Efficient steel pipe bending equipment

A steel pipe, high-efficiency technology, applied in the field of high-efficiency steel pipe bending equipment, can solve the problems of difficult to ensure the bending radius of the steel pipe, difficult to accurately control the bending angle of the steel pipe, etc., to achieve the effects of saving production time, ensuring smoothness, and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

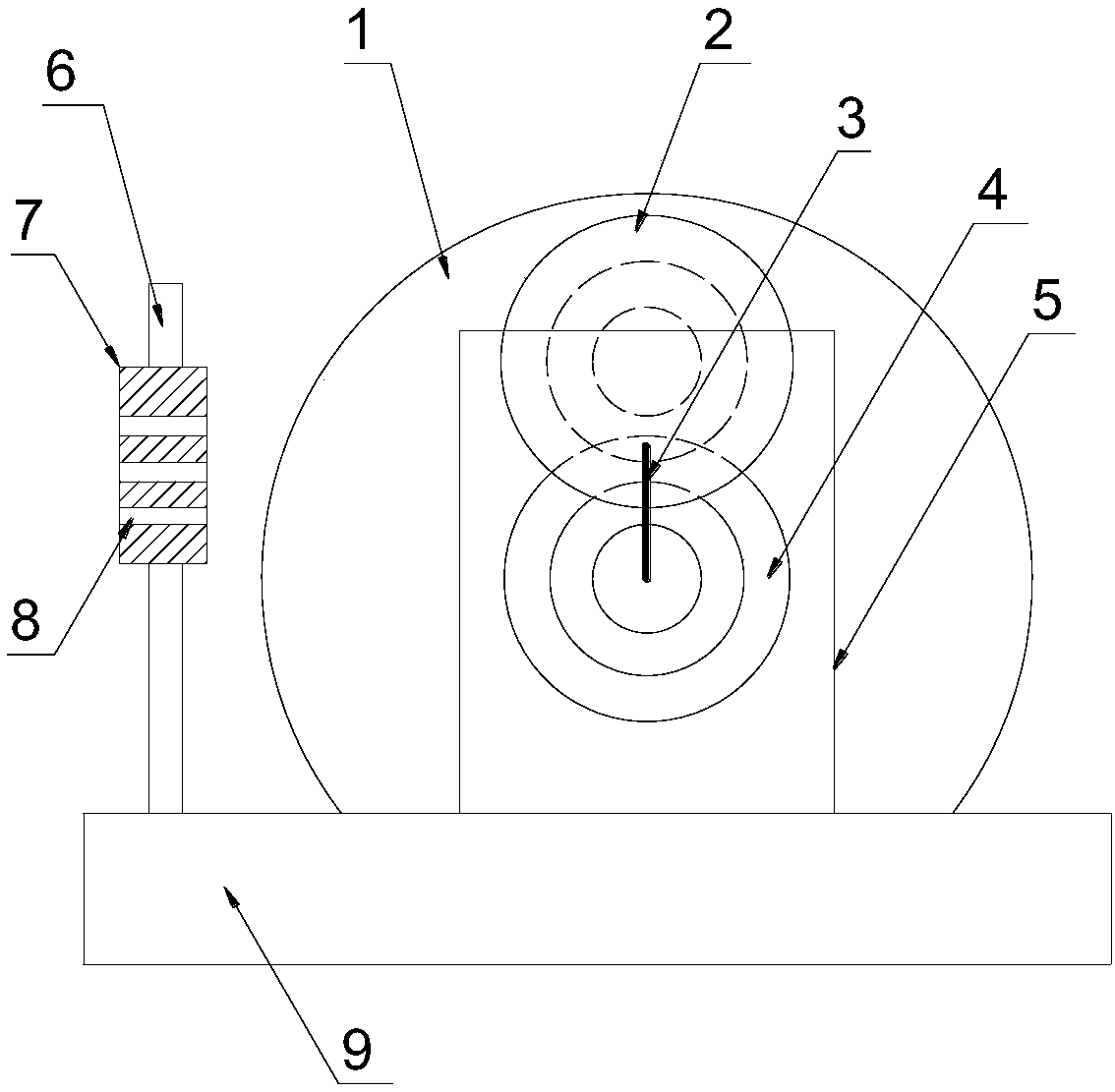

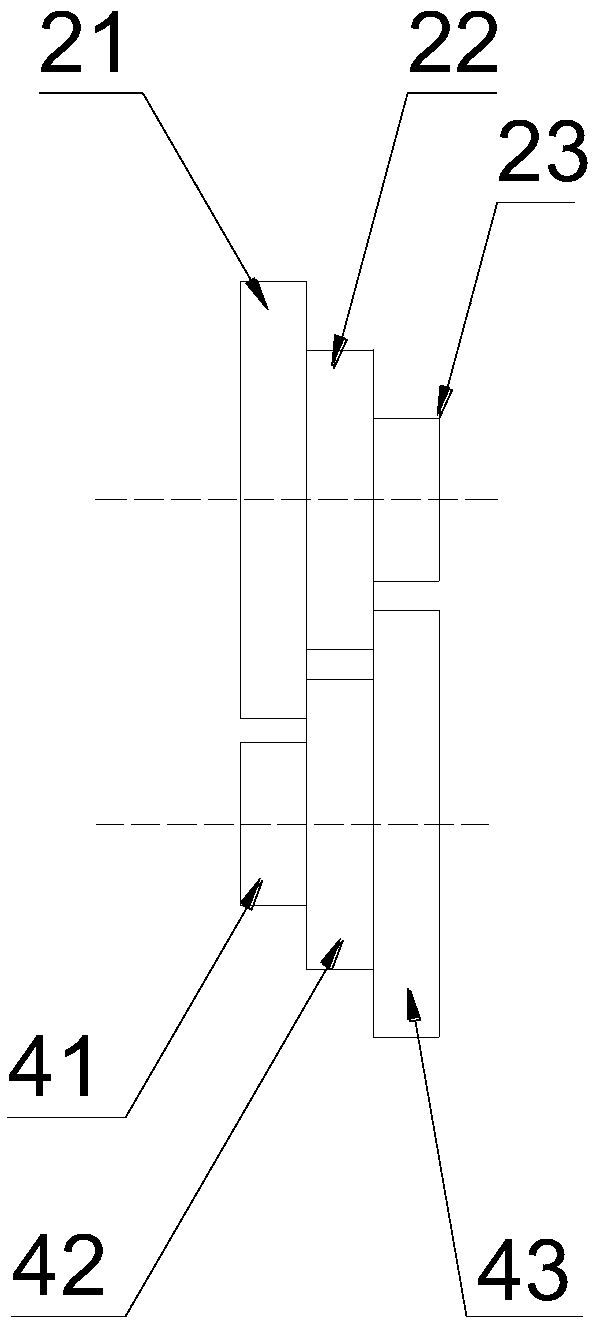

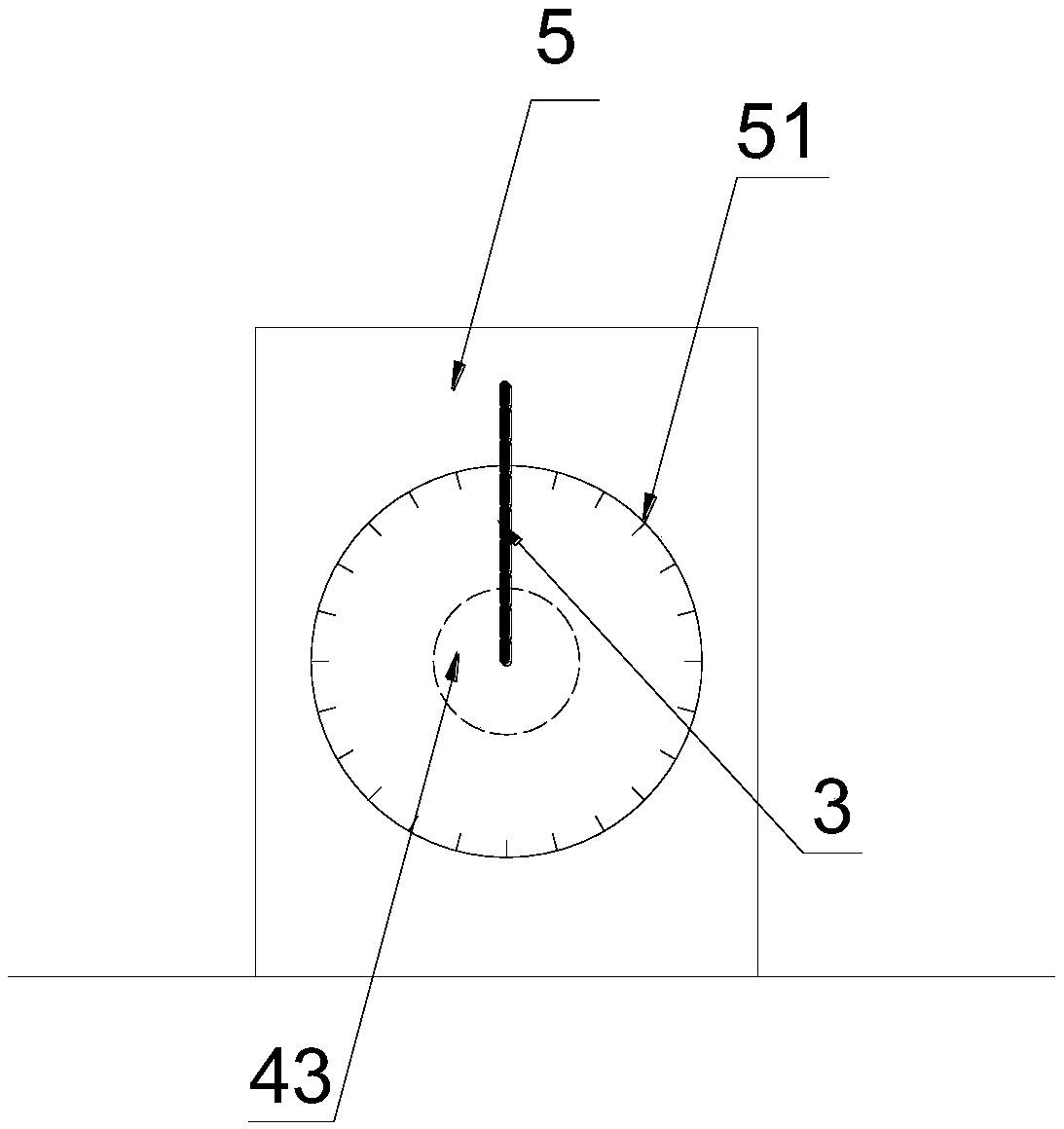

[0028] like Figure 1-3 as shown, figure 1 It is a structural schematic diagram of the high-efficiency steel pipe bending equipment proposed by the present invention; figure 2 It is a schematic diagram of part of the structure of the high-efficiency steel pipe bending equipment proposed by the present invention; image 3 It is a structural schematic diagram of the scale plate in the high-efficiency steel pipe bending equipment proposed by the present invention.

[0029] refer to Figure 1-3 , a high-efficiency steel pipe bending equipment proposed by the present invention includes a base 9, a turntable 1, a fixed wheel set 4, a pressing wheel set 2, a pointer 3, a scale plate 5, a support rod 6 and a fixing piece 7;

[0030] The turntable 1 is arranged on the frame, and the frame is arranged on the base 9; the frame is provided with a motor that drives the turntable 1 to rotate; the fixed wheel group 4 and the pressing wheel group 2 are all arranged on the turntable 1;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com