High-temperature-resistant heat-insulation paint and preparation method thereof

A heat-insulating coating and high-temperature-resistant technology, applied in the material field, can solve the problem that a single and comprehensive performance index is difficult to meet the harsh requirements of aviation, and achieve the effect of excellent comprehensive performance index, strong impact resistance, and guaranteed strength and rigidity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

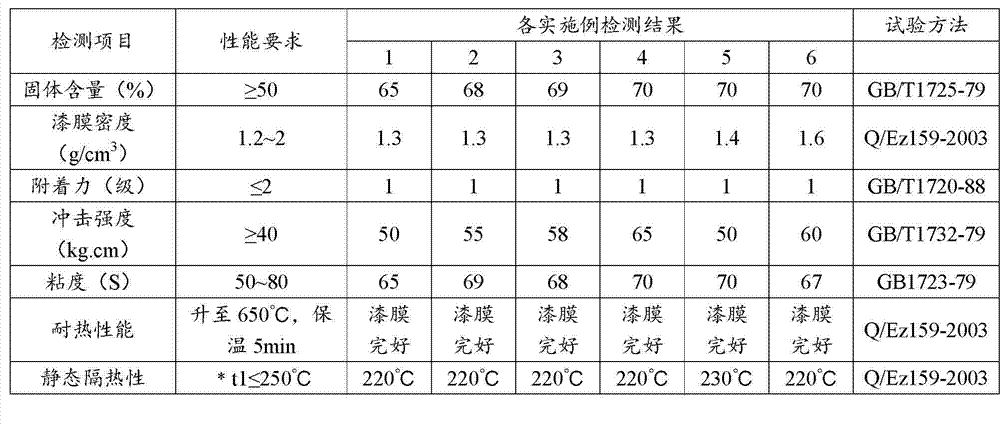

Examples

Embodiment 1

[0022] A heat-resistant heat-insulating paint, based on parts by weight, whose raw materials are composed of 25 parts of epoxy resin modified silicone resin with nano particles, 20 parts of polybenzimidazole, 8 parts of boron carbide, and 30 parts of hollow ceramic beads. Parts, 1.5 parts of amino polyhedral oligomeric silsesquioxane and 27 parts of toluene.

[0023] The nano particles are nano titanium dioxide, and the weight ratio of the nano particles to the epoxy resin modified silicone resin is 1:9. The epoxy resin modified silicone resin is FJN-9803 epoxy modified silicone resin.

[0024] The specific steps of the coating include:

[0025] (1) Add other raw materials except toluene into the reaction kettle in proportion, and stir for 125min at a speed of 650r / min;

[0026] (2) Grind the above-mentioned uniformly mixed raw materials and pass through a 65-mesh sieve;

[0027] (3) Add toluene to the sieved raw materials in proportion to make the coating evenly.

Embodiment 2

[0029] A high-temperature heat-resistant heat-insulating paint, based on parts by weight, whose raw materials are composed of 35 parts of epoxy resin modified silicone resin with nano-particles, 15 parts of polybenzimidazole, 5 parts of silicon carbide, and 20 parts of mica powder. One part of amino polyhedral oligomeric silsesquioxane and 5 parts of toluene.

[0030] The nano particles are nano silica, and the weight ratio of the nano silica to the epoxy resin modified silicone resin is 1:6. The epoxy resin modified silicone resin is epoxy modified silicone resin SH-023.

[0031] The specific steps of the coating include:

[0032] (1) Add other raw materials except toluene into the reaction kettle in proportion, and stir for 100min at a speed of 550r / min;

[0033] (2) Grind the above-mentioned uniformly mixed raw materials and pass through a 68-mesh sieve;

[0034] (3) Add toluene to the sieved raw materials in proportion to make the coating evenly.

Embodiment 3

[0036] A high-temperature heat-resistant heat-insulating paint, in parts by weight, the raw material composition is: 30 parts of epoxy resin modified silicone resin with nano particles, 10 parts of polybenzimidazole, 7 parts of boron nitride, 28 parts of fly ash Parts, 2 parts of amino polyhedral oligomeric silsesquioxane, 10 parts of solvent.

[0037] The nano particles are nano aluminum oxide, and the weight ratio of the epoxy resin modified silicone resin is 1:9. The epoxy resin modified silicone resin is FJN-9803 epoxy modified silicone resin.

[0038] The solvent is a mixed solvent of toluene and xylene, and the mass ratio of the two is 1:1.

[0039] The specific steps of the coating include:

[0040] (1) Add other raw materials except the solvent into the reaction kettle in proportion, and stir for 150min at a speed of 600r / min;

[0041] (2) Grind the above-mentioned uniformly mixed raw materials and pass through a 70-mesh sieve;

[0042] (3) Add the solvent to the sieved raw mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com