Offshore engineering vessel loading and launching system and method

A marine engineering and ship technology, applied in the field of ship loading and launching, and horizontal loading system, can solve problems such as cabin painting requirements, low product integrity, and unfavorable equipment installation, so as to improve the loading safety factor and reduce construction costs. cost, and the effect of shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions in the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the present invention.

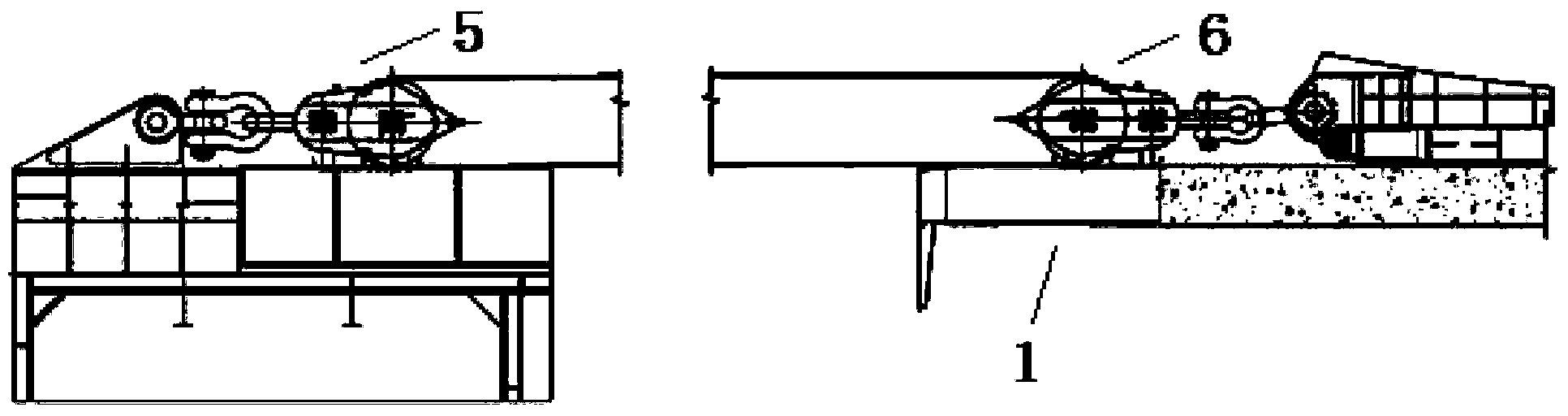

[0023] The specific embodiment of the present invention is illustrated by taking a large-scale marine product pipe-laying ship as an example. The system and method for horizontal loading and launching of a pipe-laying ship with a maximum length of 153.6 meters, a width of 35 meters, and a weight of 12,500 tons can be used in When the size of the hull and the loading weight reach the limit of the entire loading system, the loading safety is guaranteed.

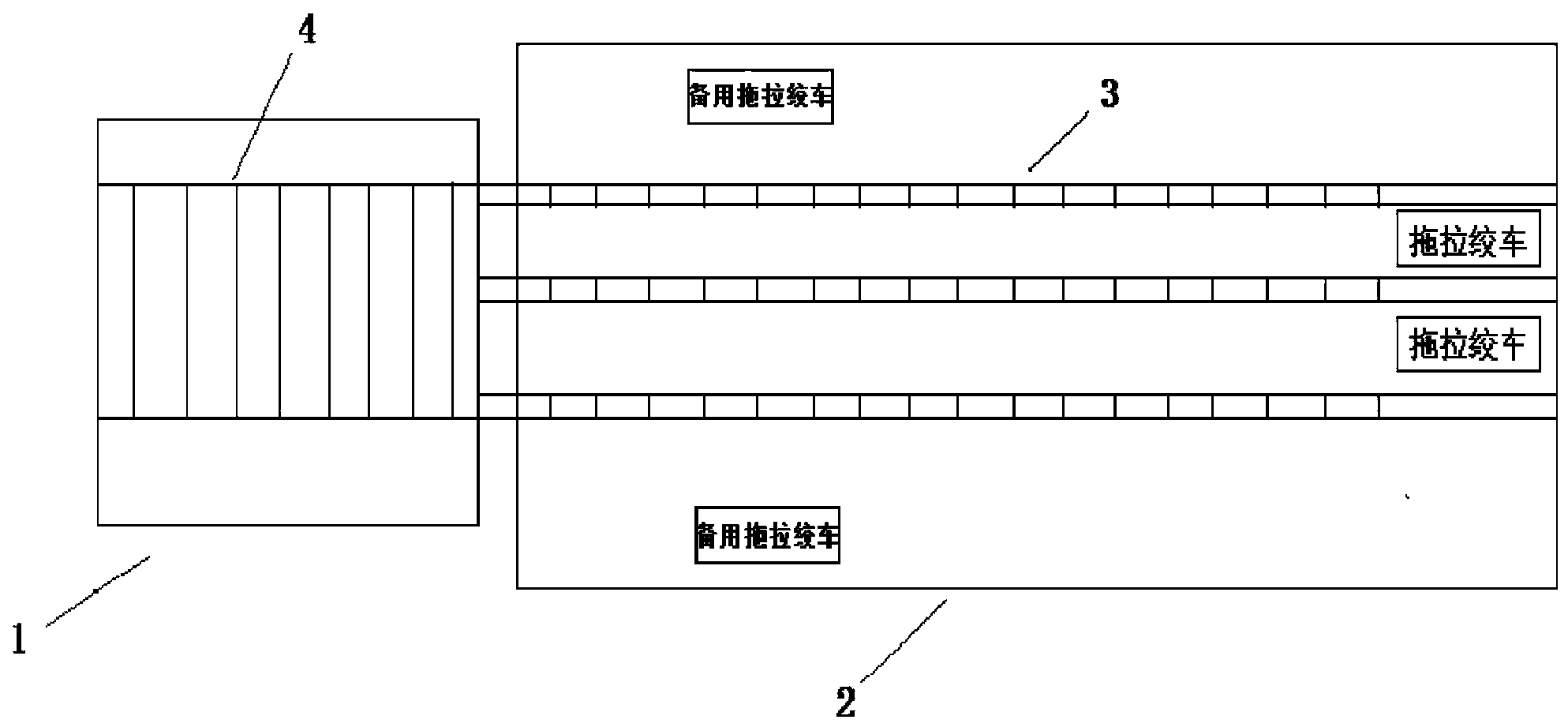

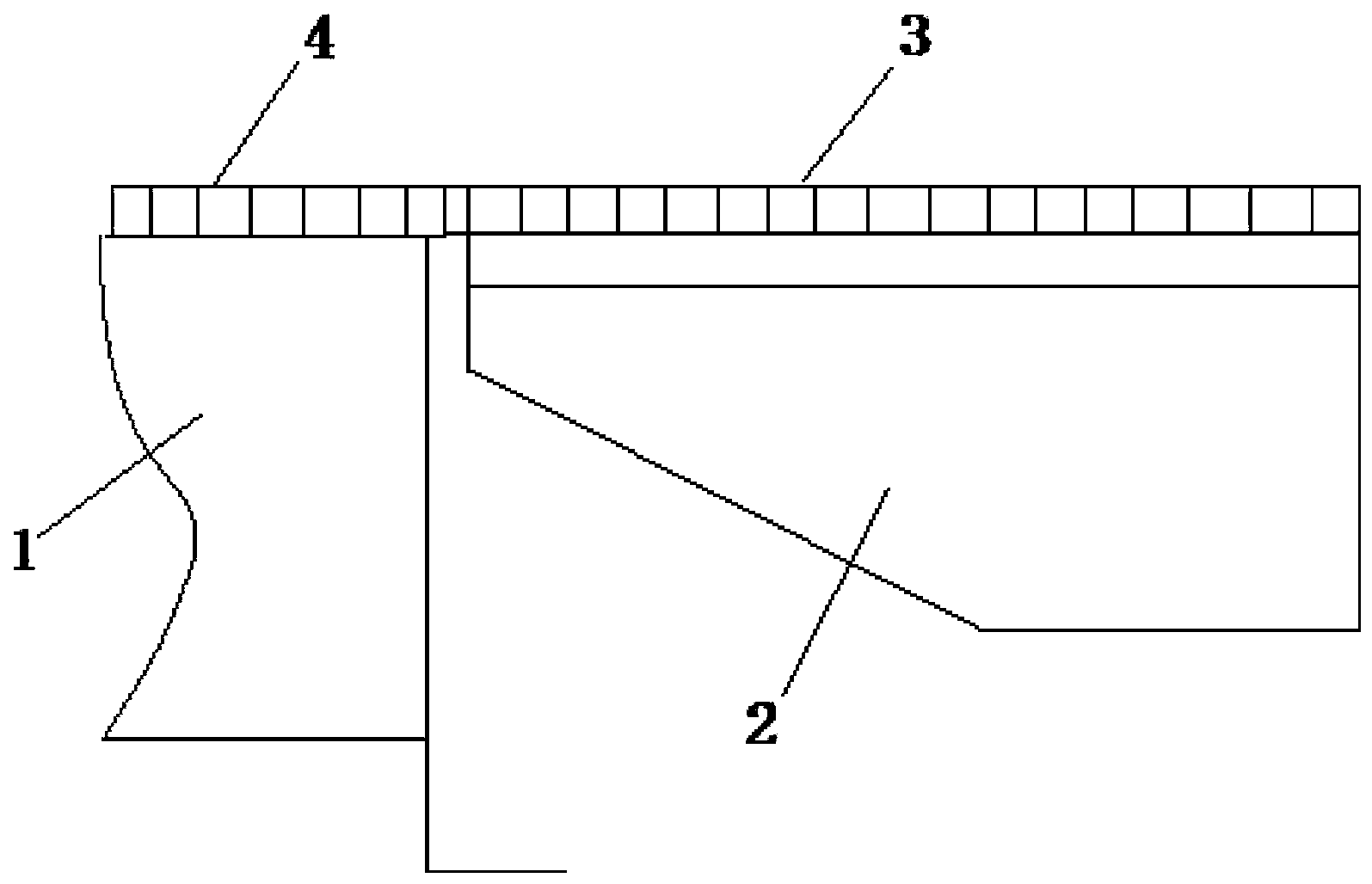

[0024] Such as figure 1 and figure 2 As shown, the present invention provides a system for loading and launching large-scale marine engineering products. The system includes a semi-submersible barge 2 and a towing system. The semi-submersible barge 2 performs loading and launching operations for large-scale offshore products under construction, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com