Ultraviolet-rejected solid asphalt, preparation and application thereof

A UV barrier and asphalt technology, applied in building components, building insulation materials, buildings, etc., can solve the problems of unstable asphalt performance, long time-consuming, complicated construction, etc., achieve convenient operation, simple on-site process, and reduce construction time and energy consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] According to the number of parts by mass, 50 parts of SK70 # Base asphalt and 10 parts of co-solvent (the co-solvent is mixed by 80 parts of polyethylene resin and 20 parts of ethylene vinyl acetate copolymer in parts by mass) at 180 ° C, shearing and stirring at a speed of 6000 rpm for 1 hour, and then in Add 40 parts of LT-1 magnesium-aluminum-based layered double hydroxide produced by Ruifa Chemical Co., Ltd. (hereinafter referred to as Ruifa LT-1) several times at 160 ° C, stir evenly for 1 hour, then lower it to room temperature for grinding, and prepare Solid particles into UV blocking solid bitumen.

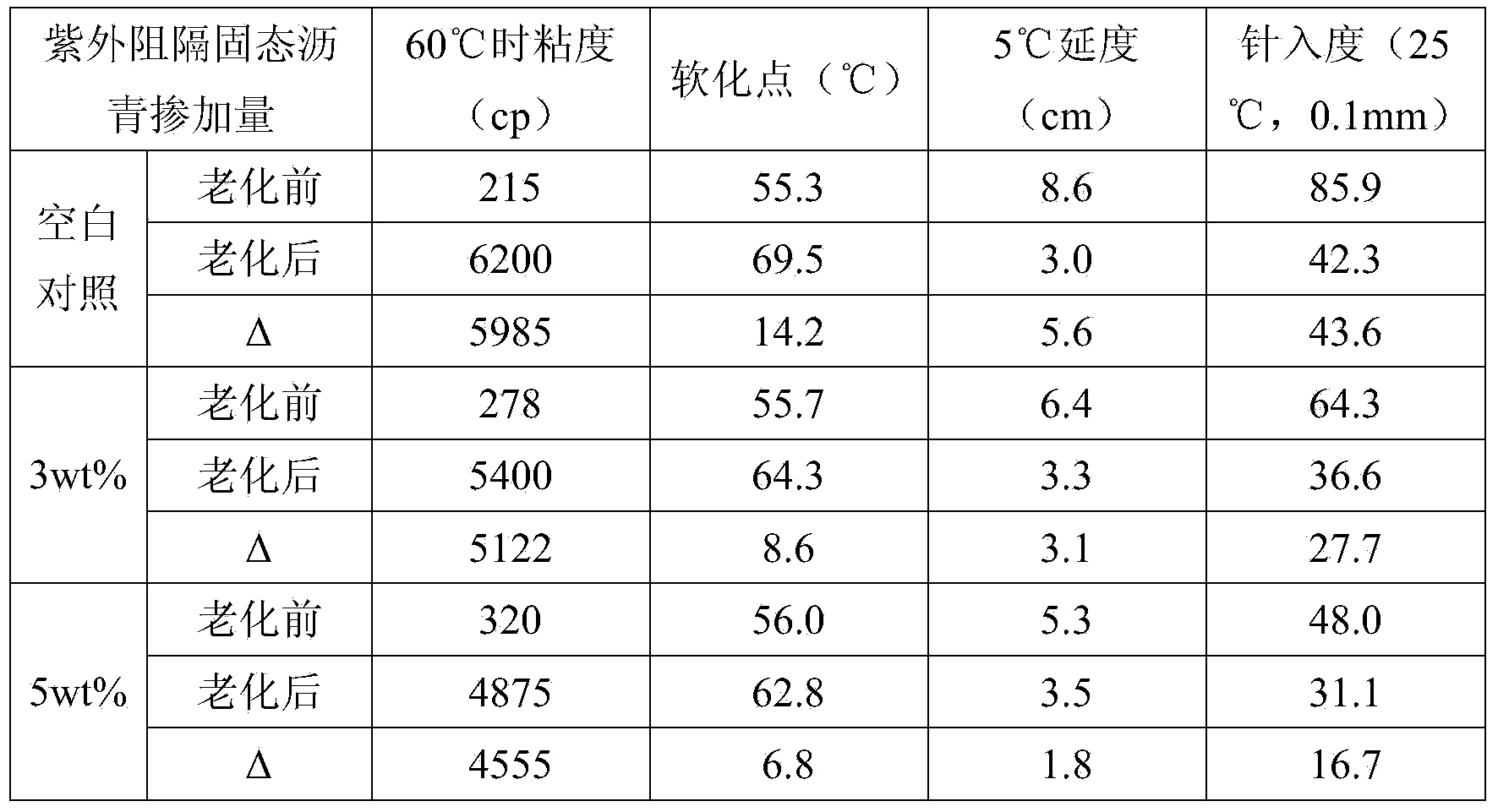

[0029] Add solid particles of UV-blocking solid asphalt to SK90 at 150°C # In road asphalt, UV barrier modified SK90 was obtained after stirring for 0.5h # road asphalt. Carry out ultraviolet aging test (ultraviolet intensity is 1200μw / cm2) to the obtained modified road asphalt 2 , aging for 6 days, the same below), the following tests are based on the "Test Reg...

Embodiment 2

[0035] According to the number of parts by mass, 65 parts of SK70 # Base bitumen and 2 parts of co-solvent (according to the mass parts are mixed by 40 parts of polyethylene resin, 20 parts of styrene-butadiene rubber, 20 parts of styrene-butadiene-styrene block copolymer (SBS) and 20 parts of zinc oxide. into) at 160°C, shear and stir at 3000rpm for 1 hour, then add 35 parts of Ruifa LT-1 several times at 140°C, stir evenly for 2 hours, then drop to room temperature and grind to make a UV-blocking solid Solid particles of bitumen.

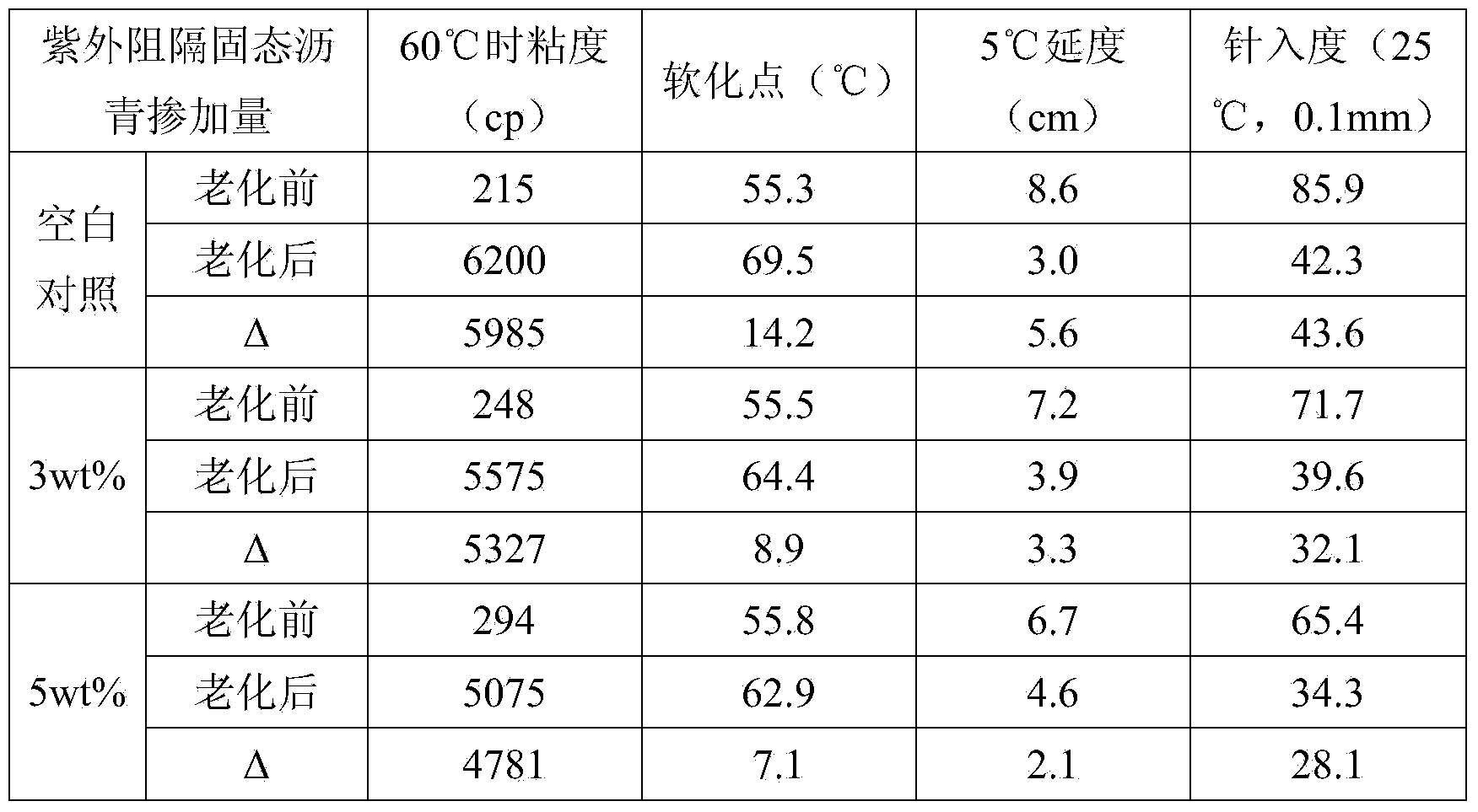

[0036]Add solid particles of UV-blocking solid asphalt to SK90 at 145°C # In road asphalt, get UV barrier modified SK90 # road asphalt. Carry out ultraviolet aging test (ultraviolet intensity is 1200μw / cm2) to the obtained modified road asphalt 2 , aging for 6 days, the same below), the test data are shown in Table 2:

[0037] Table 2

[0038]

[0039] Compared with the blank group, the viscosity increase, softening point increase and duc...

Embodiment 3

[0042] In parts by mass, 54 parts of PG70-28SBS modified asphalt and 1 part of cosolvent (by mass parts by 50 parts of carboxylated nitrile rubber, 25 parts of epoxy natural rubber and 20 parts of styrene-butadiene-styrene Block copolymer (SBS) mixed with 5 parts of magnesium oxide) at 170°C, shear and stir at 5000rpm for 2 hours, and then add 45 parts of Ruifa LT-1 at 165°C in several times , uniformly stirred for 1 hour, and then lowered to room temperature for grinding to make solid particles of UV-blocking solid asphalt.

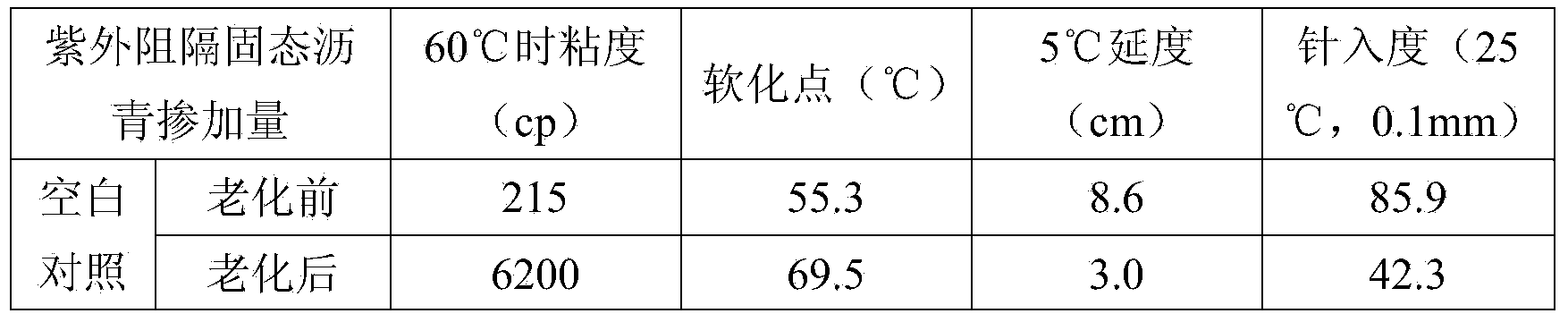

[0043] Add solid particles of UV-blocking solid asphalt to SK90 at 145°C # In road asphalt, UV barrier modified SK90 was obtained after stirring for 1 hour # road asphalt. Carry out ultraviolet aging test (ultraviolet intensity is 1200μw / cm2) to the obtained modified road asphalt 2 , aged for 6 days, the same below), the test data are shown in Table 3:

[0044] table 3

[0045]

[0046]

[0047] Compared with the blank group, the viscosity inc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Uv intensity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com