Color-temperature-variable flexible lamp strip with inverted LED chips

A technology of LED chips and flexible light strips, which is applied to optical elements, lighting devices, and components of lighting devices used to change the spectral characteristics of emitted light, and can solve complex production processes, high costs, and stress points of lamp beads major issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In this embodiment, a flexible light strip with flip-chip LED chips with variable color temperature is taken as an example, and the present invention will be described in detail below in conjunction with specific embodiments and accompanying drawings.

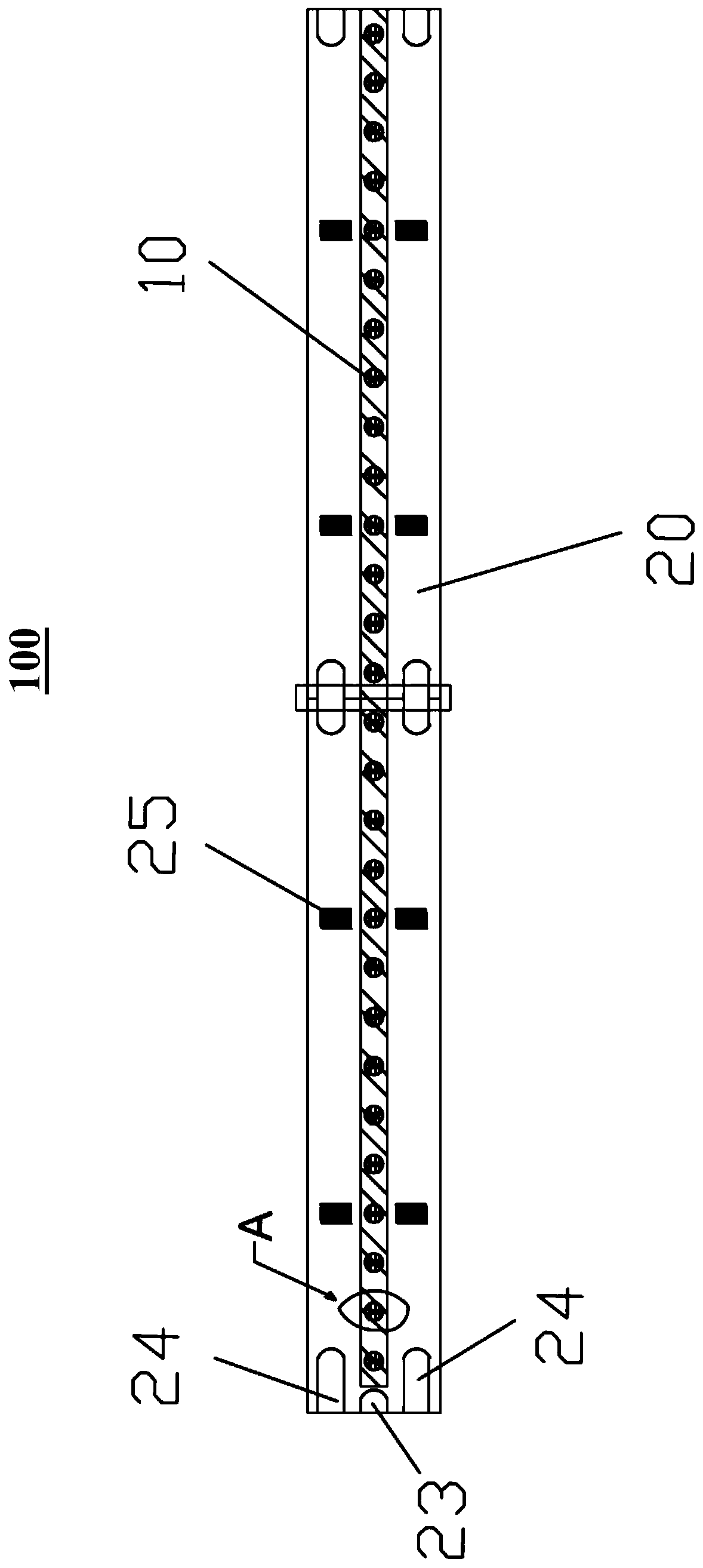

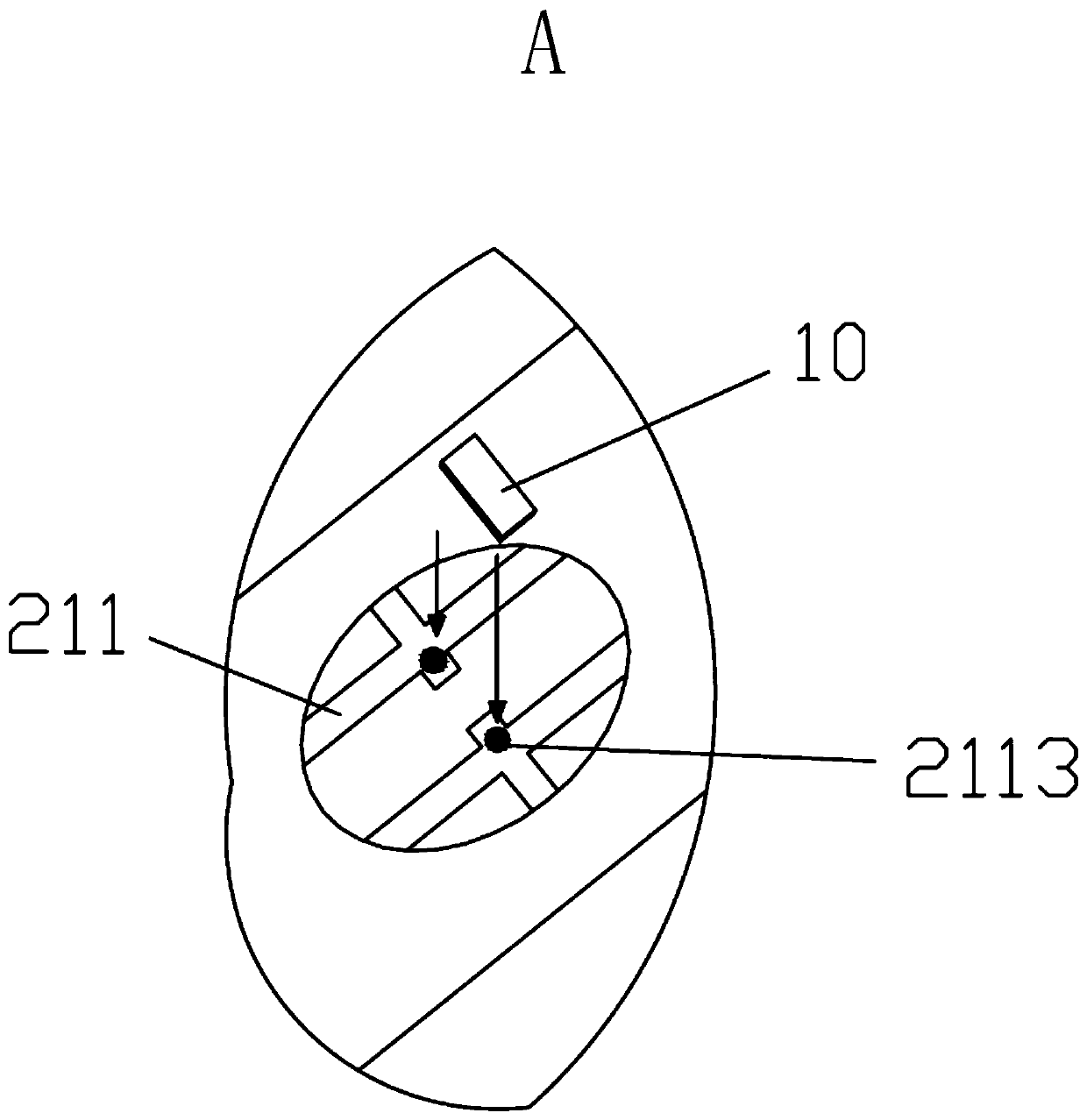

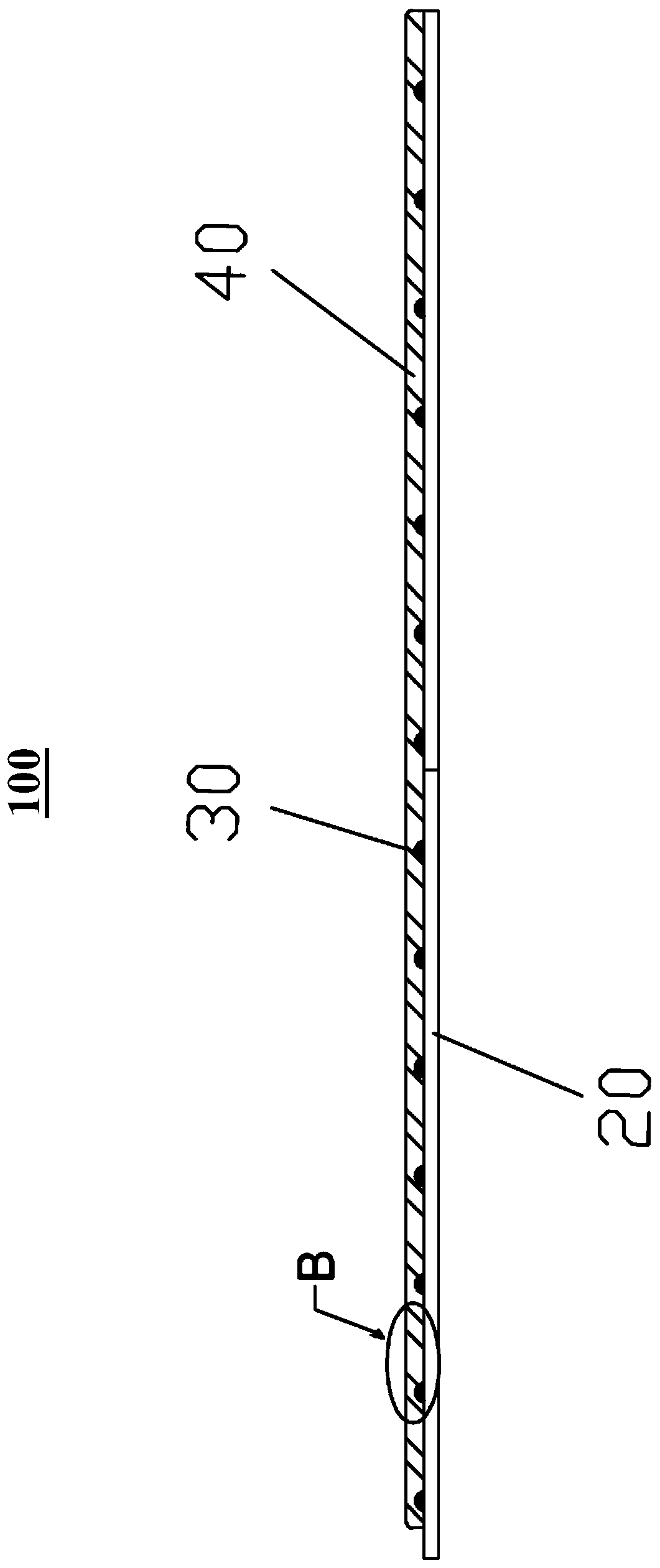

[0022] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 , shows a variable color temperature flexible light strip 100 with flip-chip LED chips provided by an embodiment of the present invention, including several flexible circuit board units 20 and several LED light-emitting chips 10 extending along the length direction of the light strip. The LED light-emitting chip 10 is fixed on the flexible circuit board unit 20 in the form of a flip-chip structure, and is covered with fluorescent glue of different color temperatures; the flexible circuit board unit 20 includes a circuit layer 21 and a supporting layer 22, and the circuit layer 21 has a plurality of wire structures 211, and the LED light...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com