A kind of preparation method of nano aluminum oxide thin film

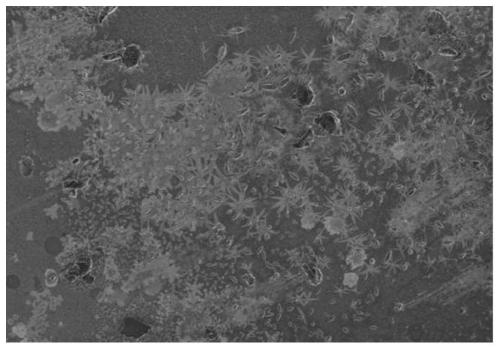

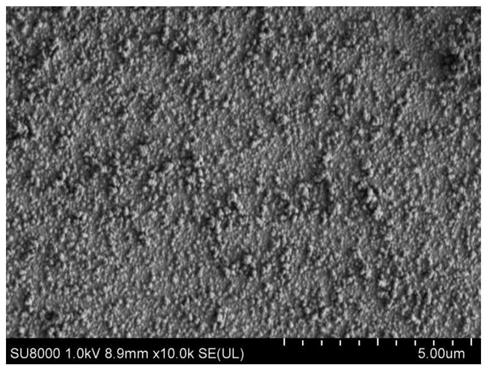

A nano-alumina and thin-film technology, which is applied to the preparation of aluminum hydroxide, chemical instruments and methods, aluminum compounds, etc., can solve the problems of high reaction temperature and complicated process, and achieve low reaction temperature, simple process, and rich surface morphology Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] A kind of preparation method of nano aluminum oxide thin film of the present invention, specifically implement according to the following steps:

[0033] Step 1. Dissolve aluminum nitrate and urea in deionized water, add the cleaned silicon chip, condense and reflux in a water bath, then take out the silicon chip, and after drying, there is a layer of Al(OH) with a diffraction spectrum on the surface of the silicon chip. ) 3 thermal dehydration film;

[0034] The size of the silicon chip is preferably 5mm × 5mm, and the silicon chip will be cleaned before use. The cleaning process is: the silicon chip will be put into the Piranha solution first, and then boiled in an oil bath at 100°C to 110°C for 11h to 13h ( Seal the mouth of the container with aluminum foil during cooking to prevent the solution from being too hot to splash out), and finally soak and clean the silicon wafer with ethanol;

[0035] Piranha (piranha) solution is composed of concentrated sulfuric acid ...

Embodiment 1

[0050] Put a 5mm×5mm silicon chip into Piranha solution (constituted by mixing concentrated sulfuric acid and hydrogen peroxide at a volume ratio of 7:3), boil it in an oil bath at 100°C for 11 hours, and finally soak and clean the silicon chip with ethanol spare;

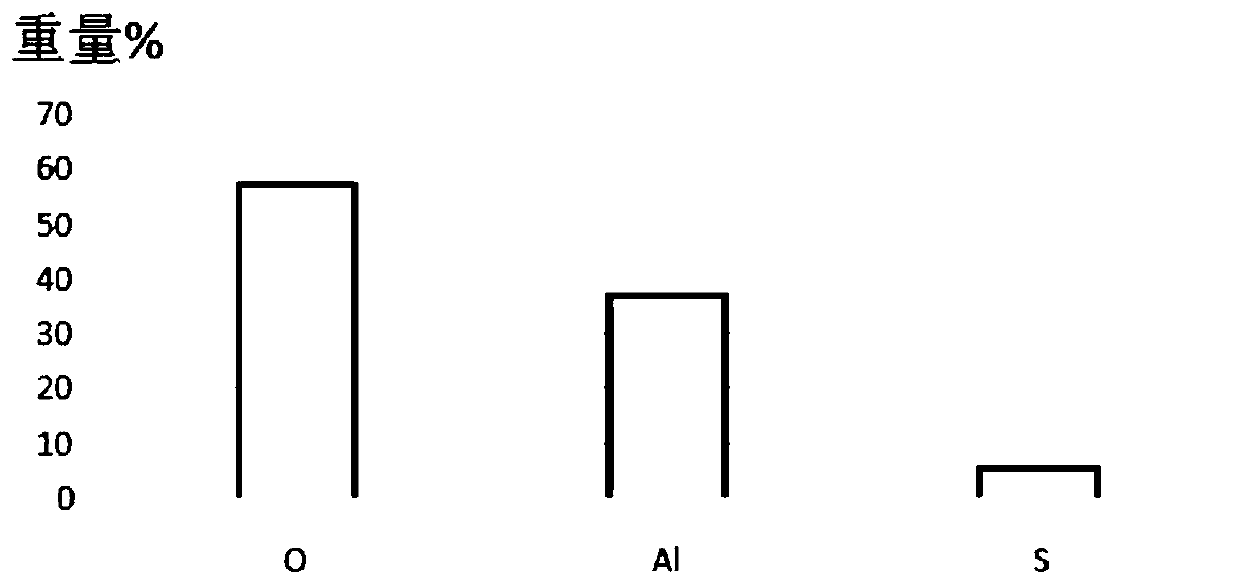

[0051] Dissolve aluminum nitrate and urea in deionized water and add to the cleaned silicon wafer. The mass ratio of aluminum nitrate to urea is 3.55:1; Ionized water; condensed and refluxed at 80°C for 2 hours in a water bath, during which the stirring speed was controlled at 25r / min; the silicon wafer was taken out and placed in a 100°C drying oven to heat and dry for 1 hour, and there was a layer of Al with a diffraction spectrum on the surface of the silicon wafer ( Oh) 3 thermal dehydration film;

[0052]Put the above treated silicon wafers into a polytetrafluoroethylene hydrothermal reaction kettle, add deionized water, wherein the mass ratio of deionized water to silicon wafers is 0.5:1, and conduct hydrot...

Embodiment 2

[0056] Put a 5mm×5mm silicon wafer into Piranha solution (concentrated sulfuric acid and hydrogen peroxide mixed at a volume ratio of 7:3), boil in an oil bath at 105°C for 11.5 hours, and finally soak the silicon wafer in ethanol, cleaning spare;

[0057] Dissolve aluminum nitrate and urea in deionized water and add to the cleaned silicon wafer. The mass ratio of aluminum nitrate to urea is 3.56:1; the standard for adding deionized water is: for every gram of the mixture of aluminum nitrate and urea, add 10.5ml Deionized water; condensed and refluxed at 82°C for 2.5 hours in a water bath, with a stirring speed of 15r / min, took out the silicon wafer and placed it in a drying oven at 100°C for 65 minutes, and there was a layer of Al(OH) with a diffraction spectrum on the surface of the silicon wafer ) 3 Thermal dehydration film;

[0058] Put the above-mentioned treated silicon wafers into a polytetrafluoroethylene hydrothermal reaction kettle, add deionized water, and the mas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com