Drill string arranging method for push-supporting-type pipe string treatment equipment under top-drive-free working condition

A technology for processing equipment and drill strings, which is applied to drilling equipment, drill pipes, casings, etc. It can solve problems such as no top drive system, excessive investment, damage to manipulators, etc., and achieve the effect of operating process and functional requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail:

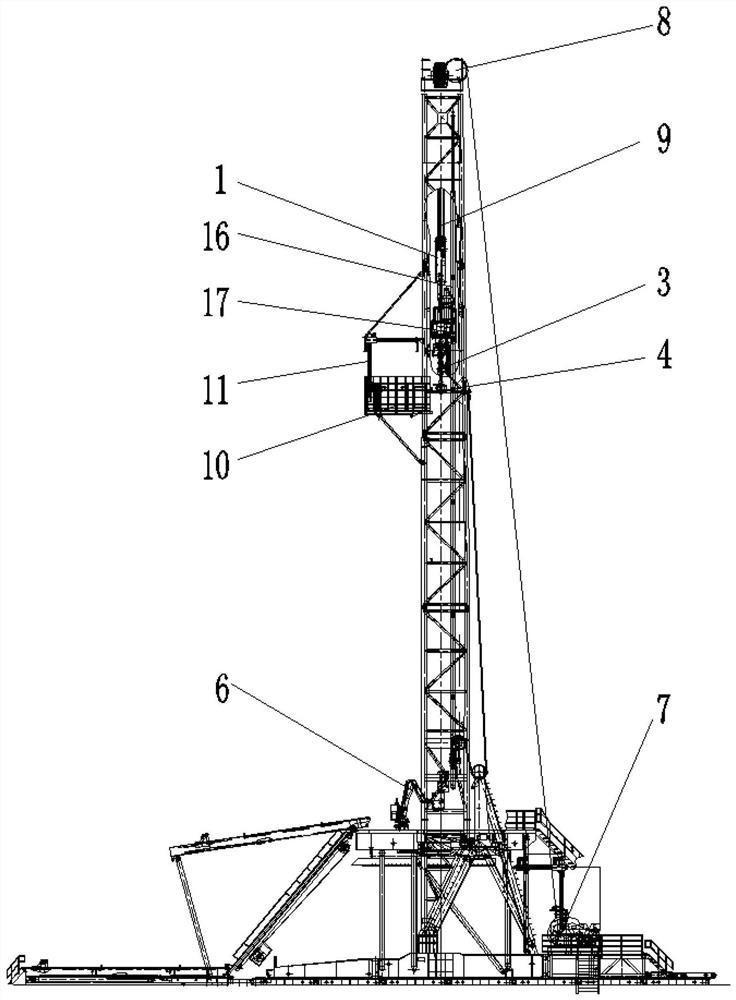

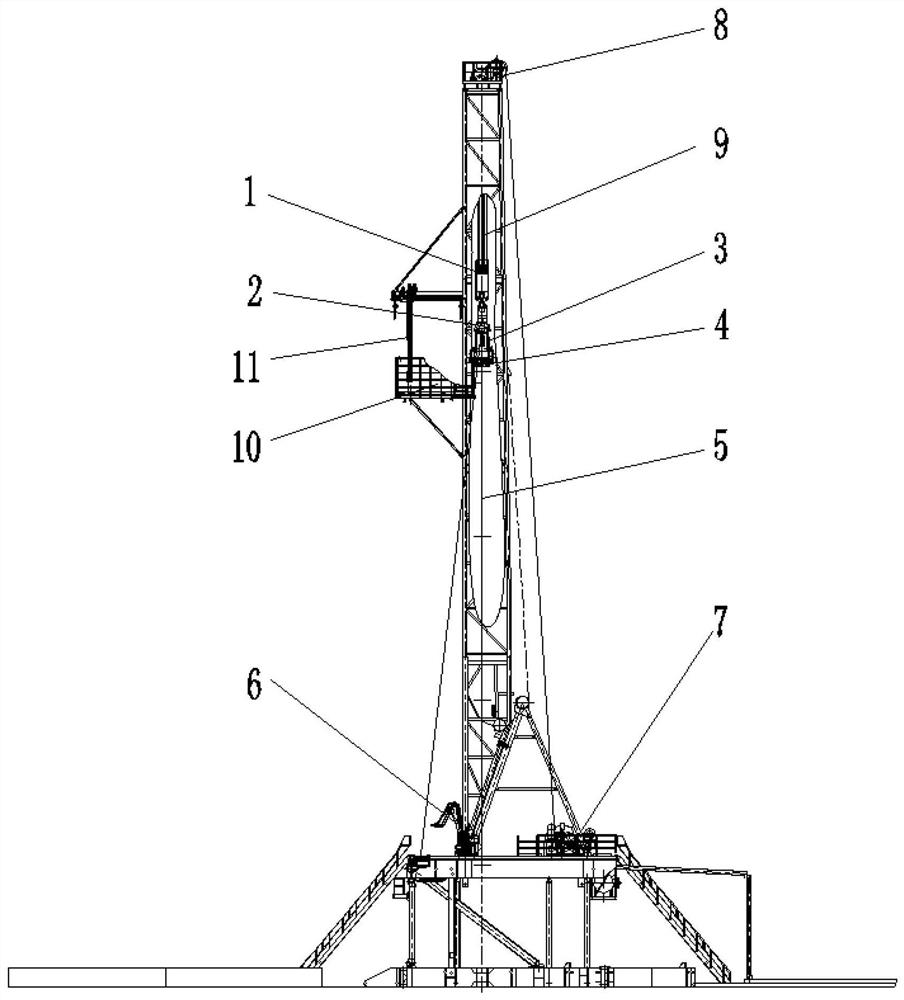

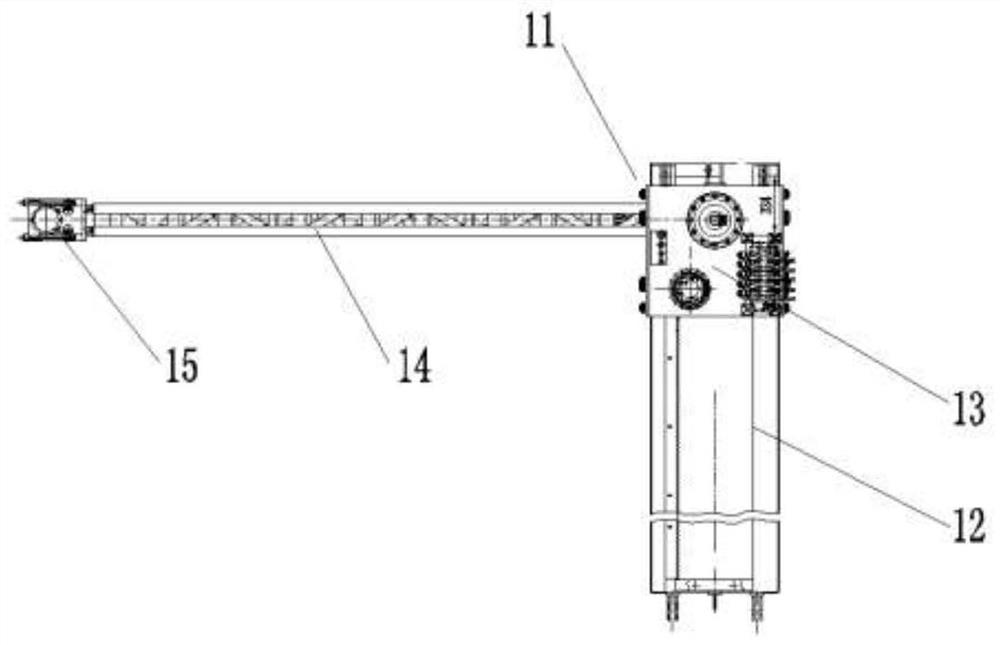

[0030] Such as figure 1 As shown, it is the drill string equipment of the existing push-support type pipe string handling system, including: travel car 1, top drive guide rail 16, top drive 17, lifting ring 3, hydraulic elevator 4, drill floor push-support arm 6, drawworks 7. Crane 8, drilling wire rope 9, second floor platform 10, and manipulator 11. The traveling crane system includes traveling car 1, top drive guide rail 16 and top drive 17. The bottom of top drive 17 is provided with top drive guide rail 16 and top drive 17. Connected with traveling block 1, the function of top drive guide rail 16 is to support top drive 17, offset the lateral force of top drive 17 under the action of drill string 5, top drive 17 hangs ring 3 and hydraulic elevator 4, and hydraulic elevator 4 passes through The lifting ring 3 is connected with the top ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com