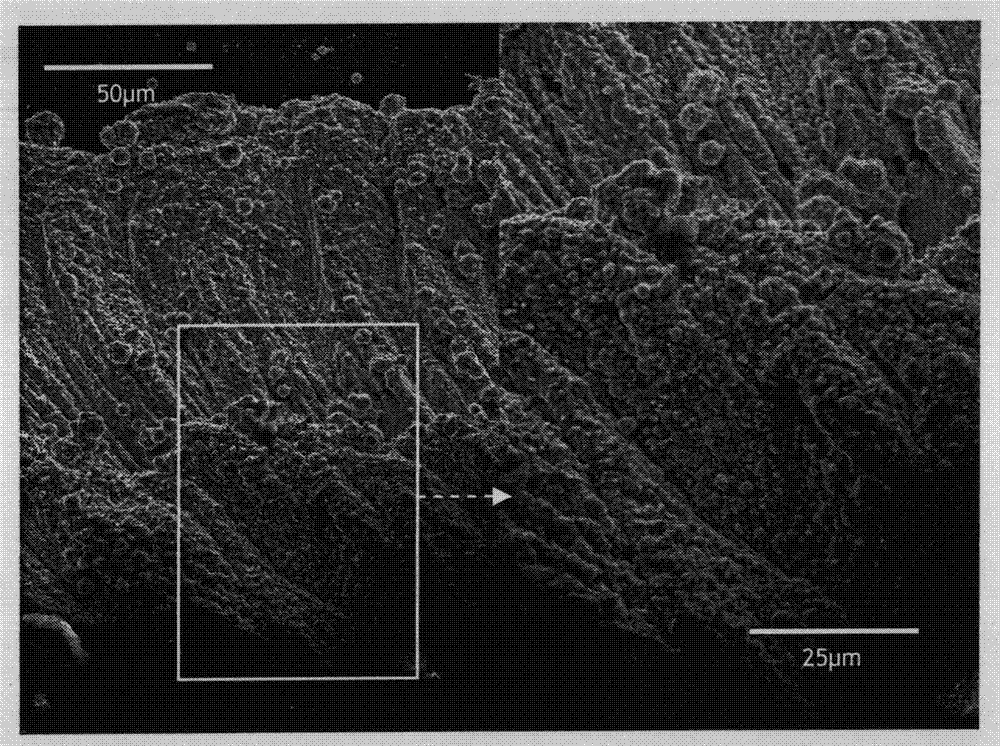

[0028] The first step is to process stainless steel fibers. The Φ60×400mm long stainless steel rod is clamped on the CM6140 lathe, and the rough part of the surface of the stainless steel rod is firstly cut off with an ordinary cylindrical turning tool. Secondly, use a multi-tooth tool with a large blade inclination to turn stainless steel fibers. The tool structure is as follows figure 1 Shown (see patent No. 200610124078.x Figure 4 and the introduction in the embodiment), the tool material is high-speed steel, and the main cutting edge composed of a plurality of S-shaped small teeth is processed by wire cutting, the tooth pitch m=0.3mm, and the tooth height h=0.2mm. The process of making stainless steel fiber by using the multi-tooth tool with large blade inclination angle is as follows: install the tool on the tool holder, the tool installation angle is 45°, and adjust the tool height. The cutting parameters are as follows: feed rate f=0.1mm / r, back cutting amount a p =...

Embodiment 2

[0034]The first step is to process stainless steel fibers. The Φ60×400mm long stainless steel rod is clamped on the CM6140 lathe, and the rough part of the surface of the stainless steel rod is firstly cut off with an ordinary cylindrical turning tool. Secondly, use a multi-tooth tool with a large blade inclination to turn stainless steel fibers. The tool structure is as follows figure 1 As shown, the tool material is high-speed steel, and the main cutting edge composed of multiple small teeth is processed by wire cutting, the tooth pitch m=0.3mm, and the tooth height h=0.2mm. Such as figure 2 The process of manufacturing stainless steel fiber with the multi-tooth cutter shown is as follows: install the cutter on the cutter holder, the installation angle of the cutter is 45°, and adjust the height of the cutter. The cutting parameters are as follows: feed rate f=0.1mm / r, back cutting amount a p =0.2mm, cutting speed v=13.19m / min, cutting condition is dry cutting. The cont...

Embodiment 3

[0040] The first step is to process stainless steel fibers. The Φ60×400mm long stainless steel rod is clamped on the CM6140 lathe, and the rough part of the surface of the stainless steel rod is firstly cut off with an ordinary cylindrical turning tool. Secondly, use a multi-tooth tool with a large blade inclination to turn stainless steel fibers. The tool structure is as follows figure 1 As shown, the tool material is high-speed steel, and the main cutting edge composed of multiple small teeth is processed by wire cutting, the tooth pitch m=0.3mm, and the tooth height h=0.2mm. Such as figure 2 The process of manufacturing stainless steel fiber with the multi-tooth cutter shown is as follows: install the cutter on the cutter holder, the installation angle of the cutter is 45°, and adjust the height of the cutter. The cutting parameters are as follows: feed rate f = 0.15mm / r, back cutting amount a p =0.1mm, cutting speed v=13.19m / min, cutting condition is dry cutting. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| shear load | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com