High solid constituent epoxy coating composition

A technology for separating epoxy and composition, applied in the field of high-solid epoxy coating composition, can solve the problems of poor flexibility and brittleness of coating film, no chemical bonding, cracking of coating film, etc., to meet environmental protection requirements, excellent anti-corrosion Effects of sex and chemical resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

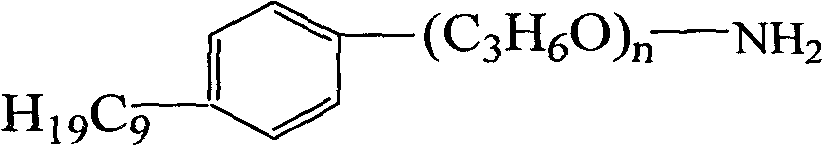

Method used

Image

Examples

Embodiment 1

[0018] Embodiment 1 prepares high solid content epoxy coating composition

[0019] (1) Preparation of component A

[0020] ① Formula

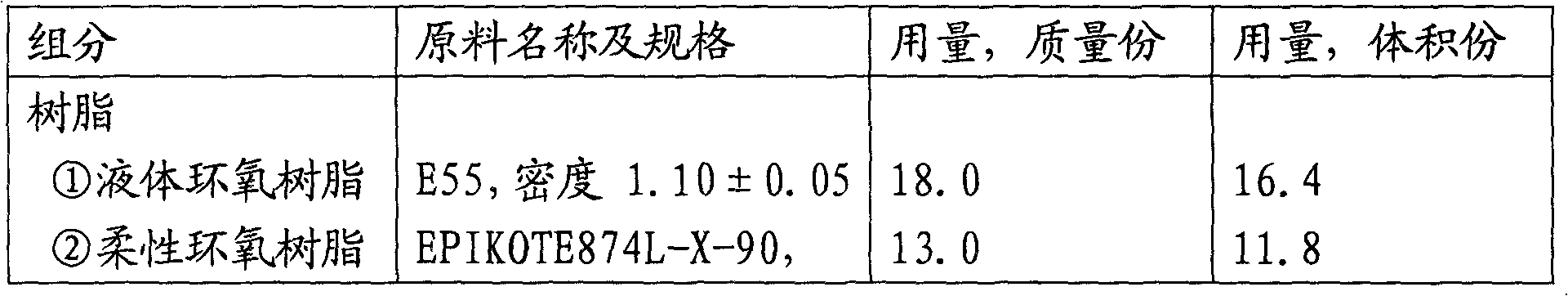

[0021] In every 100 parts by mass of component A, there are 31 parts of resin (wherein flexible epoxy resin accounts for 42%), 57 parts of pigment and filler, 1 part of auxiliary agent, and 11 parts of organic solvent. See Table 1 for details.

[0022] Table 1

[0023]

[0024]

[0025] Note: EPIKOTE874L-X-90 is the product brand of Shell; BYK 104 is the product brand of BYK.

[0026] ② Preparation

[0027] Stir the resin, additives and solvent weighed according to the formula in Table 1 evenly, then add pigments and fillers, mix evenly, and disperse through a disperser to a fineness of 40 microns to obtain component A, which is stored for future use.

[0028] (2) Preparation of component B

[0029] ① Formula

[0030] For every 20 parts by mass of component B, there are 6 parts of polyamide, 3 parts of cashew oil modified amine, 4 p...

Embodiment 2

[0040] Embodiment 2 prepares high solid content epoxy coating composition

[0041] (1) Preparation of component A

[0042] ① Formula

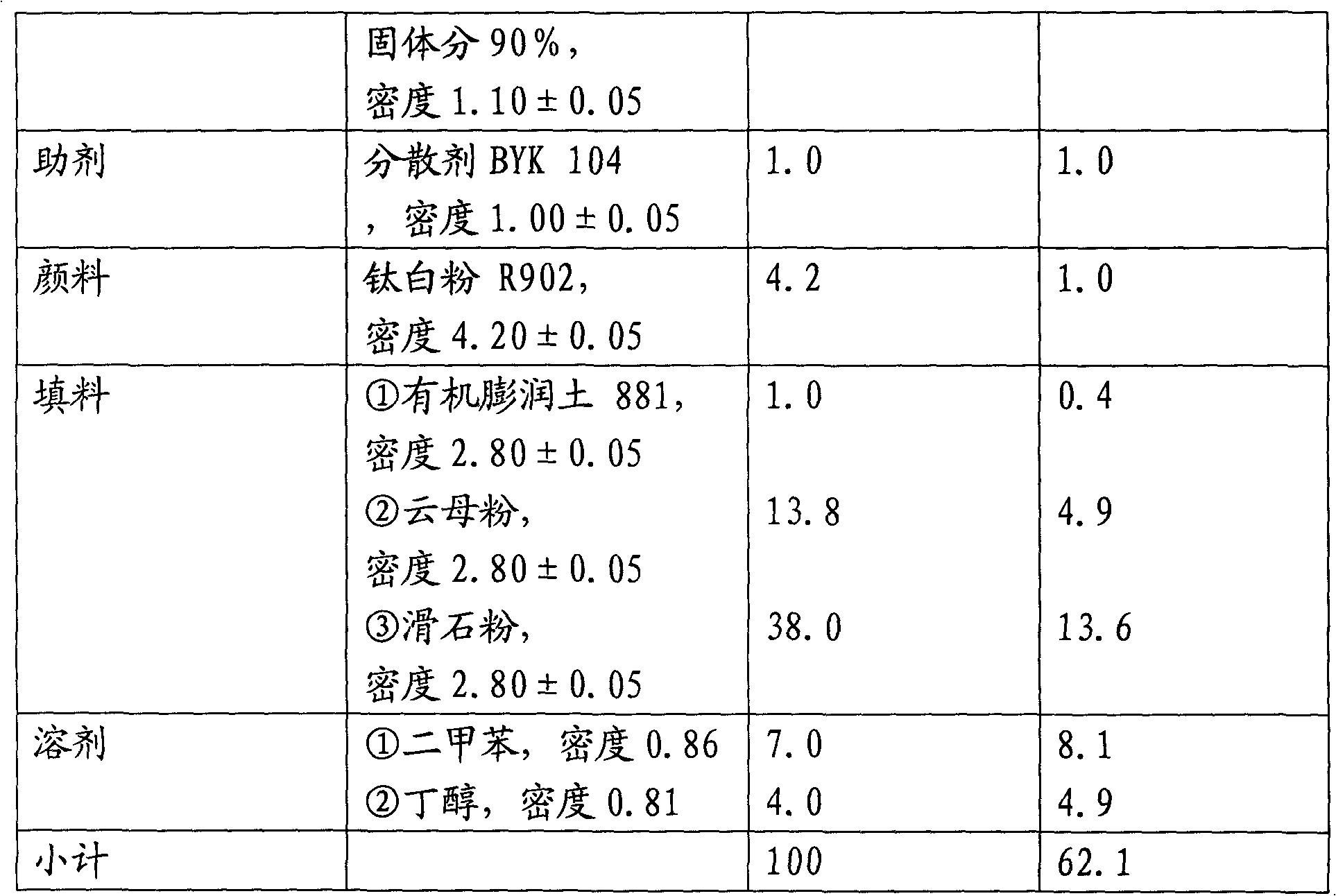

[0043] In every 100 parts by mass of component A, there are 31 parts of resin (wherein flexible epoxy resin accounts for 61%), 57 parts of pigment and filler, 1 part of auxiliary agent, and 11 parts of organic solvent. See Table 3 for details.

[0044] table 3

[0045]

[0046]

[0047] Note: BYK A.T.U is the product brand of BYK company;

[0048] ② Preparation

[0049] Stir the resin, additives and solvents weighed according to the formula in Table 3 evenly, then add pigments and fillers, mix evenly, and disperse through a disperser to a fineness of 40 microns to obtain component A, which is stored for future use.

[0050] (2) Preparation of component B

[0051] ① Formula

[0052] For every 20 parts by mass of component B, there are 7.0 parts of polyamide, 3 parts of cashew oil modified amine, 5 parts of chain extender, and the bal...

Embodiment 3

[0062] Embodiment 3 prepares high solid content epoxy coating composition

[0063] (1) Preparation of component A

[0064] ① Formula

[0065] In every 100 parts by mass of component A, there are 31 parts of resin (wherein flexible epoxy resin accounts for 61%), 57 parts of pigment and filler, 1 part of auxiliary agent, and 11 parts of organic solvent. See Table 5 for details.

[0066] table 5

[0067]

[0068] Note: EPOKUKDO KD-175X90 is the product brand of Guodu Company;

[0069] ② Preparation

[0070] Stir the resin, additives and solvent weighed according to the formula in Table 5 evenly, then add pigments and fillers, mix evenly, and disperse through a disperser to a fineness of 40 microns to obtain component A, which is stored for future use.

[0071] (2) Preparation of component B

[0072] ① Formula

[0073] For every 20 parts by mass of component B, there are 6 parts of polyamide, 4 parts of cashew oil modified amine, 5 parts of chain extender, and the balance...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com