Automatic dredging optimization control system of trailing suction hopper dredger

A trailing suction dredger, optimized control technology, applied in mechanically driven excavators/dredgers, earth movers/shovels, construction, etc., can solve the problem of low efficiency, poor safety and adaptability, and high labor costs question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

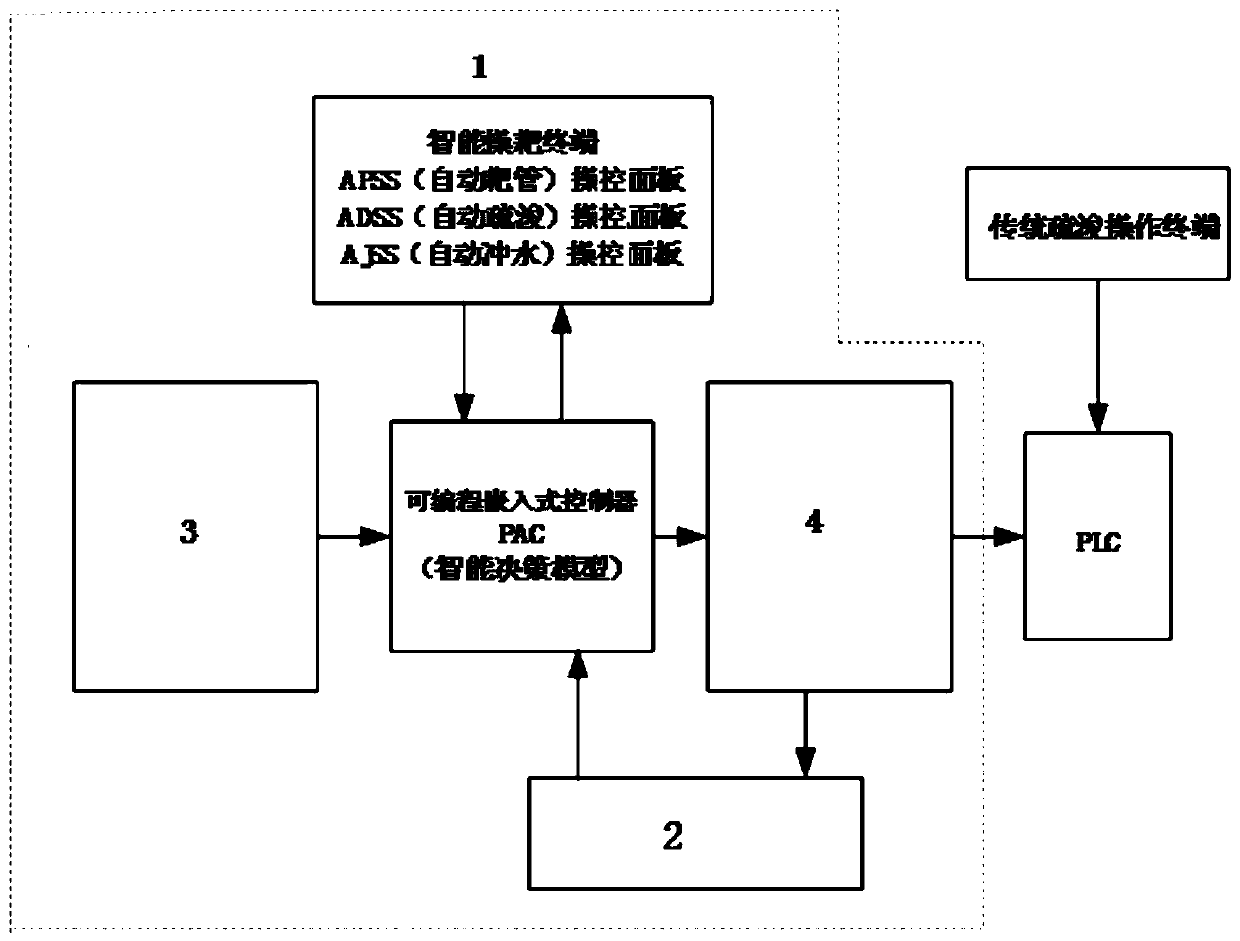

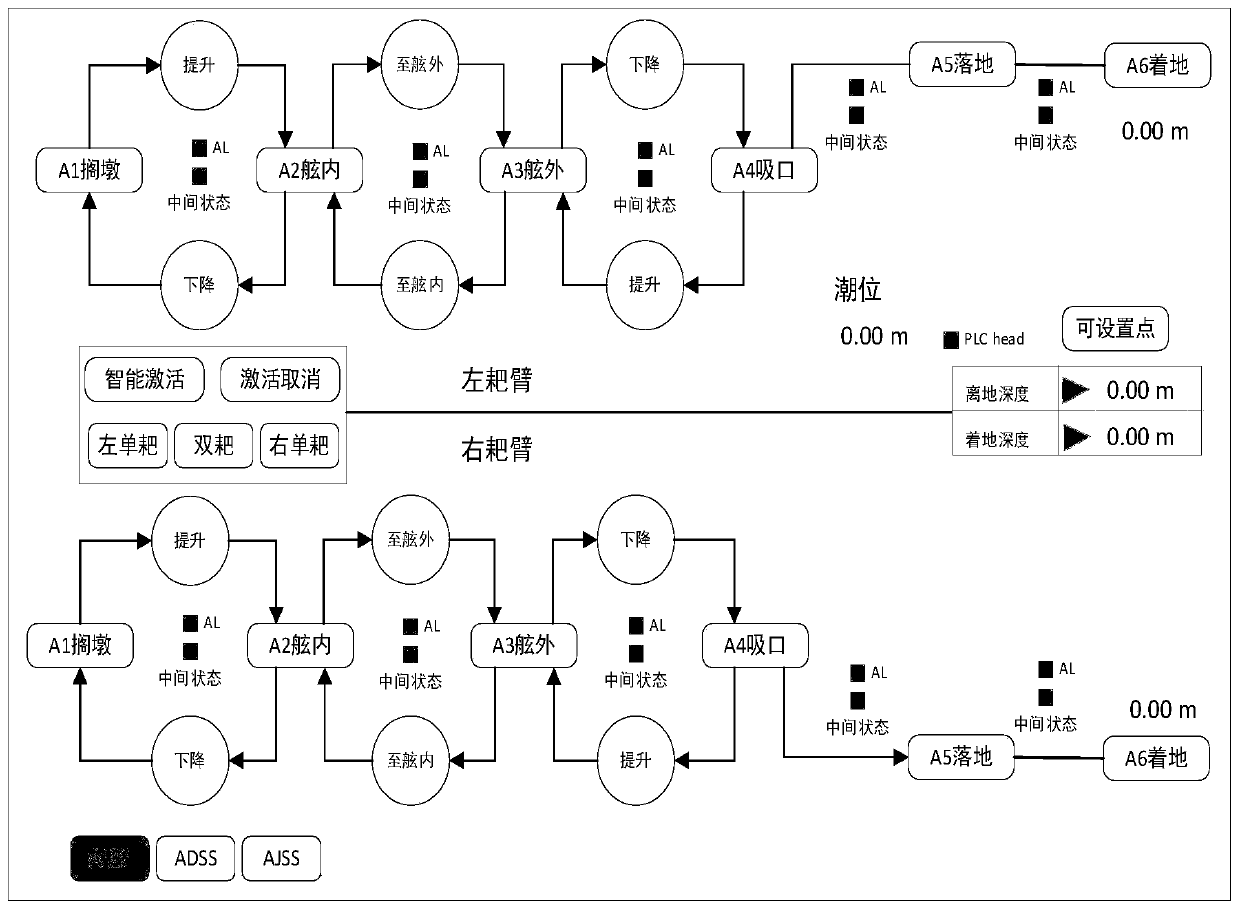

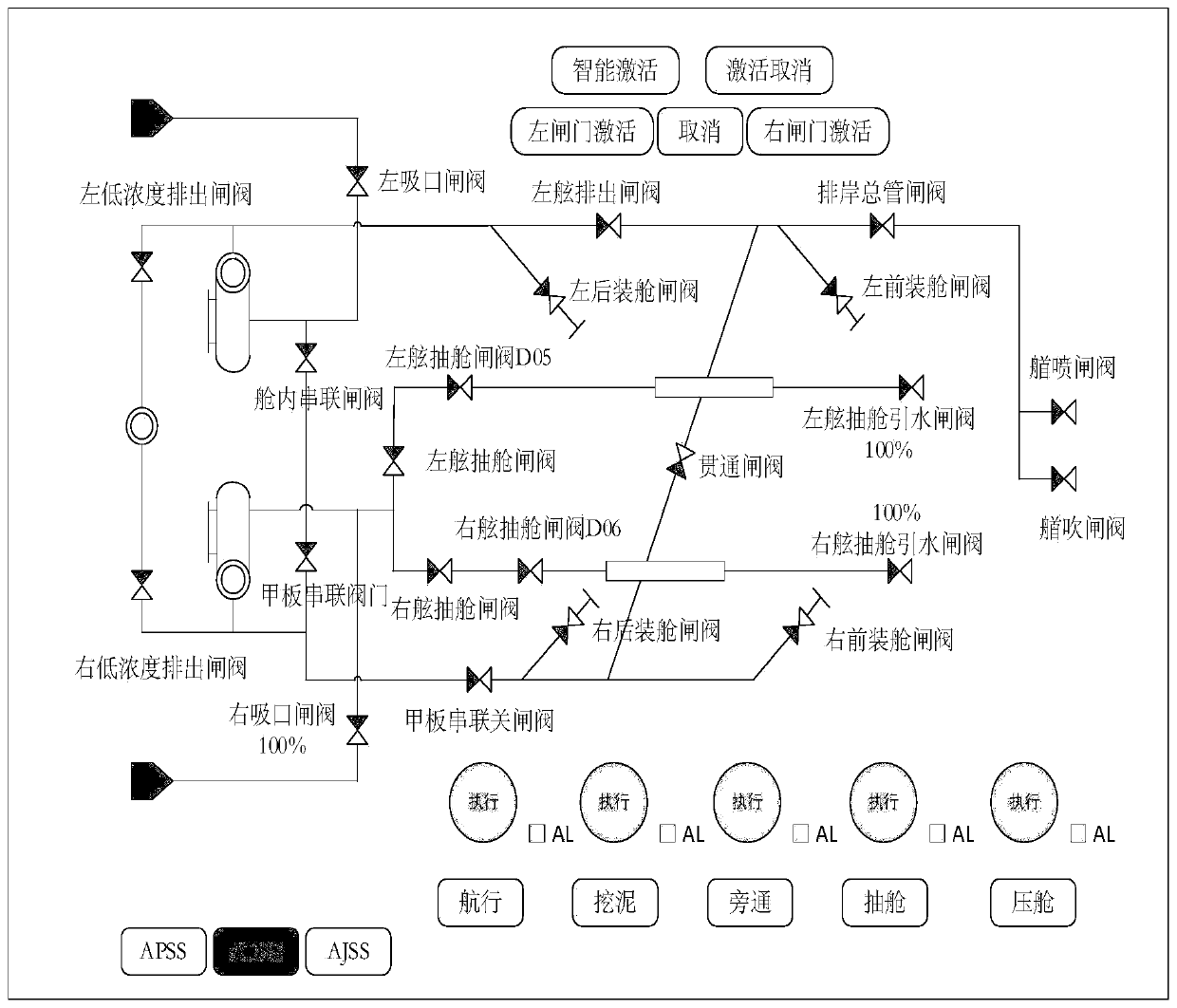

[0022] see figure 1, which shows the overall functional block diagram of an embodiment of an automatic dredging optimization control system for a trailing suction dredger proposed by the present invention. The control system includes a programmable embedded controller (PAC), an intelligent rake terminal 1 connected to the controller (PAC), an intelligent dredging monitoring interface 2, a data acquisition module 3 and an output instruction module 4. Programmable Embedded Controller (PAC) includes automatic rake pipe (APSS) serialization control module, automatic dredging (ADSS) serialization control module, automatic flushing (AJSS) serialization control module, automatic judgment module of dredging operation stage, dredging Process auxiliary decision-making module, dredging intelligent control simulation module and dredging equipment control intelligent monitoring module. The PAC collects various data of the conventional dredging monitoring system in real time through the da...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com