Drilling process bit pressure modeling method considering uncertain damping coefficient

A technology of damping coefficient and modeling method, applied in drilling equipment, earthwork drilling, special data processing applications, etc., can solve problems such as low flexibility, fixed structural parameters, inability to adjust and reflect high-frequency dynamics and formation environment effects, etc. , to achieve the effect of improving control accuracy, ensuring safety and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the purpose, technical solution and advantages of the present invention clearer, the embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

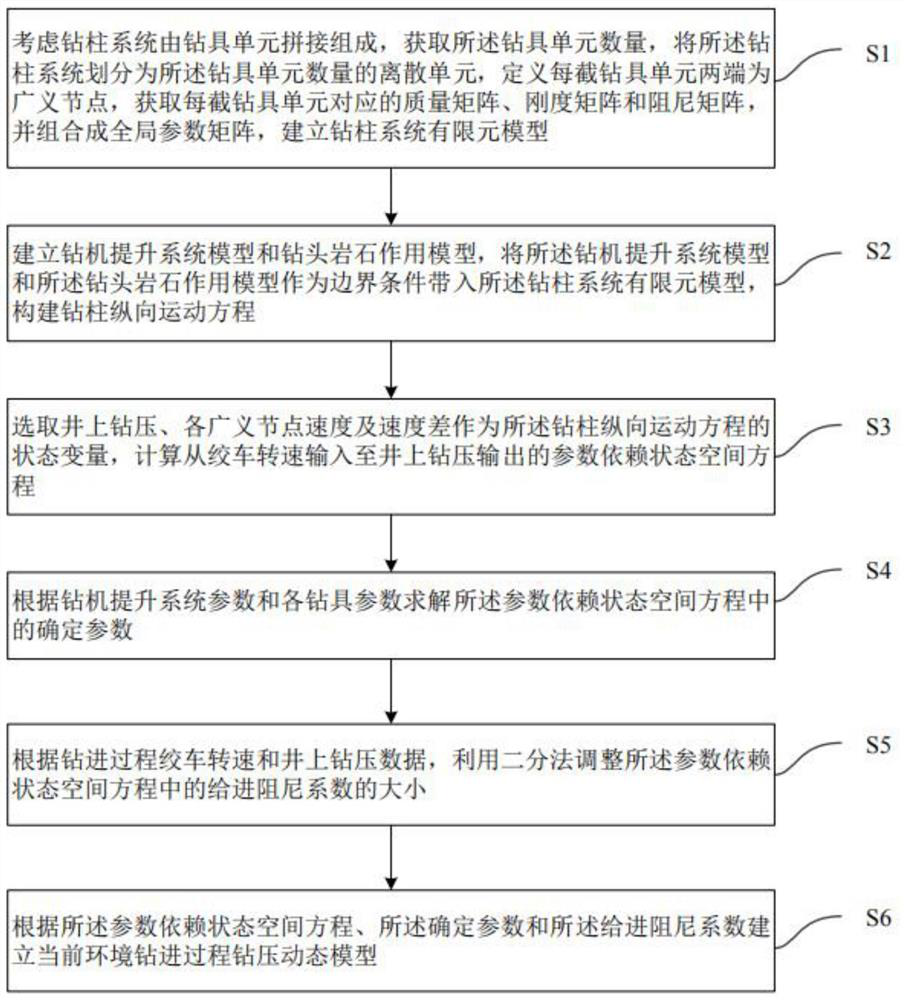

[0021] refer to figure 1 , figure 1 It is a flow chart of the WOB modeling method in the drilling process considering the uncertain damping coefficient of the present invention, and the present invention specifically includes the following steps:

[0022] S1: Establish the finite element model of the drill string system

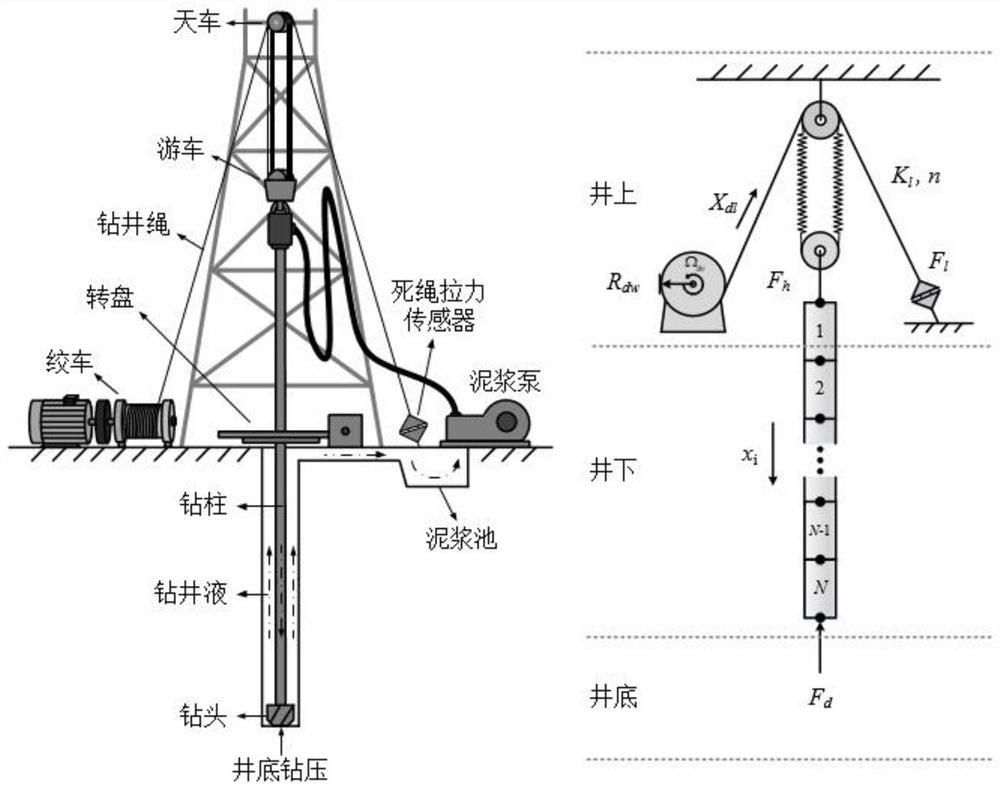

[0023] Please refer to figure 2 , The drill string system is a key component connecting the uphole and downhole. Based on the field process, the drill string is spliced by different drill tool assemblies, usually including different sizes of drill pipes, weighted drill pipes and drill collars. The length of each drilling tool is about 9 meters, and hundreds of drilling tools are often needed to reach the target layer thousands of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com