Novel energy-saving thermal insulation mortar and preparation method thereof

A thermal insulation mortar, a new type of technology, applied in the field of building materials, can solve the problems of poor thermal insulation performance and large bulk volume, and achieve the effect of excellent comprehensive performance indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

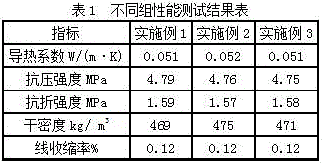

Examples

Embodiment 1

[0014] Example 1: a. 48 kg of China Resources Cement Ordinary Portland P.O42.5 cement, 9 kg of wollastonite with a particle size of 15-25 μm, 6 kg of vermiculite powder with a particle size of 35-45 μm, and ceramic polishing with a particle size of 50-80 μm 14 kilograms of waste residues are added to a vertical mixer and stirred evenly;

[0015] b. 1.2 kg of sucrose fatty acid ester, 4.5 kg of hydroxypropyl guar gum, 1.2 kg of sodium dehydroacetate, 2.3 kg of strontium carbonate, 3.8 kg of polycarboxylate superplasticizer powder of Suzhou Chenxiang Chemical Co., Ltd., Shanghai Add 2.5 kg of FH-1000 lignin fiber from Yingjia Industrial Development Co., Ltd., and 2.5 kg of polyvinyl alcohol PVA fiber for Kuraray KURALONK-II.4mm / ECC concrete into the three-dimensional mixer and mix evenly;

[0016] c. Add the mixture in step b to the mixture in step a, stir evenly through a QJLS-1500 vertical mixer, and then add Xinyang Huayu Mining Co., Ltd. vitrified lightweight hollow microsph...

Embodiment 2

[0017] Example 2: a. 45 kg of China Resources Cement Ordinary Portland P.O42.5 cement, 8 kg of wollastonite with a particle size of 15-25 μm, 6 kg of vermiculite powder with a particle size of 35-45 μm, and ceramic polishing with a particle size of 50-80 μm 12 kilograms of waste residues are added to a vertical mixer and stirred evenly;

[0018] b. 1 kg of sucrose fatty acid ester, 4 kg of hydroxypropyl guar gum, 1 kg of sodium dehydroacetate, 2 kg of strontium carbonate, 3 kg of polycarboxylate superplasticizer powder of Suzhou Chenxiang Chemical Co., Ltd., Shanghai Add 2 kg of FH-1000 lignin fiber from Yingjia Industrial Development Co., Ltd., and 2 kg of polyvinyl alcohol PVA fiber for Kuraray KURALONK-II.4mm / ECC concrete into the three-dimensional mixer and mix evenly;

[0019] c. Add the mixture in step b to the mixture in step a, stir evenly through a QJLS-1500 vertical mixer, and then add Xinyang Huayu Mining Co., Ltd. vitrified lightweight hollow microspheres 15 Kilog...

Embodiment 3

[0020] Example 3: a. 53 kg of China Resources Cement Ordinary Portland P.O42.5 cement, 10 kg of wollastonite with a particle size of 15-25 μm, 8 kg of vermiculite powder with a particle size of 35-45 μm, and ceramic polishing with a particle size of 50-80 μm 15 kilograms of waste residues are added to a vertical mixer and stirred evenly;

[0021] b. 1.5 kg of sucrose fatty acid ester, 5 kg of hydroxypropyl guar gum, 1.5 kg of sodium dehydroacetate, 3 kg of strontium carbonate, 4 kg of polycarboxylate superplasticizer powder of Suzhou Chenxiang Chemical Co., Ltd., Shanghai Add 3 kilograms of FH-1000 lignin fiber from Yingjia Industrial Development Co., Ltd., and 3 kilograms of polyvinyl alcohol PVA fiber for Kuraray KURALONK-II.4mm / ECC concrete into the three-dimensional mixer and mix evenly;

[0022] c. Add the mixture in step b to the mixture in step a, stir evenly through a QJLS-1500 vertical mixer, and then add Xinyang Huayu Mining Co., Ltd. vitrified lightweight hollow mic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com