Rectangular steel pipe bending equipment

A rectangular steel pipe and equipment technology, applied in the field of rectangular steel pipe bending equipment, can solve problems such as the difficulty of accurately controlling the bending angle of steel pipes, and achieve the effect of automatic and efficient bending and precise control of the bending angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

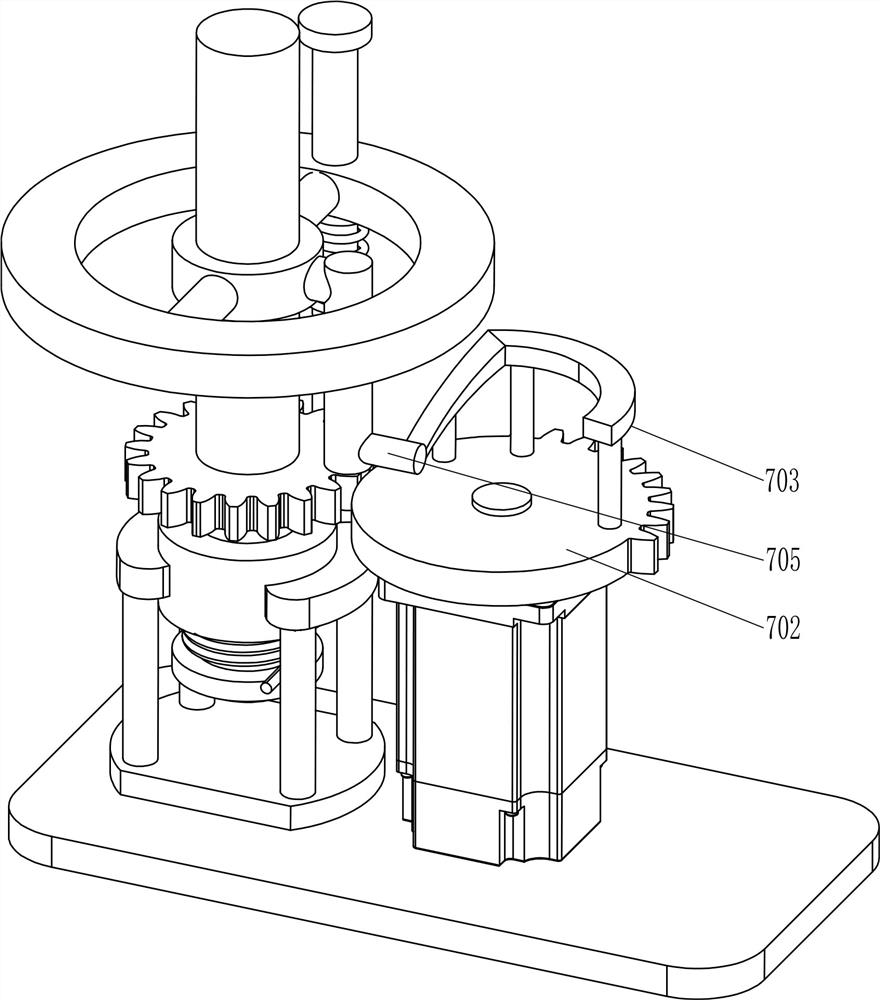

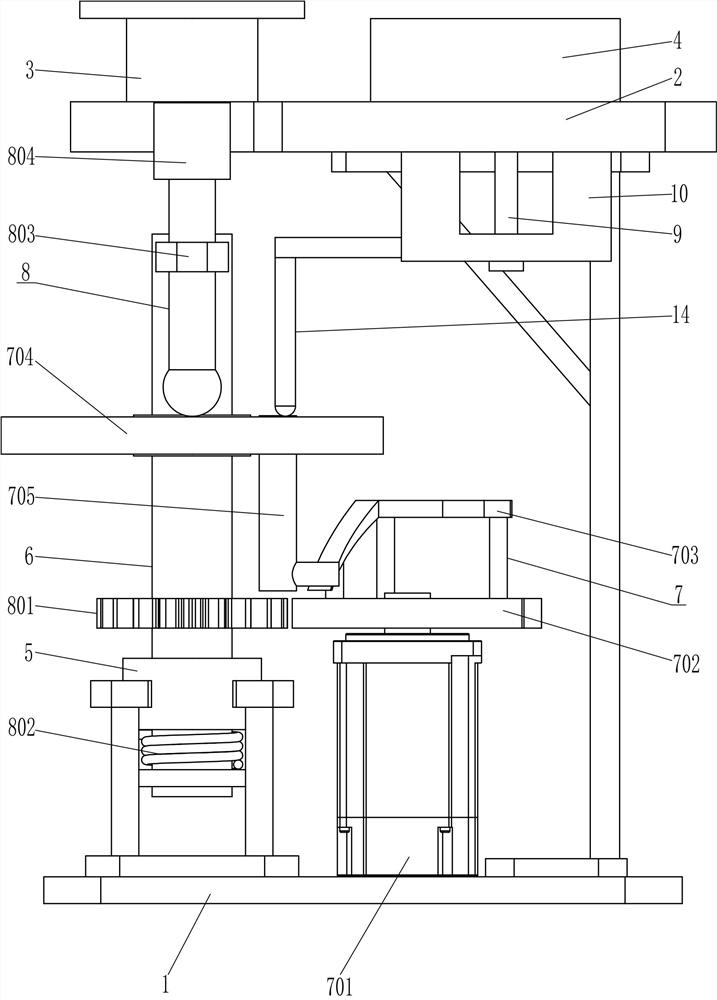

[0024] A rectangular steel pipe bending equipment, such as Figure 1-4 As shown, it includes a bottom plate 1, a workbench 2, a fixed block 3, a guide plate 4, a support sleeve 5, a rotating shaft 6, a lifting assembly 7, a rotating assembly 8, a sliding rod 9 and an N-shaped limit block 10. The top of the bottom plate 1 is provided with There is a workbench 2, a fixed block 3 is provided on the left side of the top of the workbench 2, a guide plate 4 is provided on the right side of the top of the workbench 2, a support sleeve 5 is provided on the left side of the bottom plate 1, and a rotating shaft 6 is provided in the support sleeve 5 , the rotating shaft 6 is provided with a lifting assembly 7 and a rotating assembly 8, the bottom of the right side of the workbench 2 is provided with a slide bar 9, the slide bar 9 is slidably provided with an N-shaped limit block 10, and the front side of the workbench 2 is provided with two Square groove 1001, the square groove 1001 is l...

Embodiment 2

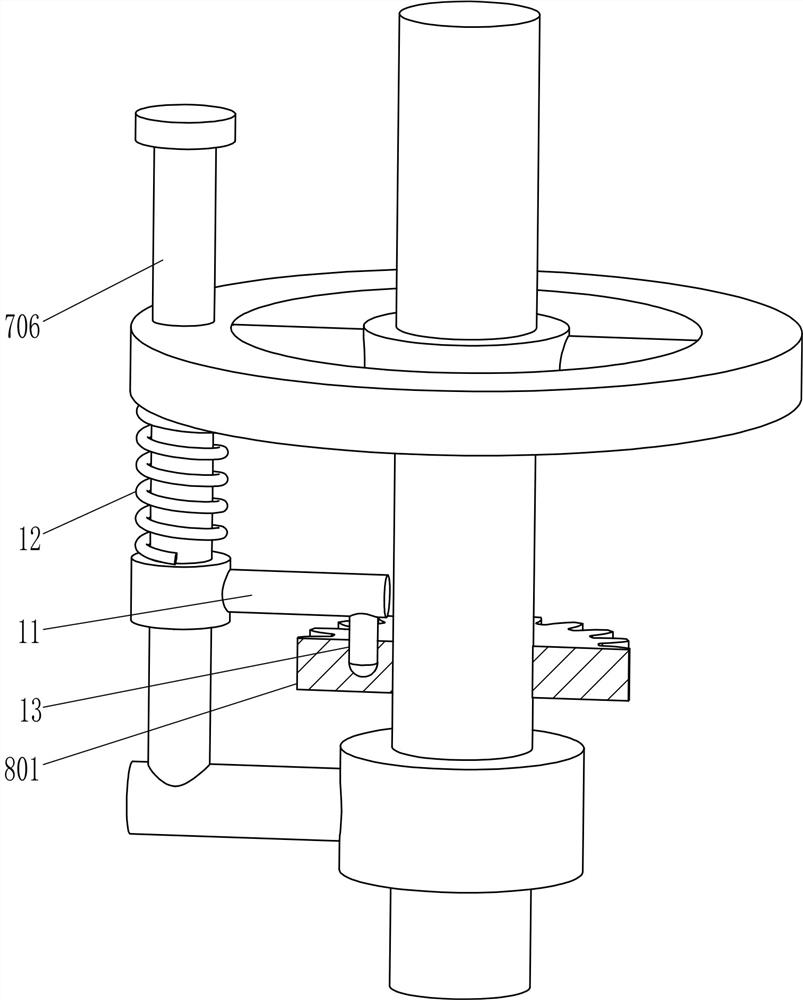

[0031] On the basis of Example 1, such as Figure 1-2 and Figure 4 As shown, it also includes a clamping rod 11 and a first spring 12. The guide rod 706 is provided with a clamping rod 11. The guide rod 706 is covered with a first spring 12. The upper end of the first spring 12 is connected to the bottom of the contact ring 704. The first The lower end of the spring 12 is connected to the top of the clamping rod 11 , the first gear 801 is provided with a clamping slot 13 , and the clamping rod 11 is matched with the clamping slot 13 .

[0032] It also includes a contact frame 14 , the left part of the N-type limiting block 10 is fixedly connected with the contact frame 14 , and the bottom of the contact frame 14 is in contact with the top of the contact ring 704 .

[0033]In the initial state, the clamping rod 11 cooperates with the clamping groove 13 so that the first gear 801 does not rotate, and when the contact ring 704 moves upwards, the clamping rod 11 is pulled upward...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com