Method for measuring dual slope of stern tube rear bearing

A measuring method and technology of rear bearing, which are applied in mechanical bearing testing, measuring device, measuring inclination, etc., can solve the problem of detecting double inclination of stern tube rear bearing, and achieve the effect of convenient construction, satisfying shipbuilding accuracy and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

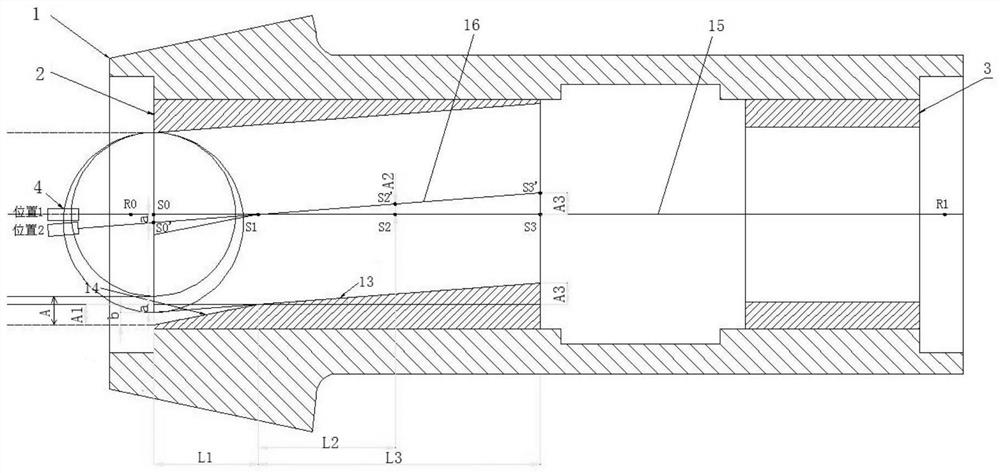

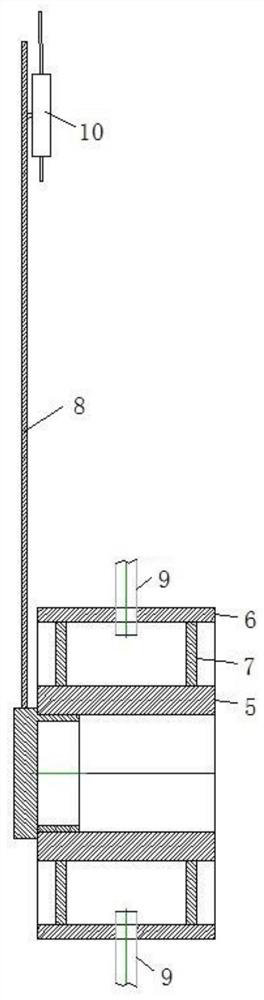

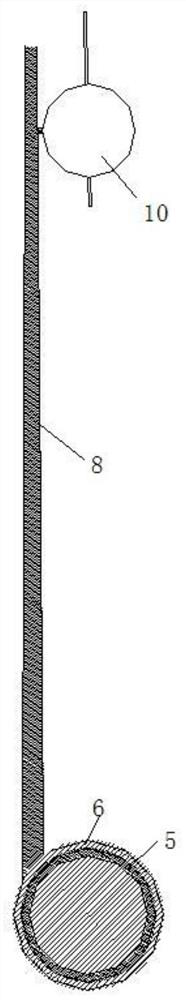

[0042] Embodiment 1, the embodiment of the present invention provides a method for measuring the double slope of the rear bearing of the stern tube, which specifically includes the following steps:

[0043] S1, along the length direction of the stern tube rear bearing 2, select four measurement positions in the stern tube rear bearing 2, wherein the first measurement position is located at the rear end surface of the stern tube rear bearing 2, and the second measurement position is located at the stern tube rear bearing Any one position on the first slope 13 in 2, the third measurement position is located at the front end face of the stern tube rear bearing 2.

[0044] S2. Set a centering tool at the first measurement position, the second measurement position and the third measurement position respectively, and adjust the three centering tools so that the bullseyes of the three centering tools are all located on the shaft housing centerline 15 .

[0045] Specifically, the foll...

Embodiment 2

[0063] Embodiment 2, the method for measuring the double slope of the rear bearing of the stern tube in this embodiment specifically includes the following steps:

[0064] S1, along the length direction of the stern tube rear bearing 2, select four measurement positions in the stern tube rear bearing 2, wherein the first measurement position is located at the rear end surface of the stern tube rear bearing 2, and the second measurement position is located at the stern tube rear bearing Any one position on the first slope 13 in 2, the third measurement position is located at the front end face of the stern tube rear bearing 2.

[0065] S2. Set a centering tool at the first measurement position, the second measurement position and the third measurement position respectively, and adjust the three centering tools so that the bullseyes of the three centering tools are all located on the centerline 15 of the axle housing.

[0066] The adjustment steps of the three centering tools ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com