Well drilling apparatus and assembling and disassembling method

A drilling and equipment technology, applied in the field of drilling equipment, can solve problems such as complex operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

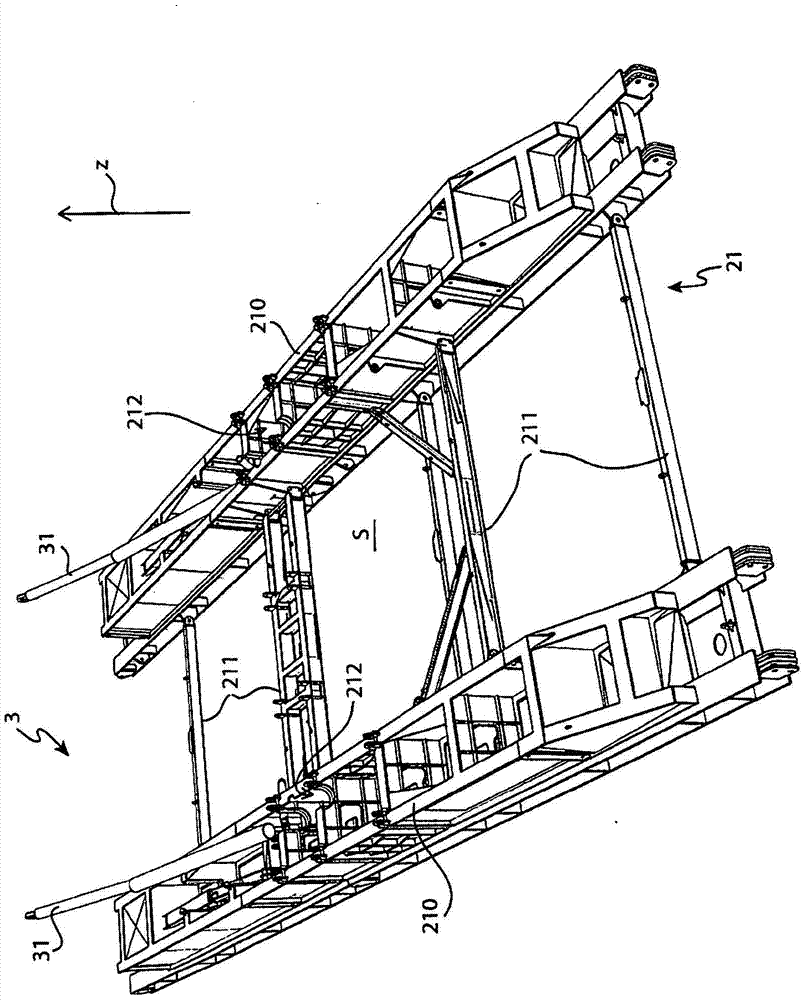

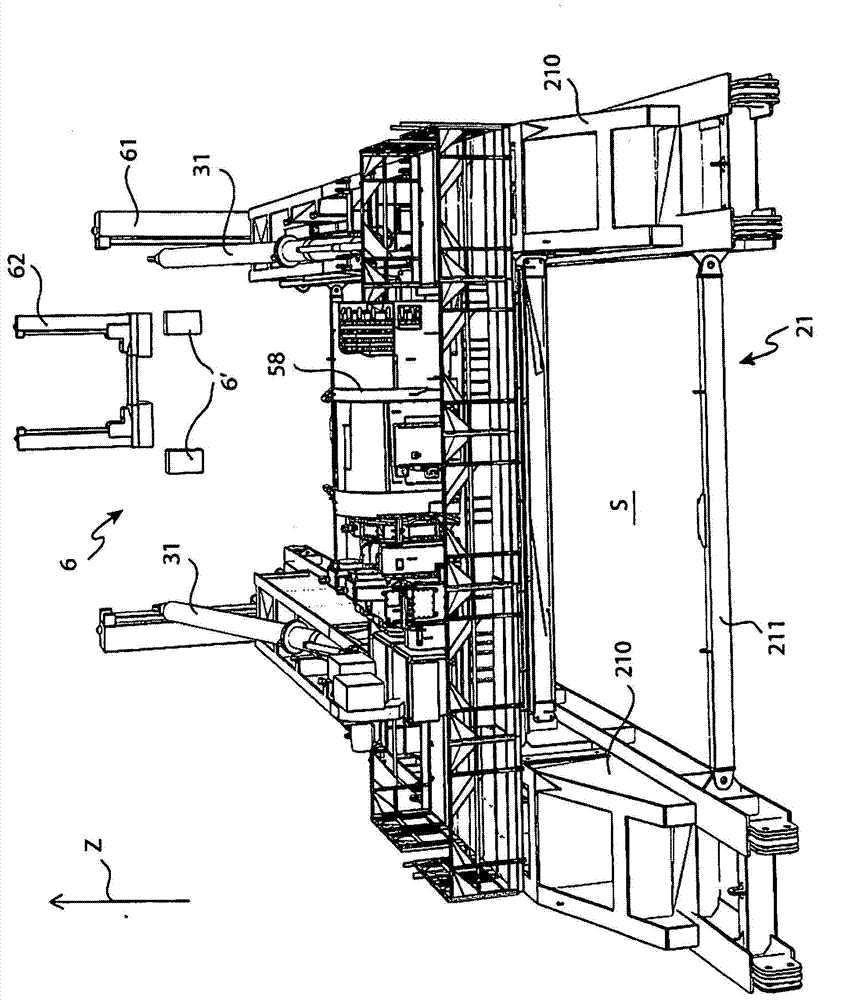

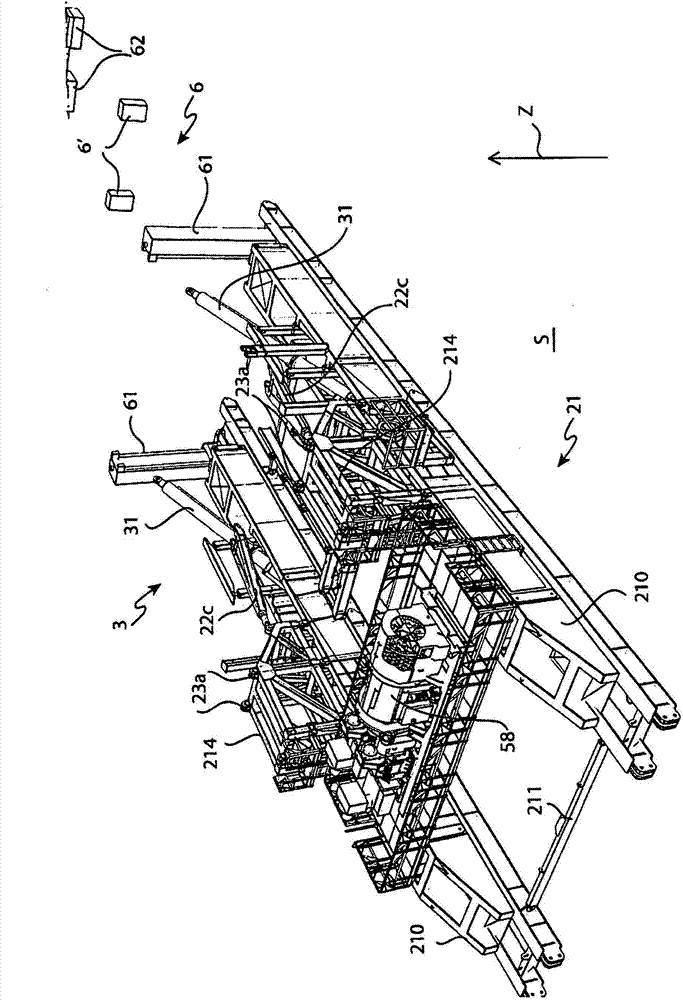

[0051] With reference to the above-mentioned figures, the drilling apparatus 2 is adapted to be transferred from a first assembled operating configuration to a second operating operating configuration, or vice versa. Said plant 2 comprises: a sub-structure 21 situated on the ground "S" and supporting said plant 2; a derrick 23 comprising a pivot point 23a and a fixed point 23a' and passing through said pivot point 23a is pivotally connected to said substructure 21, said mast 23 being rotated about said pivot point 23a so as to transition from said assembly working configuration which is generally horizontal to said vertical working configuration, or in turn.

[0052] The apparatus further comprises: a drilling floor 22, which can be raised and connected to the mast; and actuating means 3, adapted to enable the drilling apparatus to be transferred from the assembled configuration to the use configuration. The actuating means 3 are hydraulic means connected directly to the mast...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com