BFS oil well cement

An oil well cement and clinker technology, which is applied in the field of BFS oil well cement and its preparation, can solve the problems of poor corrosion resistance, late strength decline, and low cementing quality rate, and achieve good compatibility and good effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A BFS oil well cement comprises BFS and clinker, and the weight ratio of the BFS to clinker is 20:100-40:100.

[0037] Described BFS is made up of the raw material of following percentage by weight: CaO 38~46%, SiO 2 36-42%, Al 2 o 3 7~20%, MgO 4~13%, Fe 2 o 3 0.2~1%, MnO 0.1~1%, SO 3 1 to 5%.

[0038] The clinker is composed of the following raw materials in weight percentage: CaO 61-64%, SiO 2 20-23%, Al 2 o 3 3~6%, MgO 1~3%, Fe 2 o 3 3-6%, SO 3 3%.

[0039] Mix BFS and clinker at a ratio of 20:100-40:100, and grind until the specific surface area of the particles is 2800-3000cm 2 / g, you can get BFS oil well cement.

Embodiment 2

[0041] A BFS oil well cement comprises BFS and clinker, and the weight ratio of the BFS and clinker is 20:100.

[0042]Described BFS is made up of the raw material of following percentage by weight: CaO 38%, SiO 2 36%, Al 2 o 3 10%, MgO 10%, Fe 2 o 3 0.2%, MnO 0.8%, SO 3 5%.

[0043] Described clinker is made up of the raw material of following percentage by weight: CaO 61%, SiO 2 21%, Al 2 o 3 6%, MgO 3%, Fe 2 o 3 6%, SO 3 3%.

[0044] Mix BFS and clinker according to the ratio, and grind until the specific surface area of the particles is 2800-3000cm 2 / g, you can get BFS oil well cement.

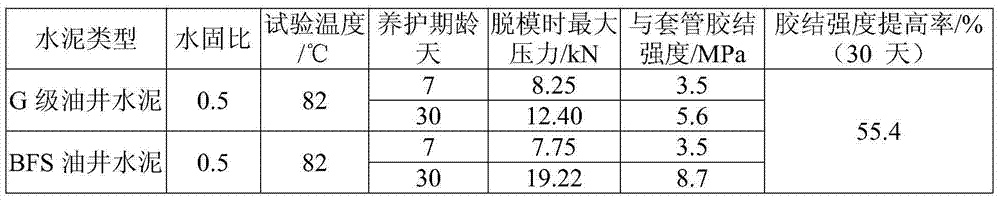

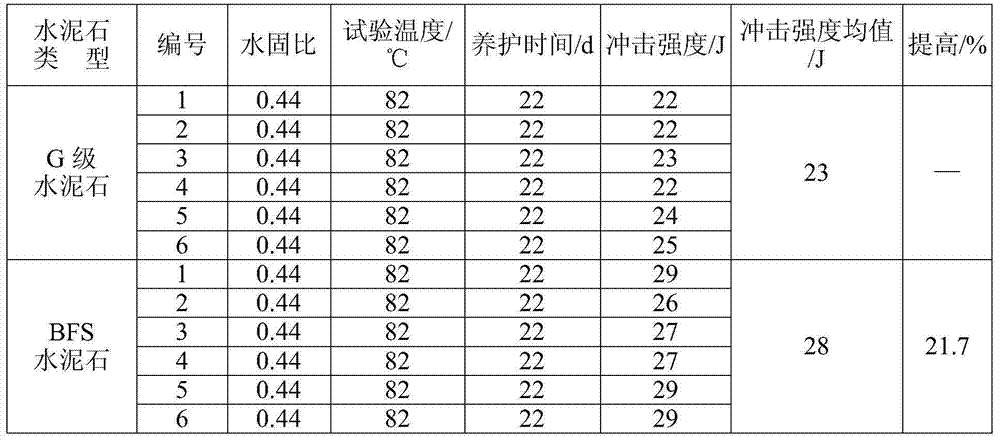

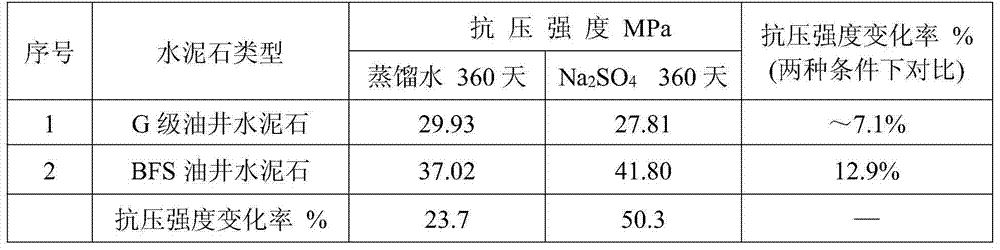

[0045] Compared with the G grade oil well cement, the BFS oil well cement disclosed in this embodiment can increase the bonding force between the cement stone and the casing and the formation by 55.6%, the shock resistance toughness can be increased by 21.8%, and the strength of the cement stone can be increased by 50.5% in the sulfate environment. , the late strength incr...

Embodiment 3

[0047] A BFS oil well cement comprises BFS and clinker, and the weight ratio of the BFS and clinker is 25:100.

[0048] Described BFS is made up of the raw material of following percentage by weight: CaO 46%, SiO 2 38%, Al 2 o 3 7%, MgO 4%, Fe 2 o 3 0.9%, MnO 0.1%, SO 3 4%.

[0049] Described clinker is made up of the raw material of following percentage by weight: CaO 64%, SiO 2 23%, Al 2 o 3 3%, MgO 3%, Fe 2 o 3 4%, SO 3 3%.

[0050] Mix BFS and clinker according to the ratio, and grind until the specific surface area of the particles is 2800-3000cm 2 / g, you can get BFS oil well cement.

[0051] Compared with the G-grade oil well cement, the BFS oil well cement disclosed in this example can increase the bonding force between the cement stone and the casing and the formation by 55.8%, the shock resistance toughness can be increased by 21.9%, and the strength of the cement stone can be increased by 50.7% in the sulfate environment. , the late strength increase...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com