High-temperature salt well directional well butt joint navigation conveying system and application method

A conveying system and directional well technology, applied in directional drilling, wellbore/well components, drilling equipment and methods, etc., can solve the problems of inability to turn on the pump for circulation, the weight of the instrument is small, and it is easy to encounter obstacles, so as to improve construction safety. Stability, precise docking, high accuracy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

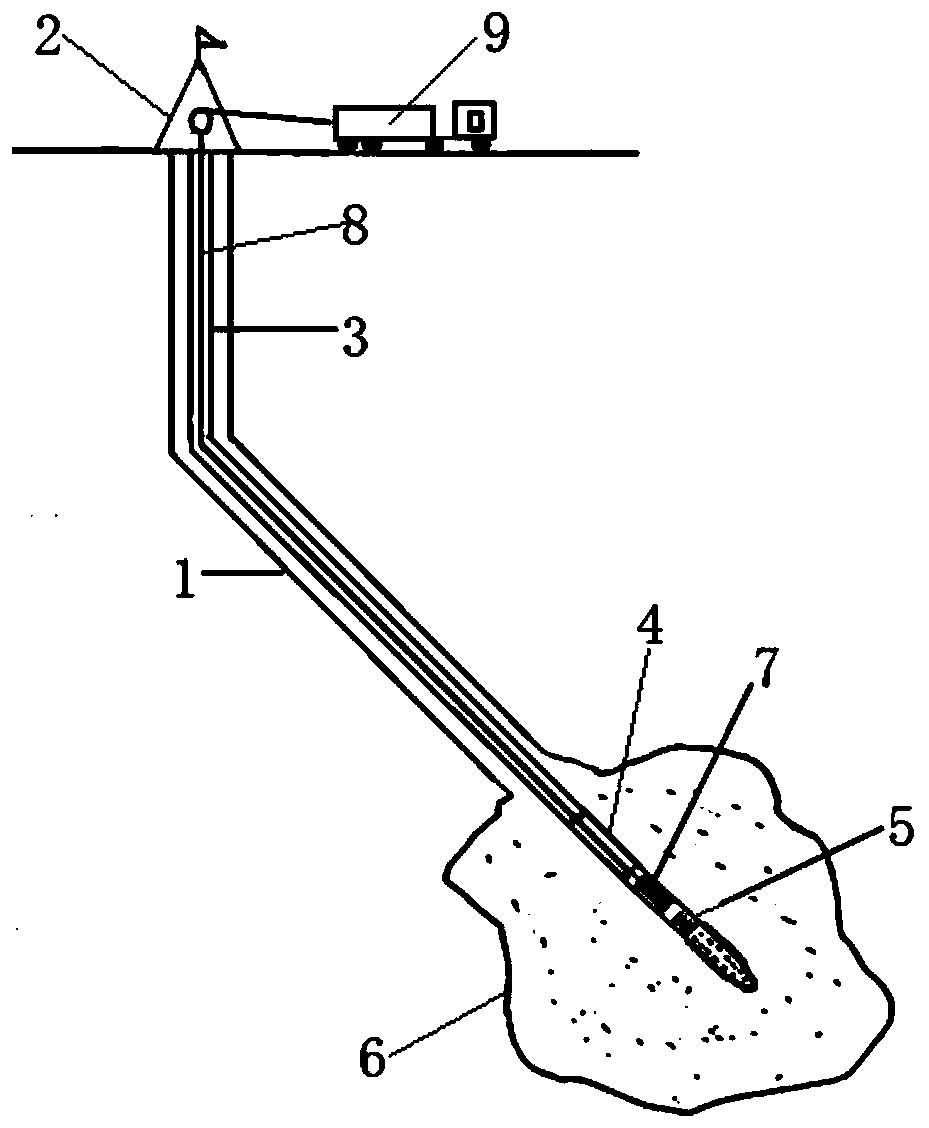

[0051] First, the drilling rig 2 lowers the drill string 3, the non-magnetic drill collar 4 and the navigation delivery device 5 into the directional well 1, and adjusts the length of the drill string 3 and the non-magnetic drill collar 4 so that the navigation delivery device 5 is in the high-temperature salt well solution cavity 6 central position, make the magnetic guide docking instrument 7 sit in the geometric center position of the high temperature salt well dissolution cavity 6, which is beneficial to improve the success rate of high temperature salt well docking.

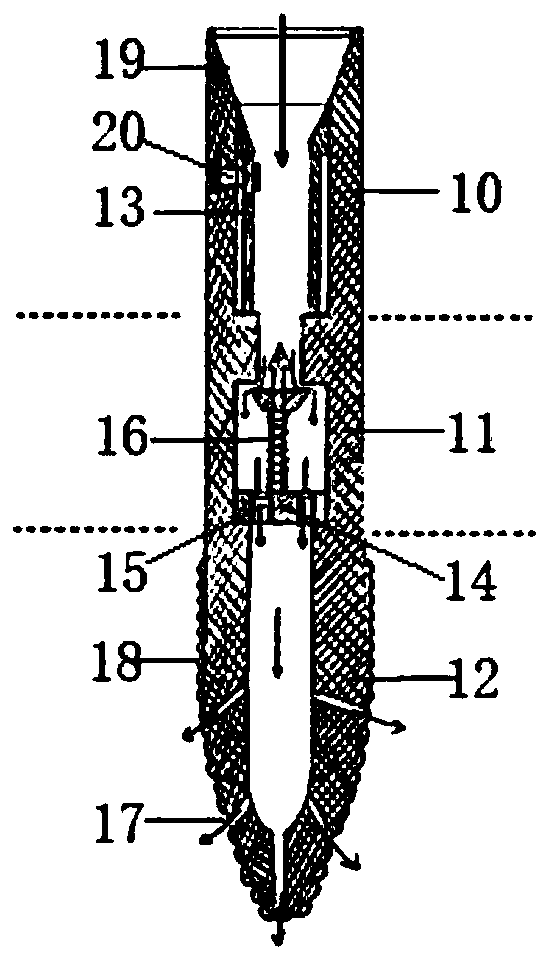

[0052] Secondly, the drilling rig 2 pumps saturated brine, and the saturated brine enters the cavity of the sit-and-hang assembly 10 of the navigation delivery device 5 along the inner holes of the drill string 3 and the non-magnetic drill collar 4, and the pressure of the saturated brine in the sit-and-hang assembly 10 cavity Make the spring of the spring return sleeve 16 in the one-way flow assembly 11 shri...

Embodiment 2

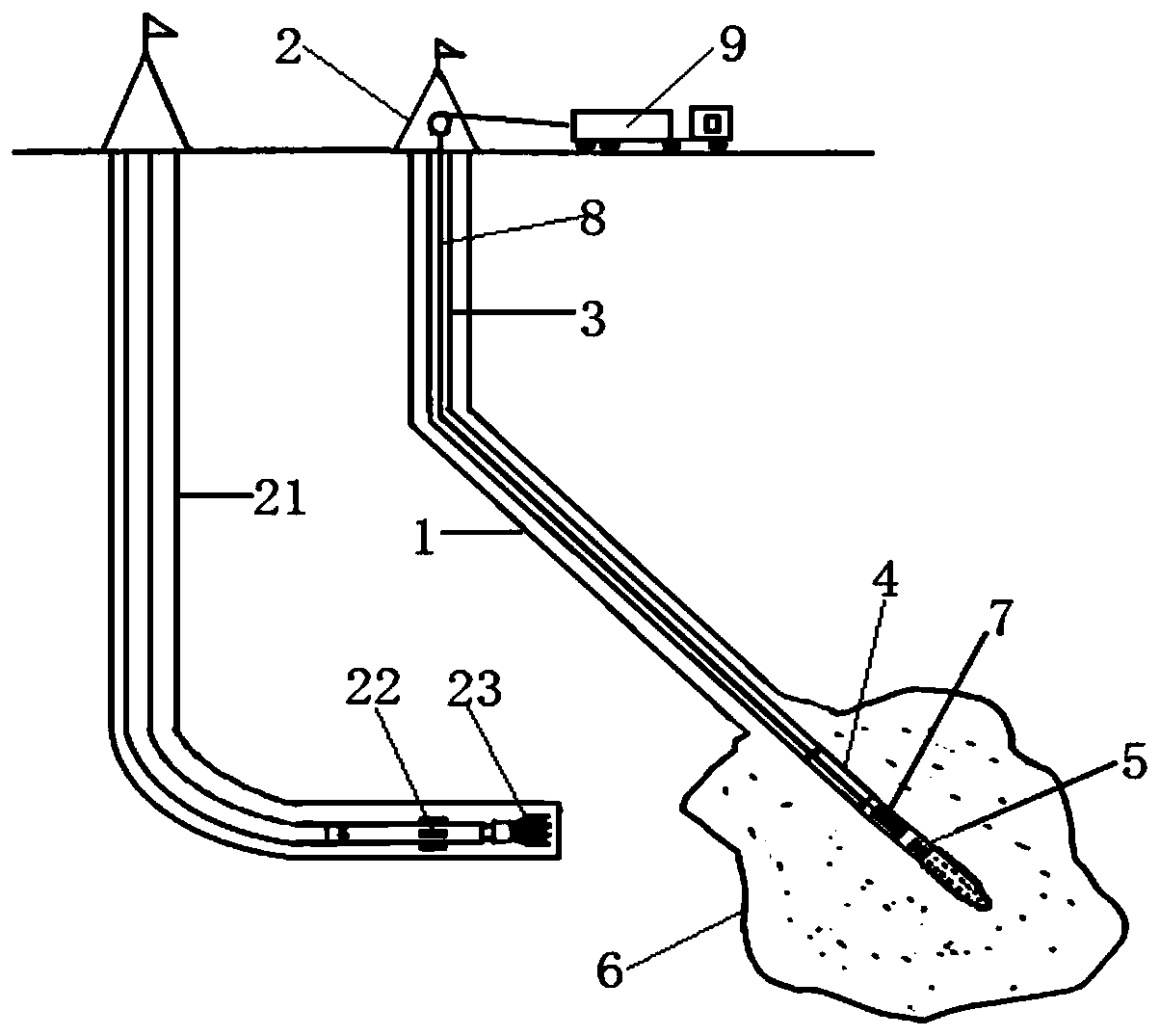

[0068] The specific construction method of the high-temperature salt well directional well 1 docking navigation delivery system is as follows:

[0069] Step 1. Connect the upper end of the drill string 3 to the drilling rig 2, and connect the non-magnetic drill collar 4 at the lower end of the drill string 3 to the navigation delivery device 5, that is, the drilling rig 2, the drill string 3, the non-magnetic drill collar 4 and the navigation delivery device 5 Assemble together.

[0070] Step 2. Start the drilling rig 2, lower the drill string 3, the non-magnetic drill collar 4 and the navigation delivery device 5 into the directional well 1, and when the navigation delivery device 5 enters the open hole, start to control the lowering speed, especially for those with salt layers In the well section, if the navigation conveying device 5 encounters obstacles during the lowering process, then perform step 21, and if the navigation conveying device 5 is smoothly lowered, then perf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com