Hot-melt pressure-sensitive adhesive with high heat resistance for macromolecular waterproof roll and preparation method thereof

A hot-melt pressure-sensitive adhesive and polymer waterproof technology, which is applied in the field of materials, can solve the problems of the decrease of the cohesive strength of the hot-melt pressure-sensitive adhesive, the decrease of the adhesive force of the polyethylene sheet, and the impact on the waterproof effect, so as to achieve anti-ultraviolet aging Excellent performance, improved bonding performance, easy production and coating effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

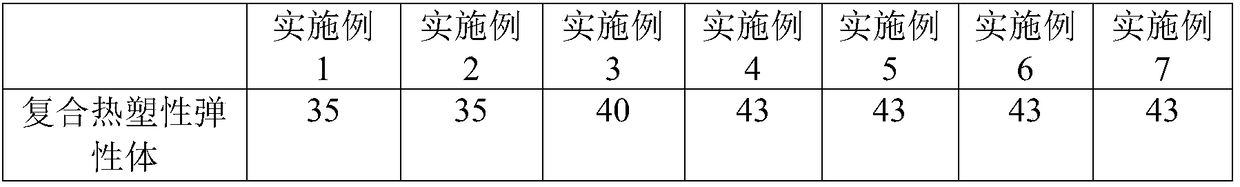

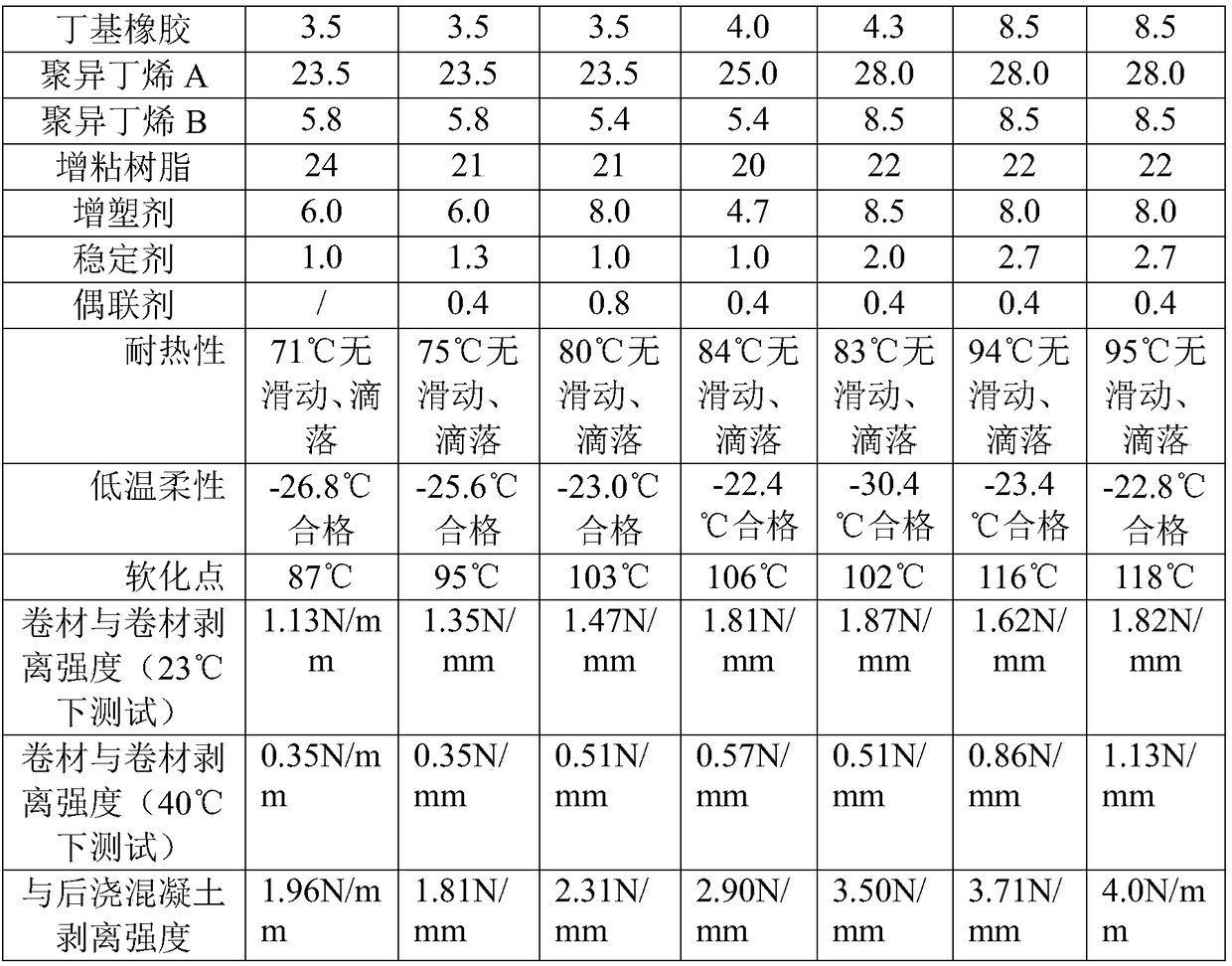

Embodiment 1

[0024] Heat the equipment to 140°C, add 23.5kg polyisobutylene A, 5.8kg polyisobutylene B and 6.0g plasticizer, stir evenly and keep warm to 120°C, then add 35kg composite thermoplastic elastomer, 3.5kg butyl rubber and heat up to 160°C , keep the stirring frequency at 50HZ and stir for 35min until the composite thermoplastic elastomer and butyl rubber are completely melted without particles. Add 24kg of tackifying resin and 1.0kg of stabilizer to keep warm at 150°C and stir for 40 minutes, turn on the vacuum pump for 20 minutes to remove air bubbles in the system, and then discharge.

[0025] In this embodiment, the composition of the composite elastomer SIS and SEPS, SIS:SEPS=1:1 in the composite elastomer, wherein the styrene content of SIS is 15%-30%, and the styrene content of SEPS is 10% %-30%. The tackifying resin is petroleum resin. The plasticizer is naphthenic oil. Stabilizer is the combination of antioxidant, ultraviolet absorber and light stabilizer, and ratio i...

Embodiment 2

[0027] Heat the equipment to 140°C, add 23.5kg polyisobutylene A, 5.8kg polyisobutylene B and 6.0g plasticizer, stir evenly and keep warm to 140°C, then add 35kg composite thermoplastic elastomer, 3.5kg butyl rubber, 0.4kg bismuth Raise the temperature of the joint agent to 160°C, keep the stirring frequency at 50HZ and stir for 35min until the composite thermoplastic elastomer and butyl rubber are completely melted without particles. Add 21kg of tackifying resin and 1.3kg of stabilizer to keep warm at 150°C and stir for 40 minutes, turn on the vacuum pump for 20 minutes to remove air bubbles in the system, and then discharge.

[0028] In this embodiment, the composition of the composite elastomer SIS and SEPS, SIS:SEPS=1:1 in the composite elastomer, wherein the styrene content of SIS is 15%-30%, and the styrene content of SEPS is 10% %-30%. The tackifying resin is petroleum resin. The plasticizer is one or more combination of naphthenic oil, paraffin oil and rubber extende...

Embodiment 3

[0030] Heat the equipment to 130°C, add 23.5kg polyisobutylene A, 5.4kg polyisobutylene B and 8.0kg plasticizer, stir evenly and keep warm to 160°C, then add 40kg composite thermoplastic elastomer, 3.5kg butyl rubber, 0.8kg Raise the temperature of the joint agent to 170°C, keep the stirring frequency at 50HZ and stir for 45min until the composite thermoplastic elastomer and butyl rubber are completely melted without particles. Add 21kg of tackifying resin and 1.0kg of stabilizer to keep warm at 150°C and stir for 40 minutes, turn on the vacuum pump for 20 minutes to remove air bubbles in the system, and then discharge.

[0031]In this embodiment, the composition of the composite elastomer SIS / SEPS and SIS / SEBS, in the composite elastomer, SIS:SEPS:SEBS=1:1:0.5, wherein the styrene content of SIS is 10%-30% , The styrene content of SEPS is 15%-30%, and the styrene content of SEBS is 10%-40%. The tackifying resin is a terpene resin. The plasticizer is one or more combination ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

| dispersity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com