Method for disassembling and assembling superaqueous bridge

A bridge and tire frame technology, which is applied in the field of dismantling or erecting bridges on water, can solve the problem of not being able to use floating cranes for integral hoisting, etc., and achieve the effect of convenience and adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

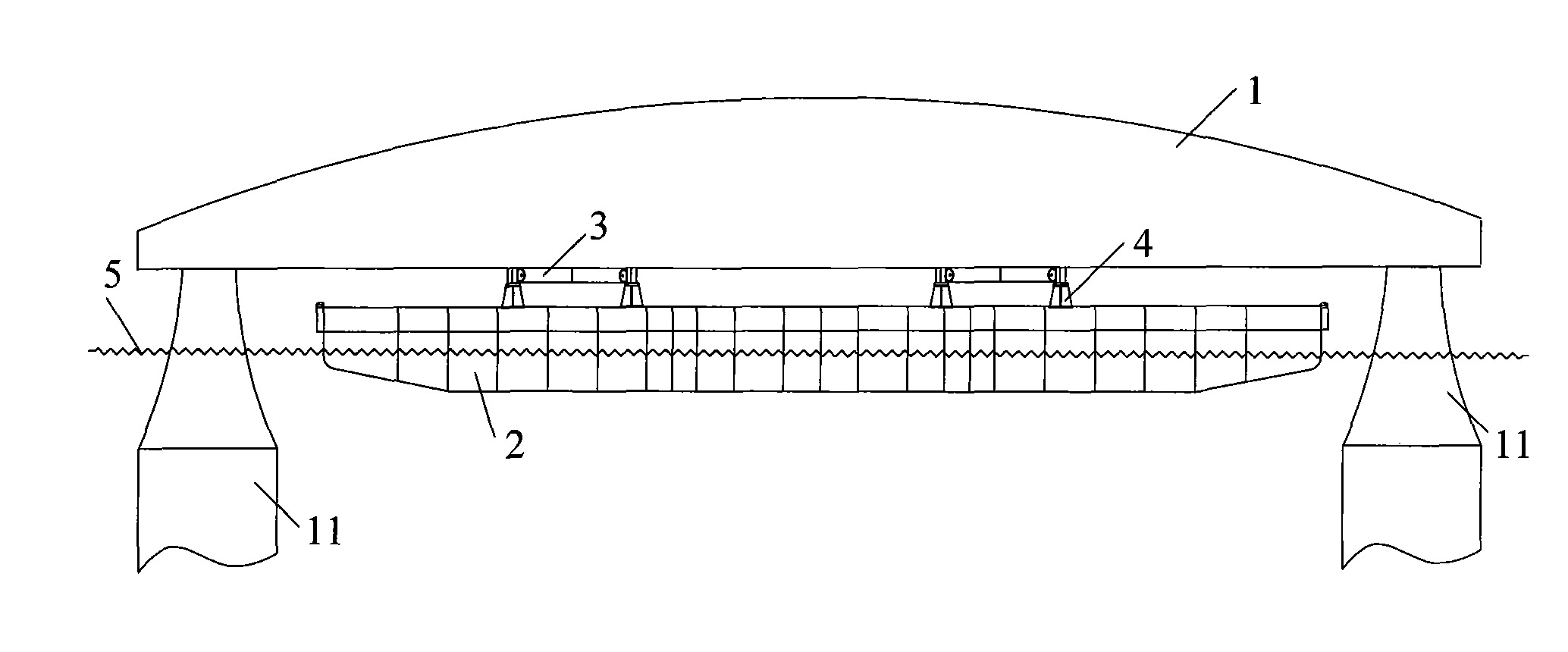

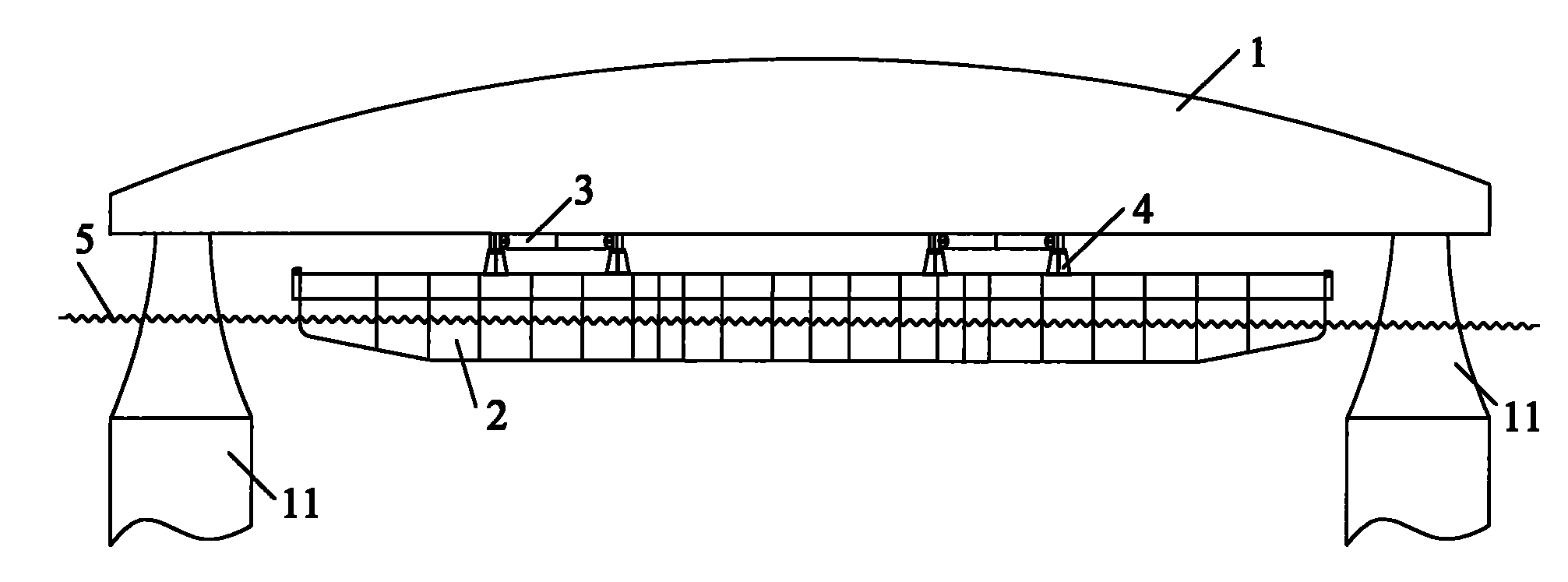

[0030] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

[0031] The present invention provides a method for dismantling or erecting a bridge 1 over water, which is mainly carried out through the following steps: in dismantling or erecting the bridge 1 as a whole, according to the water level 5, rising / falling tide, etc. of the water area where the bridge 1 is located, the When the tide is low, the buoyancy generated by releasing the ballast water in the barge 2 is lifted to complete the dismantling of the bridge 1 at high tide; The bridge 1 is loaded into the pre-installation position, and the erection of the bridge 1 is completed. details as follows:

[0032] (-) Bridge dismantling

[0033] 1. Measure the water level 5, tide and environment in the water area where the elevation of the bridge 1 is located, and determine the required water le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com