Device and method for handling drill string components in rock drilling and rock drill rig

A control device and drill string technology, which is applied to drilling equipment and methods, drill pipes, rotary drilling rigs, etc., can solve the problems of operator lifting and clamping injuries, people's pressure, etc., and achieve great control advantages and good performance. The Effects of Drilling Economics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

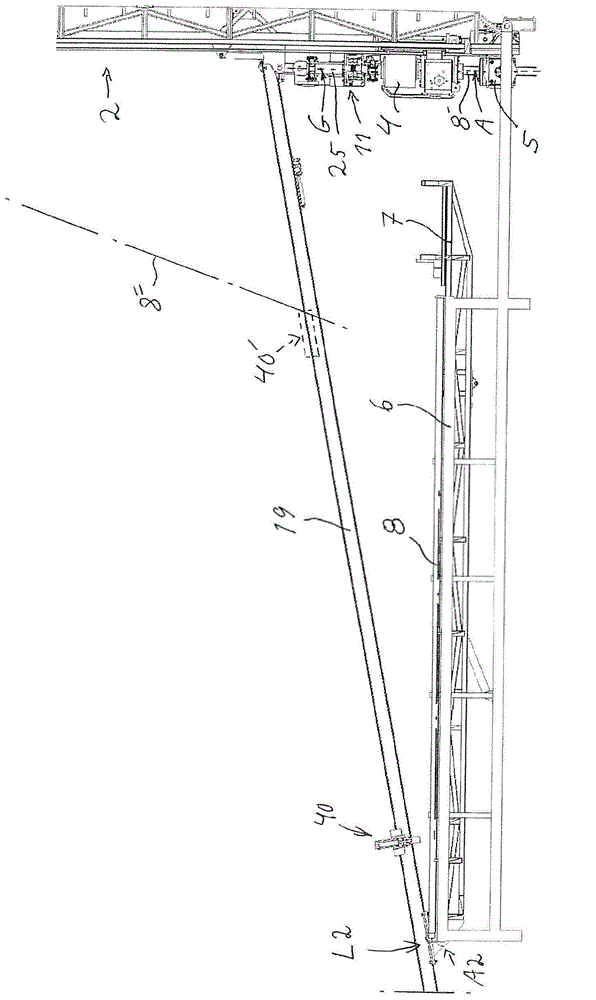

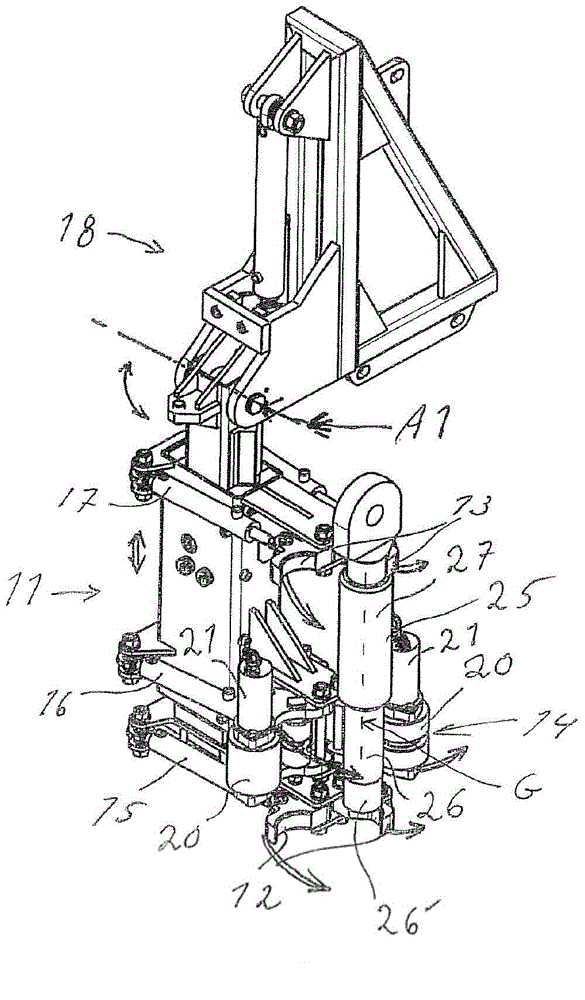

[0040] figure 1 Shown is a feed beam 2 of a rock drilling machine for core drilling that can be adjusted to different angles. The drilling rig comprises a rotary device 4 which is supported on the feed beam 2 to move back and forth. Below (in the figure) the rotating device 4 is provided a pipe holder 5 for temporarily holding a drill string when necessary.

[0041] Beside the feeding beam 2, a power drive kit (not shown) and a drawworks (not shown) for supplying pressurized fluid and the like to the rock drilling machine are arranged. The charging rack 6 is arranged to receive drill string components (indicated by broken line 8) which are respectively entered into and removed from the rock drilling machine in the manner described below.

[0042] Charging rack 6 can be constituted in various ways, but in figure 1 Illustrated in the form of a generally horizontal table, the clamping member 6 can be tilted so that the drill string component 8 can be rolled towards the swing a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com