Copper bar processing system and processing method

A processing system and copper bar technology, applied in the direction of manufacturing tools, other manufacturing equipment/tools, etc., can solve the problems of difficult to guarantee accuracy and consistency, low efficiency, high labor costs, etc., to improve processing efficiency, improve efficiency, and automation high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

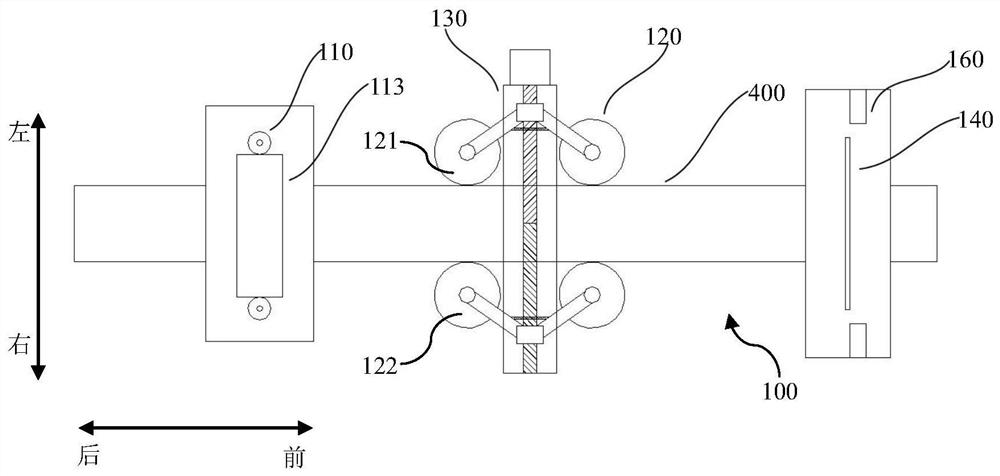

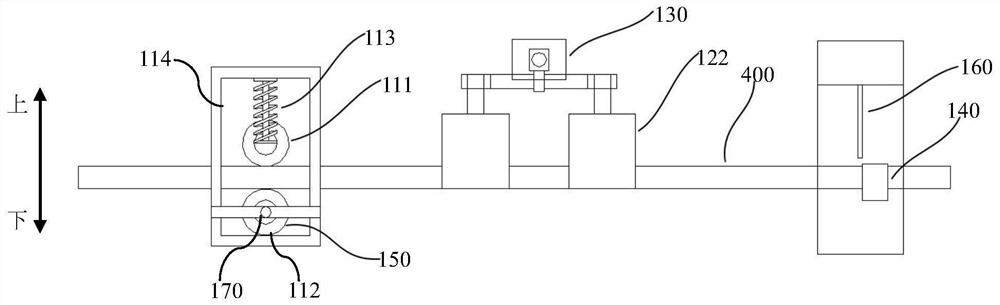

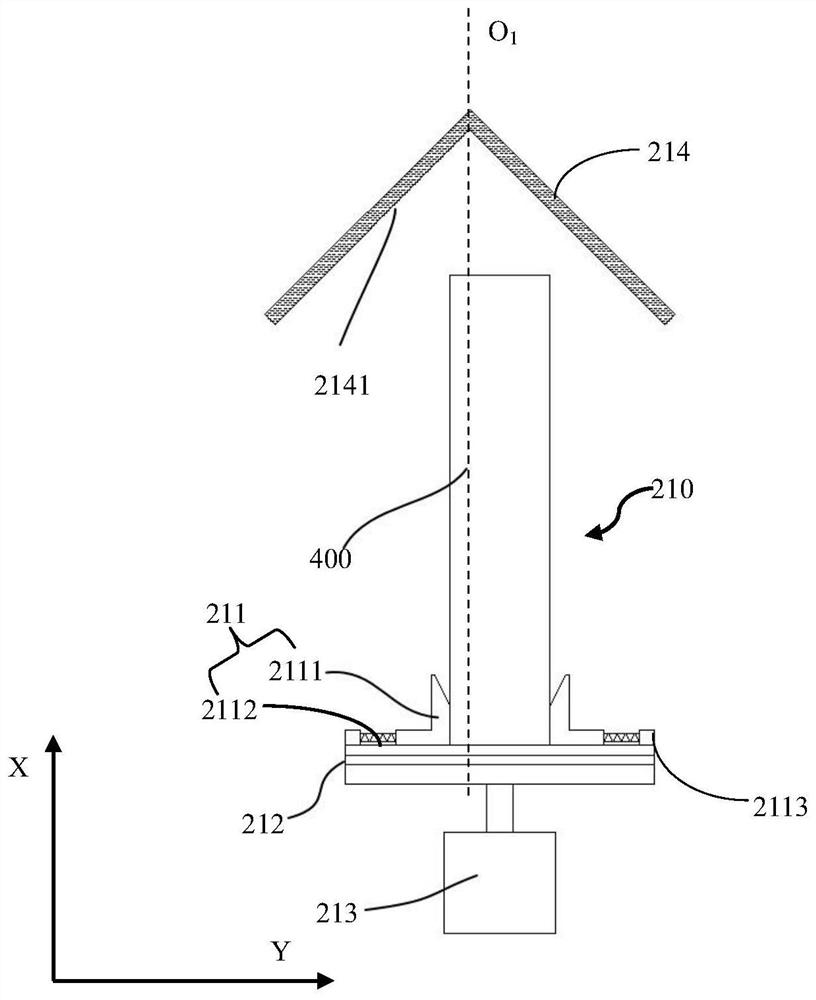

[0033] Embodiment 1: The copper bar processing system of the present invention includes a shearing system 100, a punching system 200, and a bending system 300. The shearing system 100, the punching system 200, and the bending system 300 of the present invention are all integrated with the PLC Control system communication connection. Such as figure 1 As shown, a shearing system 100 of the present invention includes a first clamping mechanism 110 for clamping copper bars up and down, a second clamping mechanism 120 for clamping copper bars left and right, and a second clamping mechanism 120 for controlling the first Two clamping mechanism 120 The first control mechanism 130 in the clamping state, the first identification mechanism 140 for identifying the origin position of the copper bar, the first driving mechanism 150 for driving the copper bar to move, and the shearing mechanism for copper bar cutting 160 and a second identification mechanism 170 for detecting the rotation a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com