Patents

Literature

43 results about "Draw-works" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

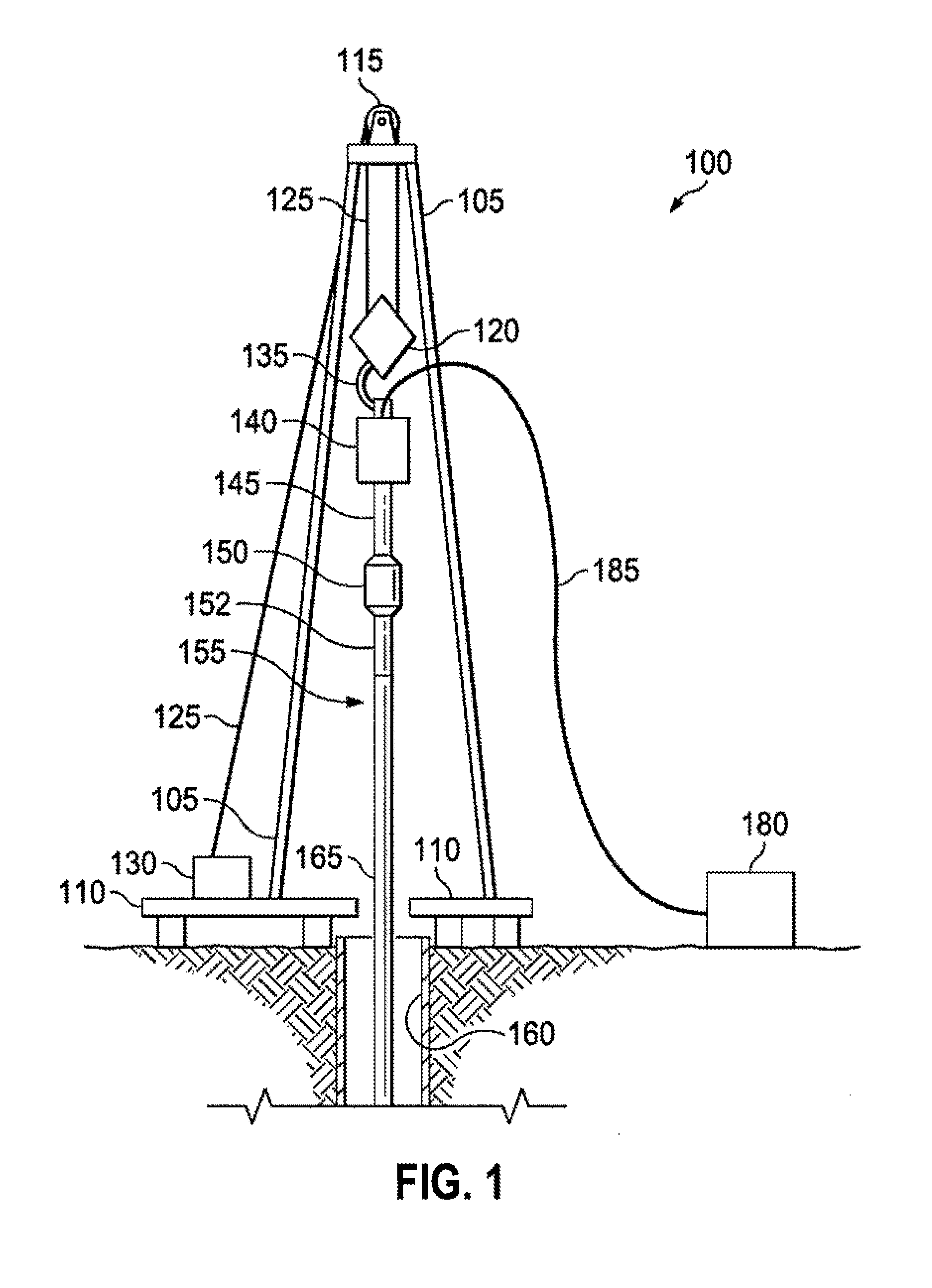

A drawworks is the primary hoisting machinery component of a rotary drilling rig. Its main function is to provide a means of raising and lowering the traveling block. The wire-rope drill line winds on the drawworks drum and over the crown block to the traveling block, allowing the drill string to be moved up and down as the drum turns. The segment of drill line from the drawworks to the crown block is called the "fast line". The drill line then enters the first sheave of the crown block and makes typically 6 to 12 passes between the crown block and traveling block pulleys for mechanical advantage. The line then exits the last sheave on the crown block and is fastened to a derrick leg on the other side of the rig floor. This section of drill line is called the "dead line."

Draw-works and method for operating the same

Owner:GRANT PRIDECO LP

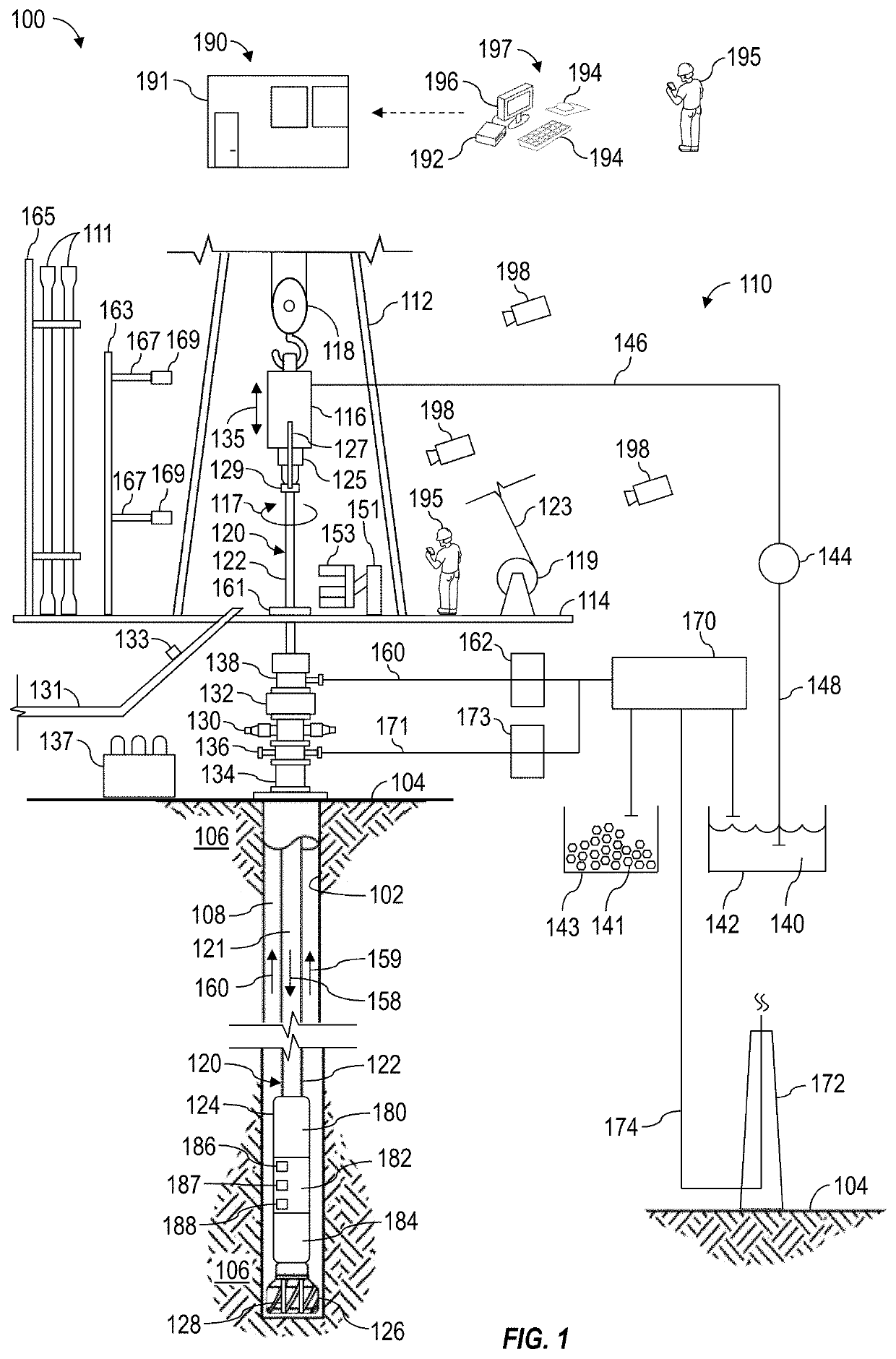

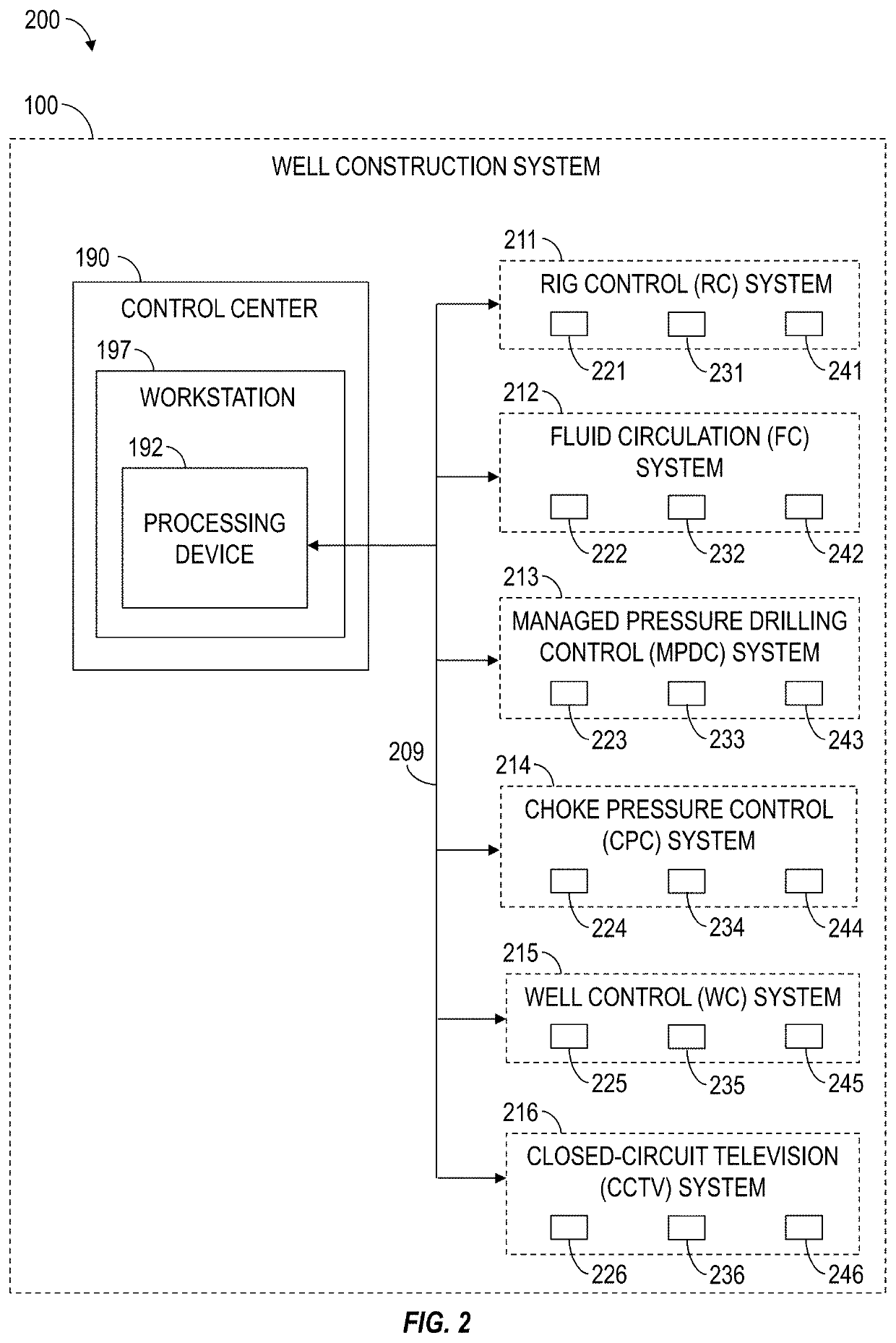

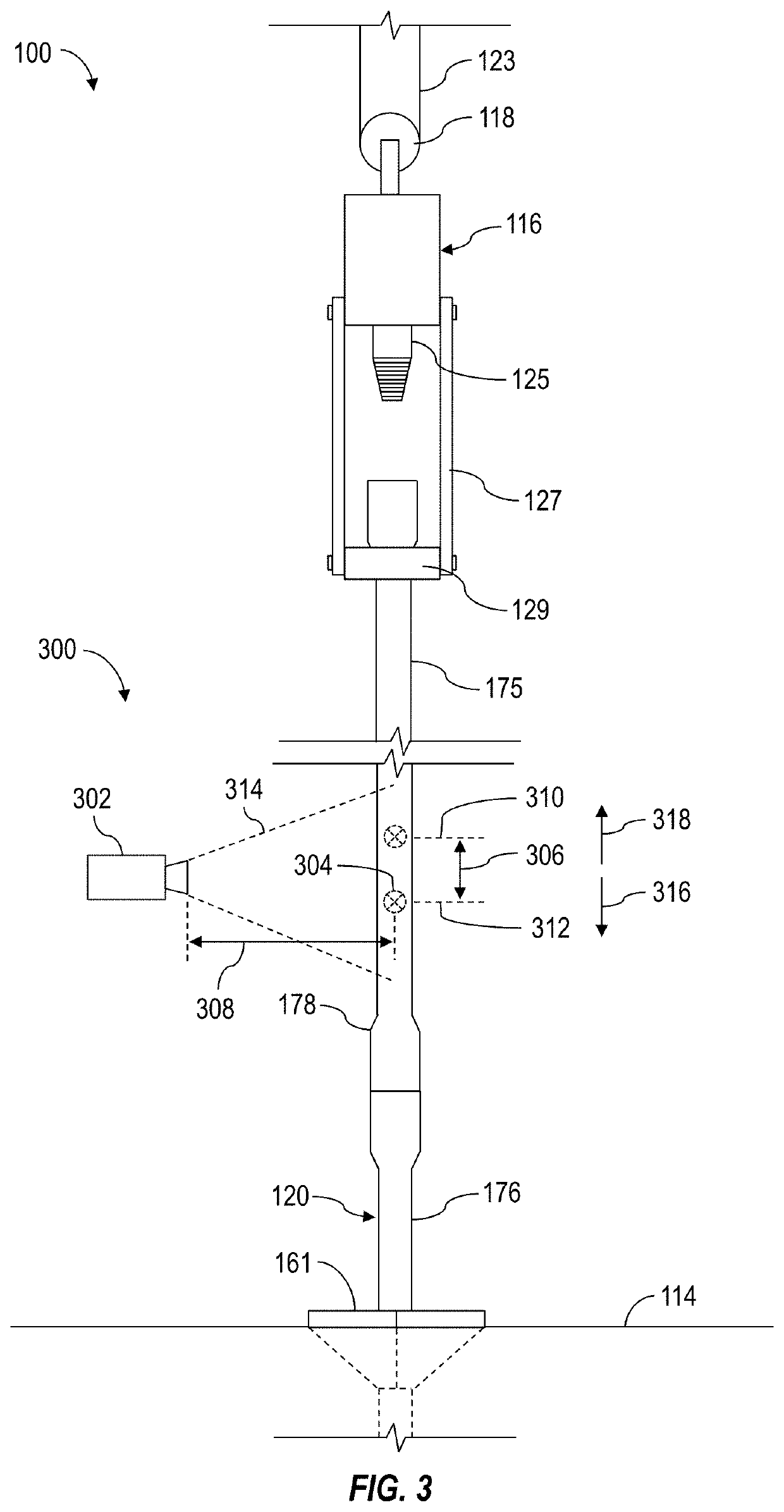

Wellsite control employing three-dimensional imaging

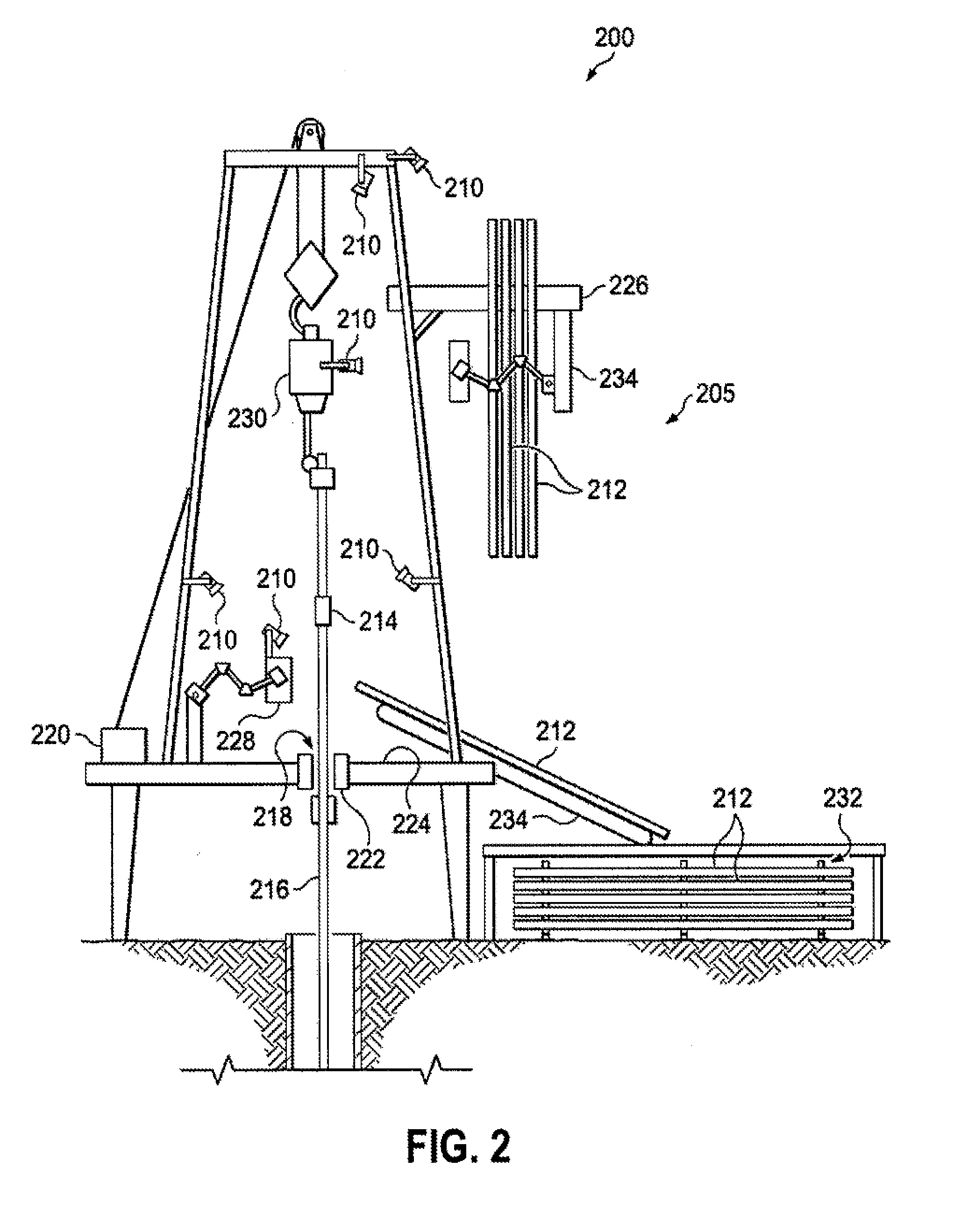

According to one aspect, a three-dimensional model of at least a portion of a wellsite is generated. A three-dimensional camera system is calibrated to the three-dimensional model. A draw-works encoder is calibrated. The motion of a component is monitored. The draw-works encoder is recalibrated based on the monitoring. According to another aspect, three-dimensional imaging data sets are received, the three-dimensional imaging data sets being associated with a control volume in which the portion of the wellsite is disposed. A predefined three-dimensional model is augmented with the three-dimensional imaging data sets. According to another aspect, at least one three-dimensional camera employs a first three-dimensional sensing technology that is different from a second three-dimensional sensing technology employed by at least one other three-dimensional camera. A single three-dimensional model is generated by merging respective three-dimensional imaging data sets. At least one system is controlled using the single three-dimensional model.

Owner:NABORS DRILLING TECH USA INC

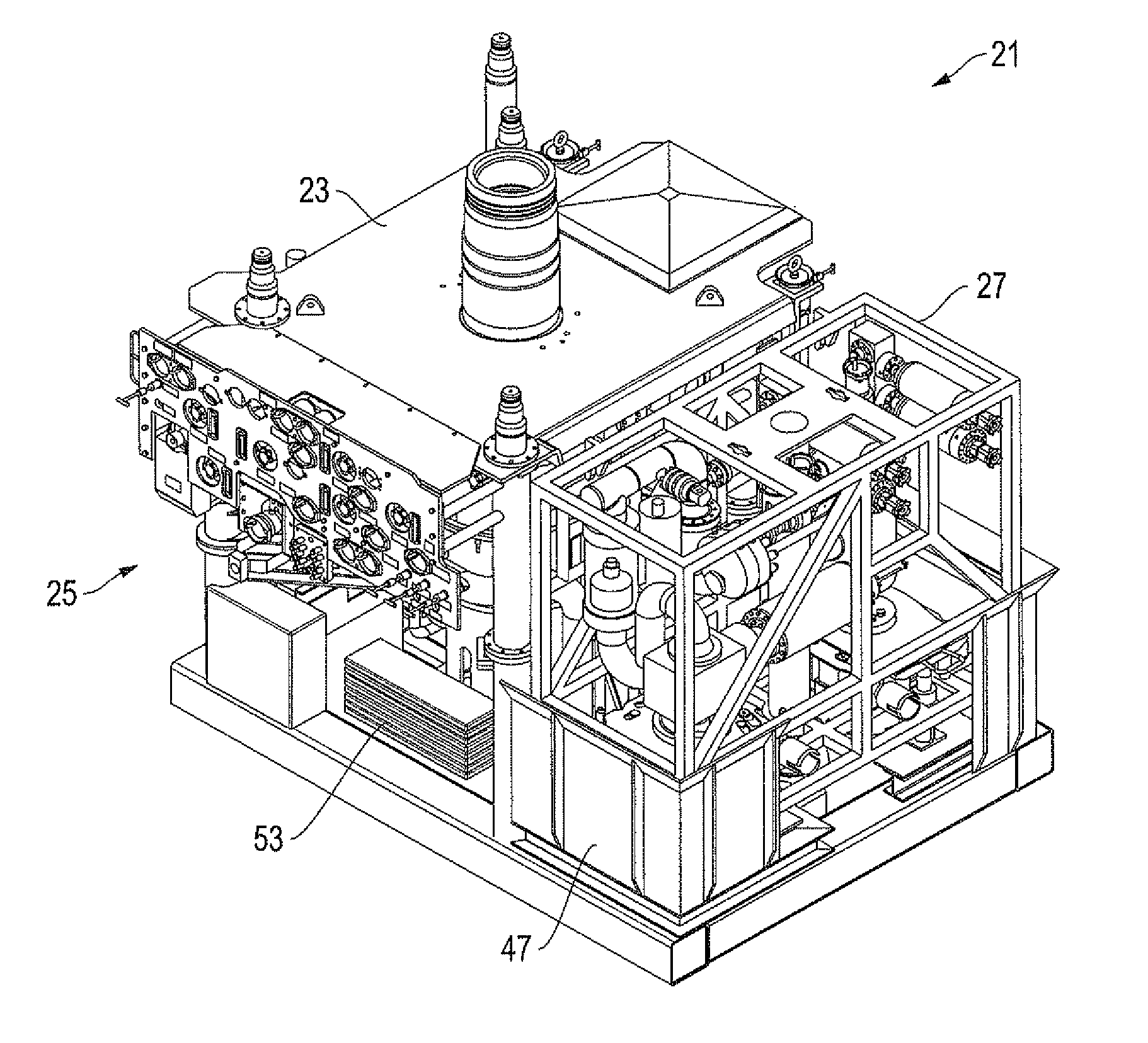

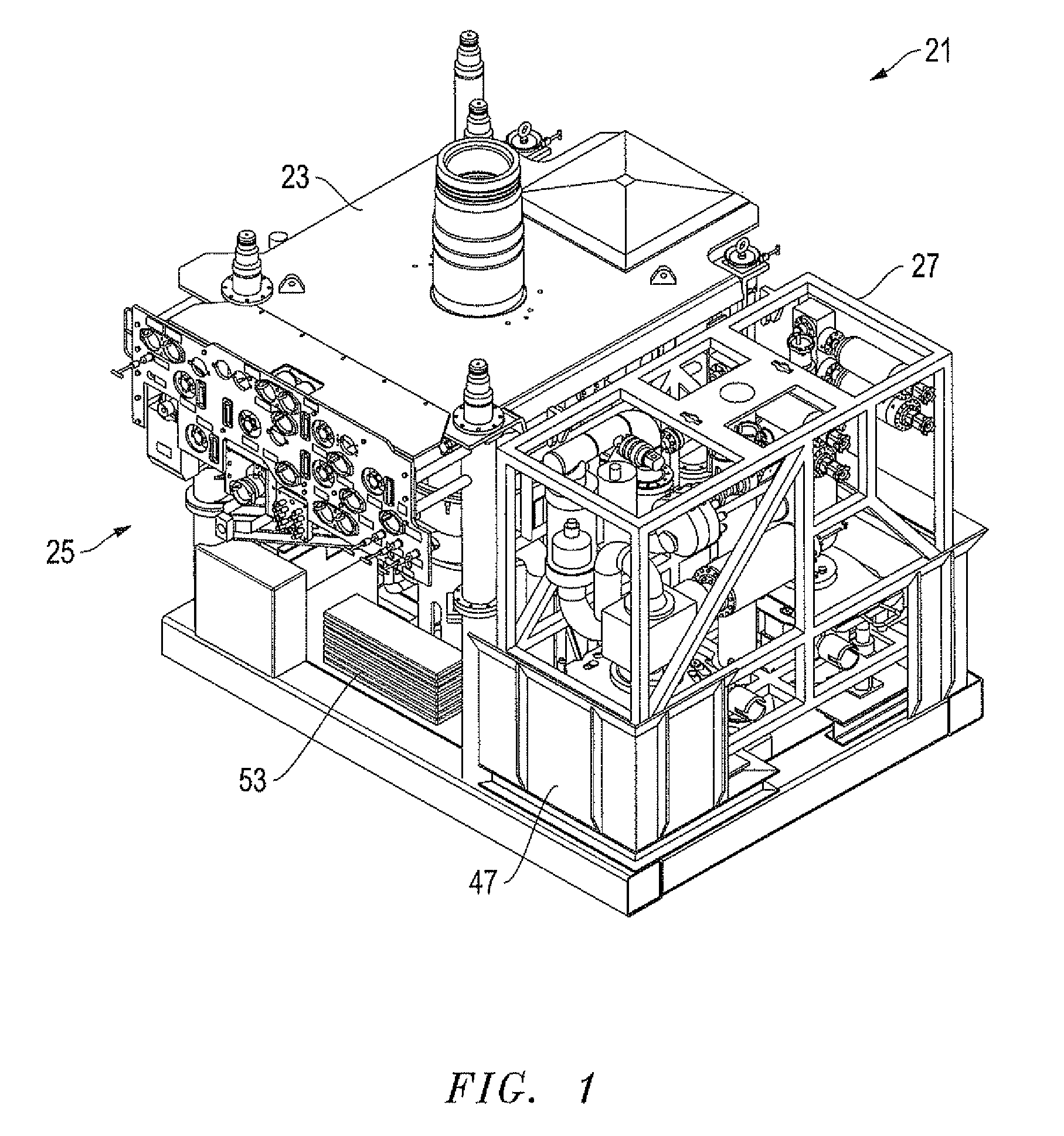

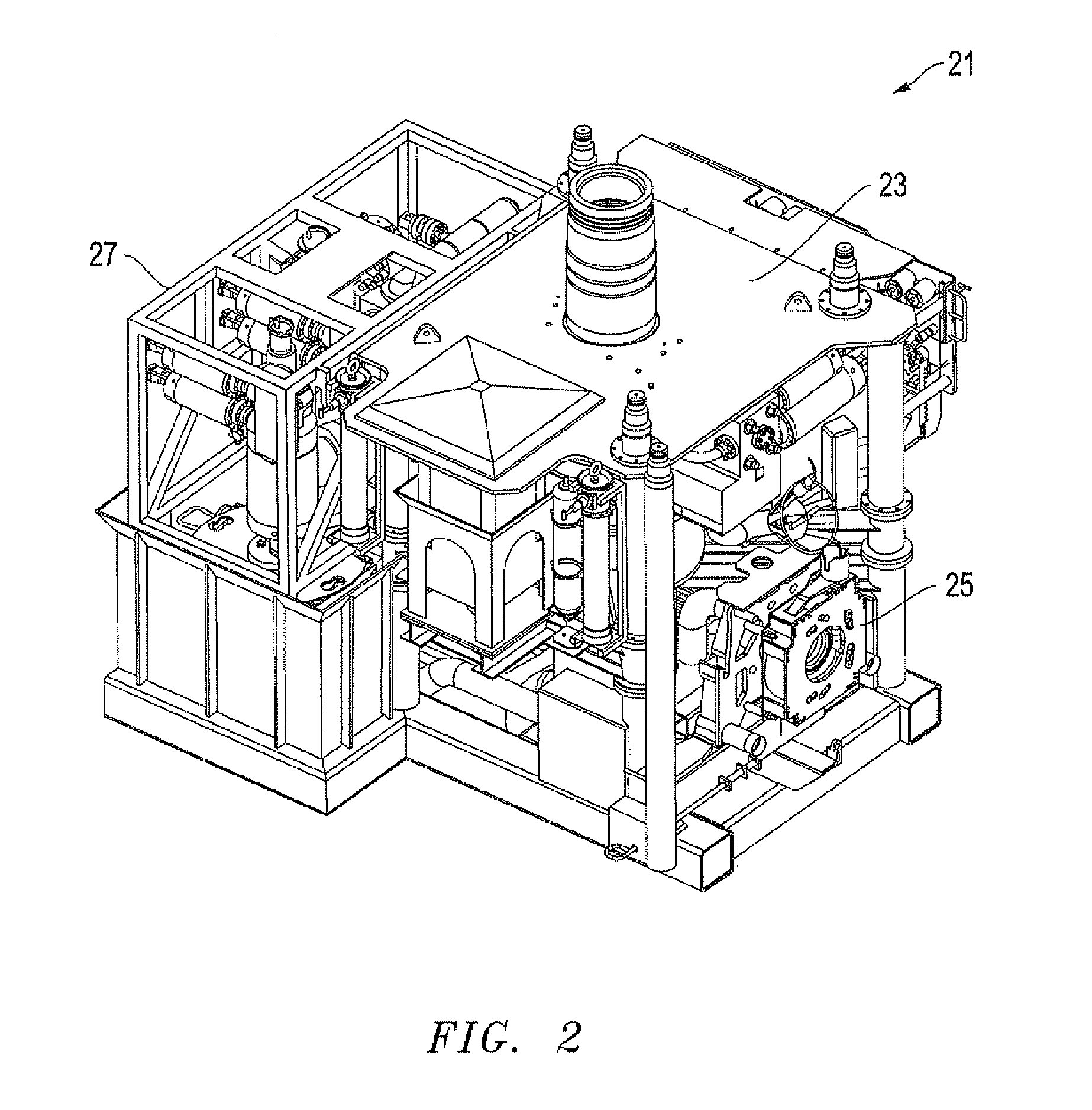

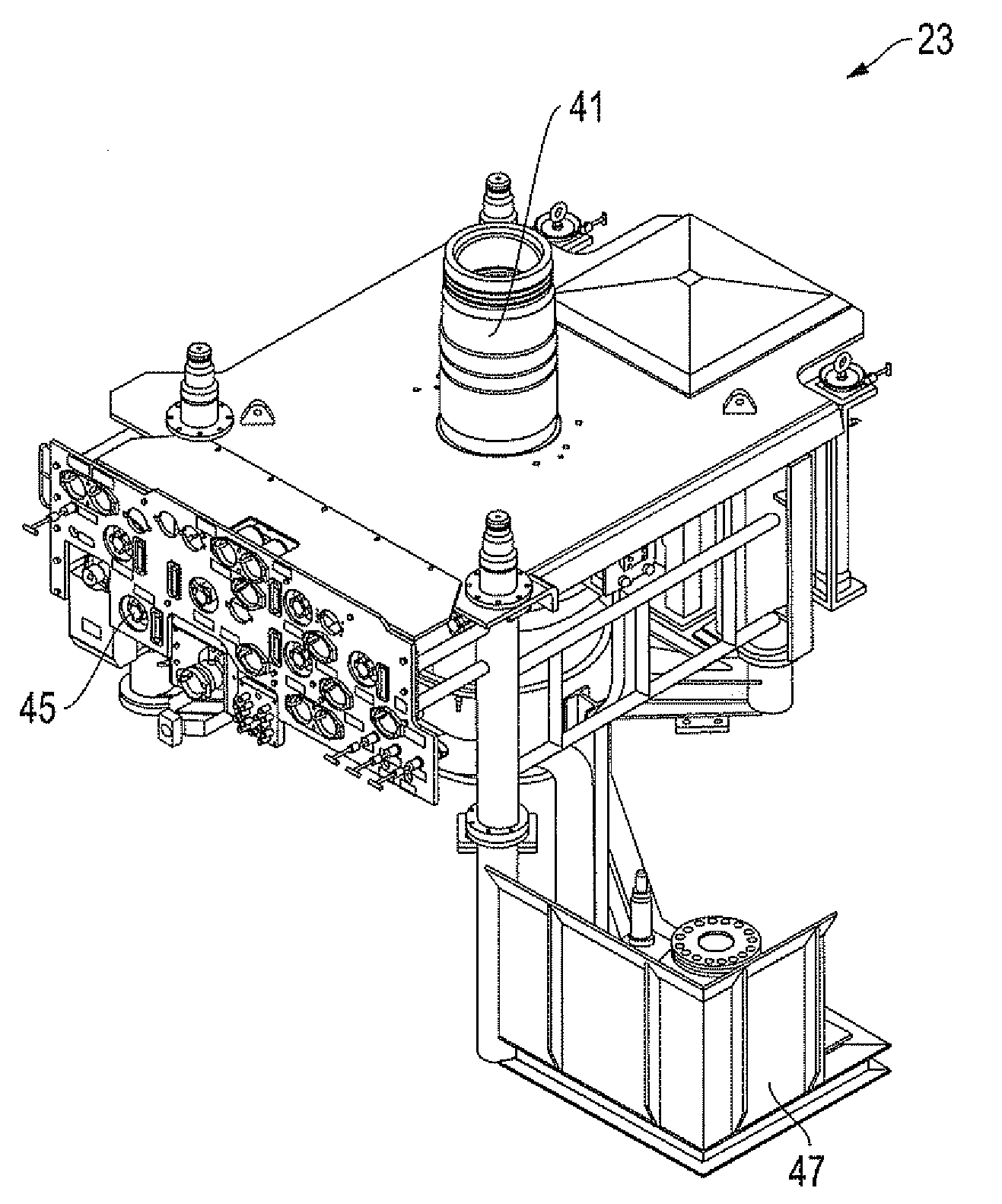

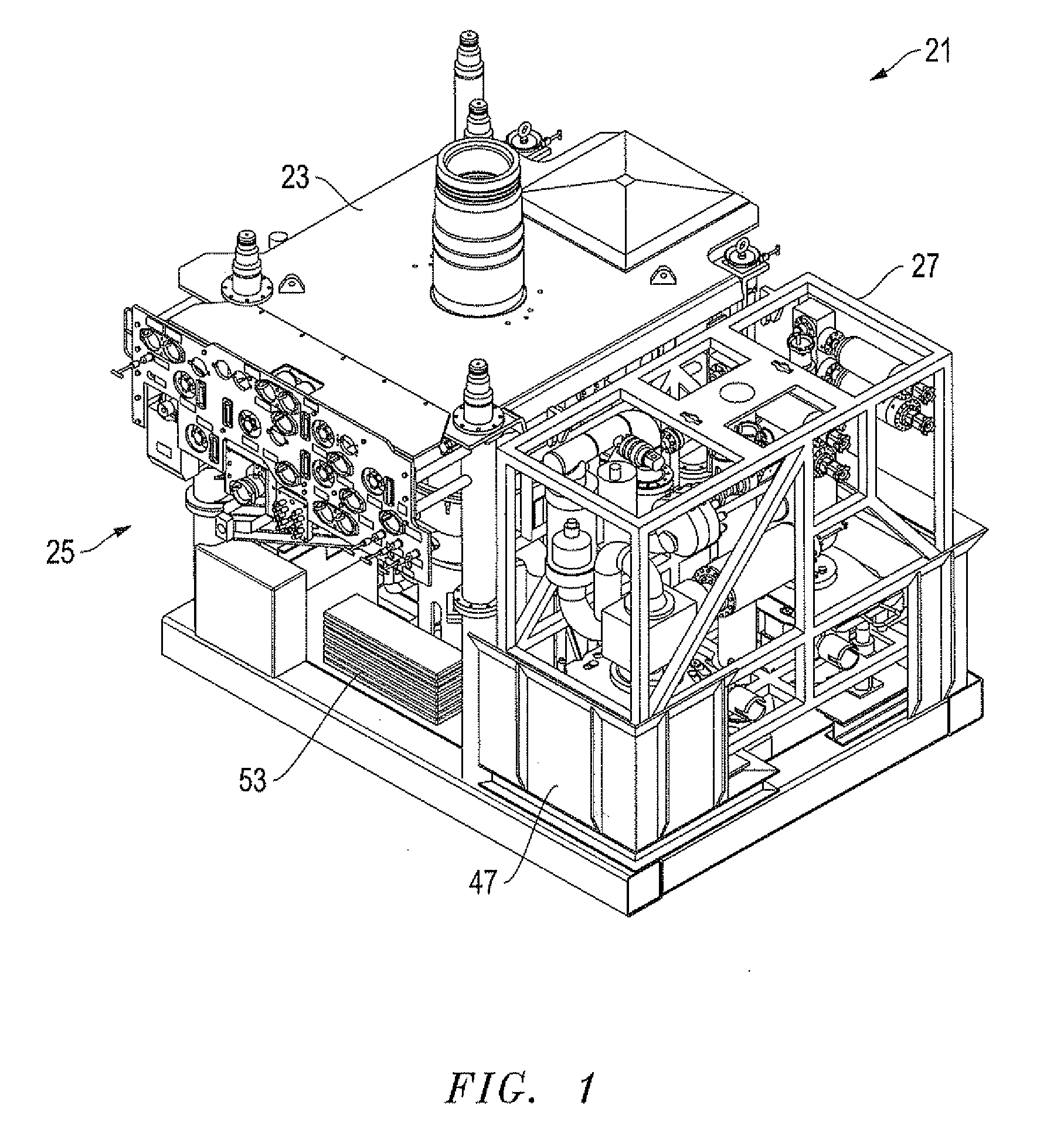

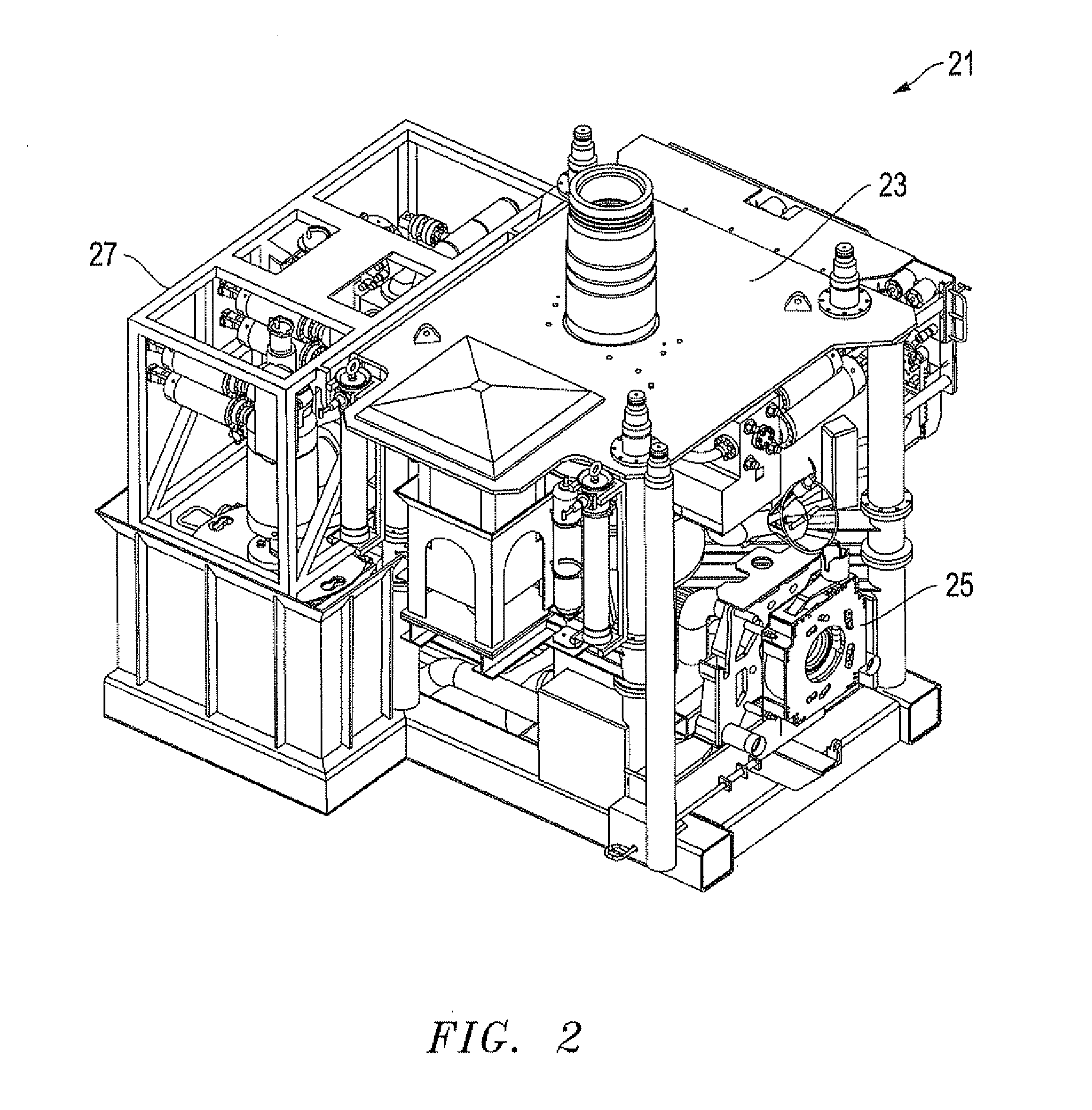

System, method and apparatus for a modular production tree assembly to reduce weight during transfer of tree to rig

A modular tree production tree assembly reduces the weight during transfer of the tree components from a barge to a production rig. The tree assembly includes an upper tree module, a lower tree module, and a choke bridge module. The upper tree module has a tree head, the lower tree module has a guidance system and ties in the flow lines to the in-field infrastructure, and the choke bridge module has the choke and instrumentation bridge to link the three components together. Prior to delivery to the rig, the components of the modular tree assembly may be joined together and tested on shore. Upon arrival at the rig, the components are individually lifted from the barge onto the rig by a crane. After the tree components are on the rig, the modular tree is reassembled and then deployed to the sea floor via the draw works.

Owner:VETCO GRAY

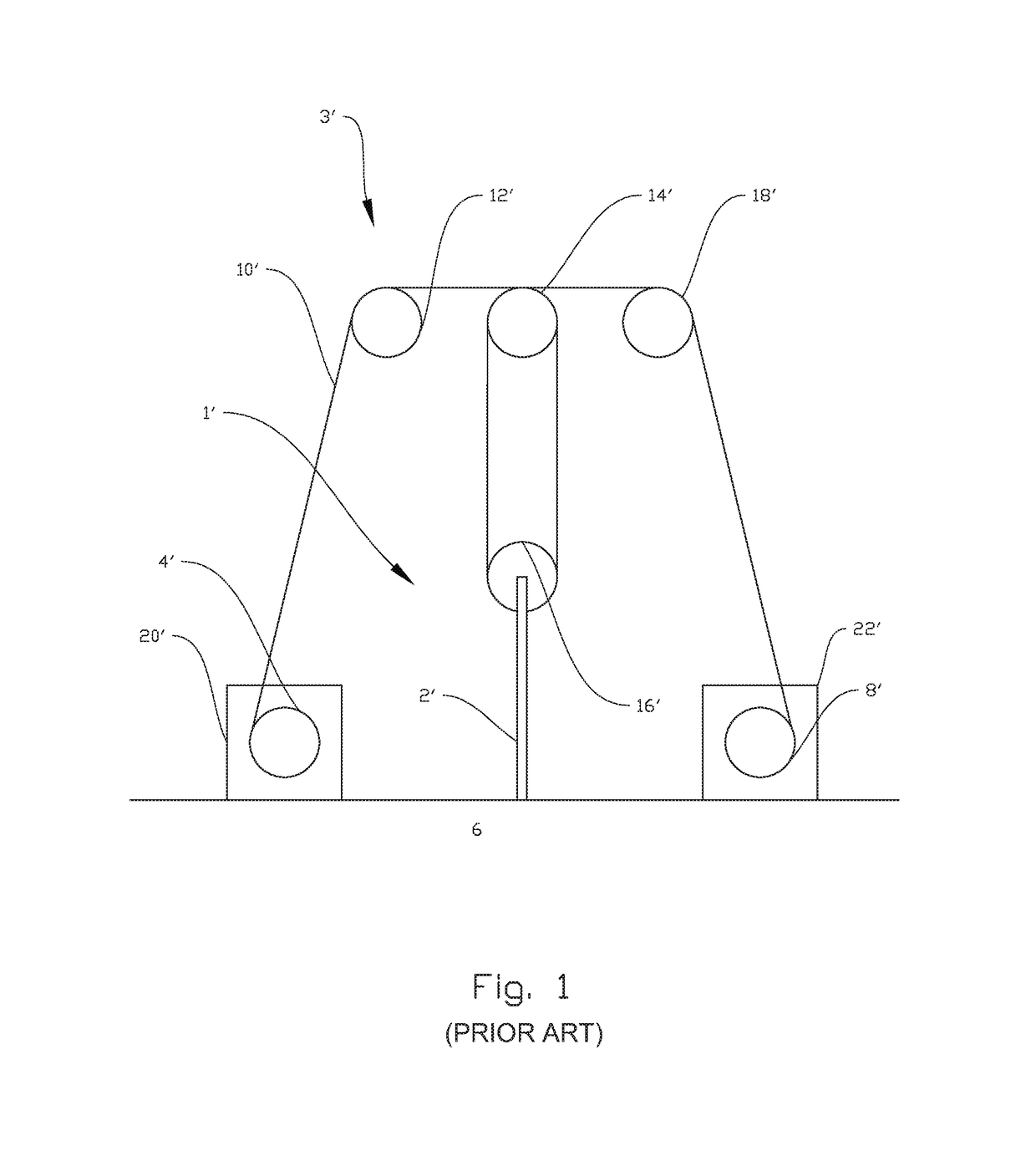

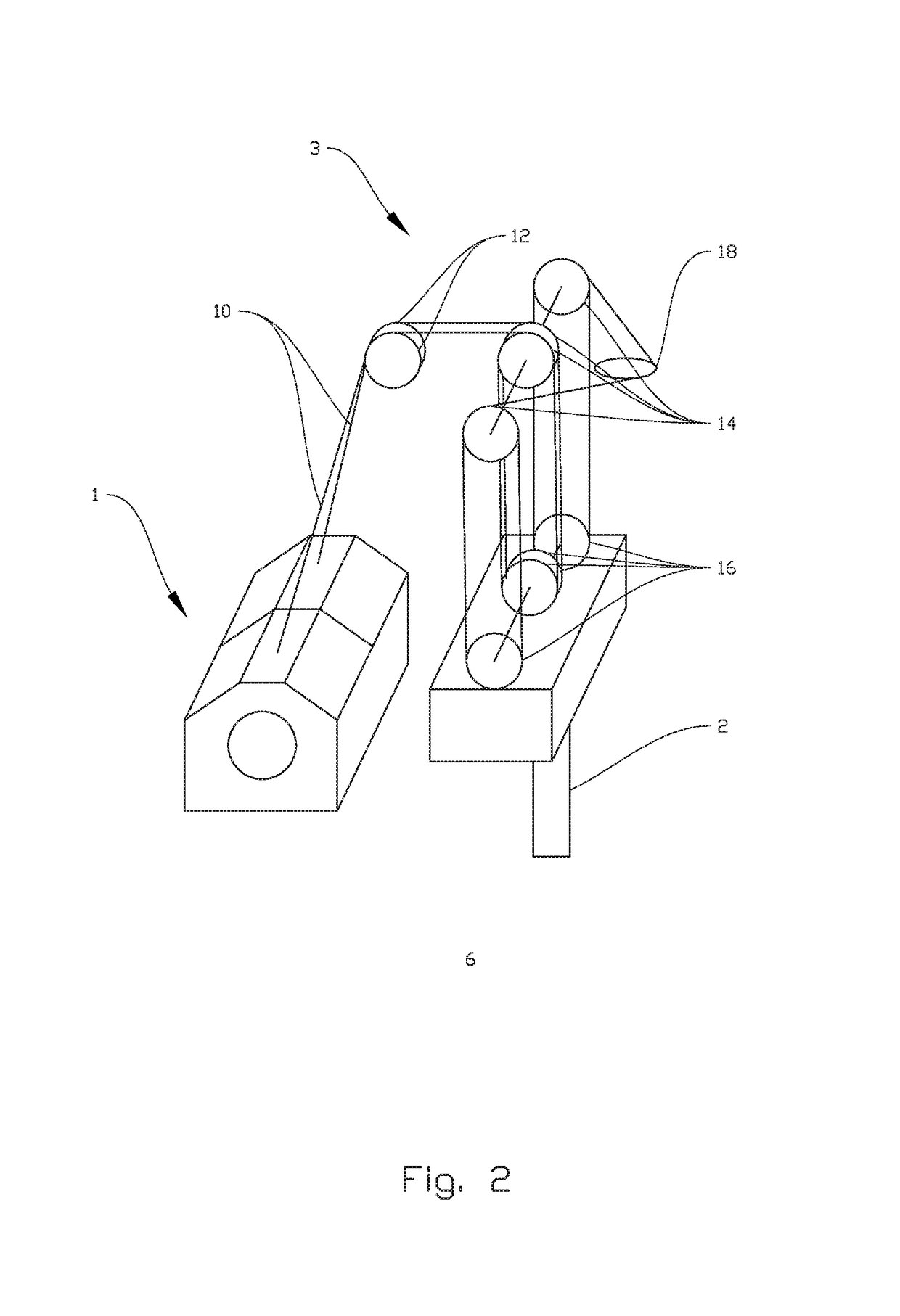

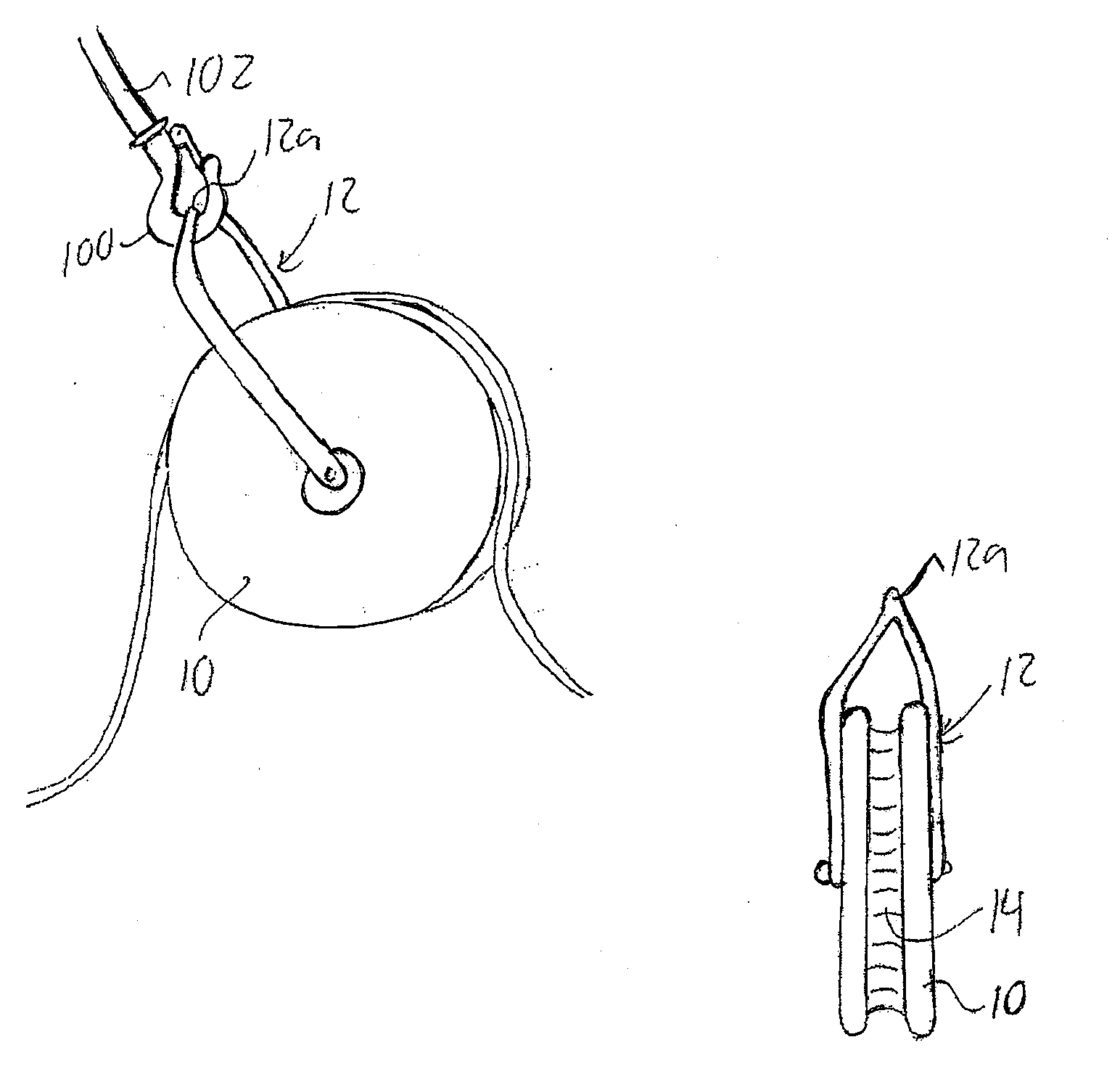

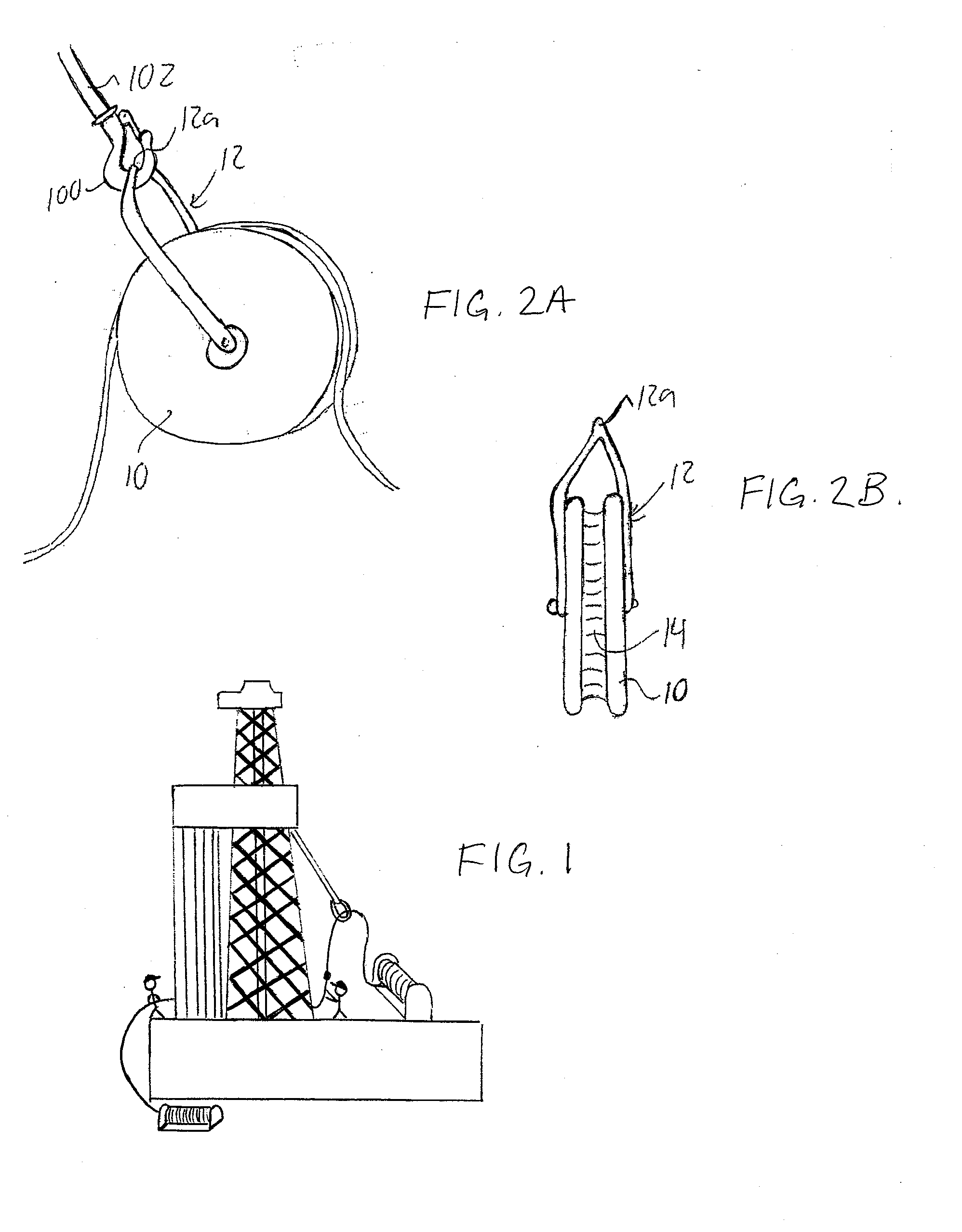

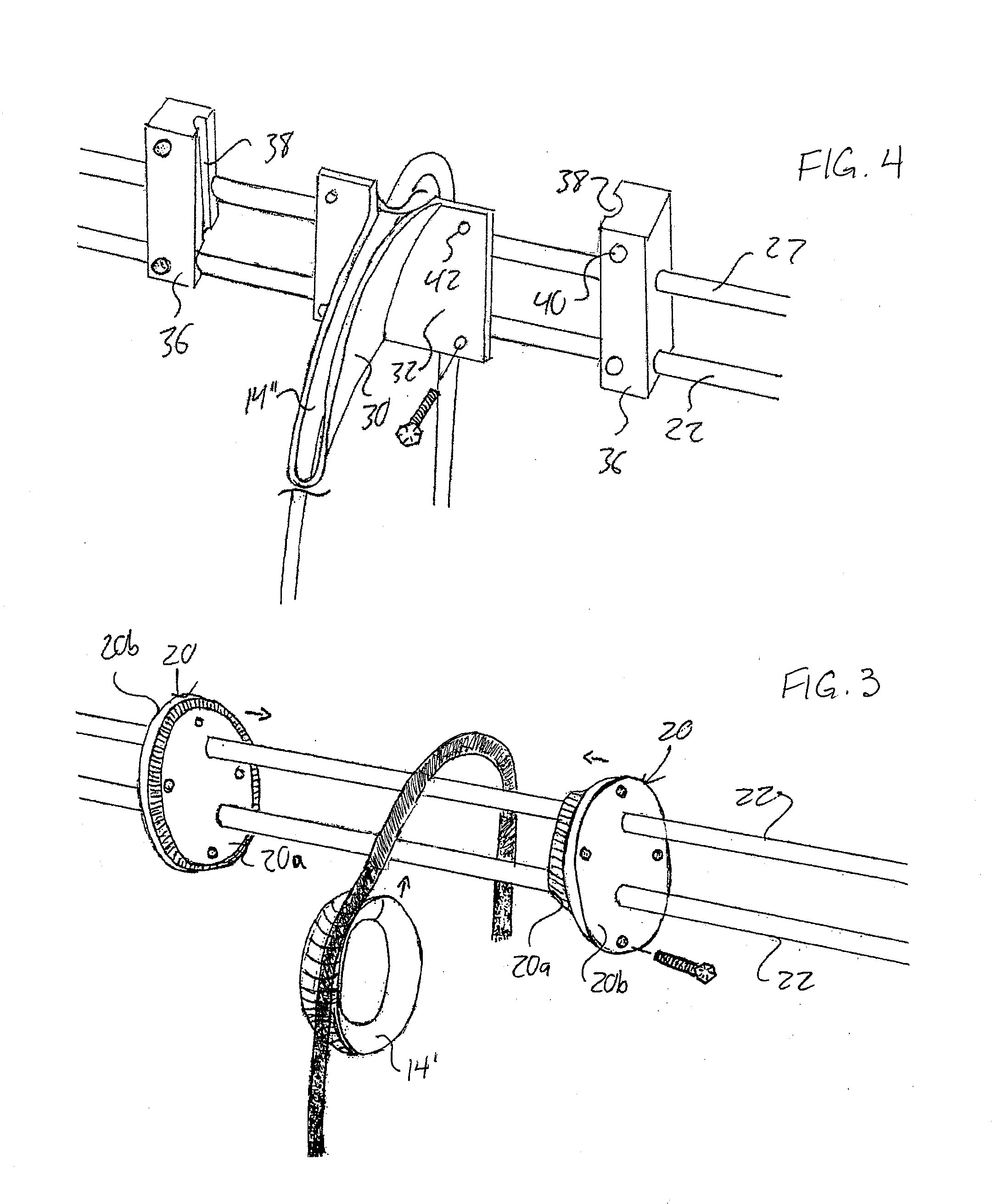

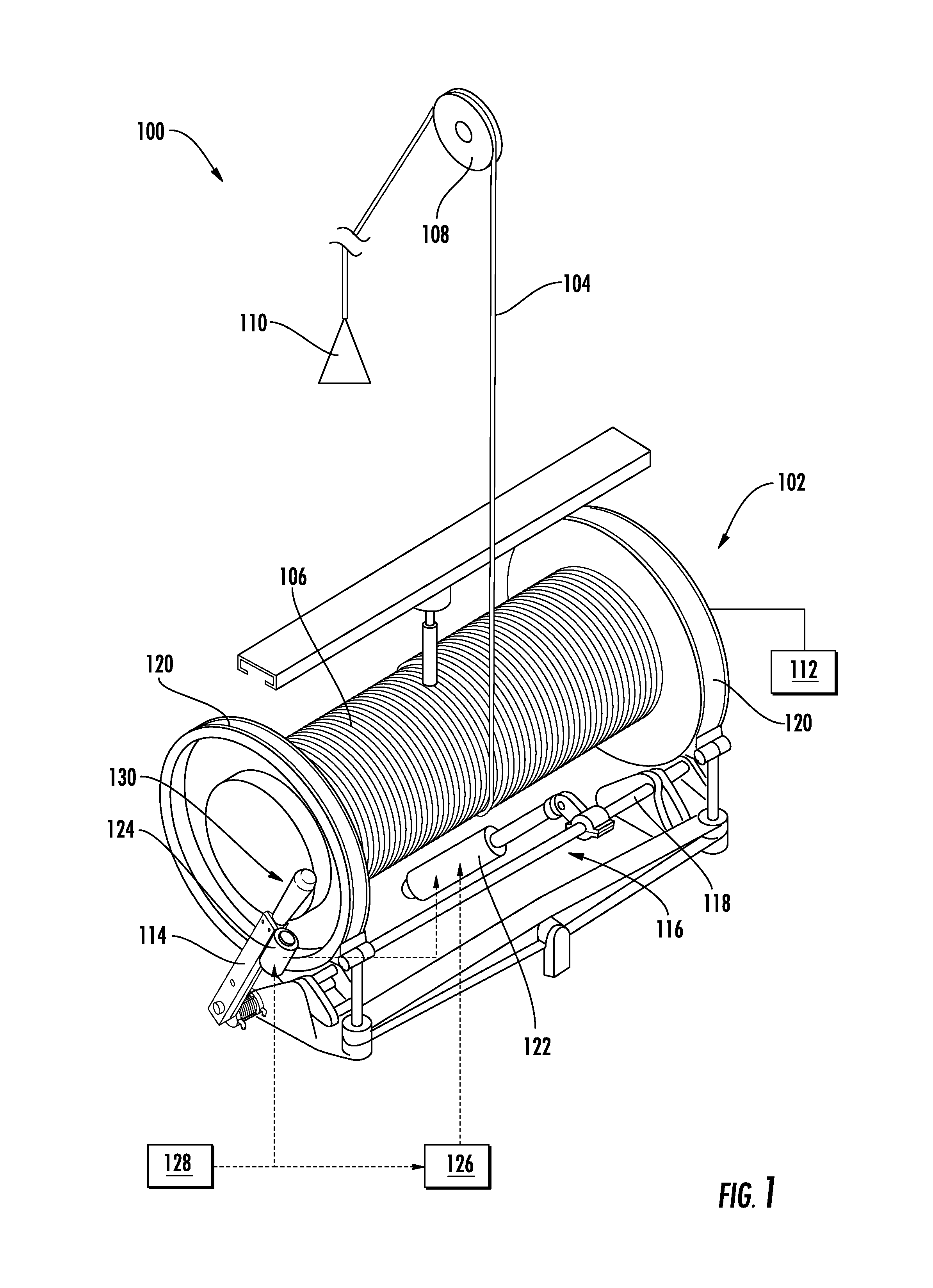

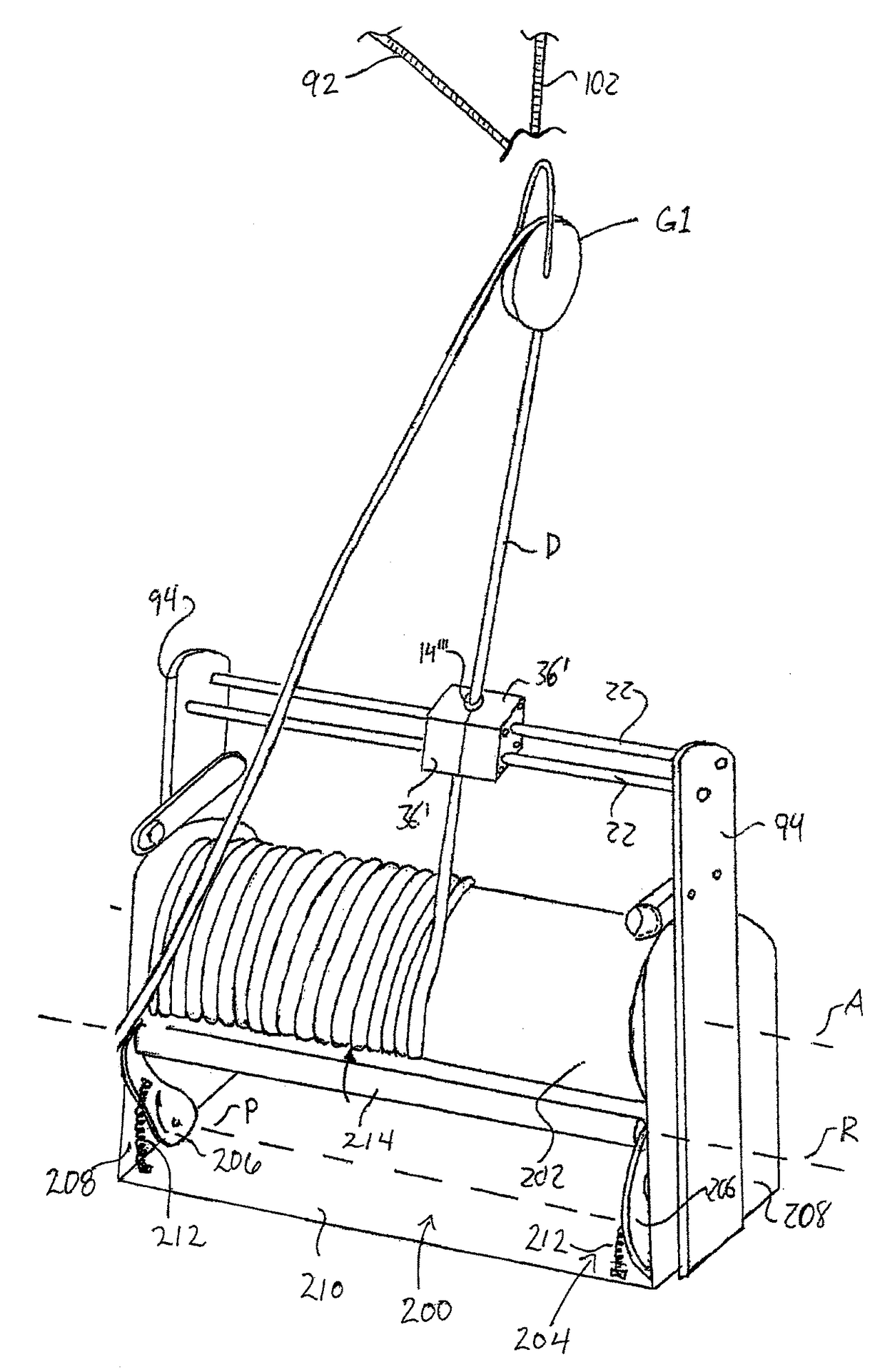

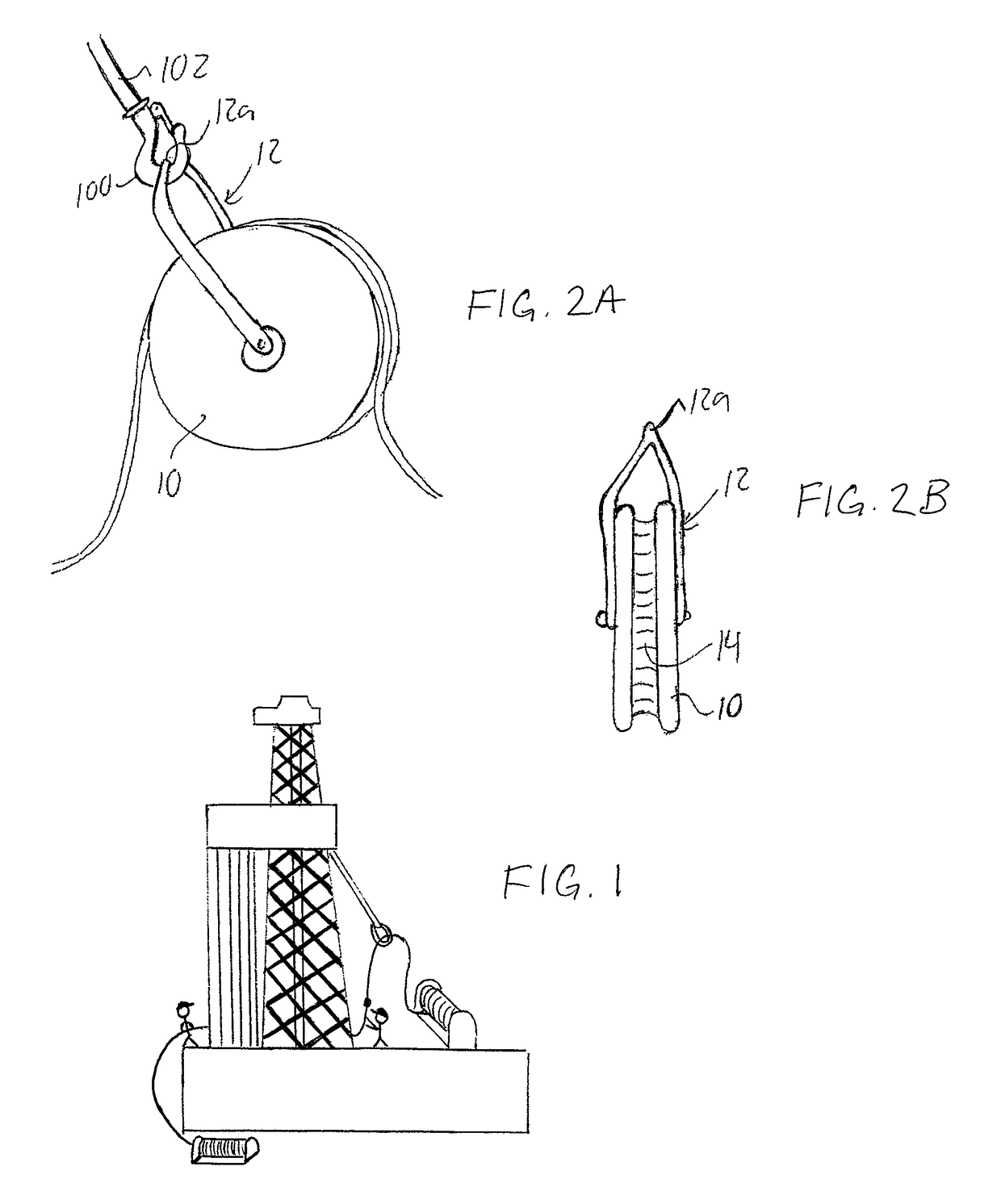

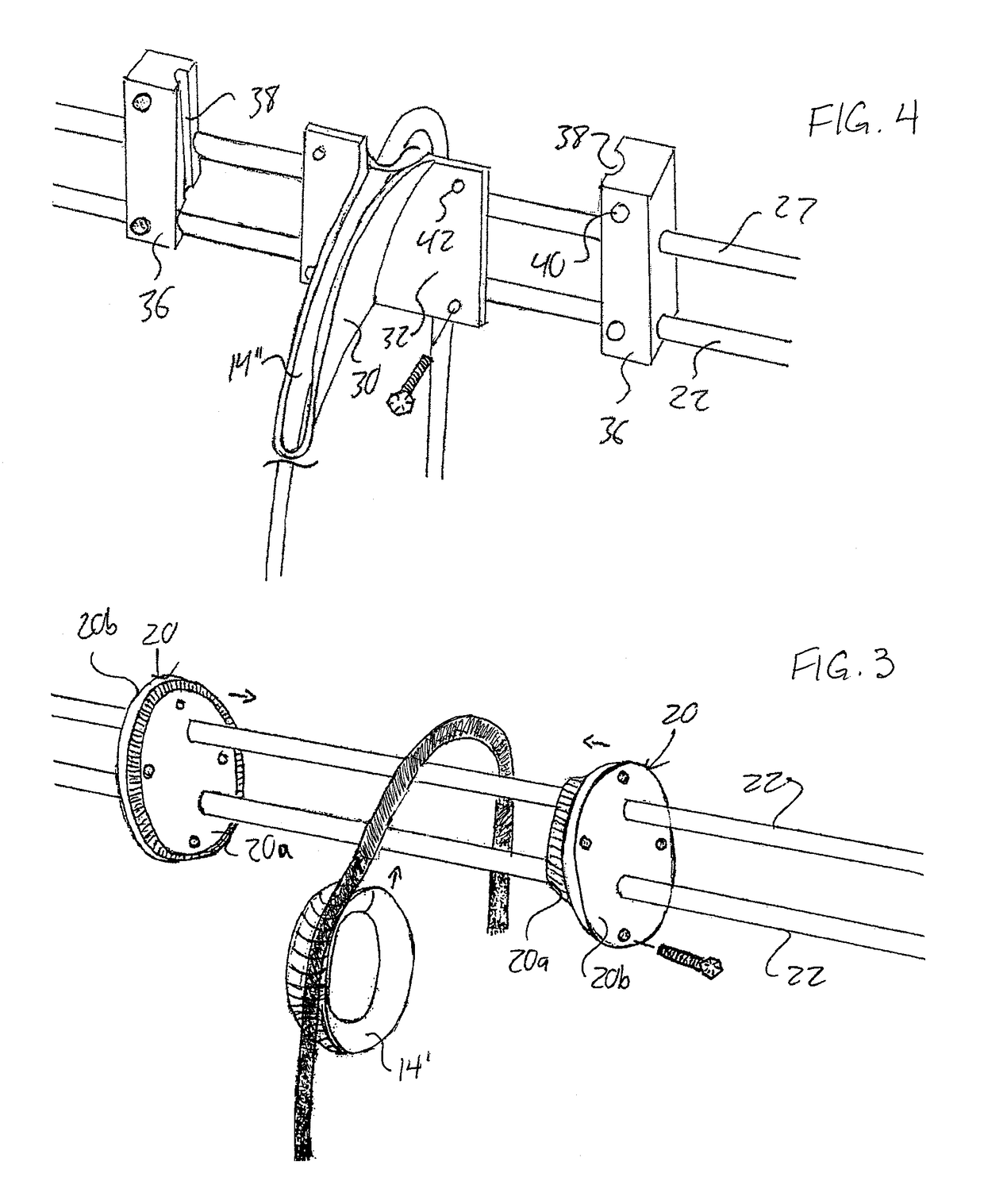

Replaceably Lined Cable Guides and Tensioning Roller for Drill Line Slip and Cut Operations on a Drilling Rig

Cable guides for overhead support of drill line on a drilling rig during a slip and cut operation feature replaceable liners of wear material supported by a re-usable base. A tensioning roller added to the draw-works resides outward from the periphery of the draw-works drum and is spring-biased toward same into order to force the incoming drill line against the periphery of the drum.

Owner:URQUHART JESSE

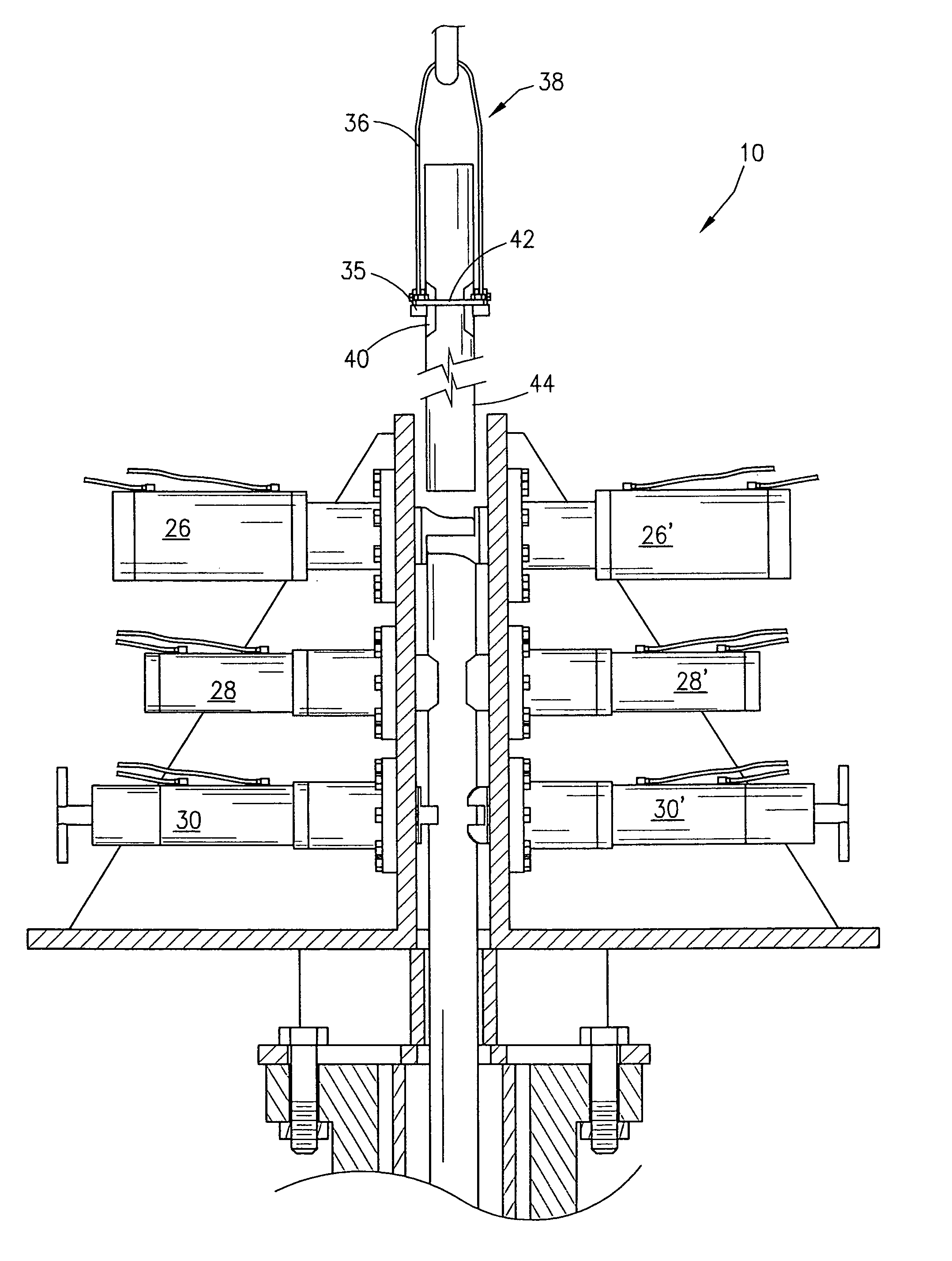

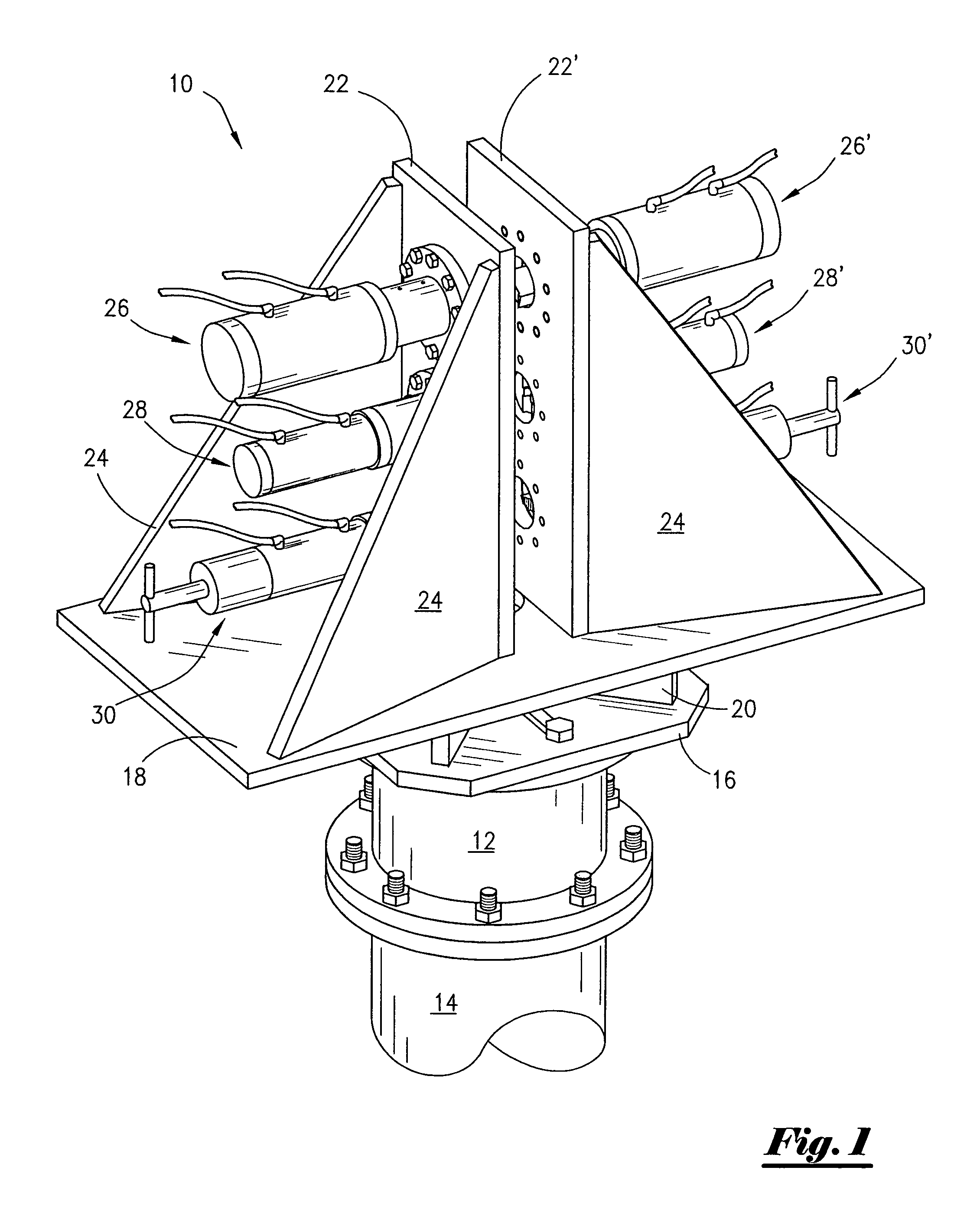

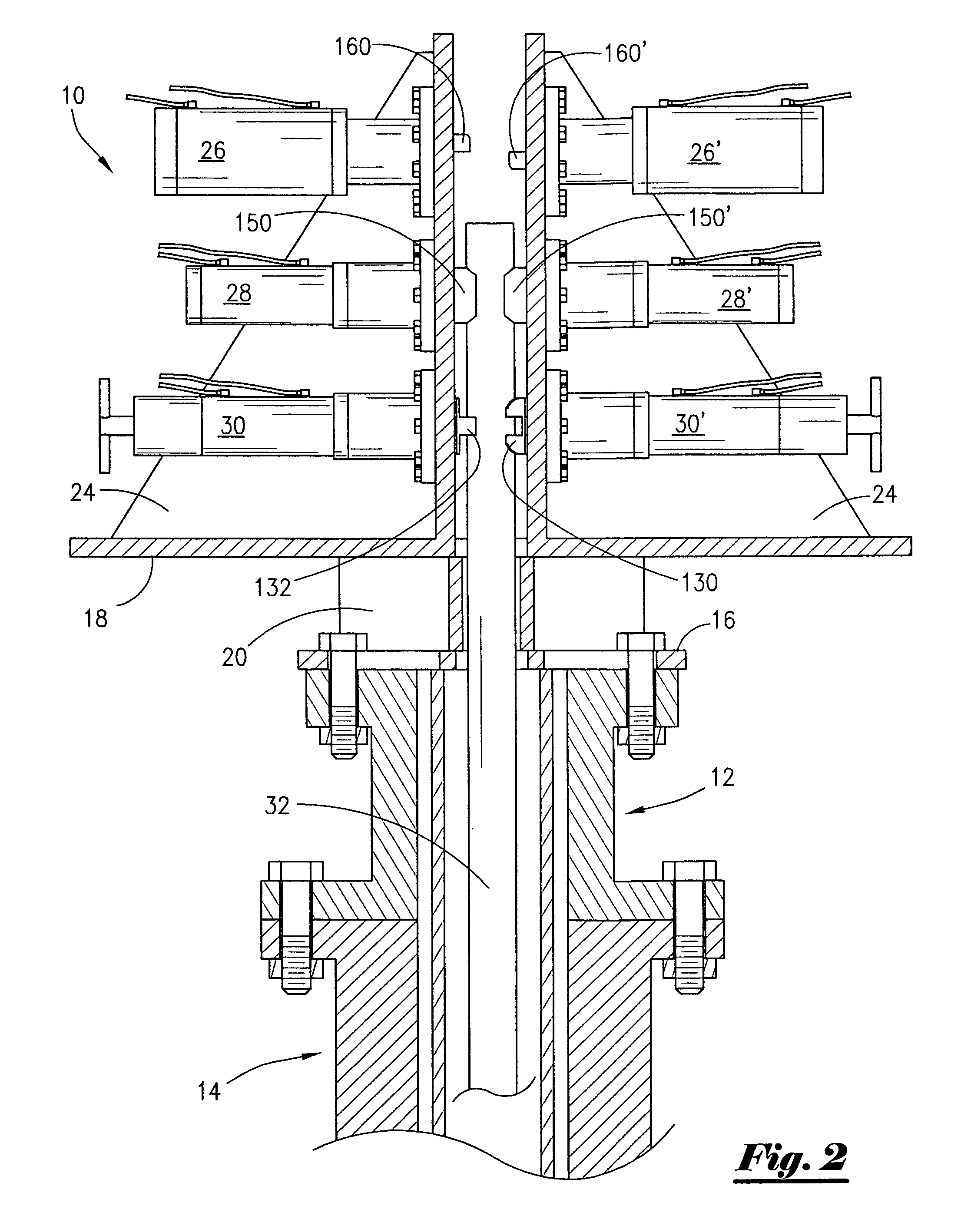

Apparatus and method for extracting a tubular string from a bore hole

A tubular extraction system for use in a plug and abandonment process and may include a structural mounting for adaptation to a well head, various mountings may be used to provide a structure for attaching actuators for griping the tubular string, indenting or crimping the tubular and shearing the tubular string. The system further use a fork supported on a lifting apparatus such as a top drive unit, draw works or portable crane, the fork is inserted within the mounting structure of the system to engage the crimped or indented portion of the tubular section being extracted and thus allow removal of sequentially sheared sections of the tubular string.

Owner:FANGUY ROBERT P

System, method and apparatus for a modular production tree assembly to reduce weight during transfer of tree to rig

A modular tree production tree assembly reduces the weight during transfer of the tree components from a barge to a production rig. The tree assembly includes an upper tree module, a lower tree module, and a choke bridge module. The upper tree module has a tree head, the lower tree module has a guidance system and ties in the flow lines to the in-field infrastructure, and the choke bridge module has the choke and instrumentation bridge to link the three components together. Prior to delivery to the rig, the components of the modular tree assembly may be joined together and tested on shore. Upon arrival at the rig, the components are individually lifted from the barge onto the rig by a crane. After the tree components are on the rig, the modular tree is reassembled and then deployed to the sea floor via the draw works.

Owner:VETCO GRAY

Utilizing Vision Systems at a Wellsite

Utilizing vision systems at a wellsite, which may include operating a video camera to generate a video signal comprising images of one or more pieces of equipment or components and receiving the video signal by a processing system, which may then process the images to determine physical and / or operational characteristics associated with the one or more pieces of equipment in the images. The video signal may contain images of a crown block and / or a drawworks of a hoisting system at an oil and gas drill rig. The processing system may then process the video signal to determine when a traveling block of the hoisting system is within a threshold distance from the crown block.

Owner:SCHLUMBERGER TECH CORP

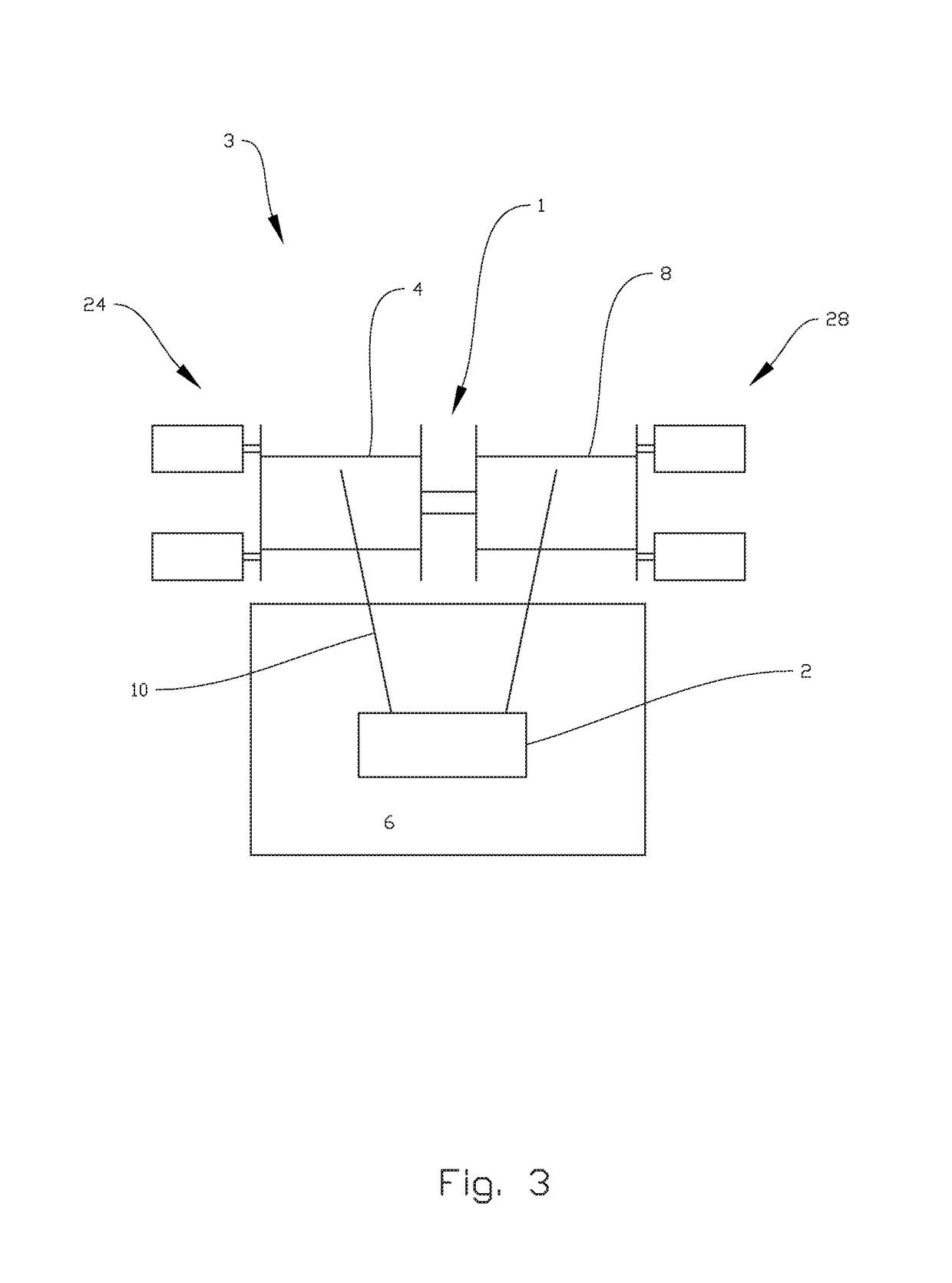

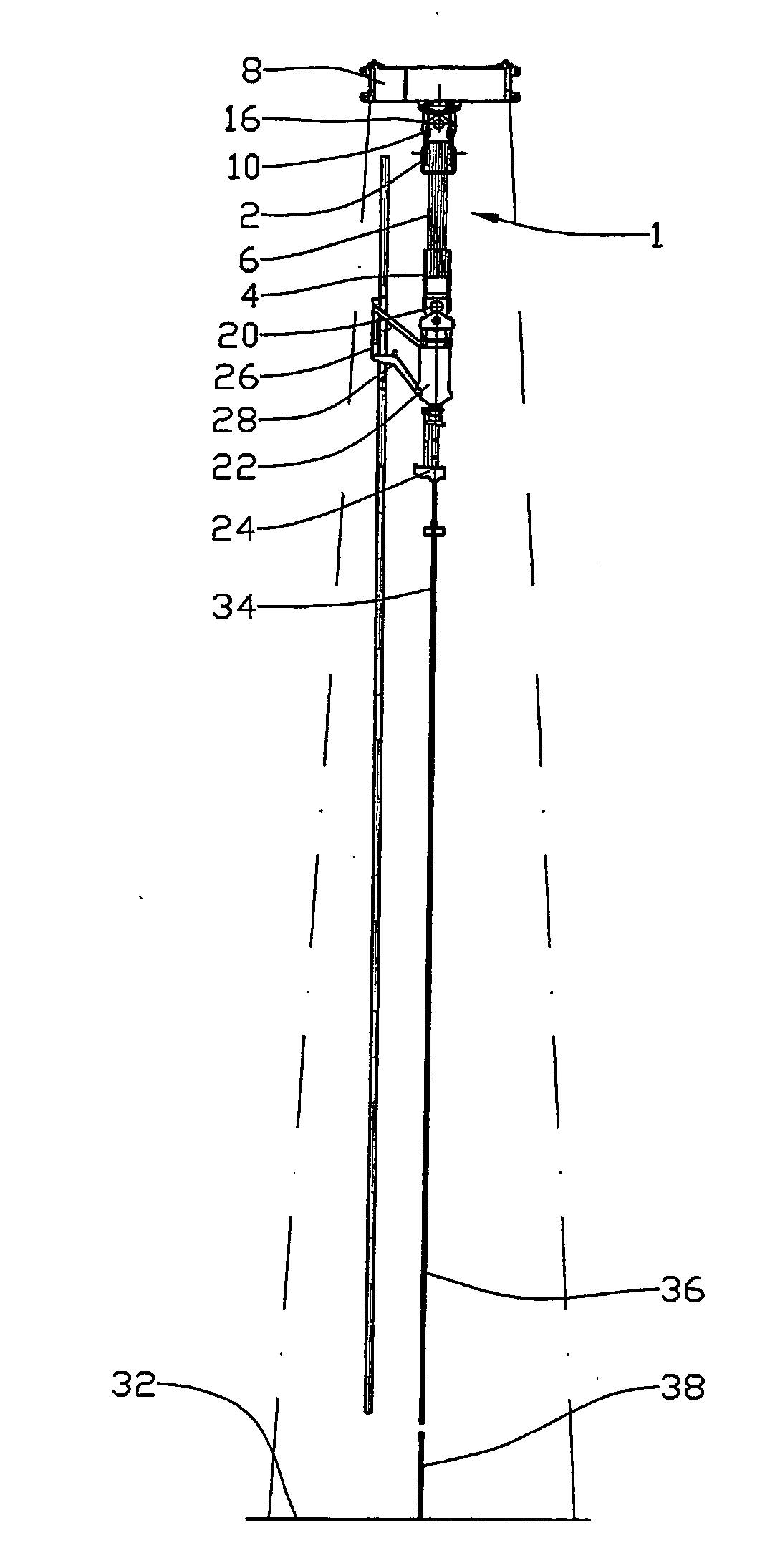

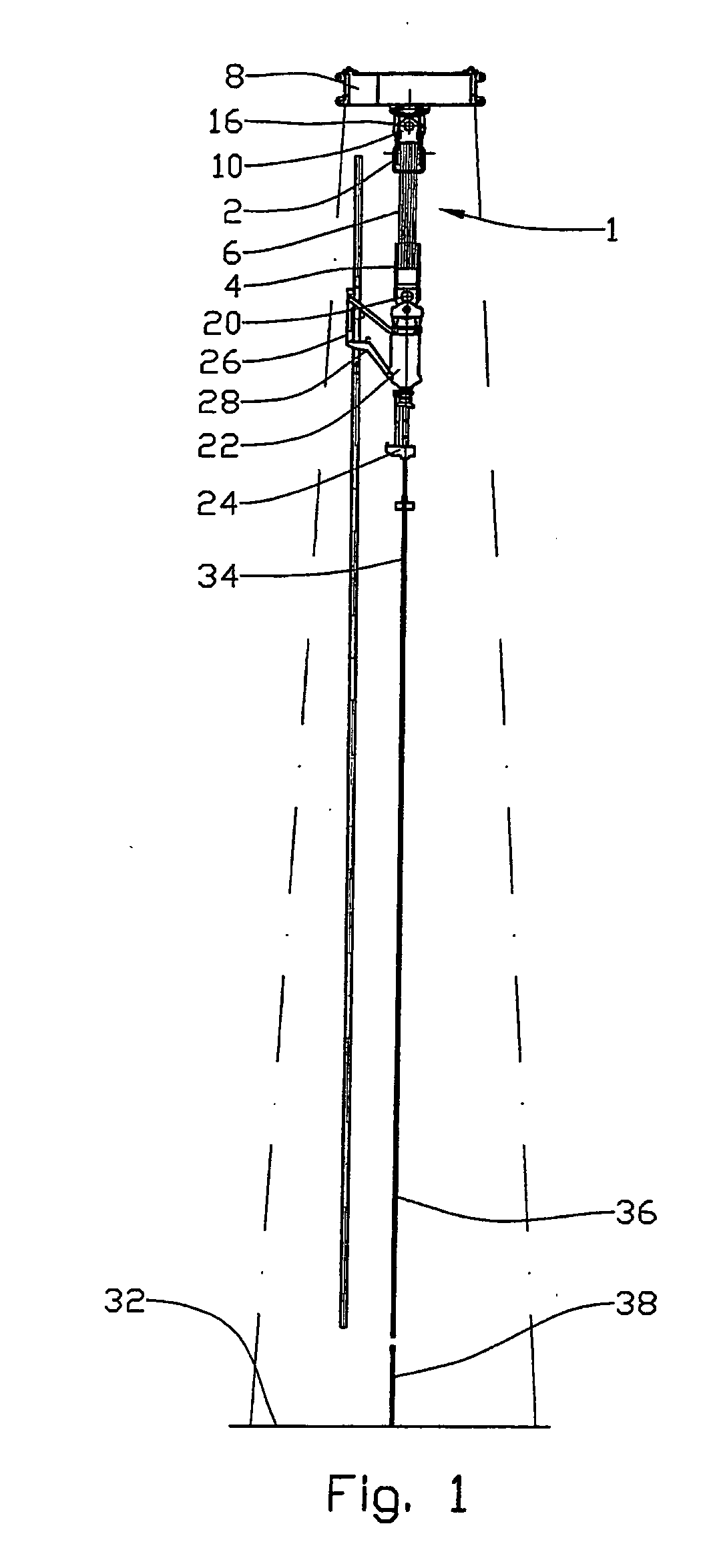

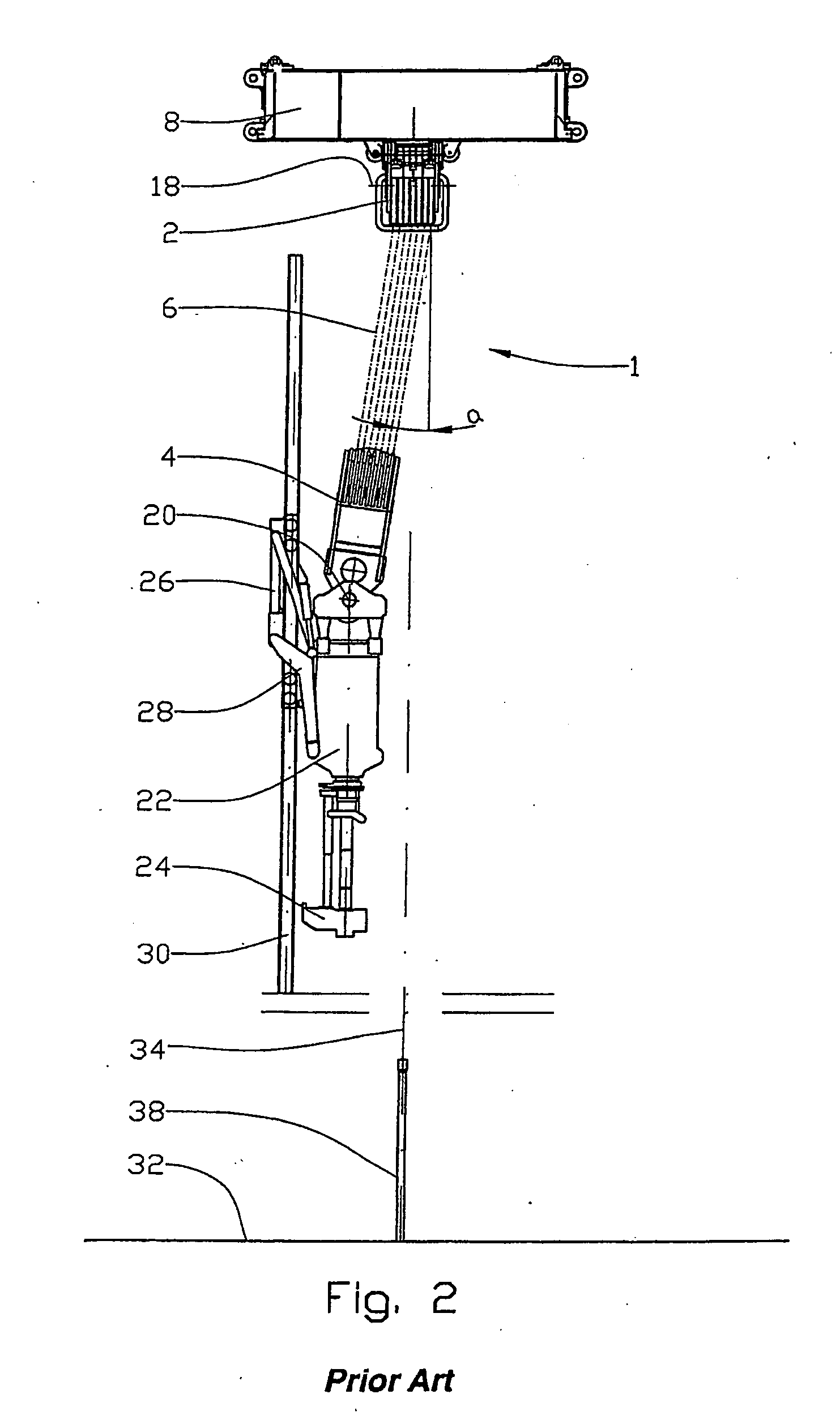

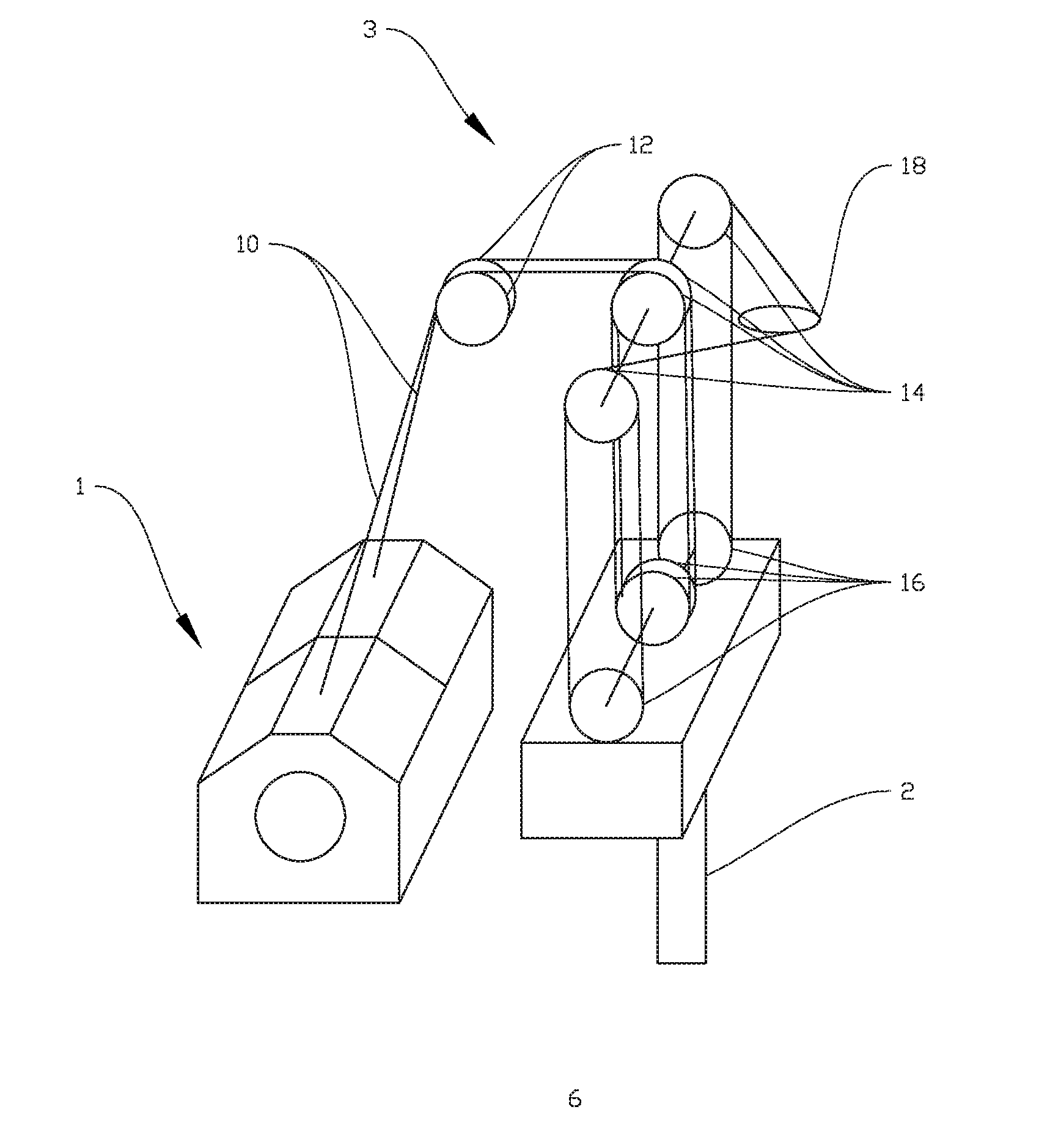

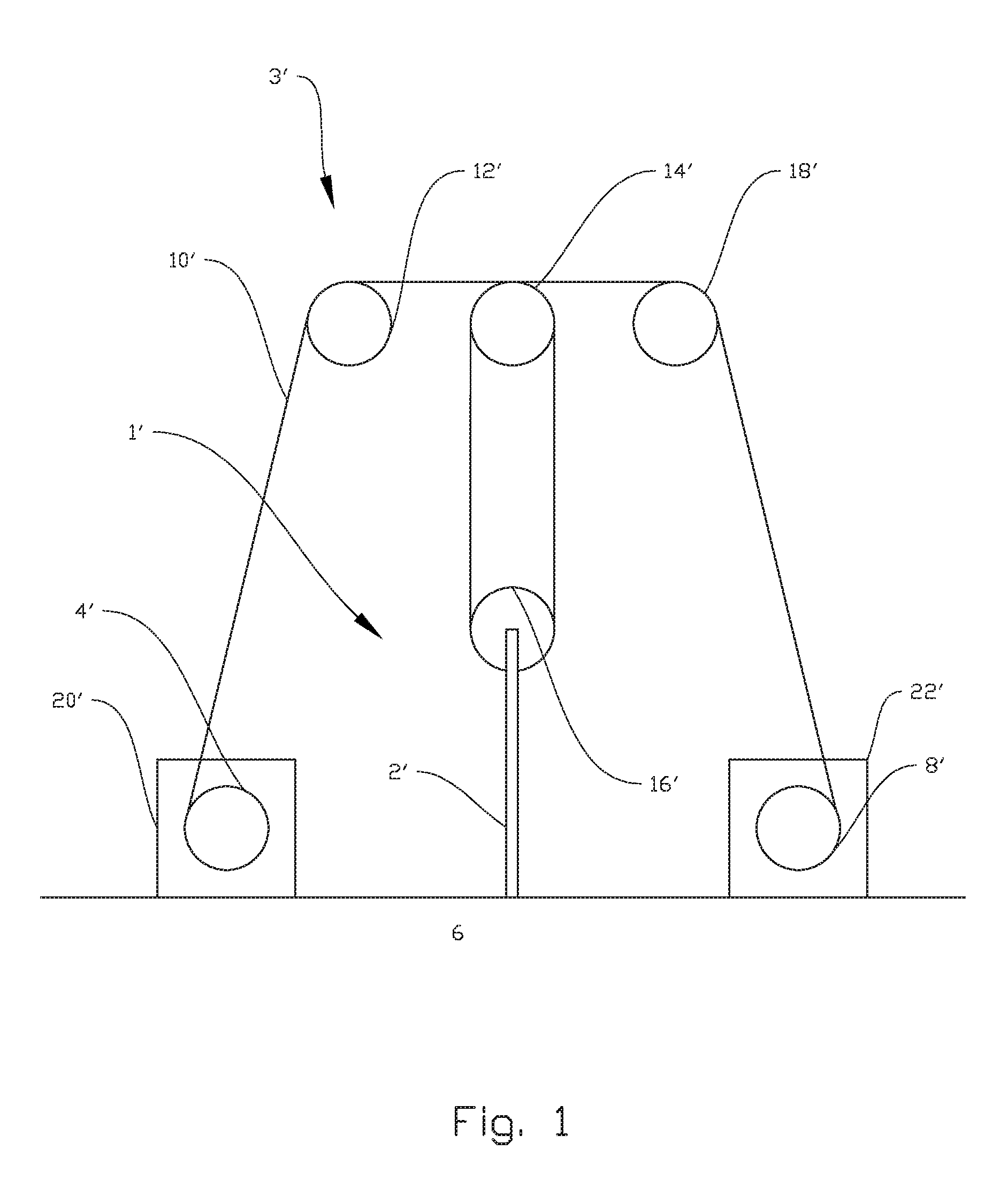

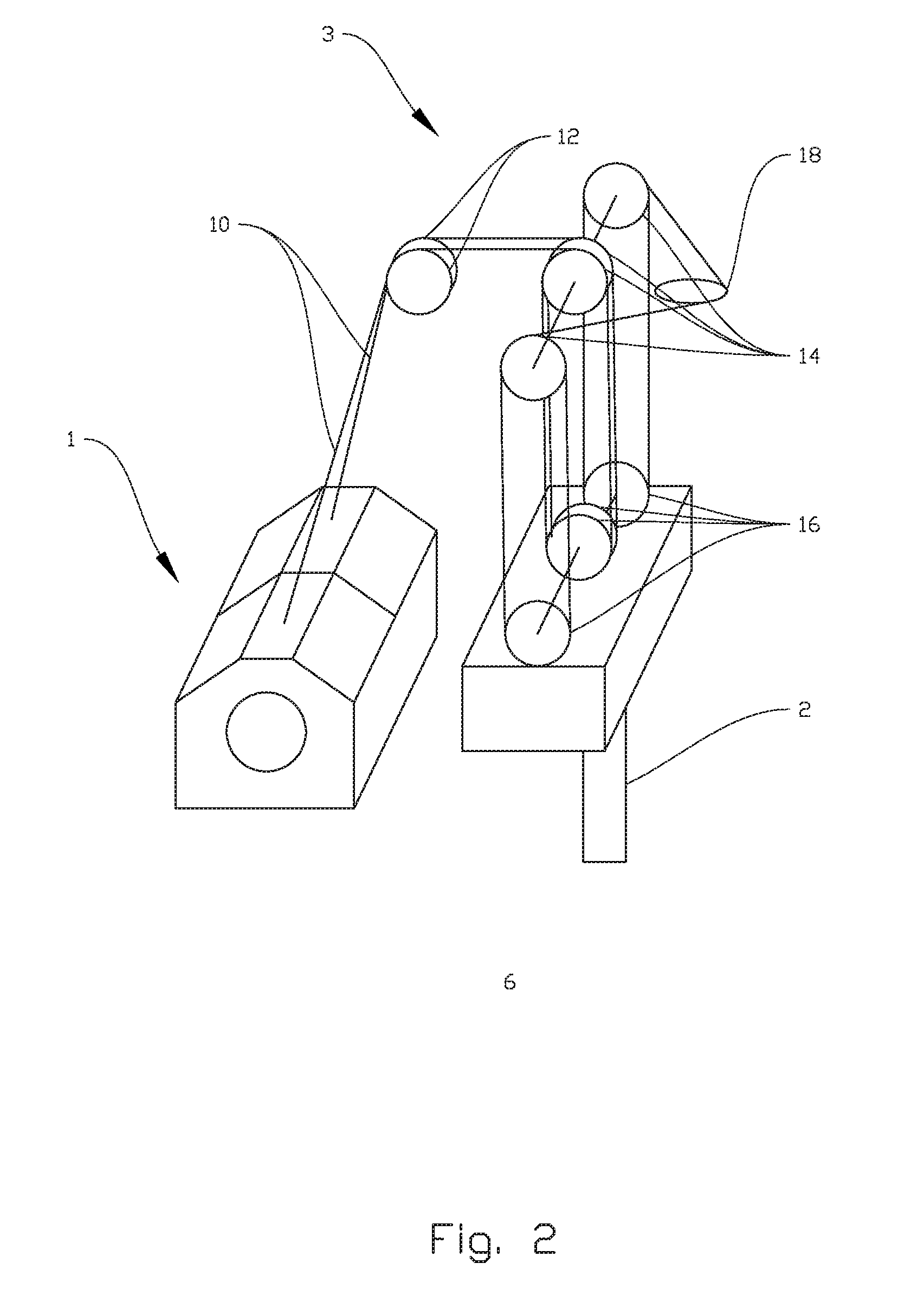

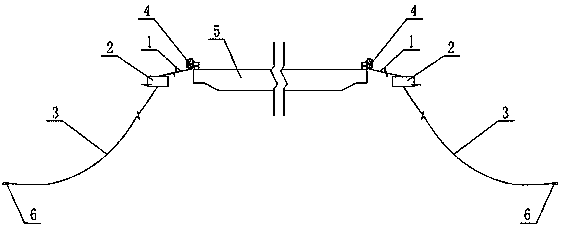

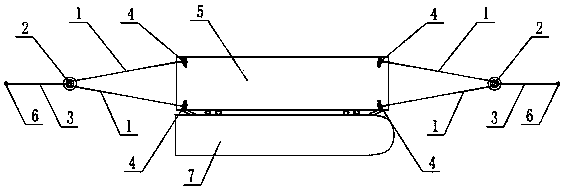

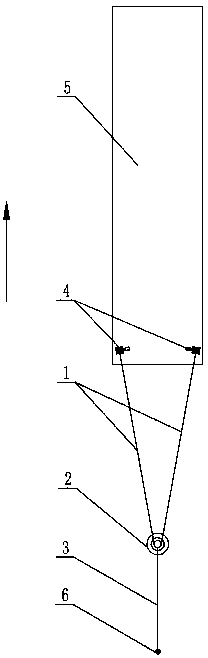

Drawworks device on a drill floor

A drawworks device on a drill floor which includes an upper pulley assembly) connected to a heave-compensated or fixed mounting, and a main block connected to a pipe mount which is laterally movable in at least one direction relative to the drilling centre of the drill floor, the pulley assembly pivotal about a horizontal first axis which is perpendicular to the direction of lateral movement.

Owner:NAT OILWELL VARCO NORMAY AS

Draw-works and method for operating the same

Owner:GRANT PRIDECO LP

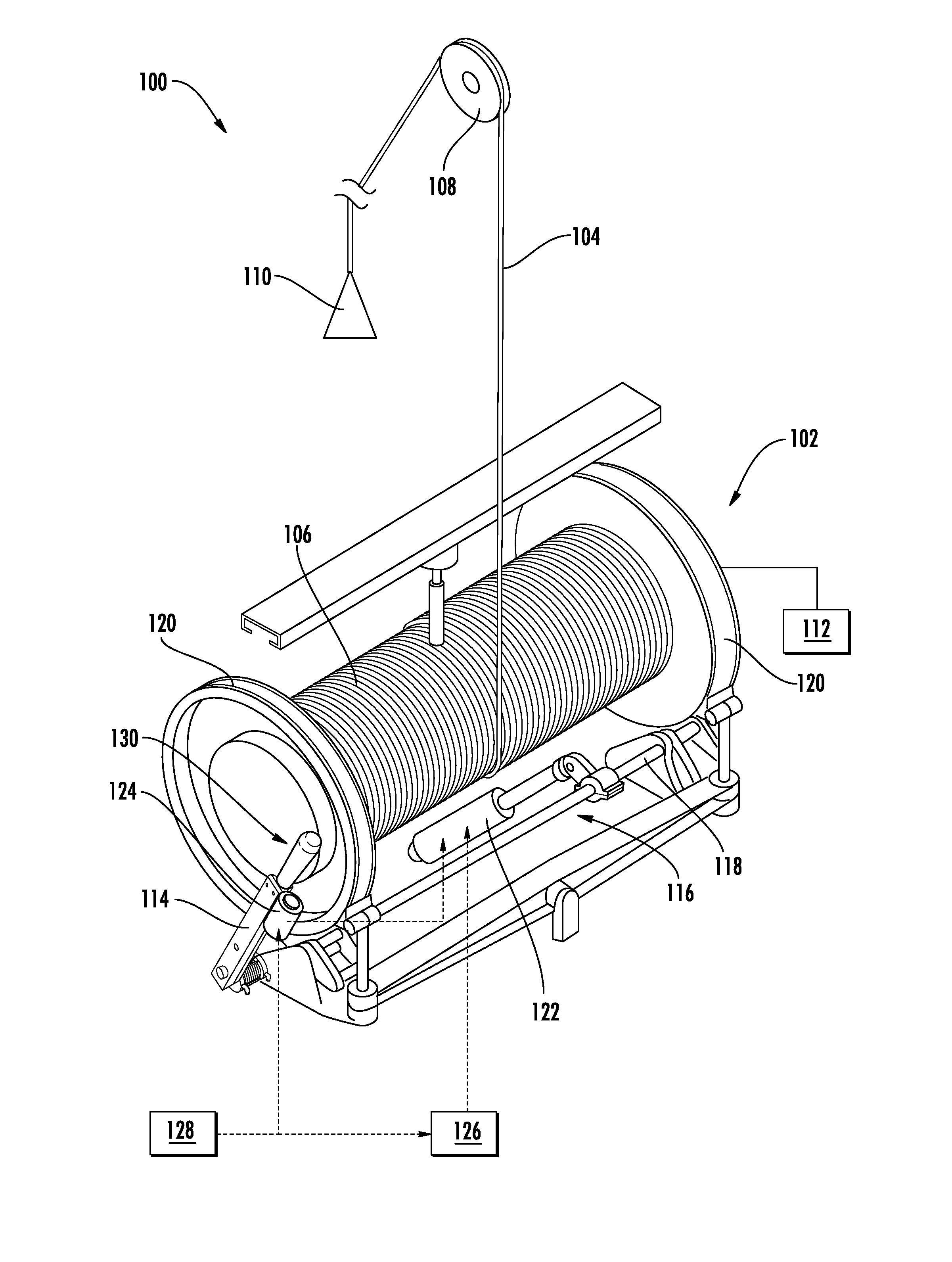

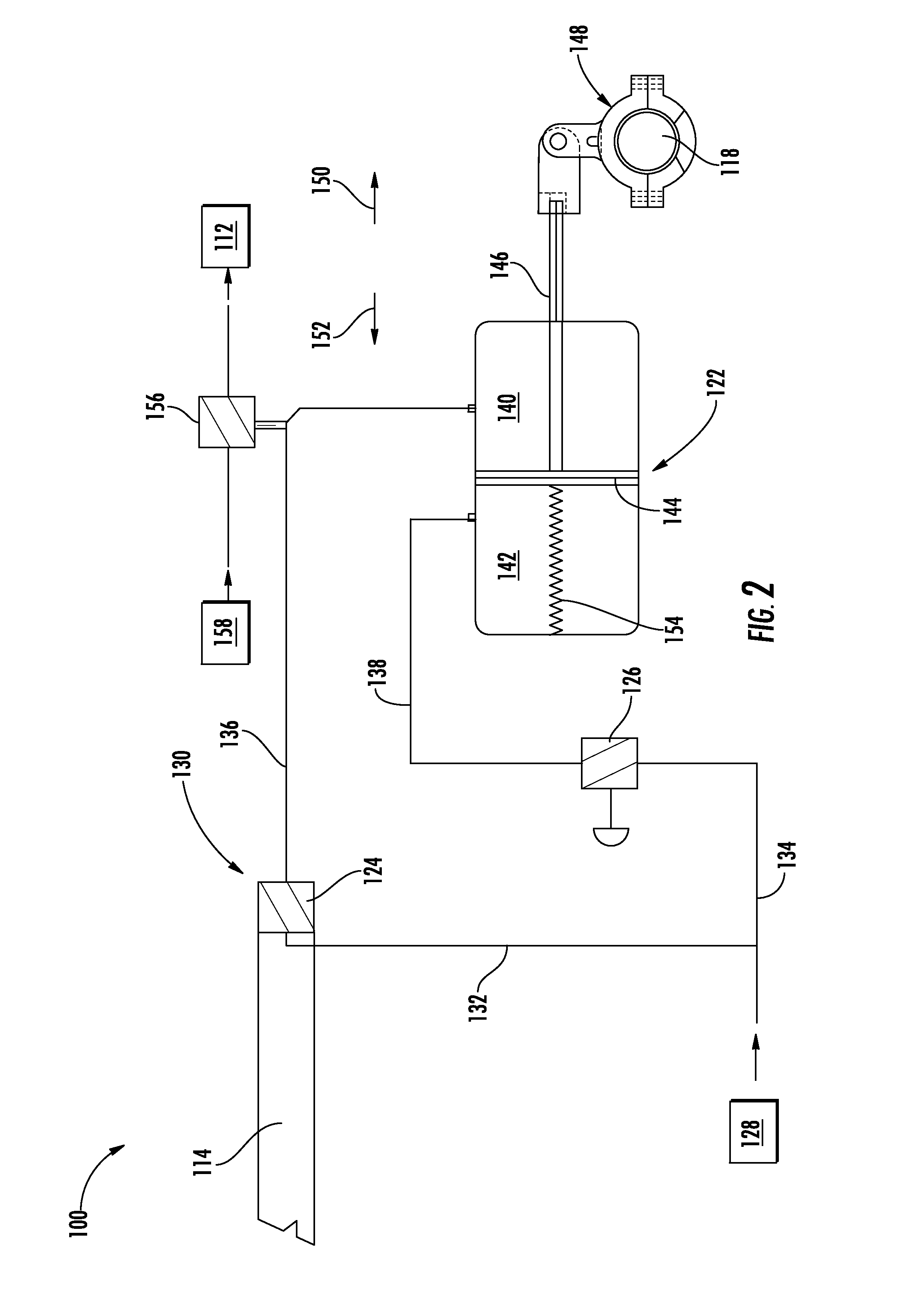

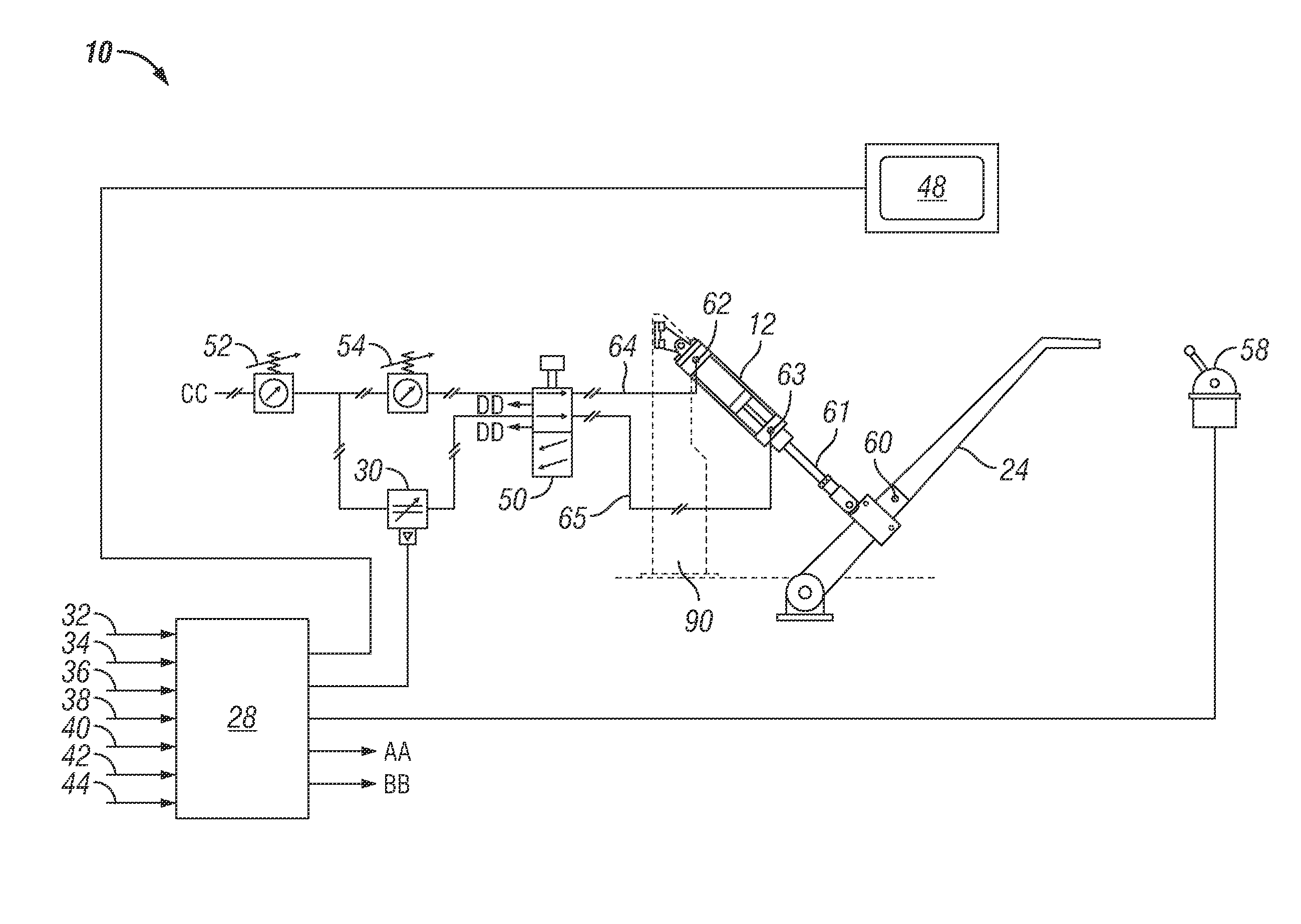

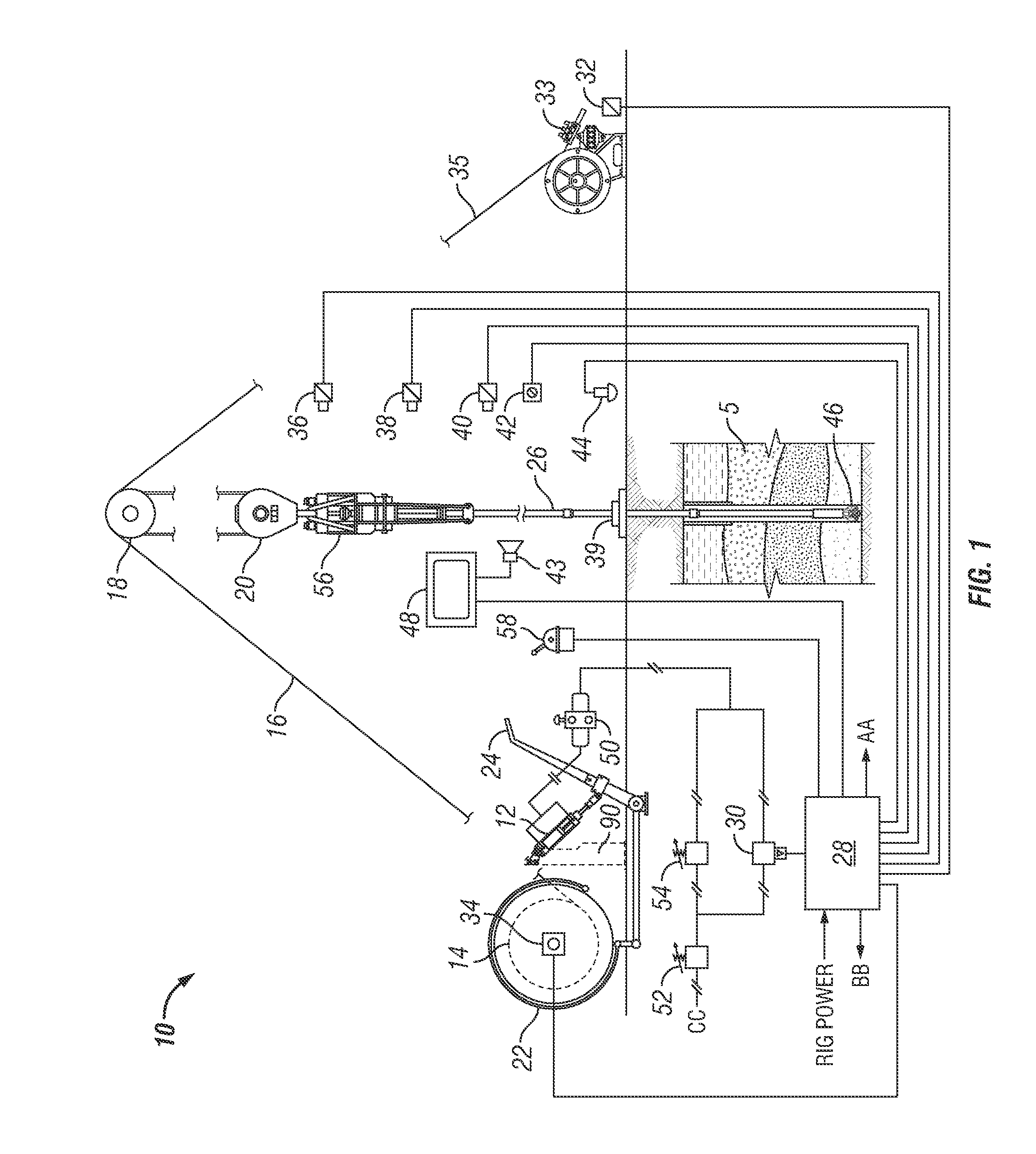

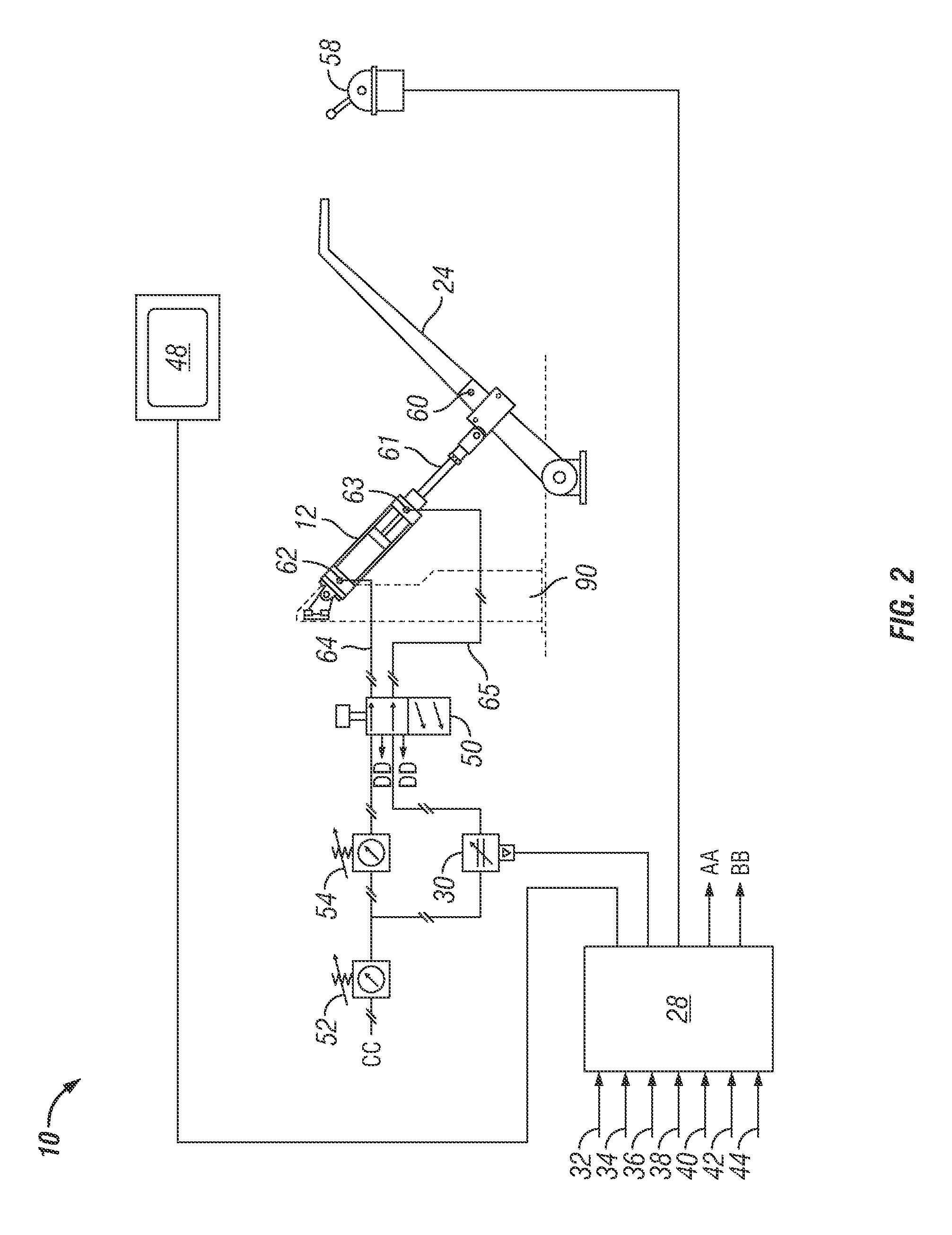

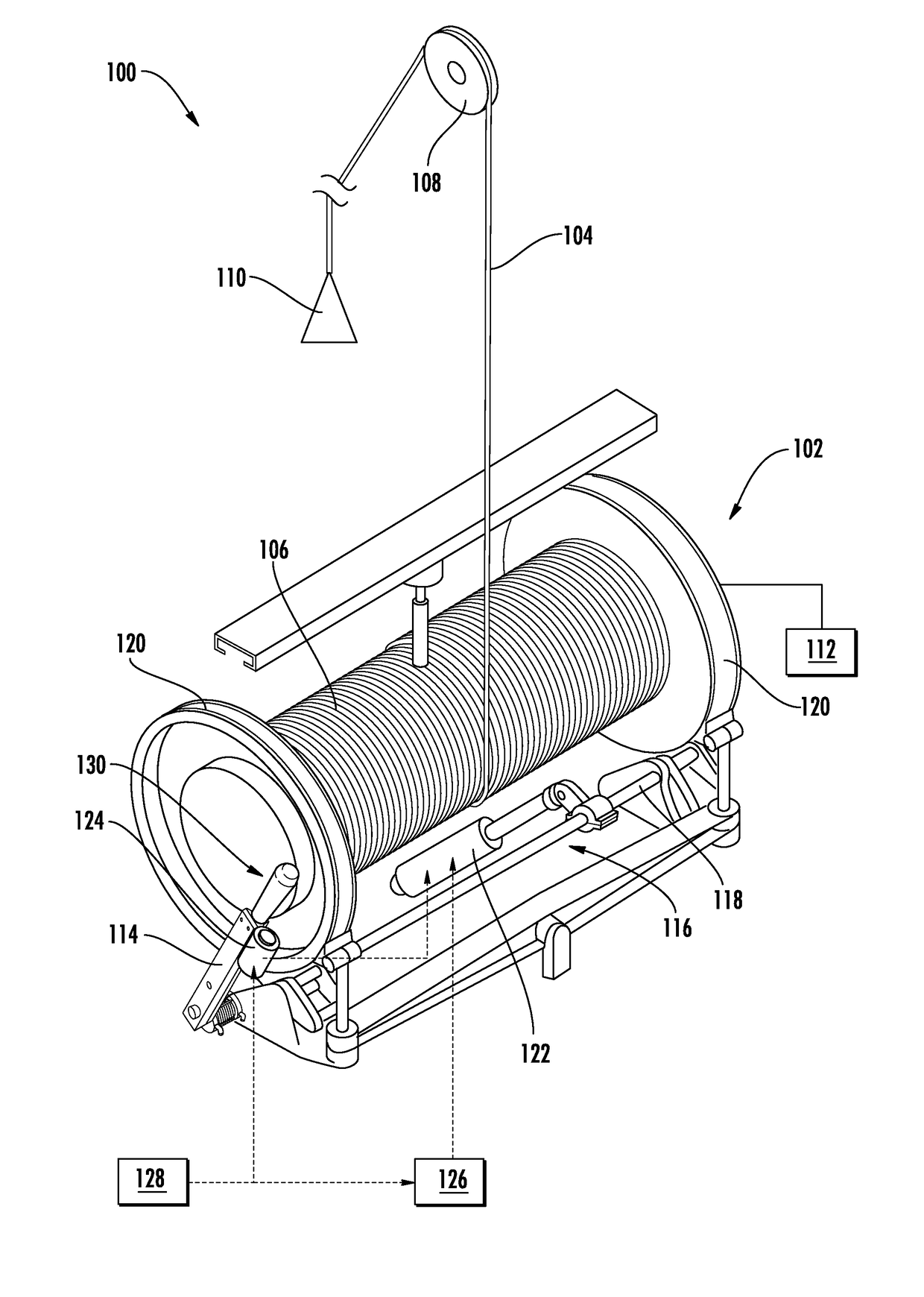

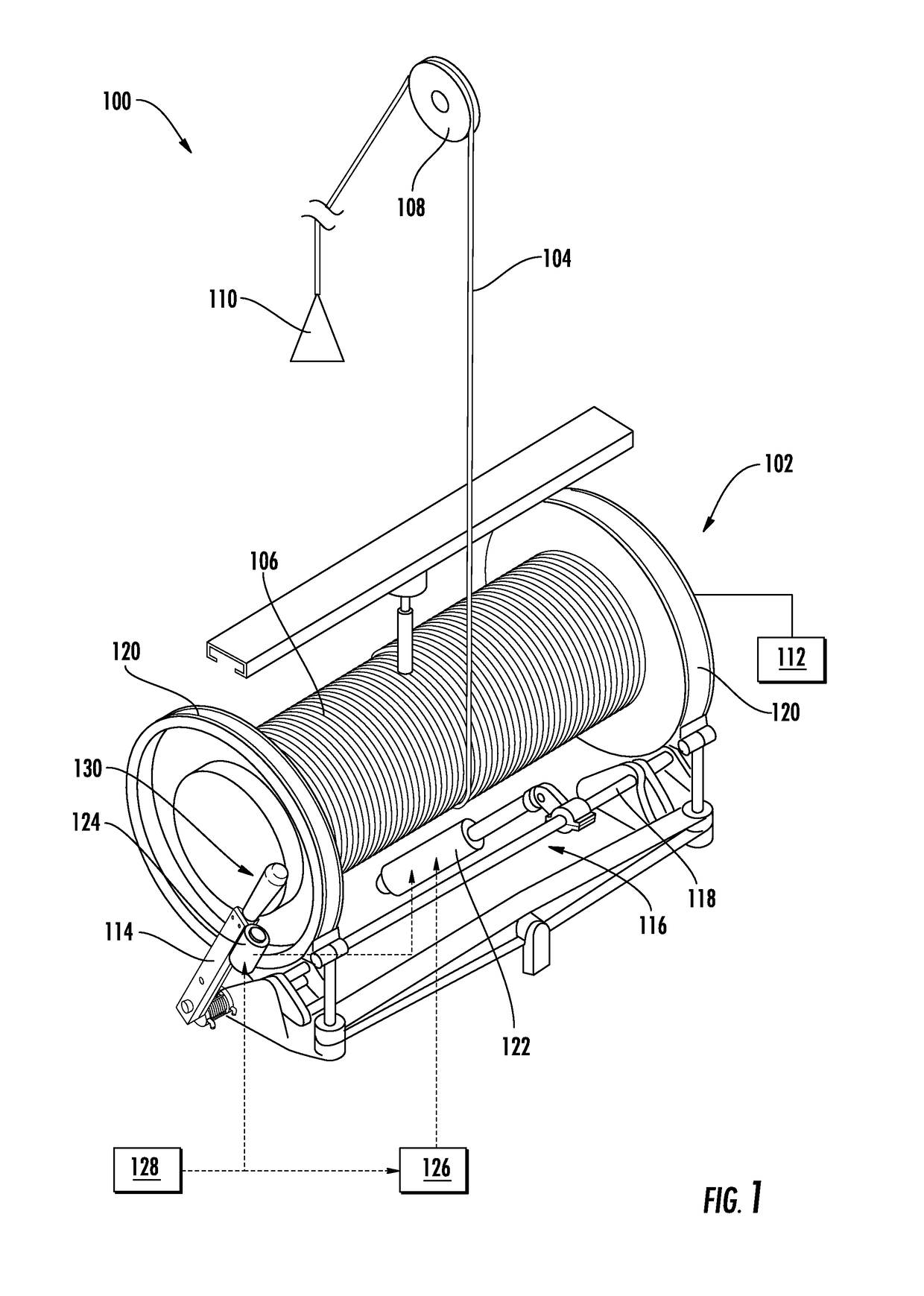

Braking system for a draw works used for drilling operations

ActiveUS20170050827A1Fluid actuated drum brakesMechanically actuated drum brakesWorking fluidPiston rod

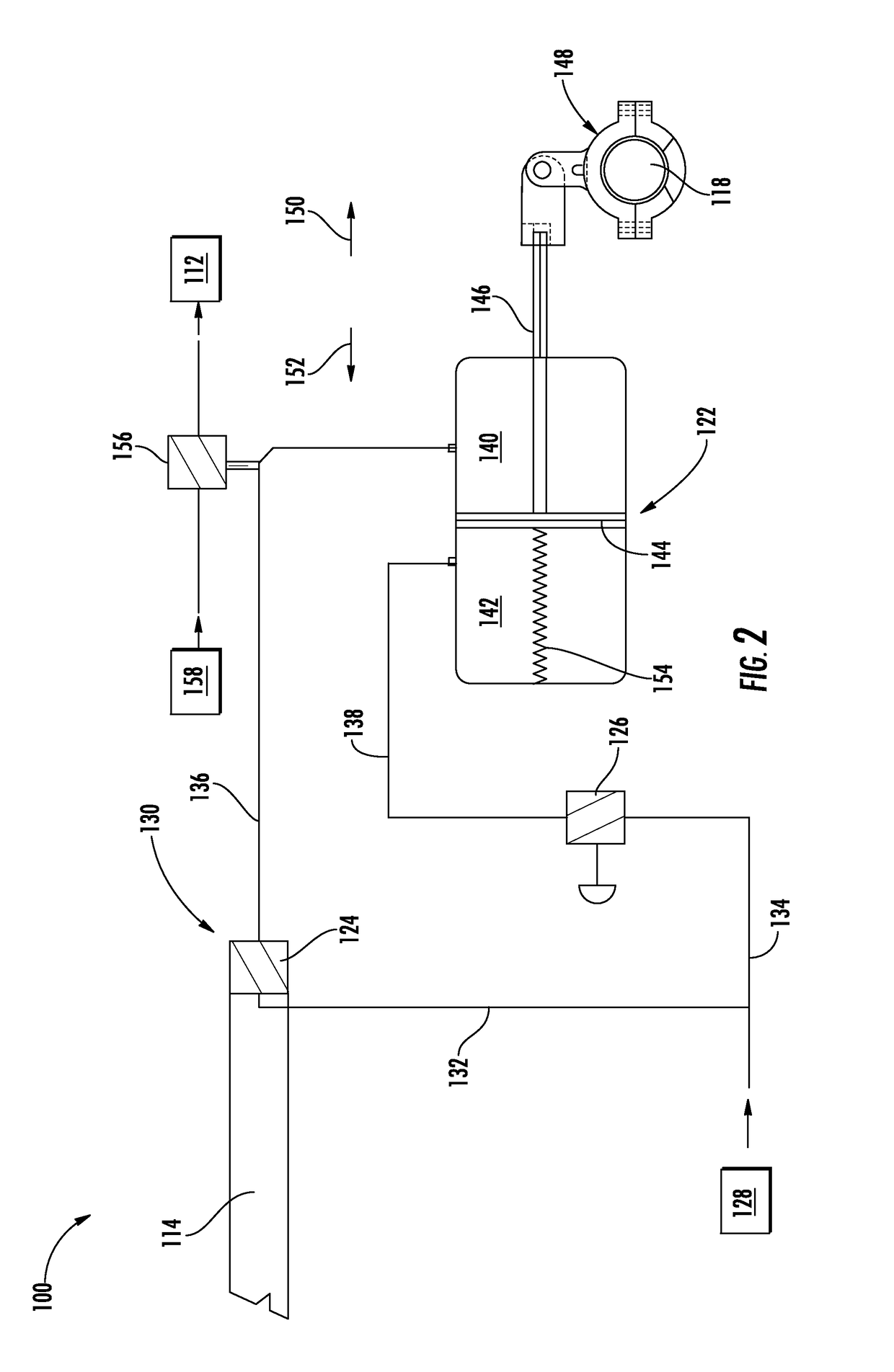

A braking system may include a brake assembly having a brake shaft and a brake lever coupled to the brake shaft. The system may also include a brake cylinder having a first chamber, a second chamber, a piston positioned between the chambers and a piston rod extending outwardly from the piston. The piston rod may be configured to be coupled to the brake shaft such that movement of the piston rod results in rotation of the brake shaft. In addition, the system may include a first valve configured to control a supply of working fluid to the first chamber and a second valve configured to control a supply of the working fluid to the second chamber. By adjusting a position of the first valve and / or the second valve, a braking force applied between the brake assembly and a drum of the draw works may be controlled.

Owner:NIELD BARRY J +1

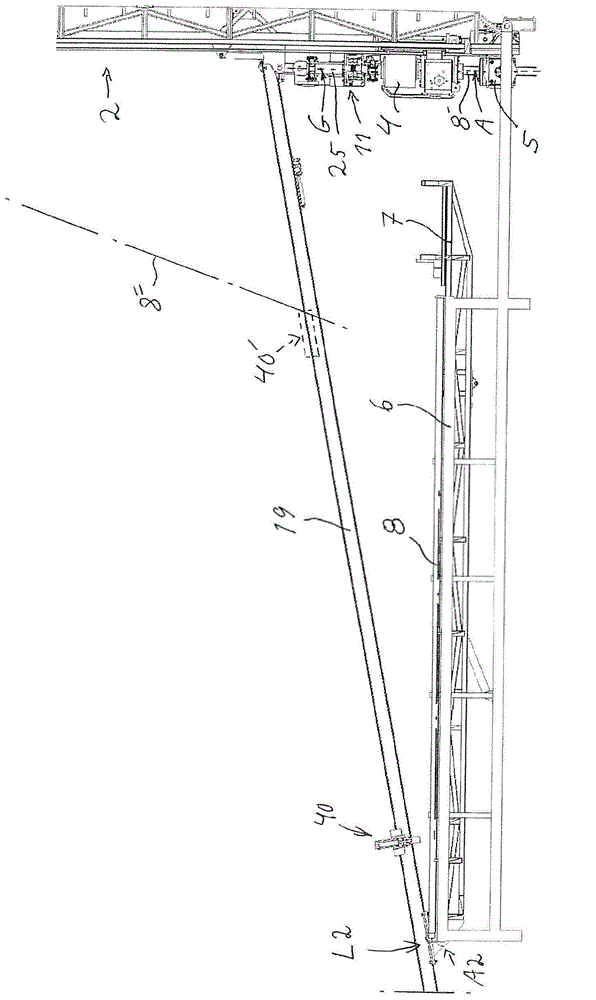

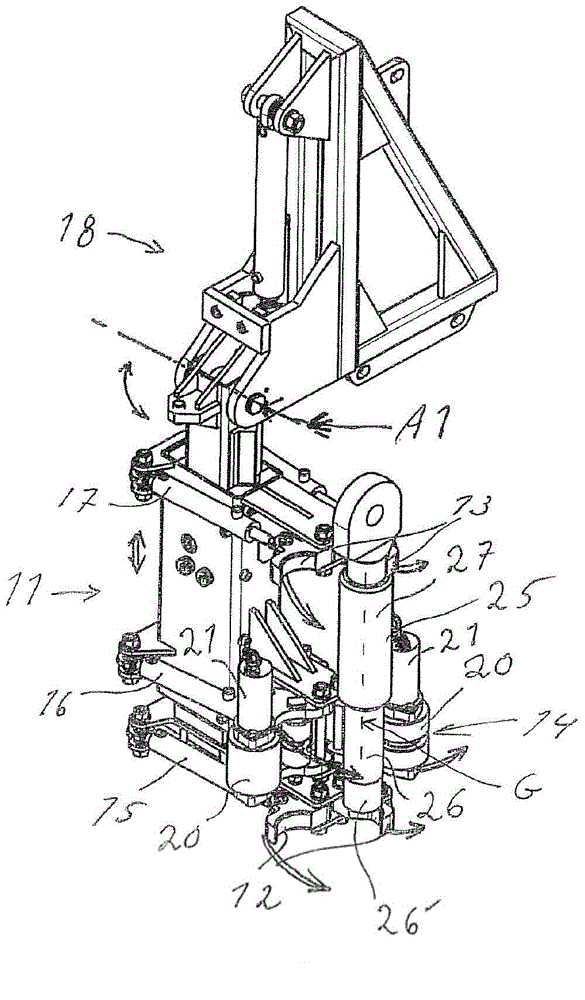

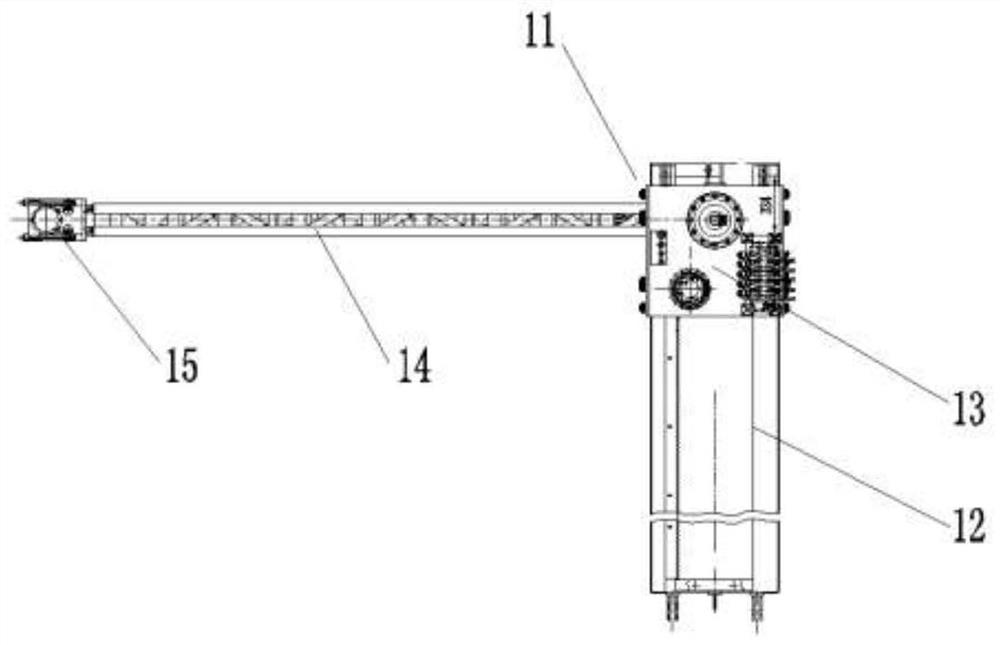

Device and method for handling drill string components in rock drilling and rock drill rig

A handling device for handling drill with a gripper shuttle (40) which is drivingly displaceable along a guiding beam (19) being fastenable to the drill rig in order to extend in a direction from the feed beam while forming an angle therewith, wherein the gripper shuttle (40) has a pivotally arranged guiding gripper (41) for in a first position in a first outermost position on the guiding beam grip a first end portion of a drill string component (8), being intended for lifting from a position outside the rig, the other end portion of which being intended to be in threaded engagement with a lifting plug or the like for co-operation with said lifting winch, and wherein the gripper shuttle (40) in a second position in a second inner position on the guiding beam adjacent to the feed beam (2) is arranged with the guiding gripper (41) to line up said gripped drill string component in the region of the drill string position.

Owner:安百拓有限公司

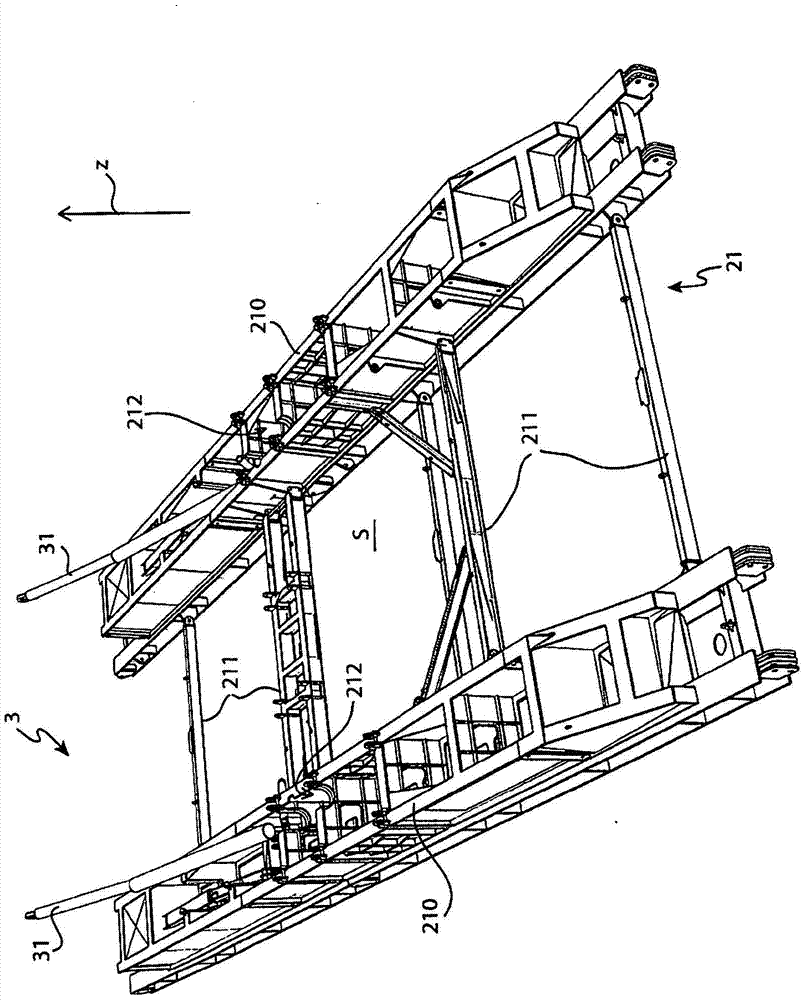

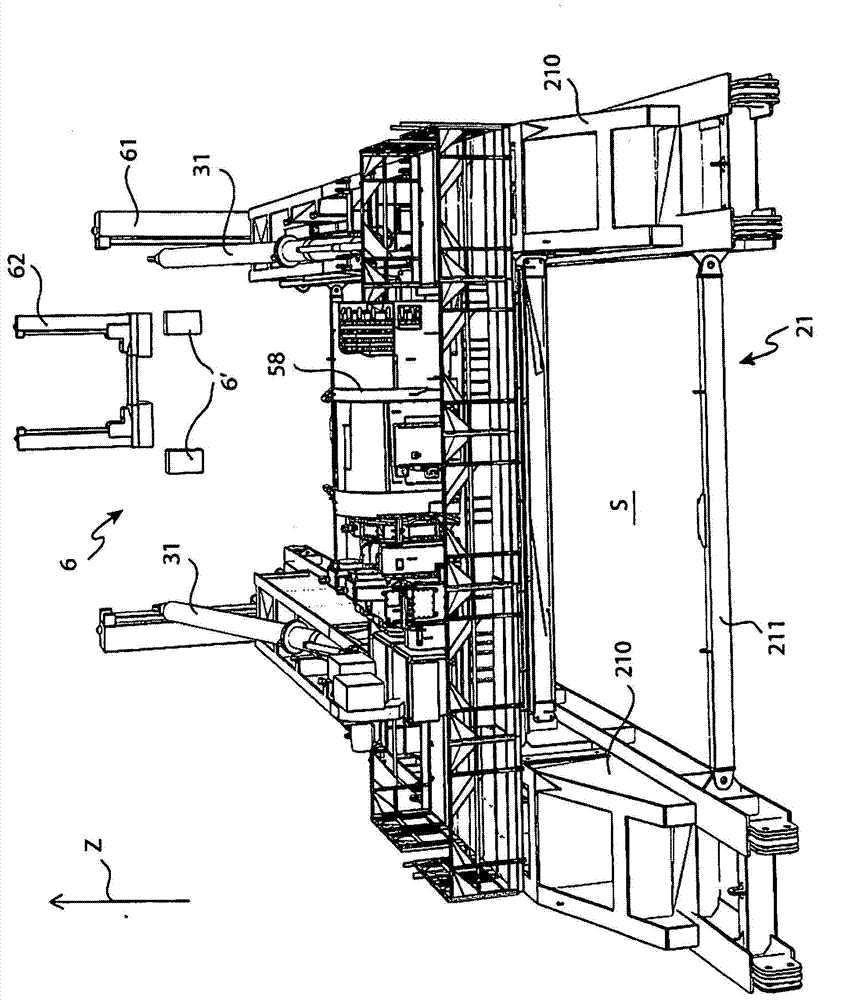

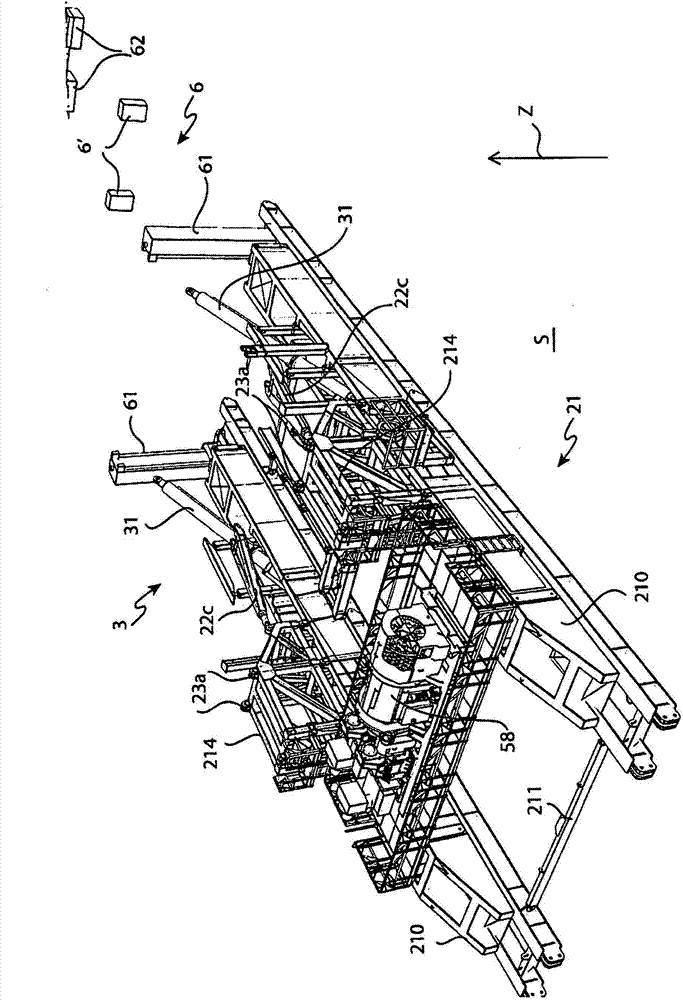

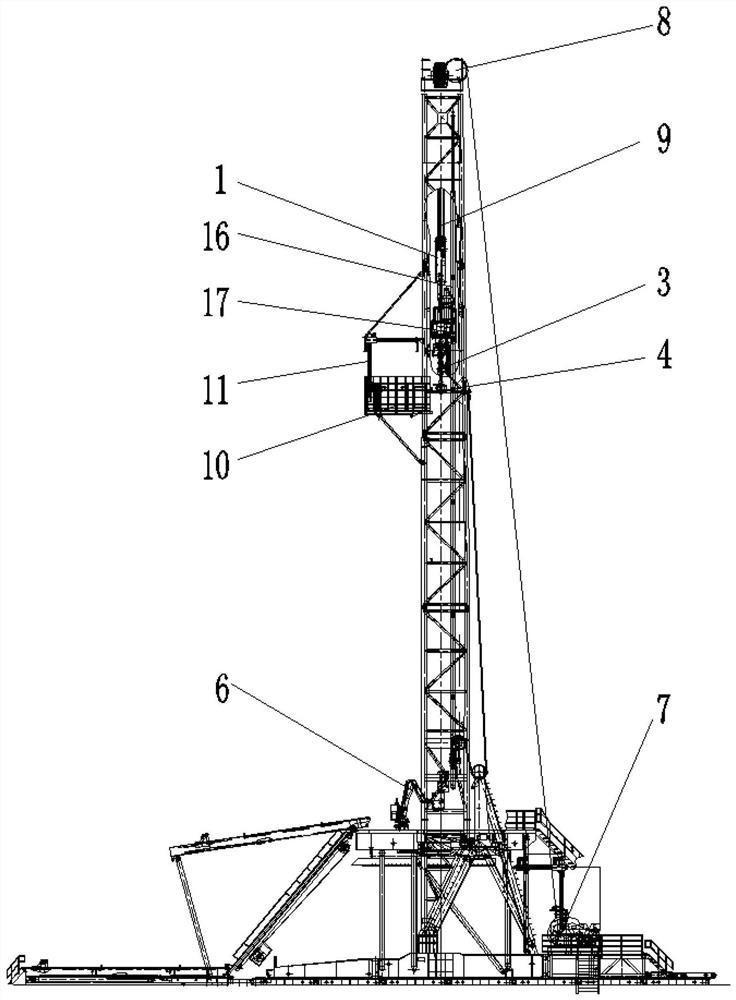

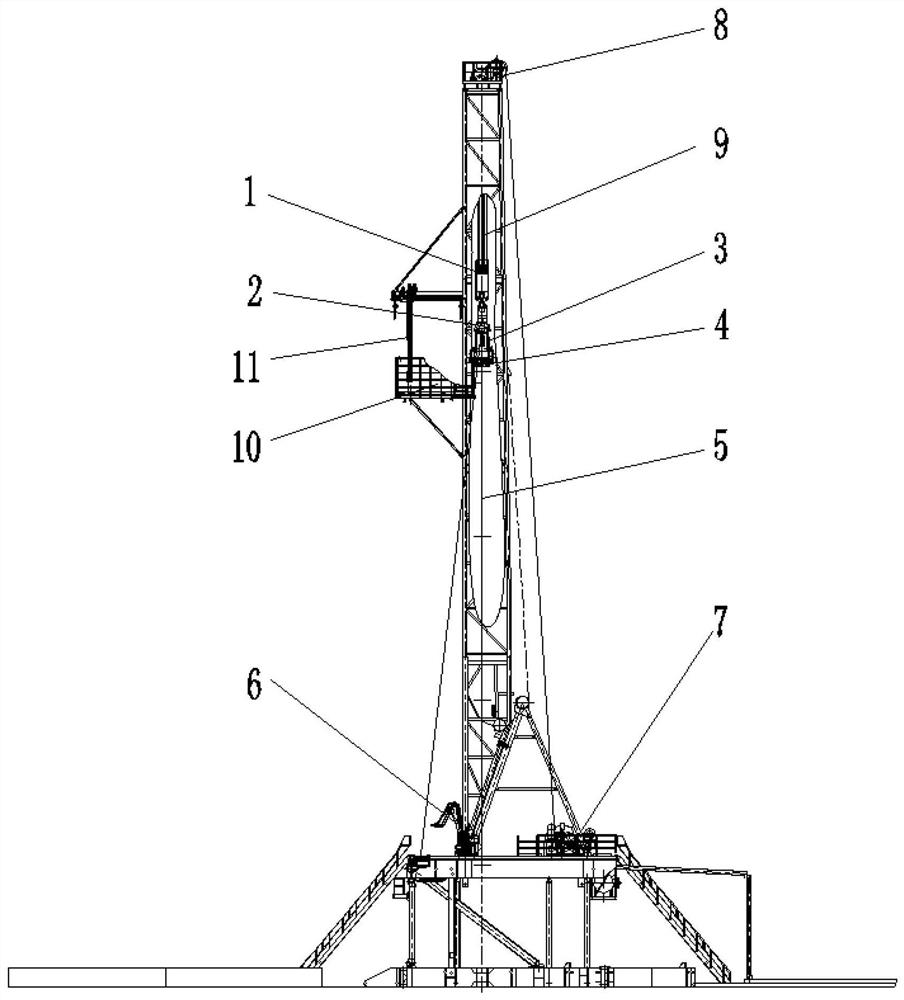

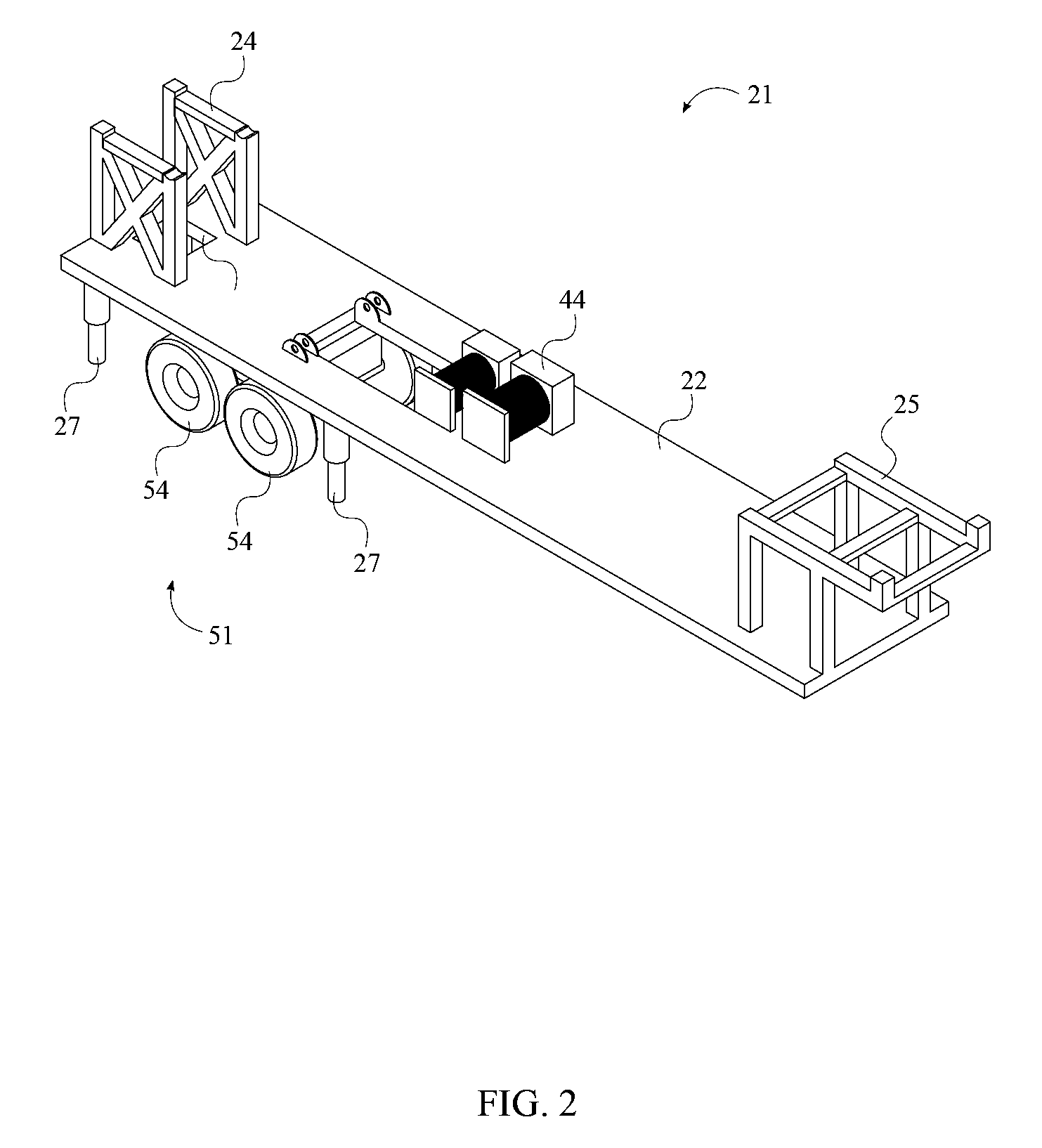

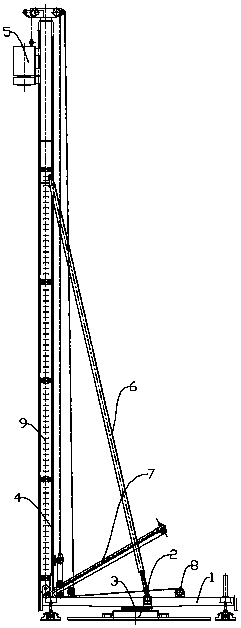

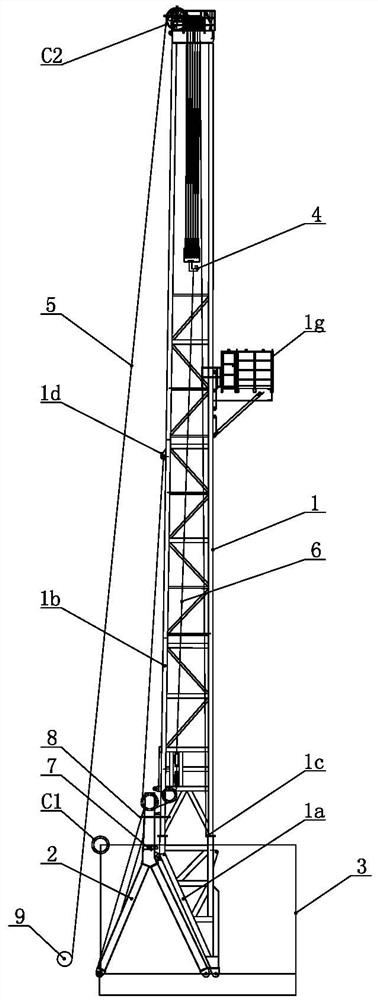

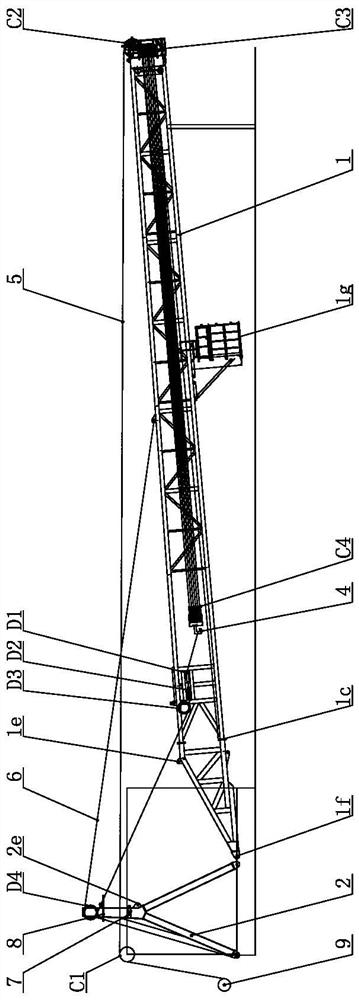

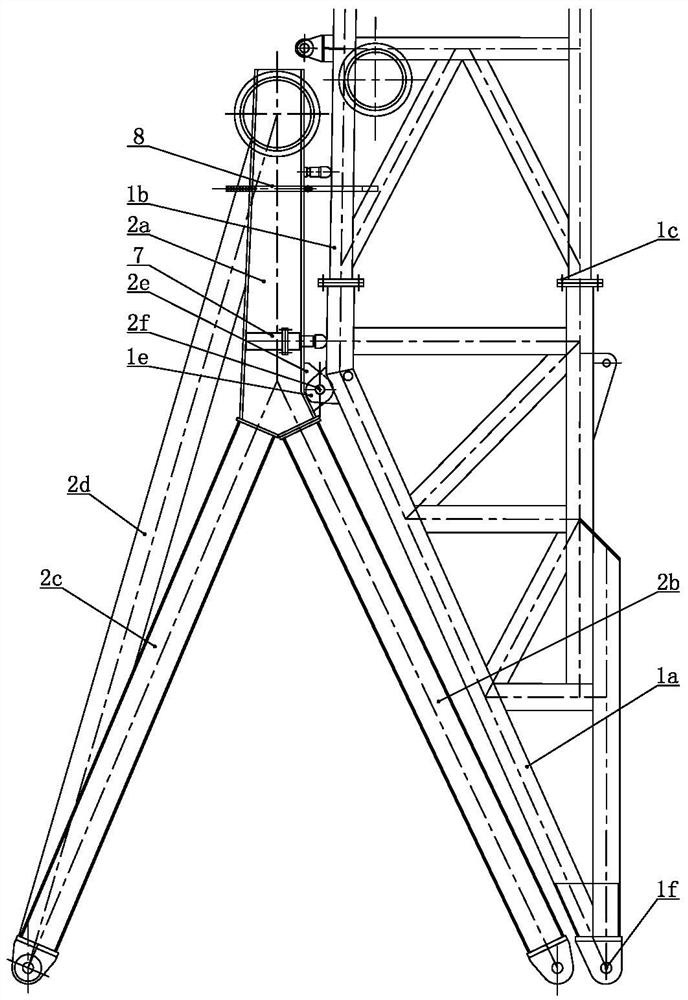

Well drilling apparatus and assembling and disassembling method

InactiveCN104520524AEasy to assembleEasy to disassembleDerricks/mastsBuilding constructionsWell drillingEngineering

Well drilling apparatus (2) and method associated therewith, which is able to shift from a first assembly operating configuration to a second use operating configuration and vice versa. Said apparatus (2) comprises a sub-structure (21), which supports said apparatus (2), a mast (23), which is pivoted to said sub-structure (21), around which it rotates so as to shift from said assembly operating configuration, which is substantially horizontal, to said use operating configuration and vice versa; a drill floor (22), which is able to be lifted and is connected to the mast (23); an actuating device (3), which is adapted to allow the drilling apparatus (2) to shift between said two operating configurations. The actuating device (3) is a hydraulic device, which is directly connected to the mast (23). The drill floor (22) comprises a first portion (22a), projects with respect to said mast (23), and a second portion (22b), which is constrained to said mast (23) and rotates with it. A draw-works (58) is installed, in a permanent manner, on the sub-structure (21).

Owner:DRILLMEC

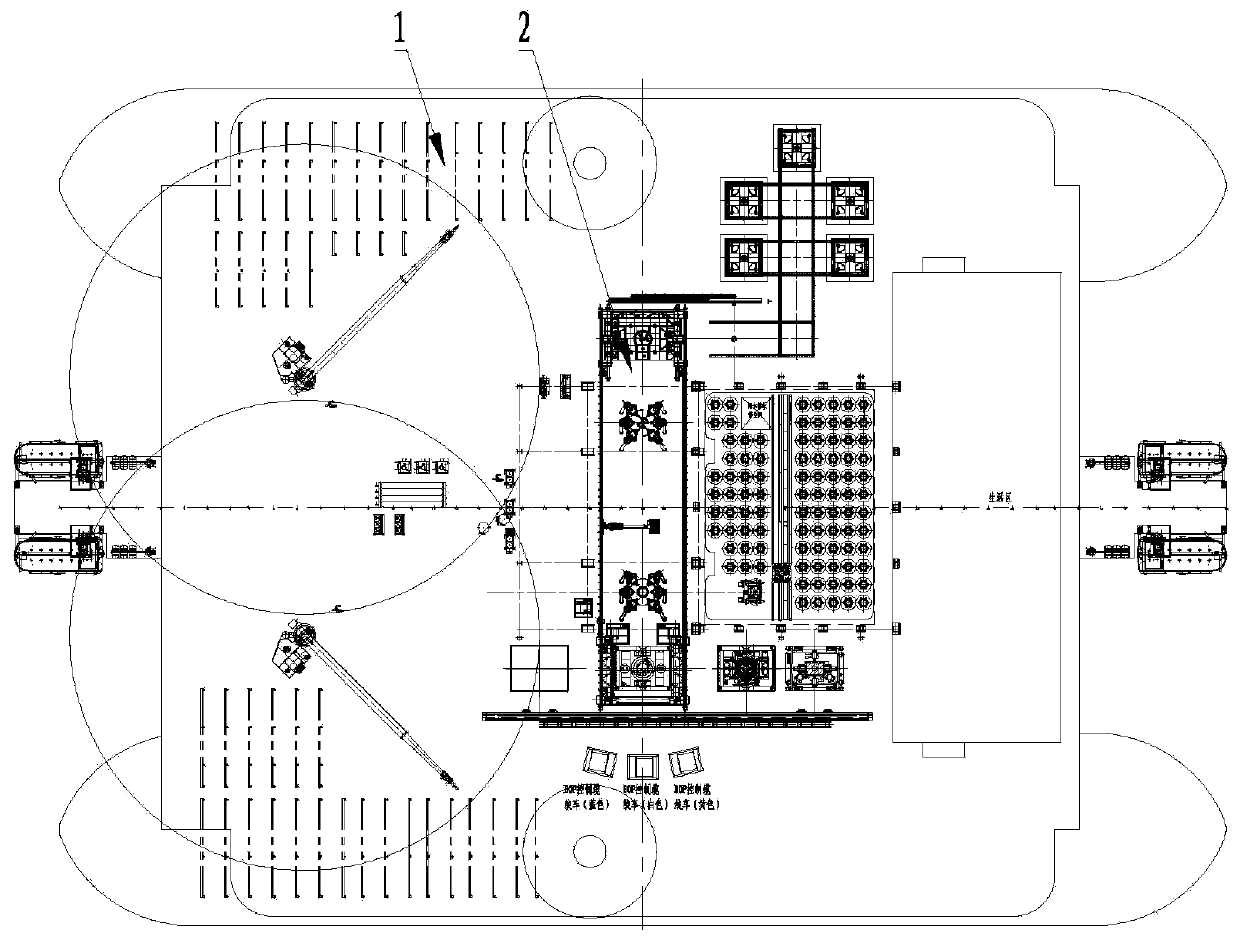

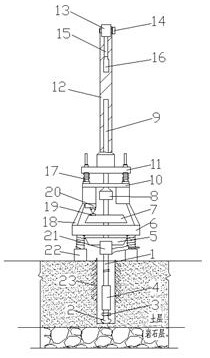

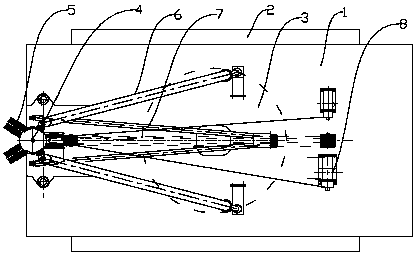

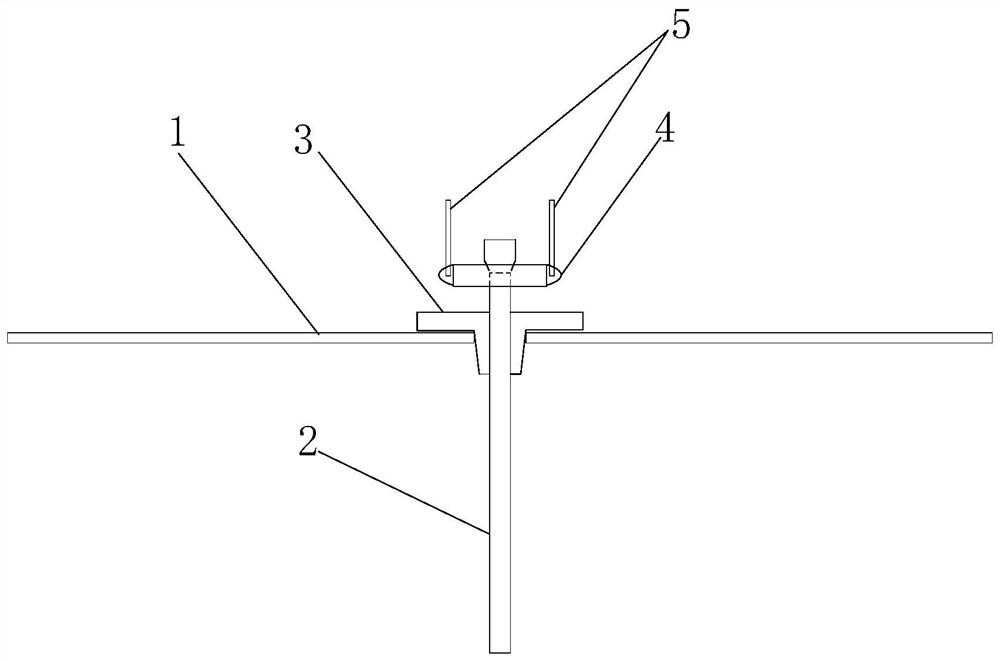

Shallow water floating platform mooring device and method

ActiveCN106114762BReduce distractionsReduce job impactCargo handling apparatusPassenger handling apparatusFloating platformStern

The invention relates to a mooring device of a shoal water floating type platform. The mooring device comprises mooring cables, water drums and anchoring chains, wherein draw-works are separately arranged at two lateral ends of a bow of the floating type platform and two lateral ends of a stern of the floating type platform; the water drums are separately arranged on the longitudinal outer side of the bow of the floating type platform and the longitudinal outer side of the stern of the floating type platform; each of the extending ends of the mooring cables which are wound on the draw-works at the two lateral ends of the bow of the floating type platform is connected with the corresponding water drum on the outer side of the bow of the floating type platform, and each of the extending ends of the mooring cables which are wound on the draw-works arranged at the two lateral ends of the stern of the floating type platform is connected with the corresponding water drum on the outer side of the stern of the floating type platform; and the two water drums are separately fixed on a seafloor anchor base through the anchoring chains. The invention further discloses a dual-water-drum mooring manner when the floating type platform is under a normal operation state, a single-water-drum mooring manner when the floating type platform is under a survival working state, and a mooring method for shifting the two mooring manners according to the sea condition. According to the mooring device disclosed by the invention, the positioning requirements for the shoal water floating type platform under the situation of mooring alongside can be met, the security requirements for the shoal water floating type platform under an anti-typhoon mooring mode can be met, a ship is convenient to moor laterally and alongside, and the mooring device has high stormy wave resistant capacity.

Owner:中国船舶重工集团公司第七〇二研究所

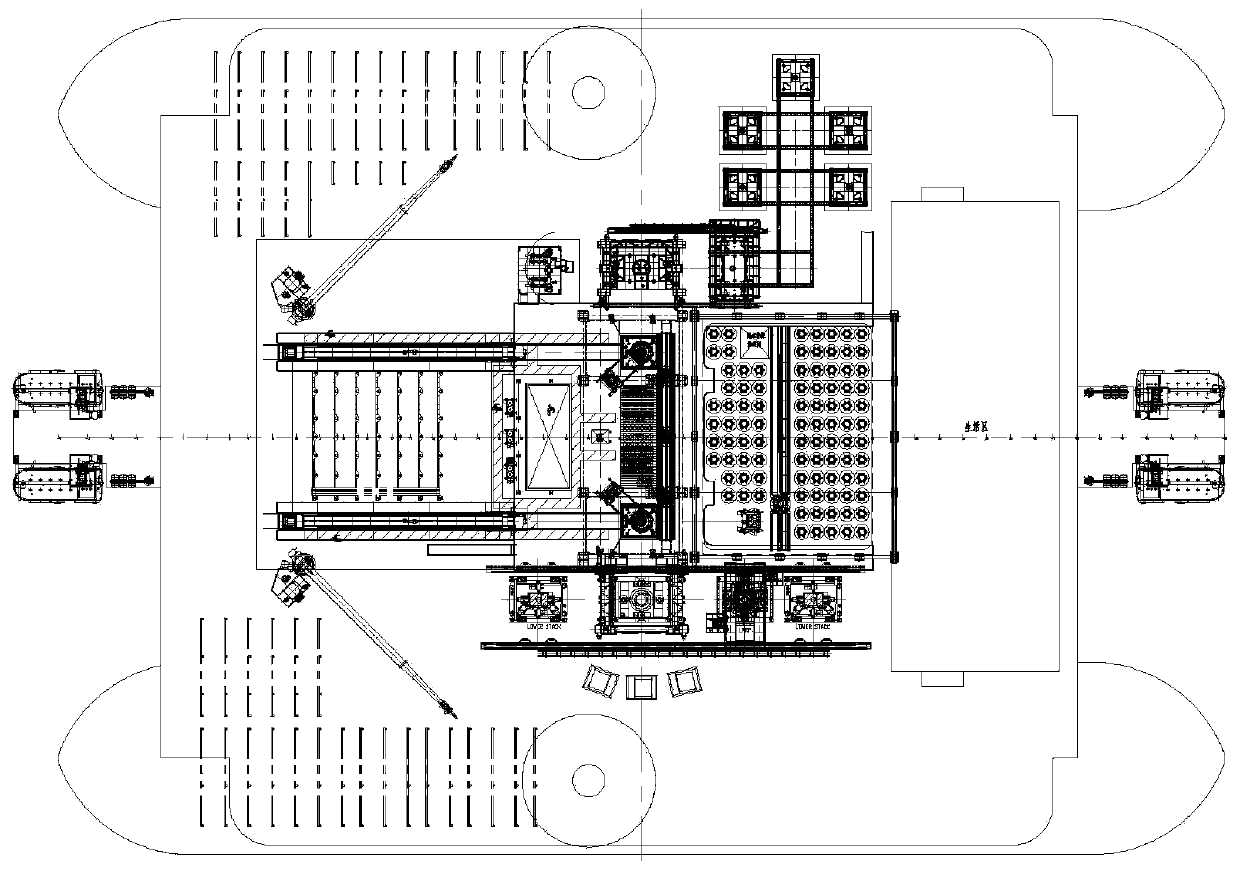

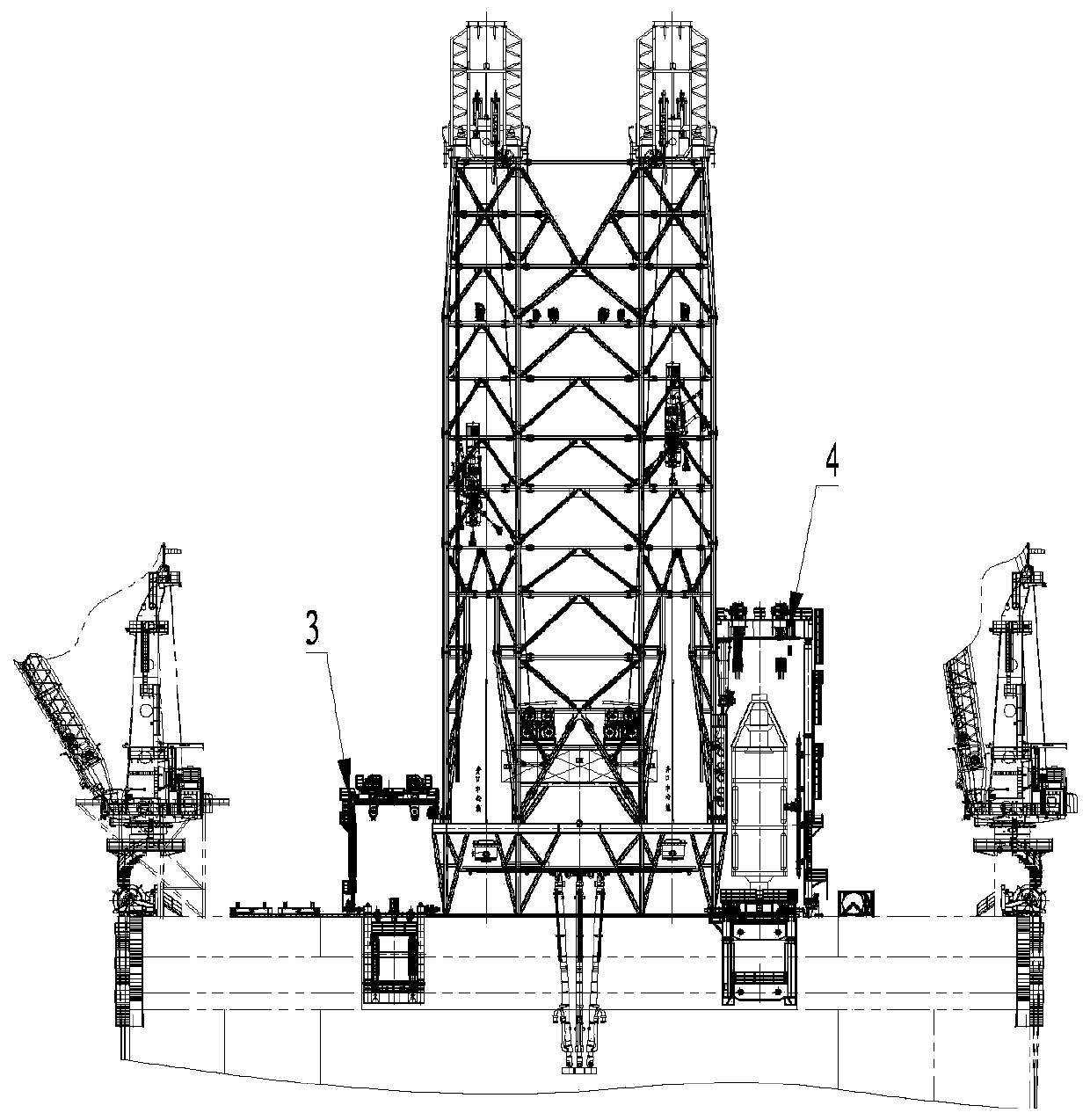

Double-main-wellhead drilling system of semi-submersible drilling platform

InactiveCN110984860AImprove drilling efficiencyImprove securityWaterborne vesselsDrilling rodsWell drillingOverhead crane

The invention discloses a double-main-wellhead drilling system of a semi-submersible drilling platform. The double-main-wellhead drilling system is arranged at the center, corresponding to two wellheads, of a main deck of a ship body of the semi-submersible drilling platform; the double-main-wellhead drilling system comprises a moon pool which is arranged at the middle part of the main deck; the larboard of the moon pool is provided with a Christmas tree treatment system; the starboard of the moon pool is provided with a blowout preventer treatment system; a drilling platform is arranged abovethe moon pool; the drilling platform is correspondingly provided with an instrument / driller's station, a winch pry unit and a duplex derrick; the position of the duplex derrick corresponds to the twowellheads; the top of the duplex well rack is provided with an overhead crane; the double-main-wellhead drilling system further comprises a pipe column stock dump, a water isolating pipe treatment system and a pipe column conveying system, wherein the pipe column stock dump, the water isolating pipe treatment system and the pipe column conveying system are arranged on the main deck; and the Christmas tree treatment system, the blowout preventor treatment system, the water isolating treatment system and the pipe column conveying system are correspondingly distributed in left, right, front andrear directions of the drilling platform. The double-main-wellhead drilling system disclosed by the invention improves the efficiency of drilling operation and improves the safety of an operator.

Owner:BAOJI PETROLEUM MASCH CO LTD +2

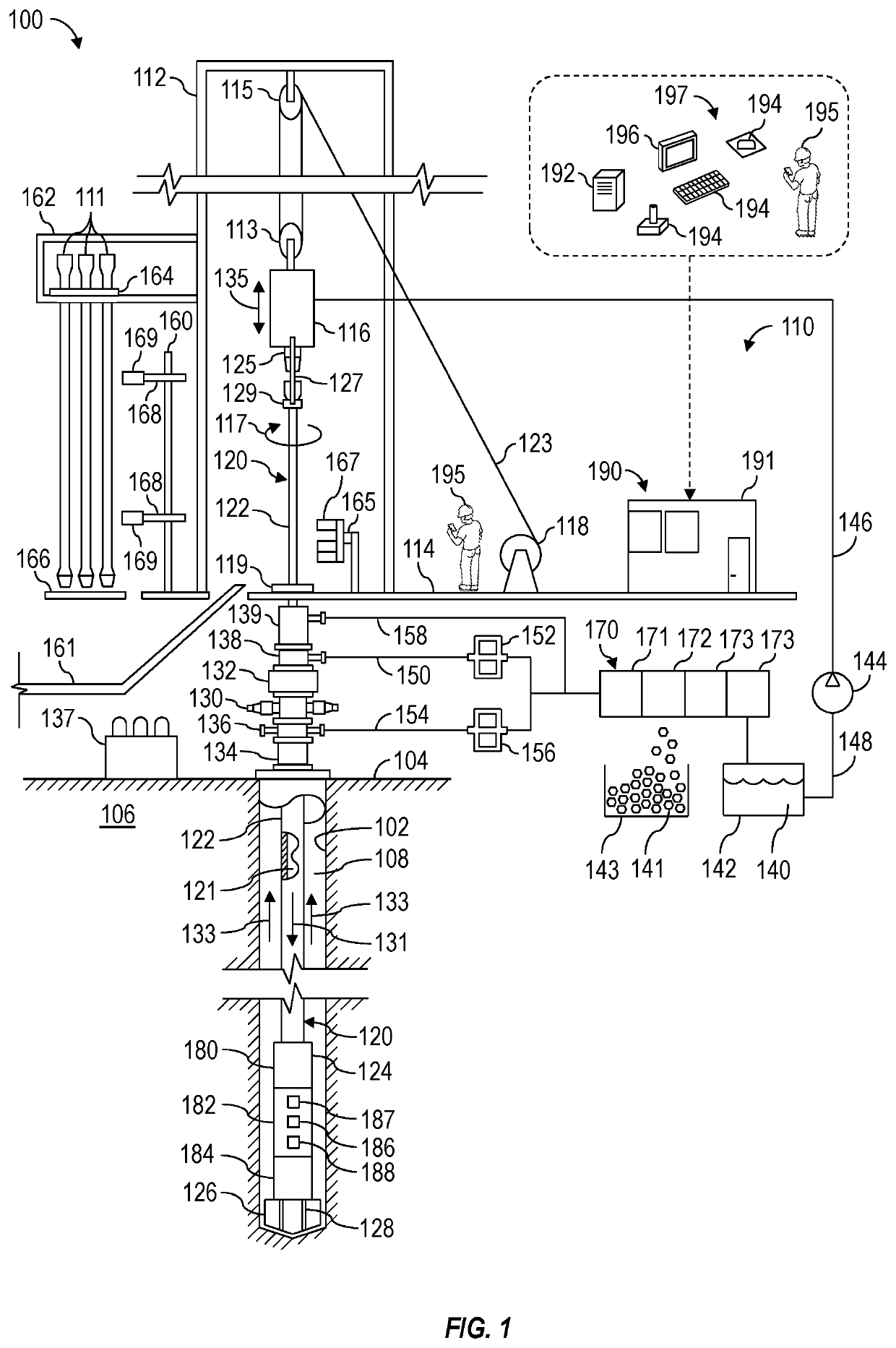

Using High Rate Telemetry to Improve Drilling Operations

Systems and methods for using high rate telemetry to improve drilling operations. A method may include performing drilling operations with a wired drill pipe (WDP) string in an oil and / or gas well. The drilling operations may include pumping drilling fluid to a mud motor of the WDP string through an internal passage of the WDP string and vertically moving the WDP string via a drawworks while controlling the drawworks to change speed of the WDP string based on downhole data received by wellsite surface equipment via electrical conductors integral to WDP of the WDP string. The received downhole data may include downhole pressure data that is generated downhole by a pressure sensor and is indicative of pressure of the drilling fluid in the internal passage.

Owner:SCHLUMBERGER TECH CORP

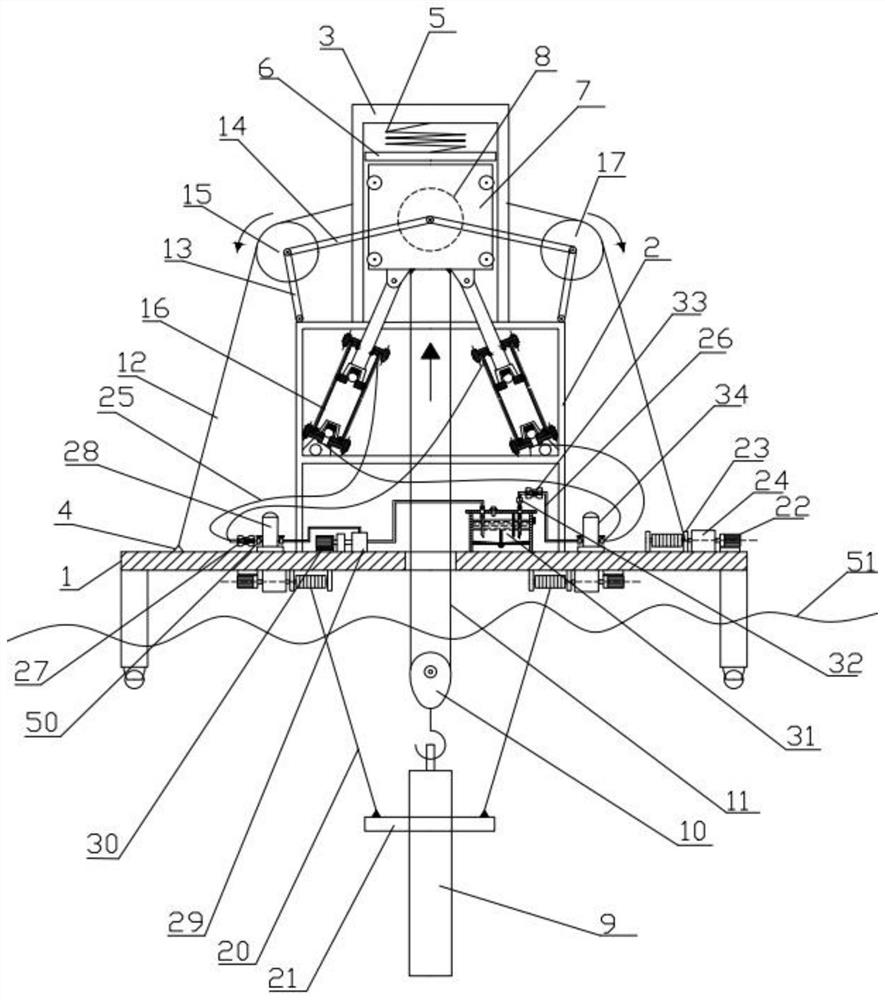

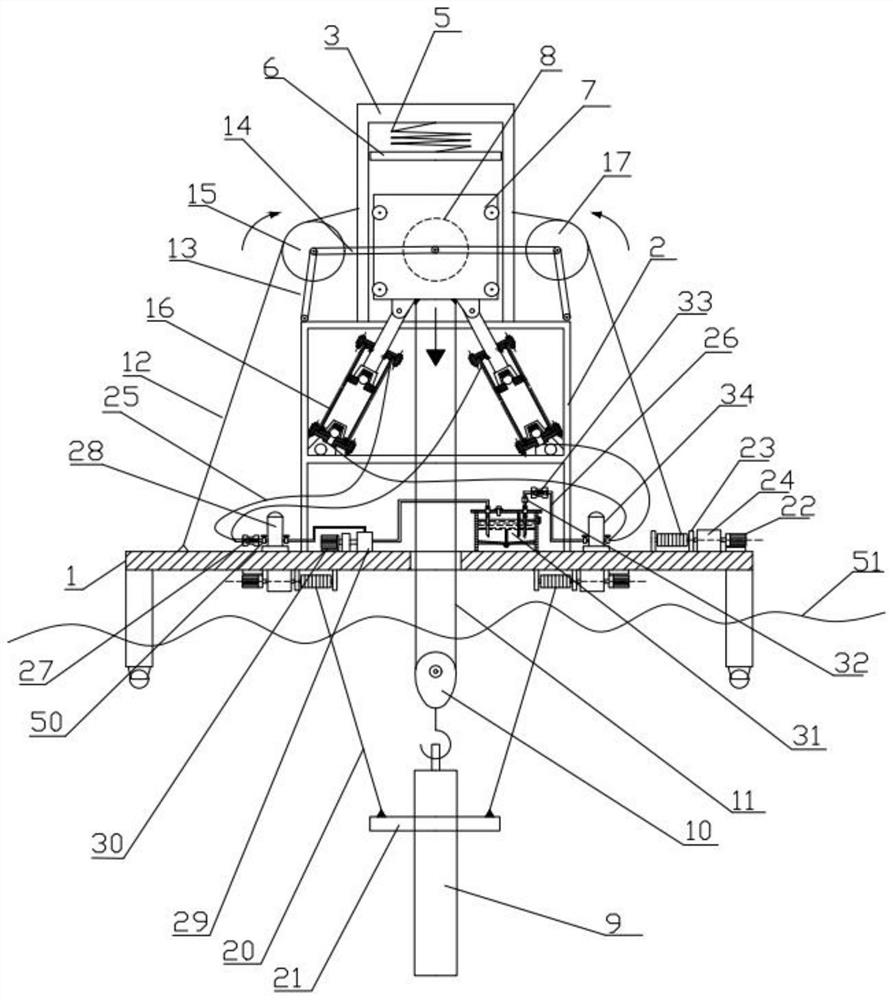

Drill string arranging method for push-supporting-type pipe string treatment equipment under top-drive-free working condition

ActiveCN112211574ARealize the craftImplement functional requirementsDrilling rodsDrilling casingsStructural engineeringTraveling block

The invention discloses a drill string arranging method for push-supporting-type pipe string treatment equipment under the top-drive-free working condition. The drill string arranging method mainly comprises the technological processes that step 1, a large hook is connected to the lower part of a traveling block of a push-supporting-type pipe string treatment system; step 2, a drill string is lifted away from the drill floor surface by using a winch through the hook, a drill floor push-supporting arm is placed at the lower end of the drill string, and drill string arranging work is prepared; 3, the lower end of the drill string is pushed and supported to the drill string arranging position through the drill floor push-supporting arm; 4, the large hook falls through the traveling block, andthe lower end of the drill string falls to the position near the designated position; step 5, a tackle assembly of a manipulator is moved to the inner side of a track, a mechanical arm assembly extends out, and the upper end of the drill string is supported through a tong head; and step 6, the large hook falls again, the lower end of the drill string is placed in place, and meanwhile the manipulator is operated to place the upper end of the drill string to the drill string arranging position specified on a racking platform. Through two times of falling of the large hook, the offset of the upper end of the drill string in the drill string arranging process is effectively controlled, and the reliability of the drill string arranging process is improved.

Owner:中油国家油气钻井装备工程技术研究中心有限公司 +2

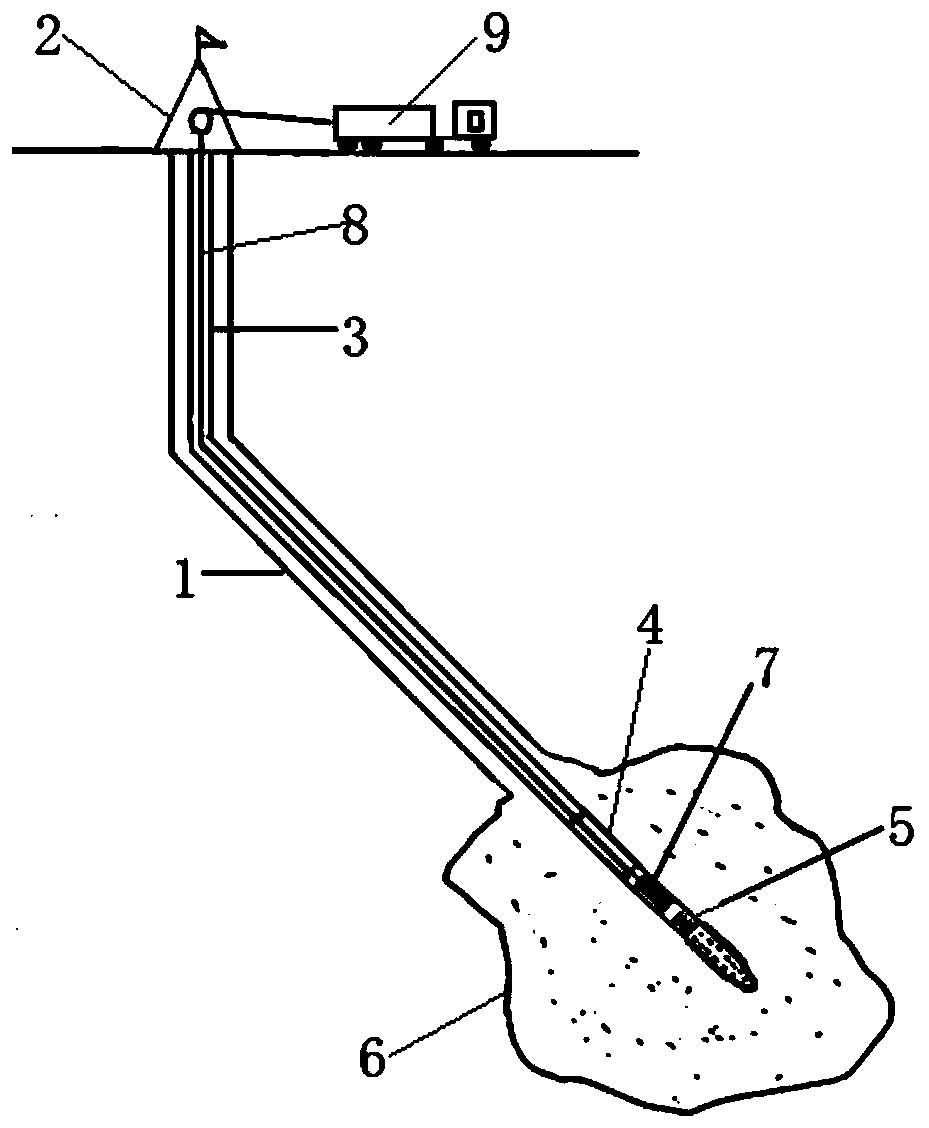

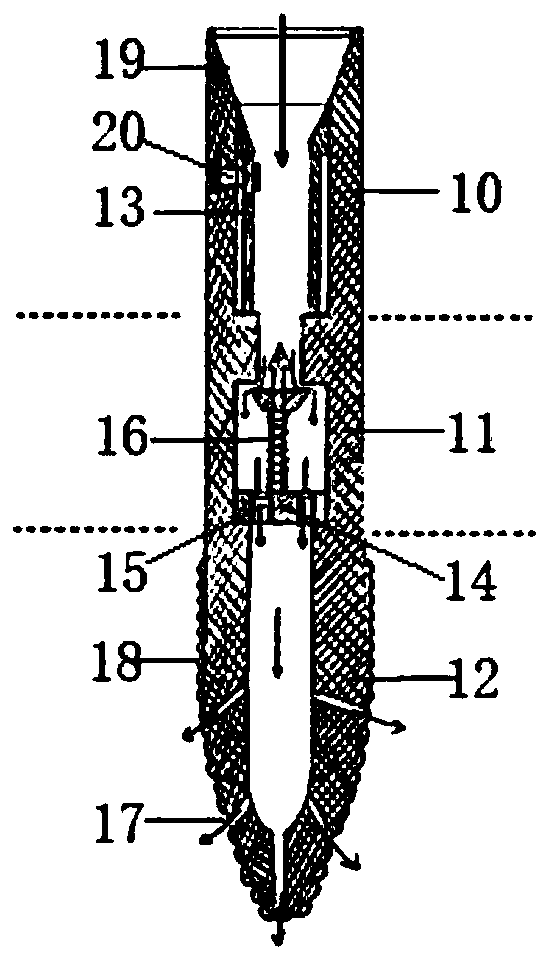

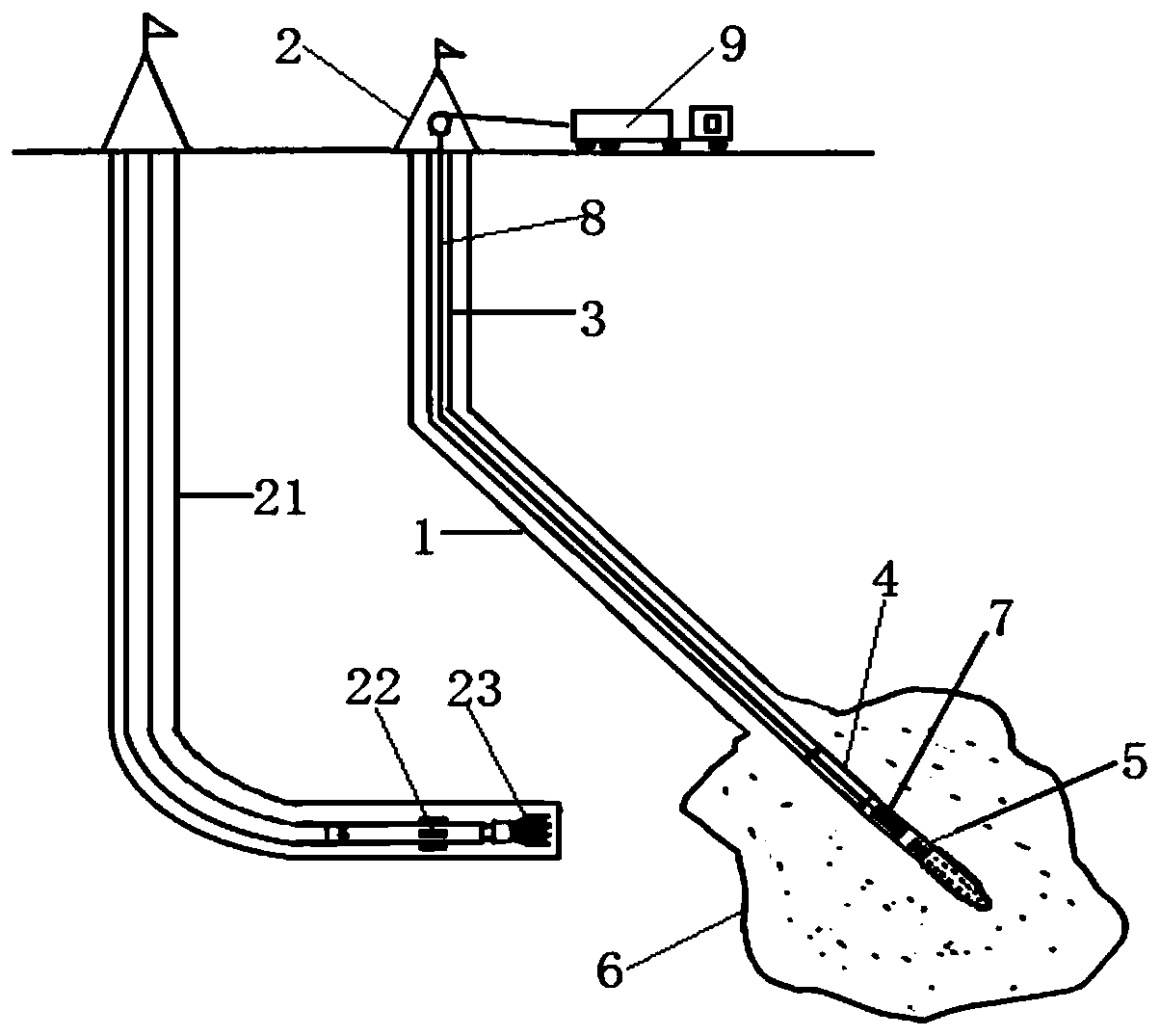

High-temperature salt well directional well butt joint navigation conveying system and application method

PendingCN111550204AAccurate graspHigh receiving docking signal accuracySurveyDirectional drillingDirectional wellClassical mechanics

The invention belongs to the technical field of high-temperature salt well directional well butt joint, and particularly relates to a high-temperature salt well directional well butt joint navigationconveying system and an application method. The high-temperature salt well directional well butt joint navigation conveying system comprises a directional well, a drilling machine, a drill stem column, a non-magnetic drill collar, a navigation conveying device, a high-temperature salt well dissolving cavity, a magnetic guiding butt-joint instrument, a cable and a winch, wherein the drilling machine is installed at a well mouth of the directional well, the drill stem column is arranged in the directional well, the upper end of the drill stem column is connected with the drilling machine, the non-magnetic drill collar at the lower end of the drill stem column is connected with the navigation conveying device; and the navigation conveying device is placed in the center of the high-temperaturesalt well dissolving cavity. The invention provides the high-temperature salt well directional well butt joint navigation conveying system and the application method in order to enable the magnetic guiding butt-joint instrument to be safely lowered into and pulled out of the high-temperature salt well dissolving cavity to improve the construction safety and stability and enable the butt-joint instrument to be located in the center of the high-temperature salt well dissolving cavity to ensure the accuracy of butt-joint signal receiving.

Owner:天津森特聚尔新能源技术有限公司

Power generation type offshore drilling platform heave compensation device

PendingCN114233212AEasy to manufactureSimple structureDrilling rodsMachines/enginesMarine engineeringWell drilling

The invention discloses a power generation type offshore drilling platform heave compensation device which is characterized in that a spring, a pressing plate and a floating crown block are arranged in a drilling derrick, one end of the spring is connected to the top of a guide groove, the other end of the spring is connected to the pressing plate, the floating crown block is installed below the pressing plate, and a center sheave with a plurality of wire grooves formed in the cylindrical surface is installed in the floating crown block; the heave compensation device mainly comprises four parts, namely a compensation mechanism part, a drilling winch part, a winding device part and a power generation device part. The compensation mechanism part is mainly used for compensating the displacement of the marine riser caused by heaving of sea surface waves, and the winding devices comprise the winding device I, the winding device II, the winding device III and the winding device IV which are arranged at the left position, the right position, the front position and the rear position around the vertical axis of the marine riser respectively. The device is simple in structure, easy in manufacturing of required parts, high in compensation efficiency, capable of generating power, capable of adjusting the lowering angle of the marine riser, capable of guaranteeing vertical lowering and high in reliability.

Owner:SOUTHWEST PETROLEUM UNIV

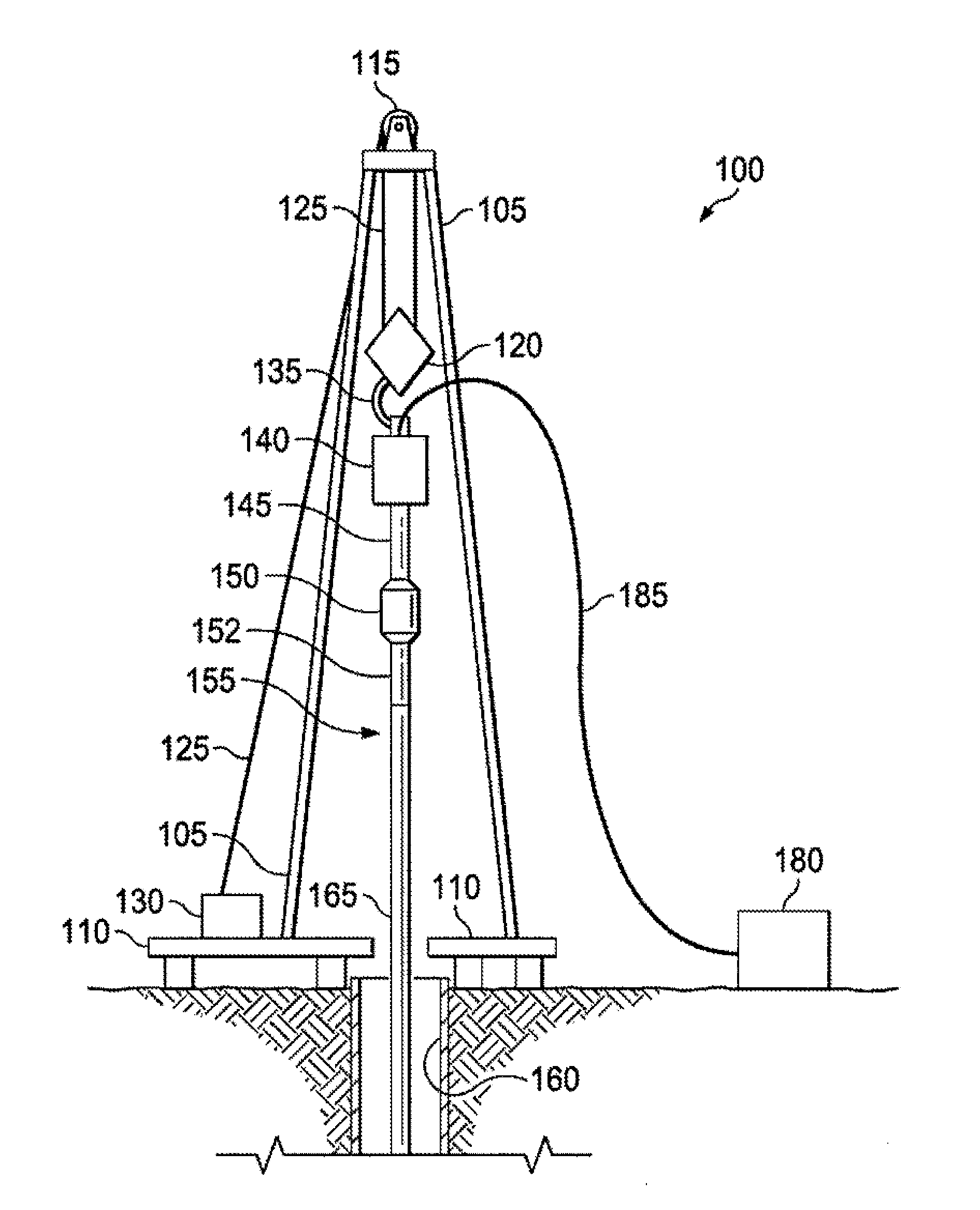

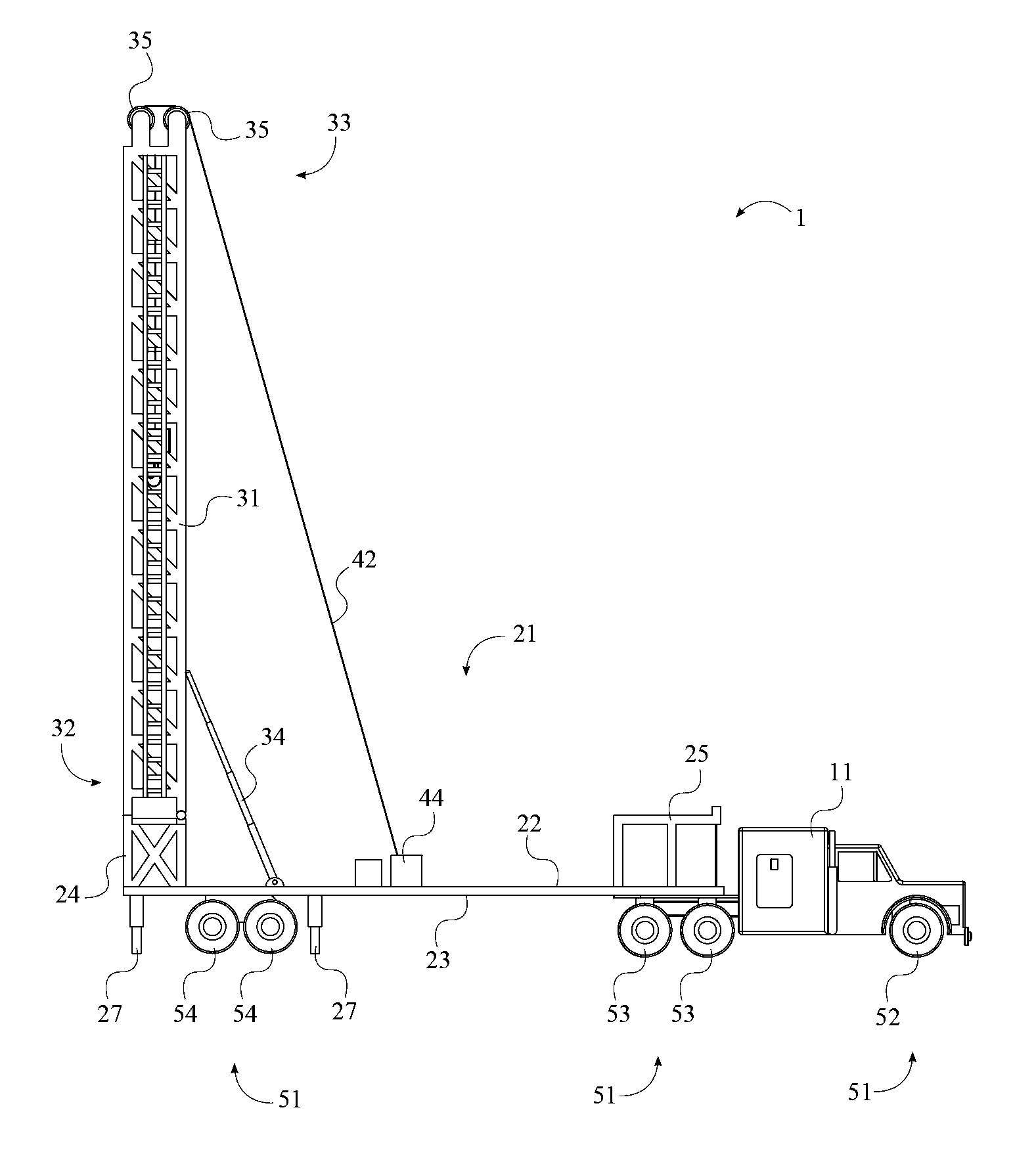

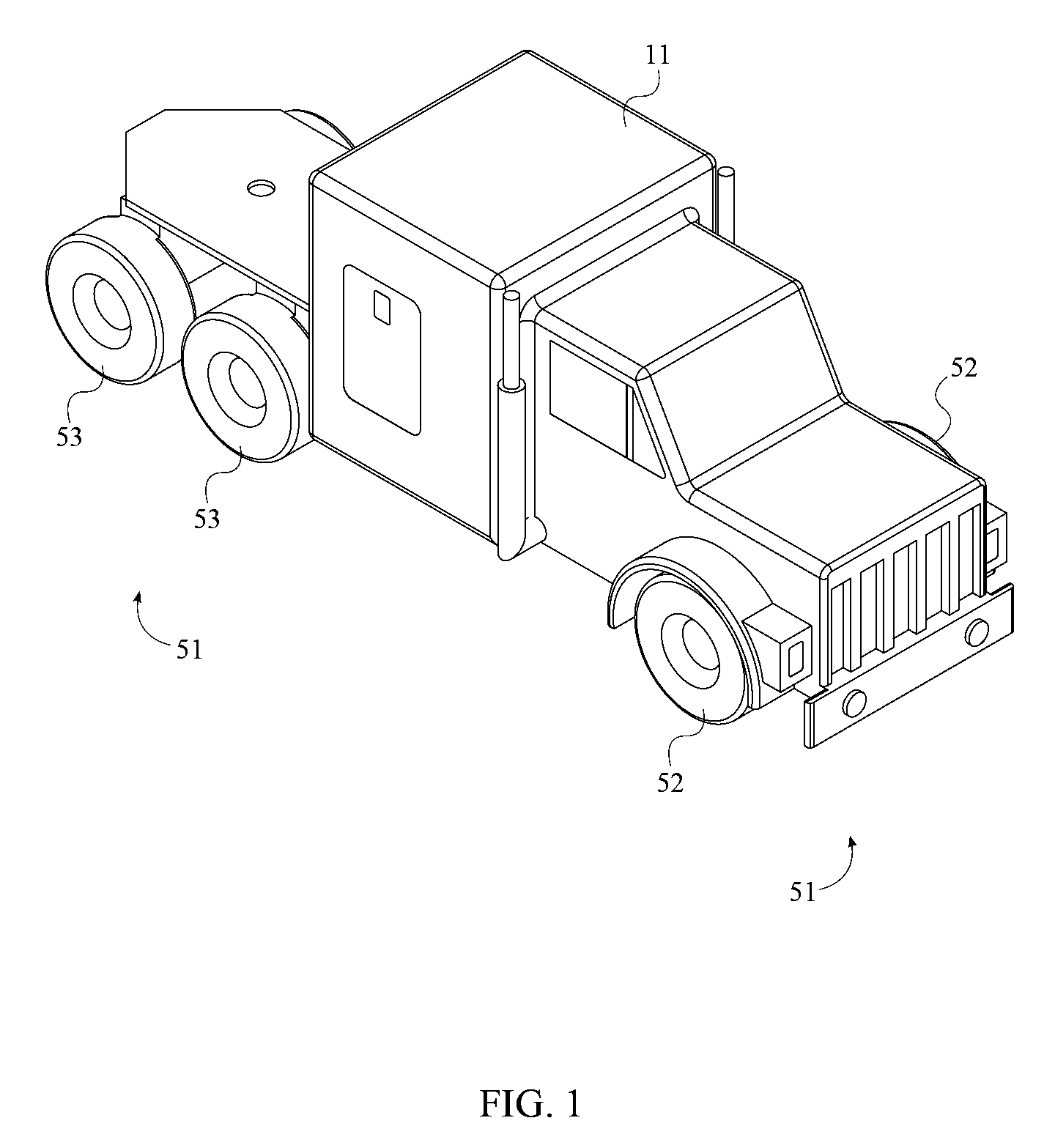

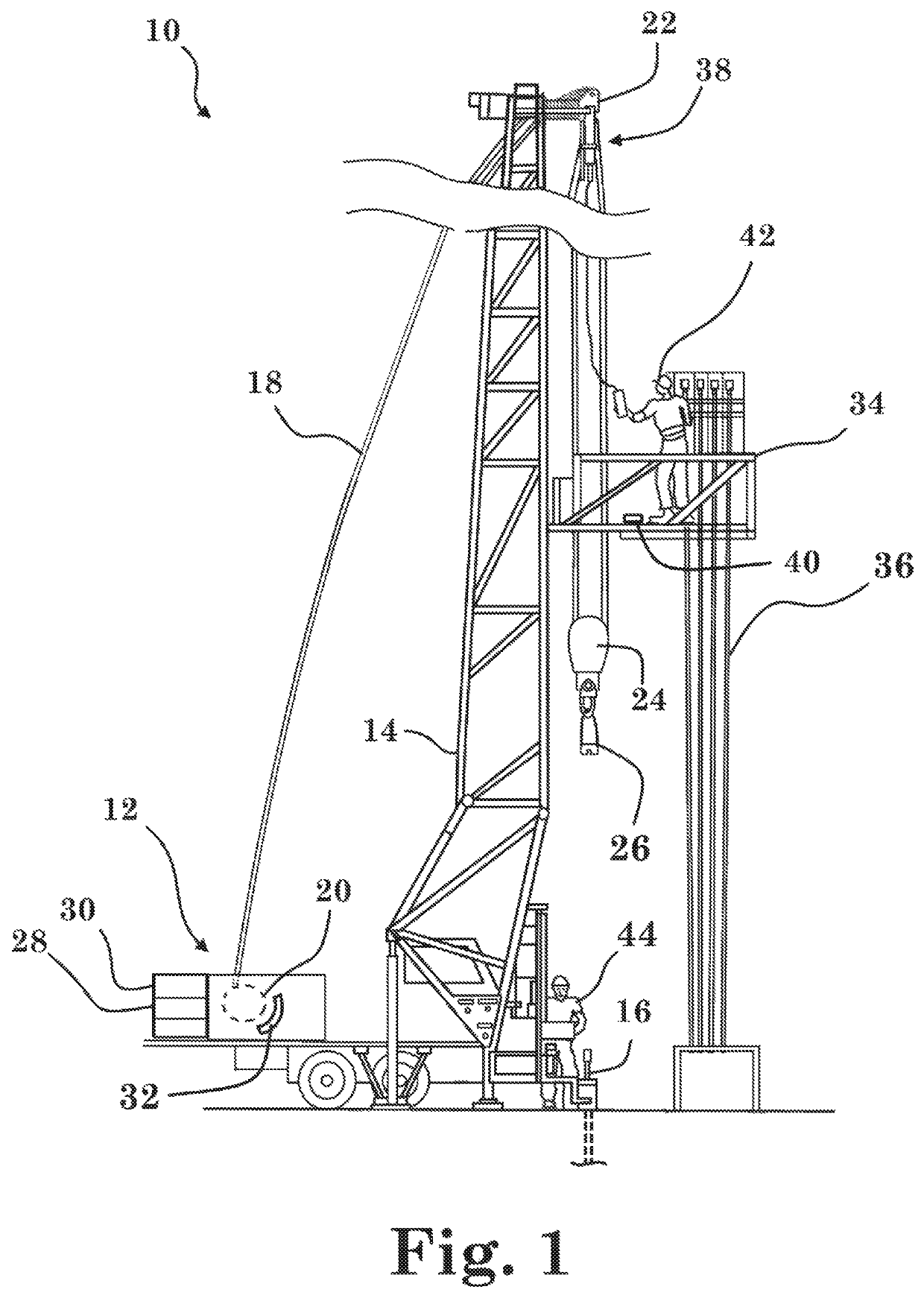

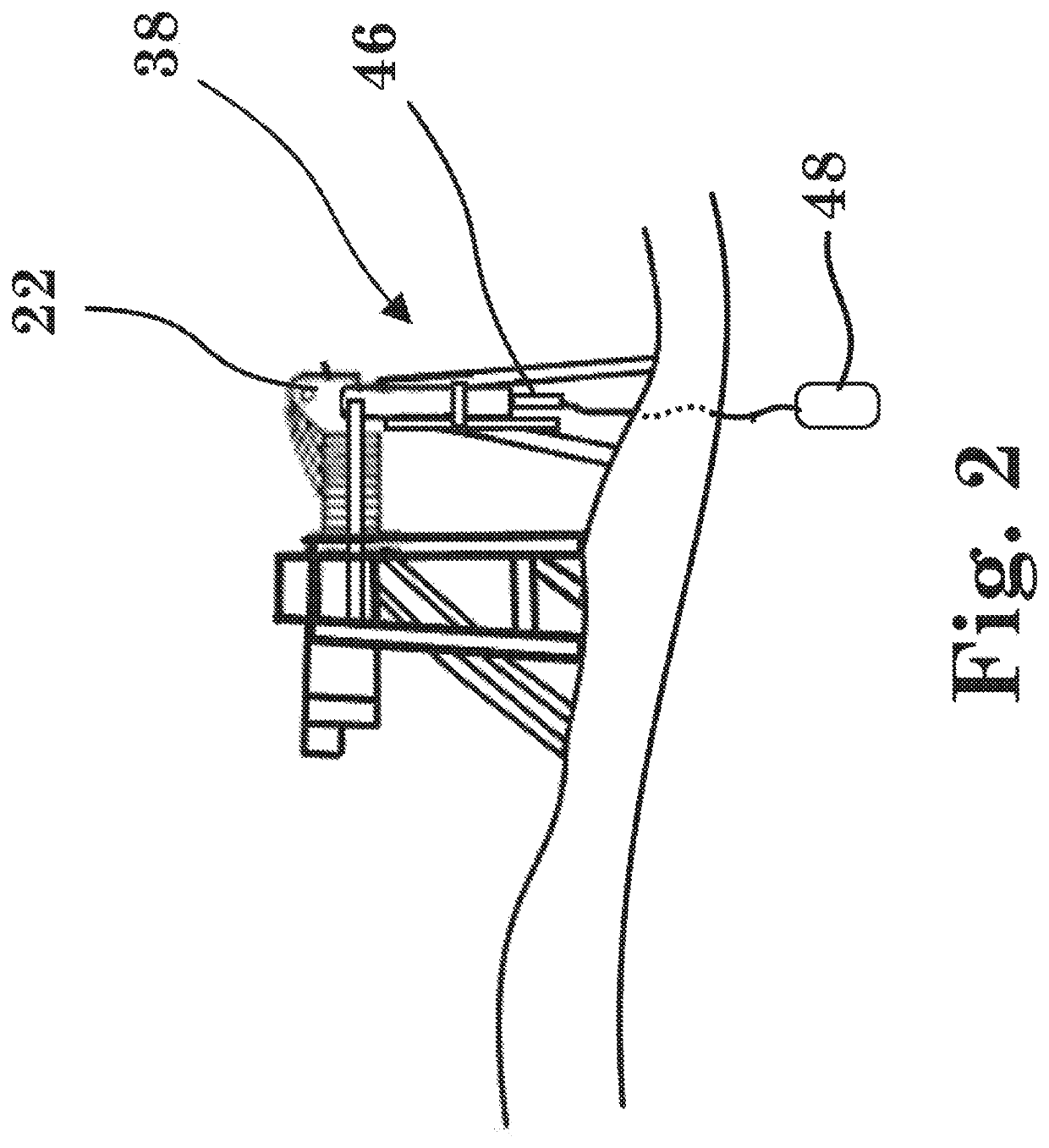

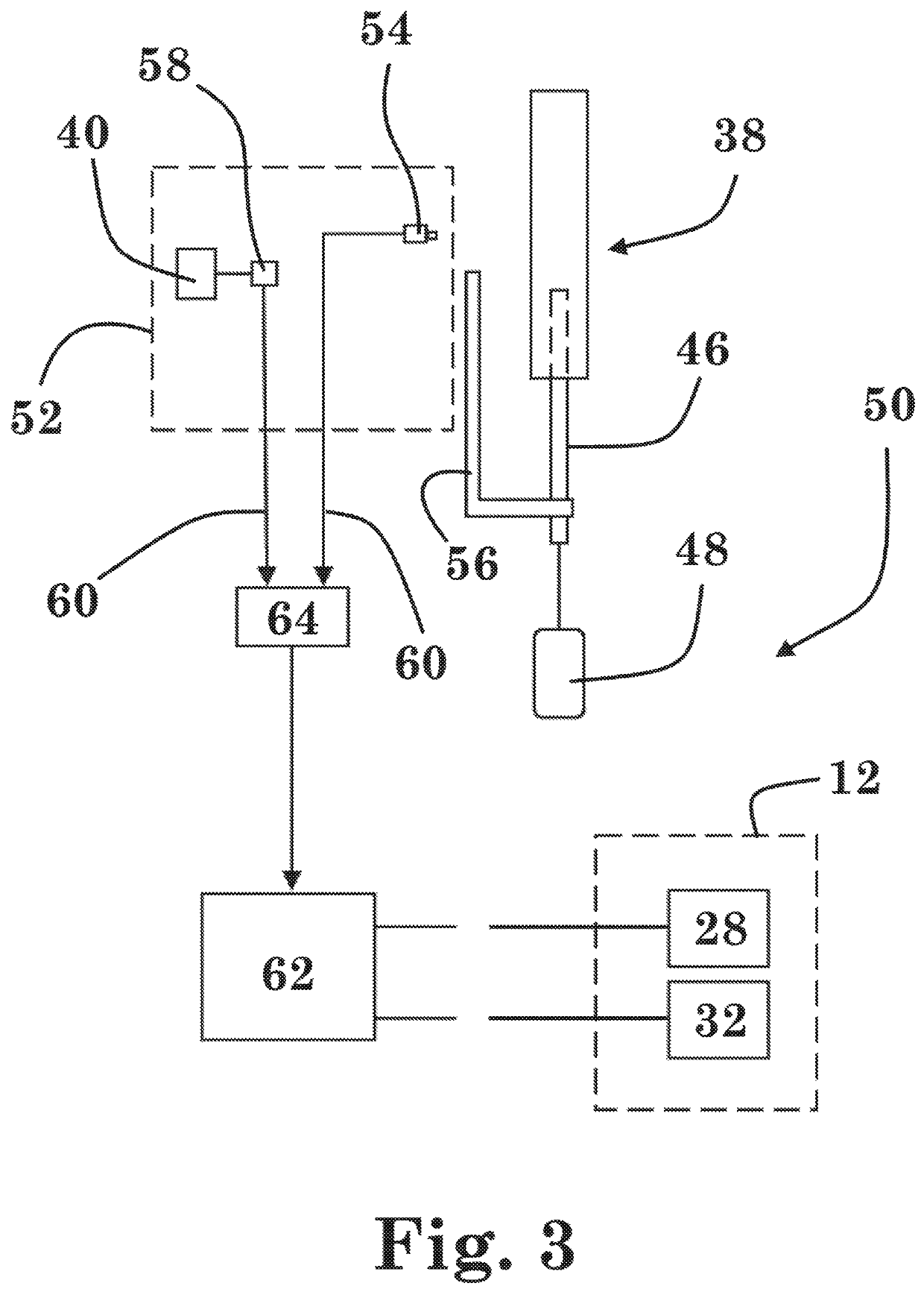

Remote controlled drilling rig

A remote controlled drilling rig that is fully functional includes a drilling rig, an electrical assembly, and a remote. The drilling rig includes a truck for towing a semi-trailer on which is positioned a derrick and a drilling assembly. The electrical assembly is positioned within the drilling rig and includes a battery for powering components of the drilling rig, in addition to a receiver and circuit board for receiving and processing command signals respectively. The receiver is communicably coupled to a transmitter housed within a casing of the remote. A plurality of controls is used to send input commands to the transmitter, which are in turn transmitted to the receiver in order to control functions of the drilling rig, such as raising and lowering the derrick. A draw-works assembly allows for raising and lowering a traveling block within the derrick by winding and unwinding a drilling cable connected between.

Owner:MANSPERGER COBY W

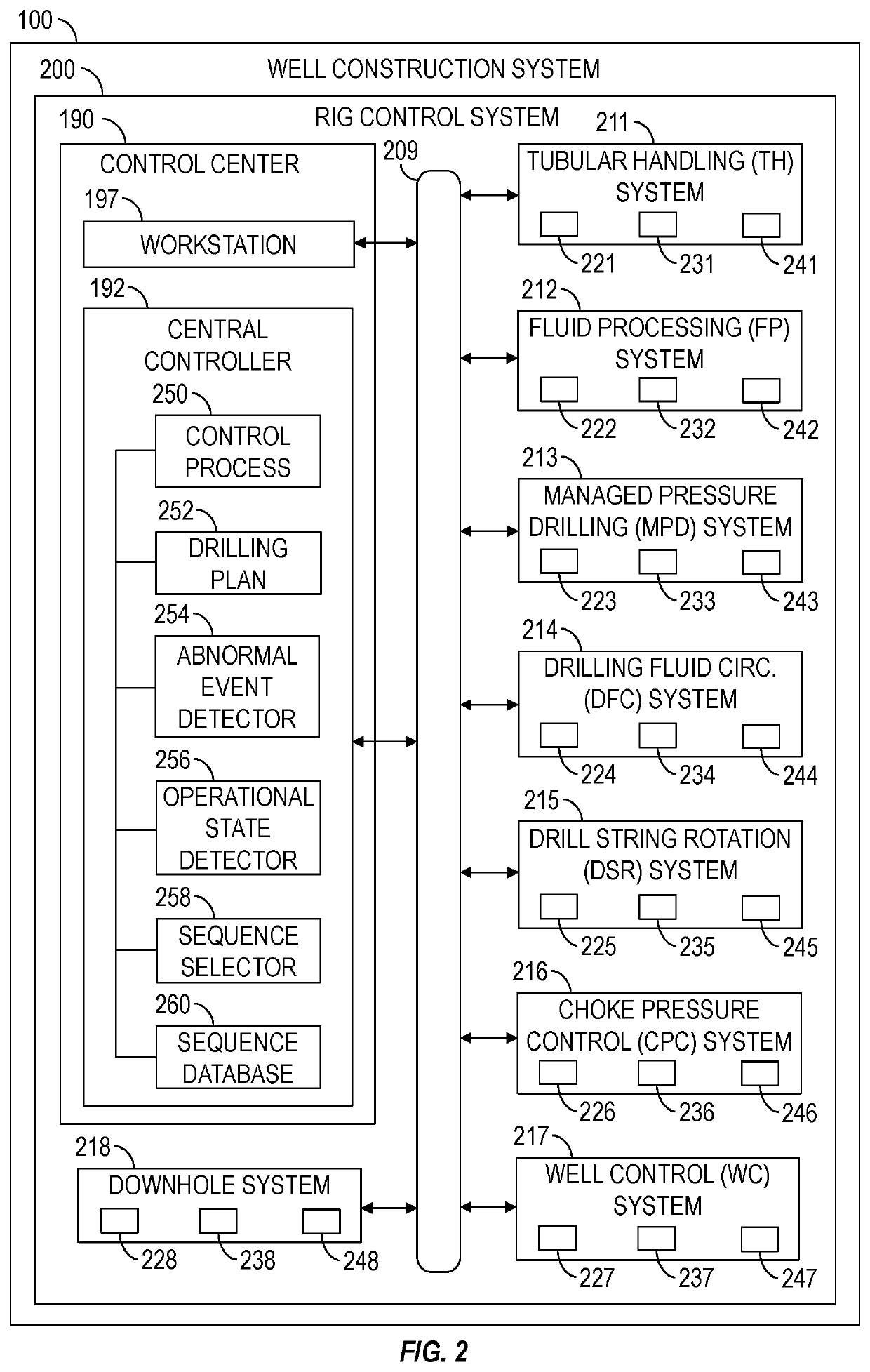

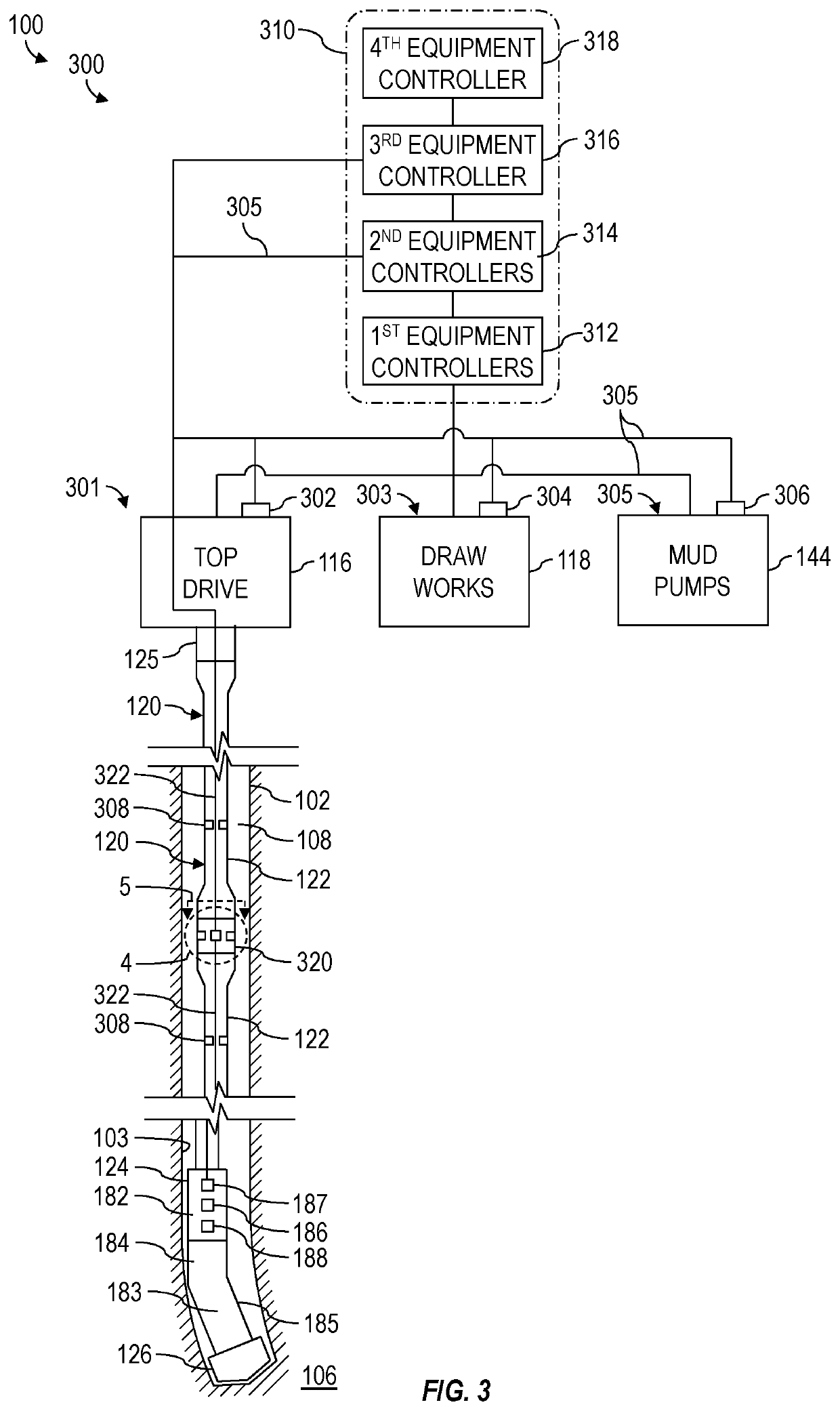

Control system for drilling operations

The present application is directed to a system providing automatic and manual control of a brake lever on band brake drawworks of a wellbore drilling rig. The system comprises a pneumatic cylinder attached to the brake lever; and a control means in fluid communication with the pneumatic cylinder, the control means being operationally configured to run the pneumatic cylinder in response to information obtained by the control means concerning one or more drilling parameters and operationally configured to disable the pneumatic cylinder.

Owner:CHAN YUN TAK

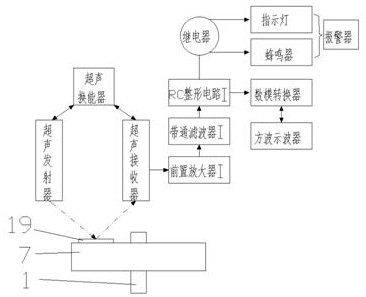

Drilled pile drilling device suitable for determining boundary depth of upper-soil low-rock stratum

PendingCN111648769ASignificantly reflected ultrasonic signalEasy to compare and observeSurveyDrilling rodsBandpass filteringFoundation engineering

The invention discloses a drilled pile drilling device suitable for determining boundary depth of an upper-soil low-rock stratum. The drilled pile drilling device comprises a drill stem, a drill bit,a positioning retainer ring, a soil taking sleeve, a drive rotary disc, a lower supporting platform, a driven rotary disc and a drill stem blocking head, wherein the drill stem blocking head is connected to a guide rod and extends into a hydraulic sleeve; a lifting rope on the top of the hydraulic sleeve is connected to a winch roller and an angle displacement sensor; an ultrasonic speed measureris arranged in a shielding cover; a torque sensor abuts against the drive rotary disc through a jacking screw; and the angle displacement sensor, the ultrasonic speed measurer and the torque sensor output a square wave signal through pre-amplification, band-pass filtering, a RC reshaping circuit and digital-to-analogue conversion, wherein an output signal of the ultrasonic speed measurer is connected to a buzzer and a signal lamp through a relay. Information such as rotation speed, torque and drilling depth of the drill stem during drilled pile drilling are acquired, processed and analyzed, and soil-rock boundary depth is quickly determined through an intermittent alarm signal, so that guide and basis are provided for determining stratum distribution information for enclosure pile construction of deep foundation engineering of the upper-soil low-rock stratum.

Owner:THE FIRST ENG CO LTD OF CTCE GRP +2

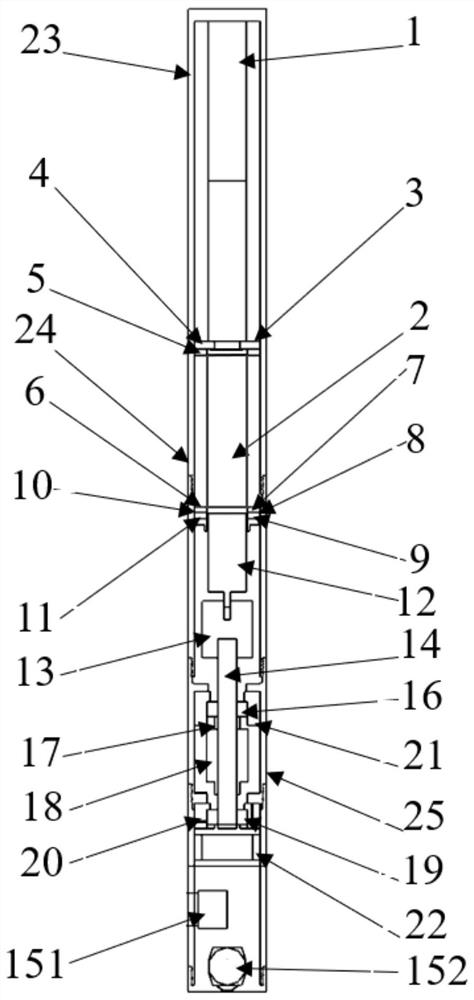

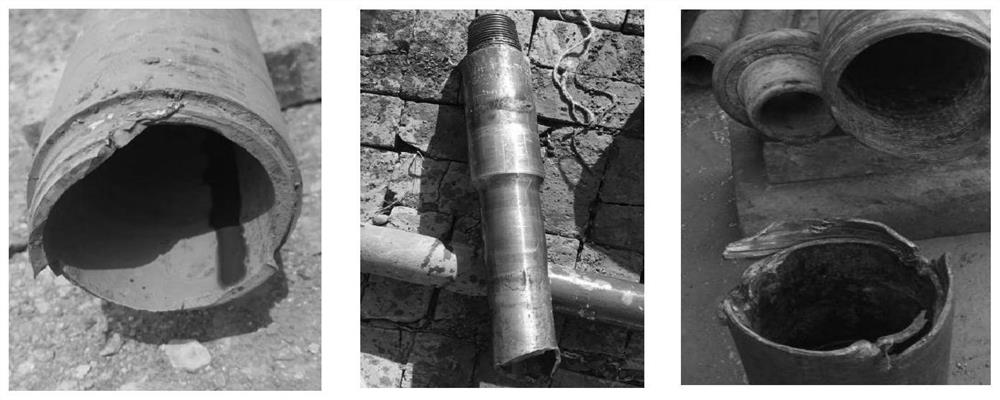

Device and method for detecting underground accidents in geological drilling process

The invention provides a device and a method for detecting underground accidents in the geological drilling process. The device is mainly composed of an underground instrument, a depth measuring unit, a high-performance computing workstation and detection software. Firstly, the small-size cable-free underground instrument is adopted for measuring the distance between an ultrasonic transducer and a fish fracture surface, the well wall diameter, the fracture surface and an ultrasonic image of the well wall, and meanwhile a pressure balance device is designed to improve the pressure resistance degree of the ultrasonic transducer in consideration of direct contact between the ultrasonic transducer and mud during work. Secondly, the depth measuring unit is additionally arranged in ground rope coring equipment to detect the depth of a fish to the ground, and in addition, a high-precision fitting algorithm is adopted for correcting depth measurement data in consideration of the tension influence of a winch steel wire rope. Finally, the high-performance computing workstation and the detection software are used for calculating the shape of the fracture surface of an underground drilling tool, the well wall diameter, the depth of the underground fractured drilling tool to the ground and three-dimensional ultrasonic images of the fracture surface and the well wall.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Braking system for a draw works used for drilling operations

ActiveUS10035687B2Fluid actuated drum brakesMechanically actuated drum brakesWorking fluidEngineering

A braking system may include a brake assembly having a brake shaft and a brake lever coupled to the brake shaft. The system may also include a brake cylinder having a first chamber, a second chamber, a piston positioned between the chambers and a piston rod extending outwardly from the piston. The piston rod may be configured to be coupled to the brake shaft such that movement of the piston rod results in rotation of the brake shaft. In addition, the system may include a first valve configured to control a supply of working fluid to the first chamber and a second valve configured to control a supply of the working fluid to the second chamber. By adjusting a position of the first valve and / or the second valve, a braking force applied between the brake assembly and a drum of the draw works may be controlled.

Owner:NIELD BARRY J +1

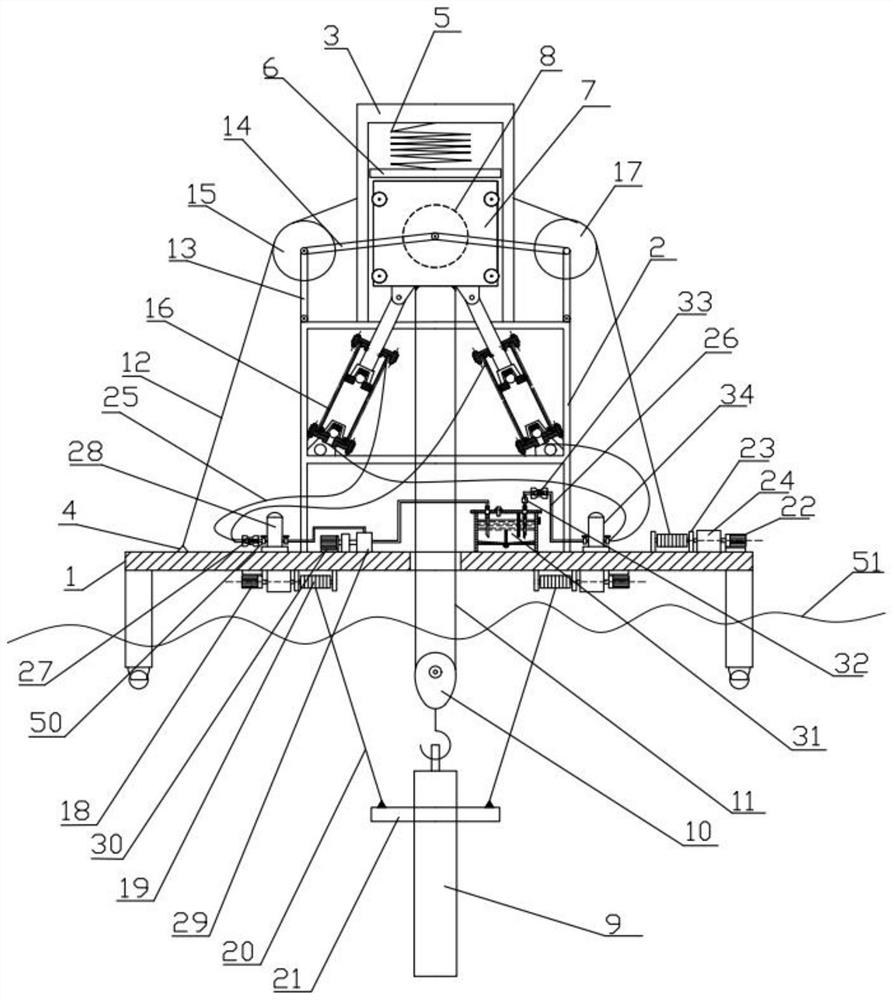

Piling machine

PendingCN107724386AHigh positioning accuracyImprove efficiencyBulkheads/pilesStructural engineeringDraw-works

The invention relates to the field of piling equipment, in particular to a piling machine. The piling machine comprises a base and a base board arranged on the base; a rotary shaft is arranged in thecenter of the base; the base board is rotationally connected with the base through the rotary shaft; one end of the base board is provided with a drilling frame; two power heads are arranged at the upper end of the drilling frame; a drill stem below each power head is provided with a corresponding slide rail; two winches are arranged at the position, at the other end opposite to the drilling frame, of the base board; and the centers of the two drill stems installed on the two power heads are separately located on the same circumference with the center of the rotary shaft as the circle center.According to the piling machine, the two power heads are arranged on the drilling frame, at the same time, through the reasonable position design of the power heads, the effect that only the base board needs to rotate on the rotary shaft by a certain angle in the switching process of soil sampling and piling is achieved, the soil sampling and piling positioning precision can be greatly improved, simpleness and convenience are achieved, and efficiency is improved.

Owner:TONGXIANG TIANSHUN MOLD CO LTD

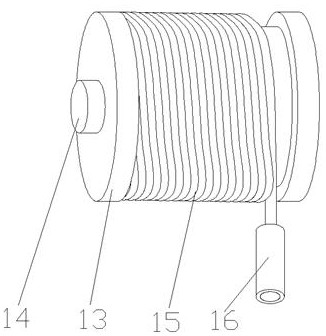

Replaceably lined cable guides and tensioning roller for drill line slip and cut operations on a drilling rig

Cable guides for overhead support of drill line on a drilling rig during a slip and cut operation feature replaceable liners of wear material supported by a re-usable base. A tensioning roller added to the draw-works resides outward from the periphery of the draw-works drum and is spring-biased toward same into order to force the incoming drill line against the periphery of the drum.

Owner:URQUHART JESSE

Drilling Rig Derrick Safety Hoisting Operation Method

ActiveCN110790165BReduce tensionNo shakingDrilling rodsWinding mechanismsMarine engineeringWell drilling

The invention relates to an operation method for safe hoisting of a drilling machine derrick. The method successively comprises the steps that (1) a well mouth base and a drilling platform are installed, and an A-bracket is installed on the well mouth base; (2) a derrick main body is pieced together, wherein the lower end of a derrick supporting leg is firstly hinged on the well mouth base by a derrick large pin, and then the derrick main body is pieced integrally from bottom to top and maintained horizontal; (3) an overhead crane and a racking platform are installed, and a hook block assemblyis placed; (4) a drilling line between an overhead crane wheel set and a block assembly wheel set is put through, a live line head of the drilling line is led downwards from an overhead crane guide wheel and led onto a winch drum after bypassing a drilling platform guide wheel, and the other end of the drilling line is fixed on a drilling line fixation device which is located under the front sideof the derrick main body; (5) a back like is led out downwards from the hook block assembly and fixed on a back line fixation lug after bypassing a derrick guide wheel and an A-bracket pulley; and (6) a winch is started to unreel the drilling line to drive upward moving of the hook block assembly, the back line is pulled by the hook block assembly, and the back line drives the derrick main body to be vertical. The method has high operation efficiency and high safety.

Owner:SINOPEC EAST CHINA PETROLEUM ENG CO LTD

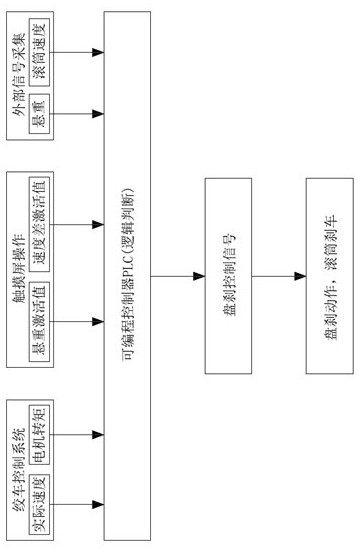

Petroleum drilling machine winch broken shaft protection method

The invention belongs to the technical field of petroleum drilling machine drilling and production and particularly relates to a petroleum drilling machine winch broken shaft protection method which comprises the following steps of: 1, collecting a roller speed and a drilling tool hanging load parameter through a PLC slave station; 2, collecting a speed and a torque of a winch through communication of a winch control system; 3, inputting a drilling tool hanging load activation value and a speed difference activation value of broken shaft protection through a touch screen; and 4, reading the drilling tool hanging load activation value and the speed difference activation value, input by the touch screen, of broken shaft protection through a PLC (programmable logic controller), conducting data processing on the drilling tool hanging load activation value, the speed difference activation value and parameters of a winch control system, then conducting logical judgment on a detected roller and the drilling tool hanging load parameter by the PLC, automatically executing a corresponding program segment when a broken shaft condition is judged according to a program logic, and outputting a brake control signal. For the petroleum drilling machine winch broken shaft protection method disclosed by the invention, by conducting double detection and judgment on a drilling tool hanging load and a torque of a motor through the PLC, a disc brake control signal is output, a disc brake is utilized to brake the roller, and equipment such as a traveling block is prevented from hitting a drill floor and being damaged.

Owner:TIANSHUI ELECTRIC DRIVE RES INST +1

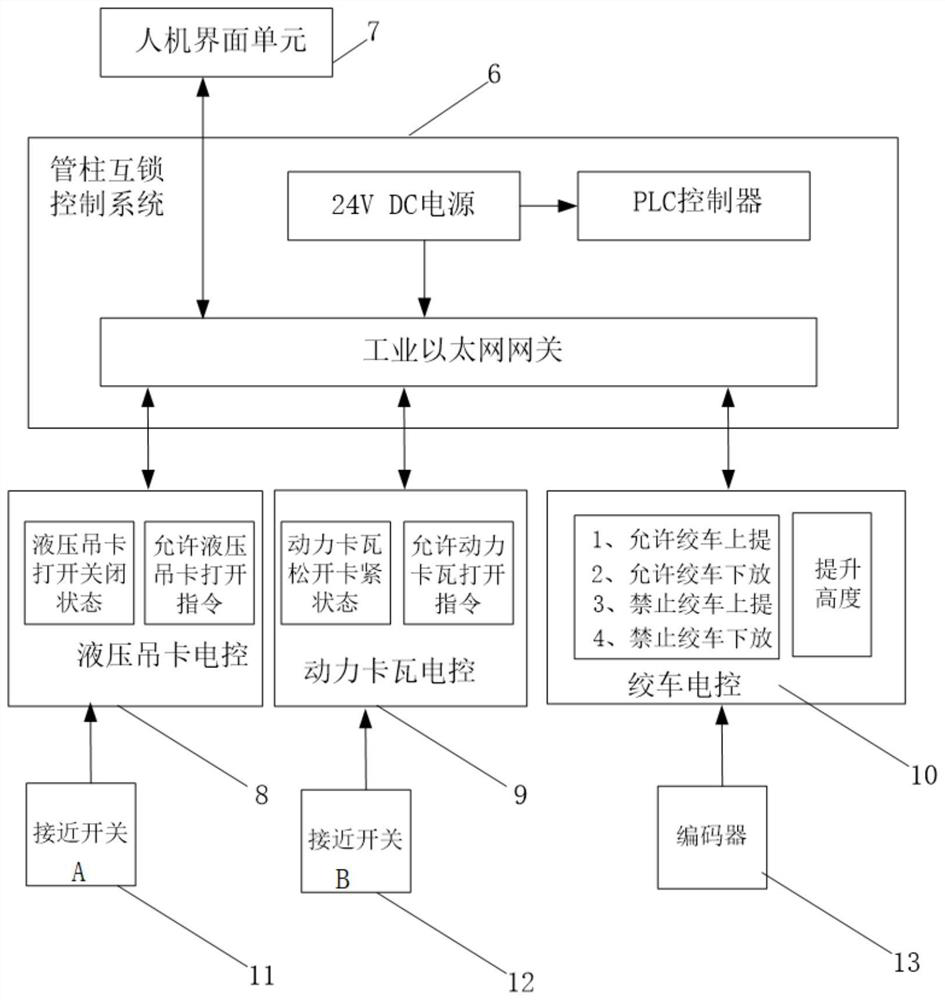

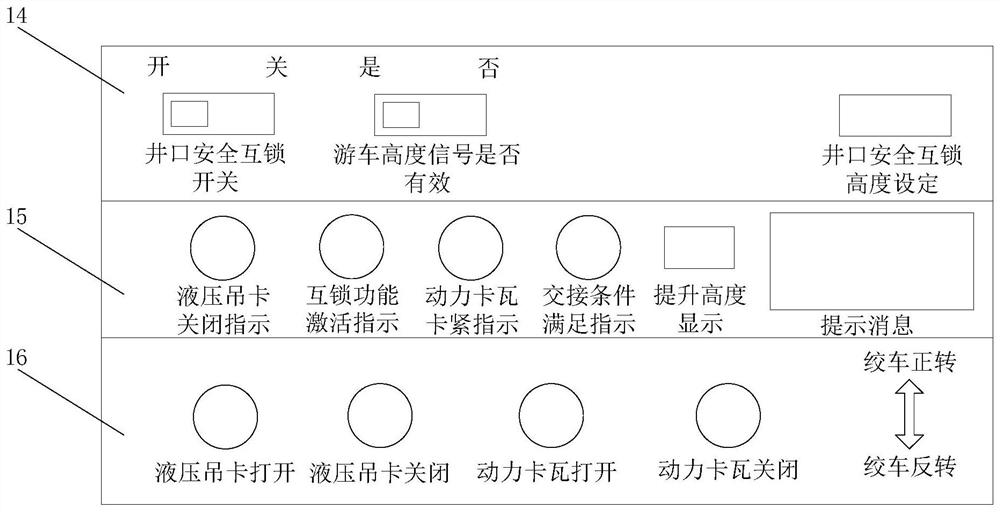

A device and method for interlocking interlocking management and control of wellhead pipe strings of drilling rig and workover rig

ActiveCN111997537BAccurate detectionEasy to set upDrilling rodsDrilling casingsHuman–machine interfaceEngineering

The invention discloses a wellhead pipe string handover interlock management and control device for a drilling rig and a workover rig. The pipe string interlock control system includes a PLC controller, an industrial Ethernet gateway, a DC power supply, a PLC controller, an industrial Ethernet gateway, The DC power supply is installed in the control box; the DC power supply is responsible for converting the AC alternating current into 24V DC control power to supply power to the PLC controller and industrial Ethernet gateway; the PLC controller is responsible for the control program in the string interlock control system Logic operation; the industrial Ethernet gateway is connected with the hydraulic elevator electric control, power slip electric control, winch electric control, man-machine interface unit and PLC controller through PROFINET communication cables. The invention also discloses a method for interlocking and interlocking management and control of wellhead pipe strings of a drilling rig and a workover rig. The above-mentioned device is used to realize process control. The device of the invention realizes the safety interlock of equipment operation in the handover process of the wellhead pipe string; the method can automatically judge whether the pipe string is handed over successfully.

Owner:中油国家油气钻井装备工程技术研究中心有限公司 +2

Interlock for a drill rig and method for operating a drill rig

Owner:NIELD BARRY J +1

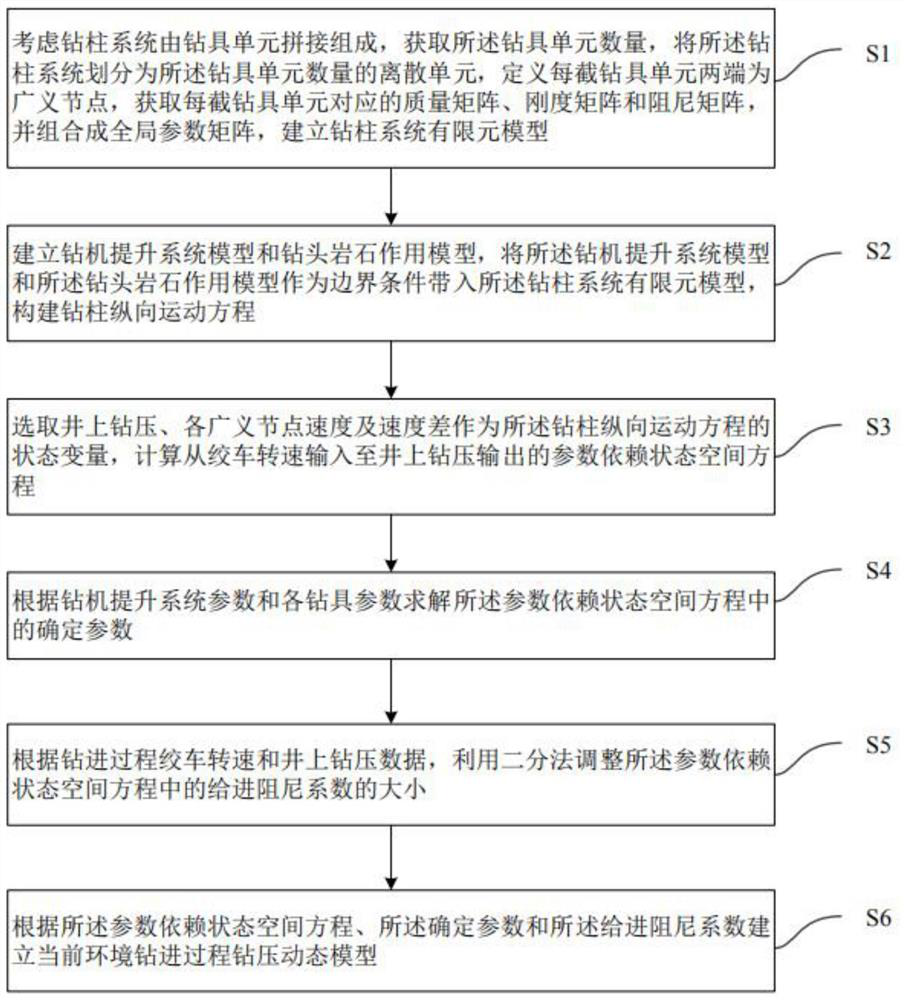

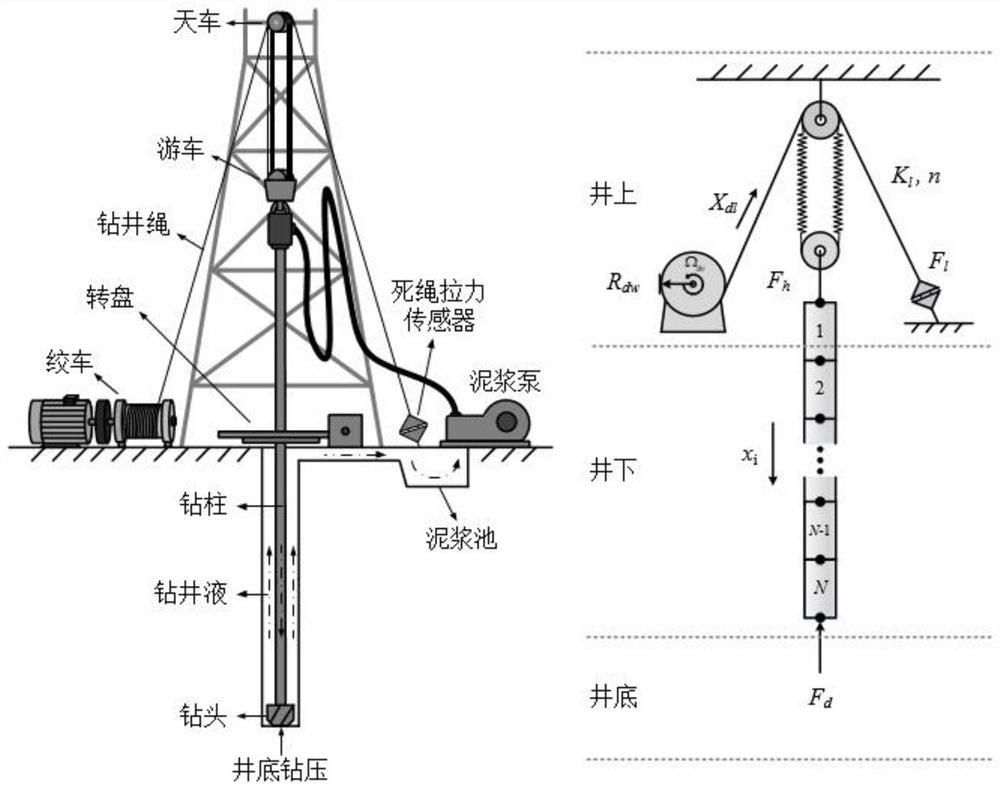

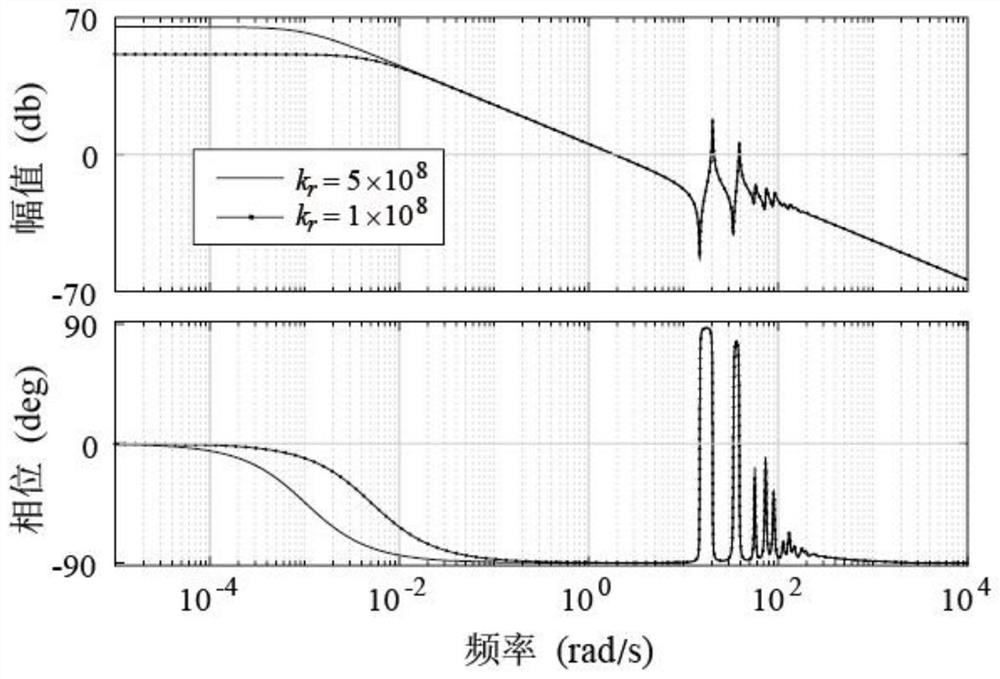

Drilling process bit pressure modeling method considering uncertain damping coefficient

ActiveCN112836406APracticalApplicableGeometric CADDesign optimisation/simulationDynamic modelsClassical mechanics

The invention aims at the field of geological drilling engineering, and discloses a drilling process bit pressure modeling method considering an uncertain damping coefficient, which comprises the following steps of: firstly, modeling a drilling machine lifting system, a drill column system and a drill bit-rock action mechanism, constructing a drill column longitudinal motion equation, and obtaining a state space model depending on the uncertain damping coefficient; and solving model parameters by using on-site drilling tool parameters and historical data, and finally setting an uncertain feeding damping coefficient. The characteristic that an actual drill string system is composed of discrete units is considered, and a high-degree-of-freedom model with the degree of freedom equivalent to the number of actual drilling tools is invented based on a finite element method. The introduced damping model can reflect the drill-rock action in the current environment by setting a damping coefficient, so that a drilling process bit pressure dynamic model suitable for different environments is established. On-site data shows that the model can better fit the dynamic response from the winch rotating speed input to the above-well bit pressure output.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com