Buoyancy type mounting method for offshore boosting station

An offshore step-up station and installation method technology, applied in water conservancy projects, artificial islands, underwater structures, etc., can solve problems such as the inability of large cranes to operate, avoid high dependence, reduce installation costs, and improve installation efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

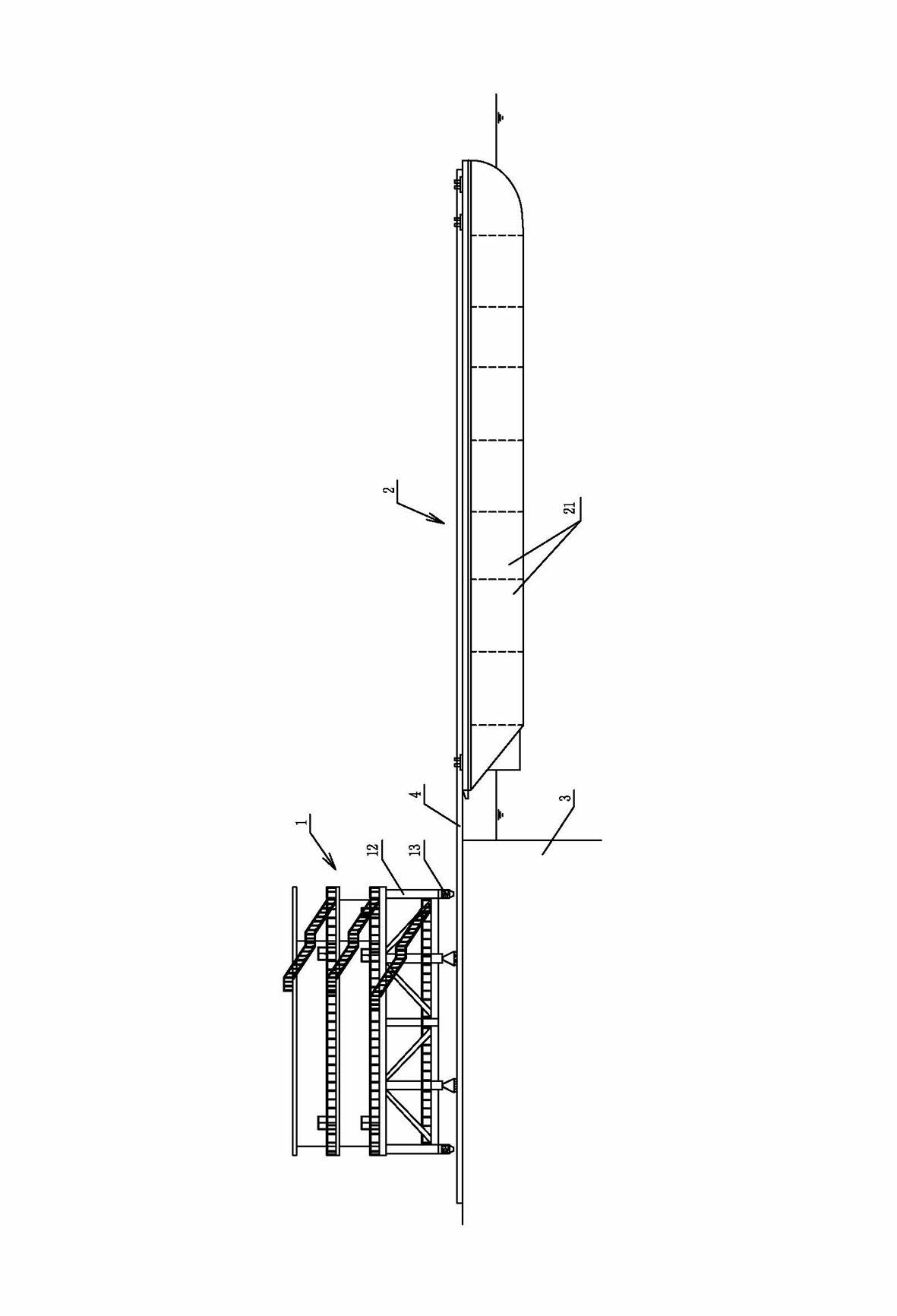

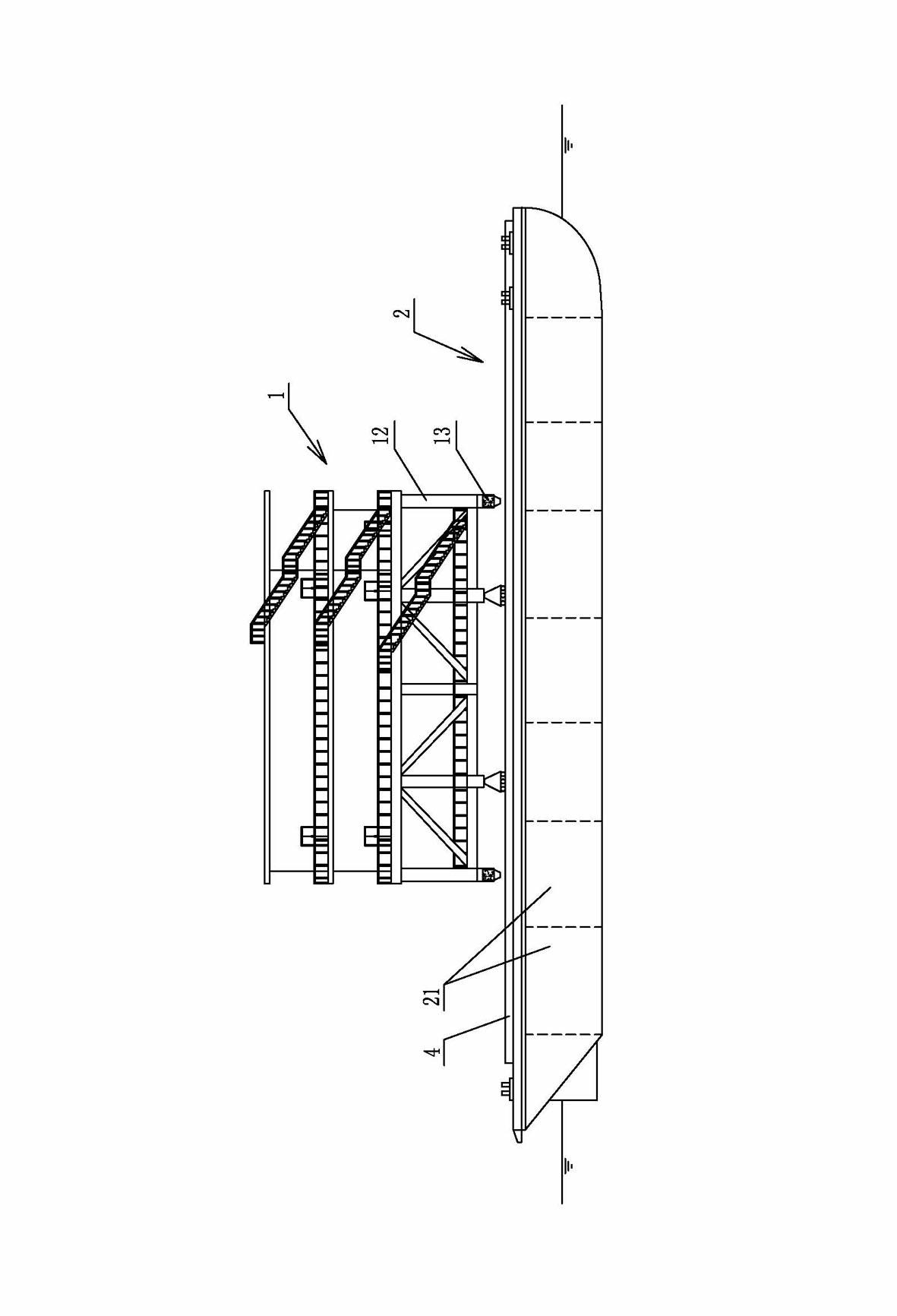

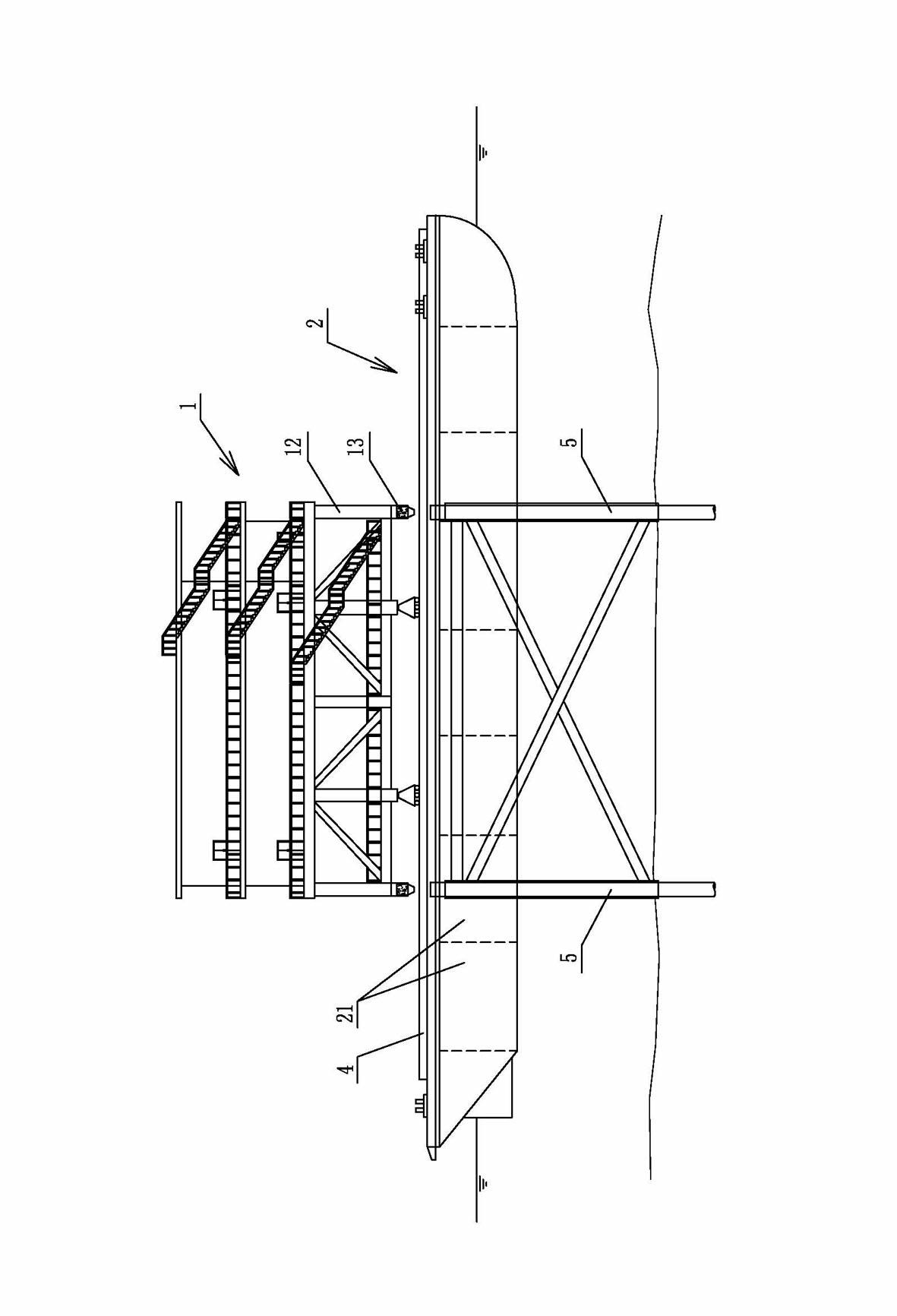

[0033] The offshore booster station 1 that needs to be installed in this embodiment has a capacity of 200MW and a voltage level of 220kV. The planar size of the offshore booster station is 30m×30m, and the overall weight is 1800t; in view of this, this example uses a 5000t-class barge 2 for floating and installation. The barge 2. The length of the ship is 80m and the width is 24m, so as to adapt to the weight of the offshore booster station 1, that is, the load capacity of the barge 2 should be able to safely carry the weight of the entire offshore booster station 1, and its stability should meet the requirements of the barge 2 and the offshore booster station. The stability requirements of Station 1 when hauling at sea; the bottom of the barge 2 is provided with a plurality of pressurized water tanks 21 whose water volume can be adjusted freely. The depth of the draft.

[0034] The specific installation steps are as follows:

[0035] a. Complete the construction of the offsh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com