Piling machine

A technology of pile driver and base plate, applied in sheet pile wall, construction, infrastructure engineering and other directions, can solve the problems of complicated operation and poor stability of pile body, and achieve the effect of improving positioning accuracy and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

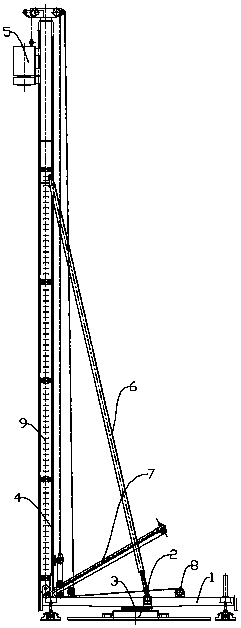

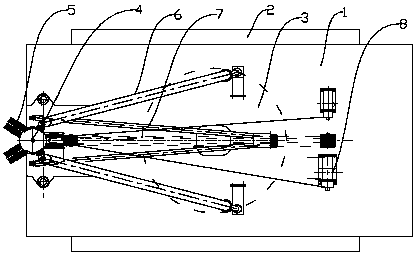

[0012] Such as figure 1 , figure 2 As shown, a pile driver described in this embodiment includes a base 2 for positional movement and a base plate 1 arranged on the base 2, a rotating shaft 3 is arranged at the center of the base 2, and the base plate 1 is rotated The shaft 3 is rotationally connected with the base 2; a drill frame 4 is arranged at one end of the base plate 1, two power heads 5 are arranged at the upper end of the drill frame 4, and corresponding The slide rail 9, the slide rail 9 is used to guide the drill rod installed on the power head 5 in the vertical direction; the landing gear 7 is arranged at the joint between the drill rod and the base plate 1, and the other end opposite to the drill stand 4 Two winches 8 are arranged on the base plate 1; the two winches 8 are respectively connected with the two power heads 5 through wire ropes and the landing gear 7; an inclined support rod 6 is set between the drill frame 4 and the base plate 1; The centers of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com