Steel element bending device

A bending device and bending technology, applied in the field of tools, can solve the problems of heavy labor intensity of workers, unsatisfactory bending effect, and difficult bending work, etc., and achieve the effect of good bending effect, simple structure, and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific implementation methods.

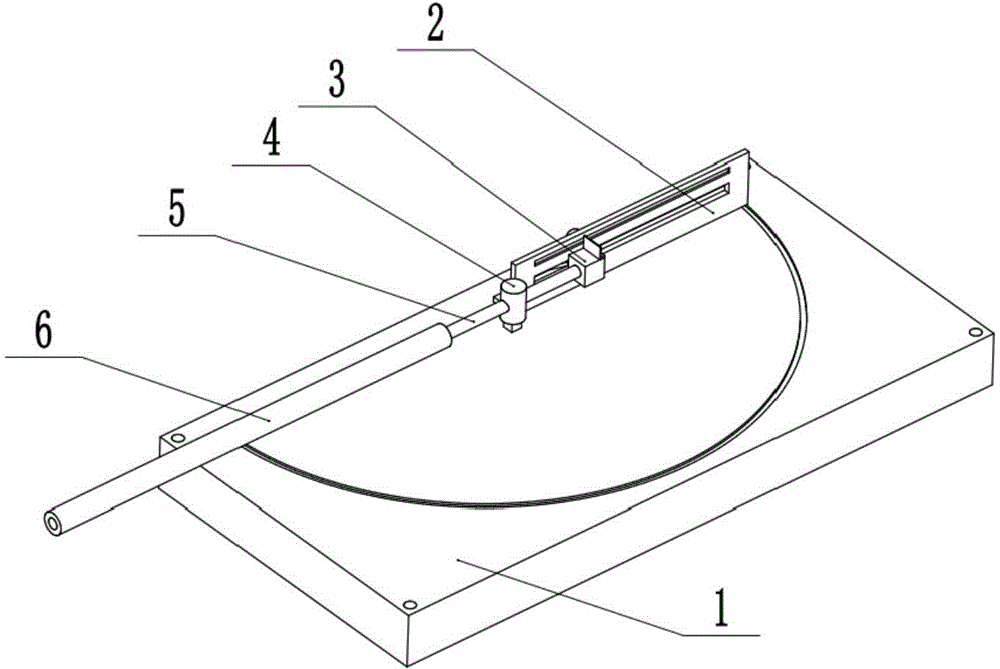

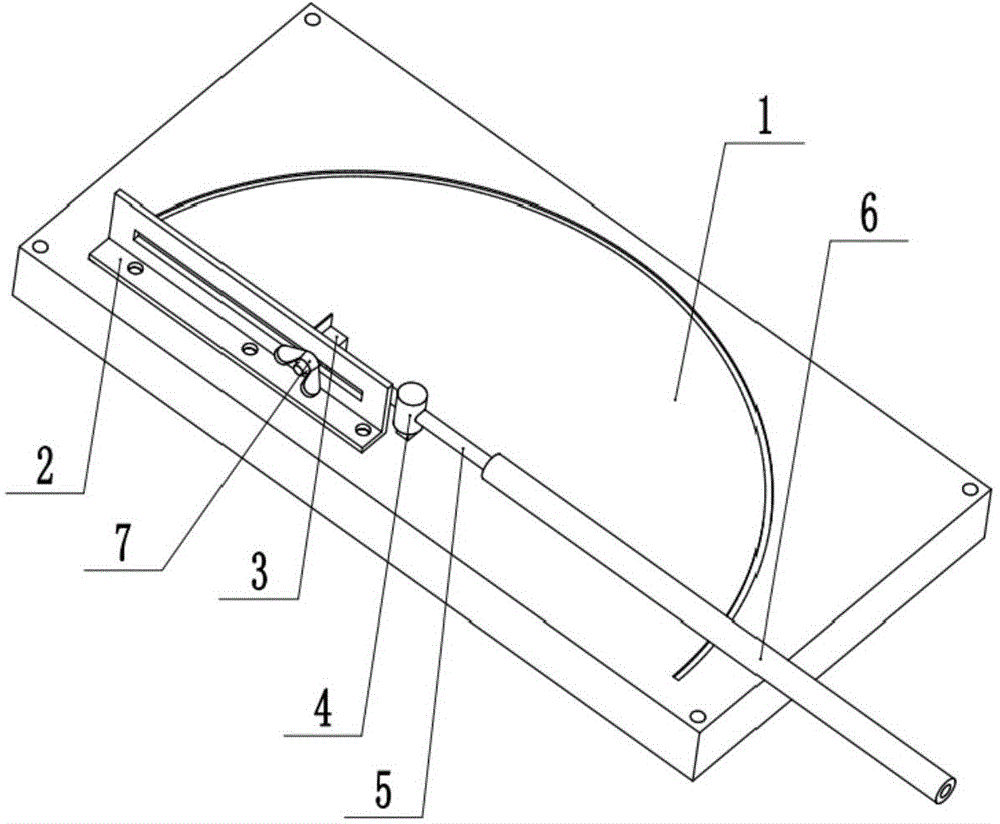

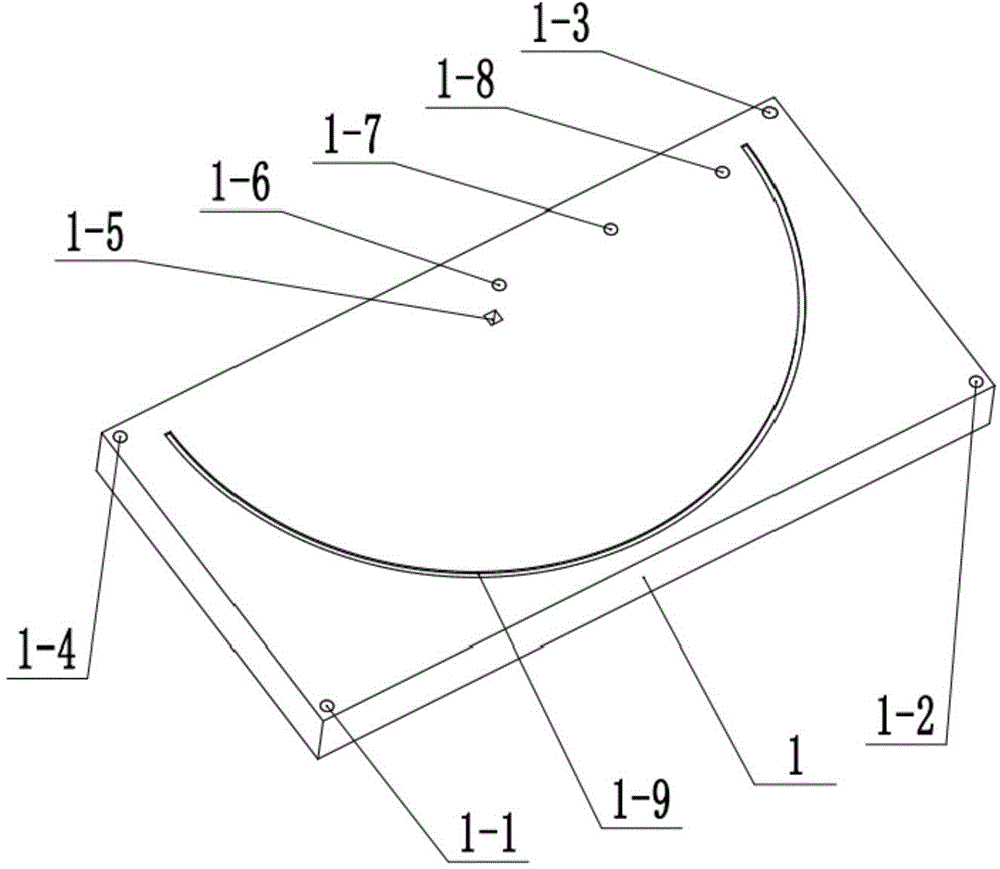

[0018] Such as Figure 1 to Figure 7 As shown, a steel element bending device according to the present invention includes a base 1 , a length scale 2 , a sliding block 3 , a bending column 4 , a push rod 6 and a wing nut 7 . Among them, the length scale 2 is fixedly connected to the base 1 through bolts; the bending column 4 is fixedly connected to the base 1 through interference fit with the first blind hole 1-5 on the base 1; the sliding block 3 is fixedly connected to the base 1 through a wing nut 7 is movably connected on the length scale 2, and can move horizontally in the chute 2-5 on the length scale 2, and is used for adjusting the length of the bending part of the steel element 5. When bending is required, first pass one end of the steel element 5 through the eighth through hole 4-2 on the bending column 4, and fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com