Preparation method of magnesium alloy steering wheel skeleton

A magnesium alloy and steering wheel technology, applied in the field of metal materials, can solve the problems of low strength and large elongation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

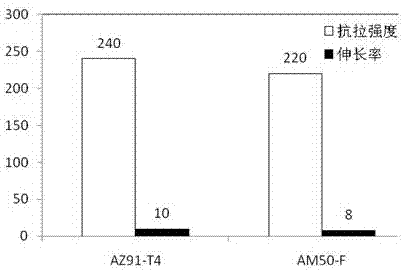

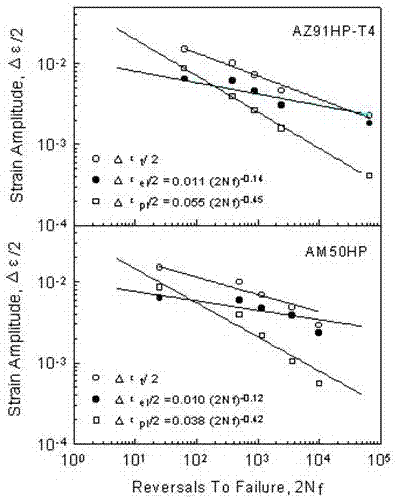

[0031] Put the AZ91-F alloy steering wheel skeleton prepared by vacuum die-casting into a heat treatment furnace for solution treatment. The solution treatment temperature is set at 415°C, the furnace is installed at room temperature, the heating rate is set at 3°C / min, and the holding time is set 4h; after the completion of solution treatment, take out the sample and air-cool. The resulting steering wheel skeleton was sampled for tensile and fatigue performance tests. The tensile strength was 245MPa and the elongation was 9.8%. like figure 2 It can be seen from the comparison of the low-cycle fatigue life curves that the solution treatment has a great influence on the low-cycle fatigue behavior of magnesium alloys. Solution treatment improves the toughness of magnesium alloys, significantly increases the transition fatigue life (NT), and exhibits a higher fatigue life at high strain amplitudes.

Embodiment 2

[0033] Put the AZ91-F alloy steering wheel skeleton prepared by vacuum die-casting into a heat treatment furnace for solution treatment. The solution treatment temperature is set at 415°C, the furnace is installed at room temperature, the heating rate is set at 3°C / min, and the holding time is set 8h; after the completion of solution treatment, take out the sample and air-cool. The resulting steering wheel skeleton was sampled for tensile and fatigue performance tests. The tensile strength was 240MPa and the elongation was 10%.

Embodiment 3

[0035] Put the AZ91-F alloy steering wheel skeleton prepared by vacuum die-casting into a heat treatment furnace for solution treatment. The solution treatment temperature is set at 415°C, the furnace is installed at room temperature, the heating rate is set at 3°C / min, and the holding time is set 12h; after the completion of solution treatment, take out the sample and air-cool. The resulting steering wheel skeleton was sampled for tensile and fatigue performance tests. The tensile strength was 238MPa and the elongation was 10.8%.

[0036] in conclusion:

[0037] The strength and toughness of the material can be significantly improved by performing solution treatment on the die-cast steering wheel skeleton of the vacuum die-cast AZ91 magnesium alloy, especially the strain fatigue transition life under R=-1 can be improved by 80-100%, and the performance is excellent at high strain amplitudes. have a high fatigue life. Its comprehensive performance index is obviously better t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com