Process method for preparing magnesium alloy through electro-slag remelting

A process method and electroslag remelting technology are applied in the field of magnesium alloy production, which can solve the problems of coarse grains and poor performance of magnesium alloys, and achieve the effects of grain refinement, low cost and simple process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

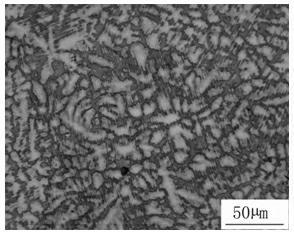

Image

Examples

Example Embodiment

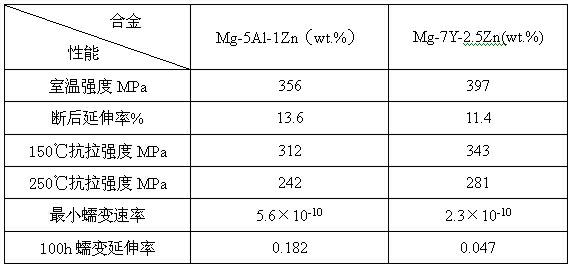

Example 1

The pure magnesium, pure yttrium and pure zinc are mixed according to the mass percentages of 90.5%, 7%, and 2.5% and then smelted in a crucible furnace at 880°C under the protection of SF6+CO2- mixed gas to make consumable electrodes; the mass percentage is 10 %CaO, 15%Al2O3, 20%MgO, 55%CaF2 are mixed uniformly, kept at 800℃ for 6 hours as electroslag slag, and kept in the oven until it is taken out before the electroslag treatment to ensure dryness; The electrode rod is loaded into the electroslag furnace for smelting. The working voltage of the electroslag furnace is 35V, the working current is 2.0kV, the ignition block is pure aluminum, and the ignition slag material is CaF2. The smelting process is carried out under the protection of SF6+CO2- mixed gas In the smelting process, add electroslag slag material as needed until the electroslag process is completed; the magnesium alloy ingots after electroslag smelting are annealed at 520℃ for 5 hours, during which argo...

Example Embodiment

Example 2

The pure magnesium, pure yttrium and pure zinc are mixed according to the mass percentages of 90.5%, 7%, and 2.5% and then smelted in a crucible furnace at 880°C under the protection of SF6+CO2- mixed gas to make consumable electrodes; the mass percentage is 10 %CaO, 15%Al2O3, 20%MgO, 55%CaF2 are mixed uniformly, kept at 800℃ for 6 hours as electroslag slag, and kept in the oven until it is taken out before the electroslag treatment to ensure dryness; The electrode rod is loaded into the electroslag furnace for smelting. The working voltage of the electroslag furnace is 35V, the working current is 2.0kV, the ignition block is pure aluminum, and the ignition slag material is CaF2. The smelting process is carried out under the protection of SF6+CO2- mixed gas In the smelting process, add electroslag slag material as needed until the electroslag process is completed; the magnesium alloy ingots after electroslag smelting are annealed at 520℃ for 5 hours, during which argo...

Example Embodiment

Example 3

Process method for preparing magnesium alloy by electroslag remelting

(A) Firstly, the magnesium alloy raw materials to be prepared are mixed and then smelted in a crucible furnace at 800℃~900℃ under the protection of SF6+CO2-mixed gas to make consumable electrode rods;

(B) Load the consumable electrode rods into an electroslag furnace for electroslag smelting. The electroslag furnace has a working voltage of 25-40V and a working current of 0.8-5kA. The pilot arc block is pure aluminum, and the arc slag material is CaF2 The smelting process is carried out under the protection of SF6+CO2- mixed gas. During the smelting process, the electroslag slag material that has been kept at 700°C to 850°C for 6 to 8 hours is added. The amount of electroslag slag added is 3% of the mass of the consumable electrode. %~4%, the electroslag slag material is composed of CaO, Al2O3, MgO and CaF2, and the mass percentage of the electroslag slag material is: 5%~15% CaO, 5%~20% Al2O3, 10%~ ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com