A device for workpiece movement

A technology of workpiece movement and moving seat, which is applied in the field of workpiece movement devices, can solve the problems of inability to break the vacuum of the suction cup, limit the direction of ventilation, and limit the transfer range, and achieve the effects of convenient implementation, reduced energy consumption, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The features of the present invention and other relevant features are described in further detail below through the embodiments, so as to facilitate the understanding of those skilled in the art:

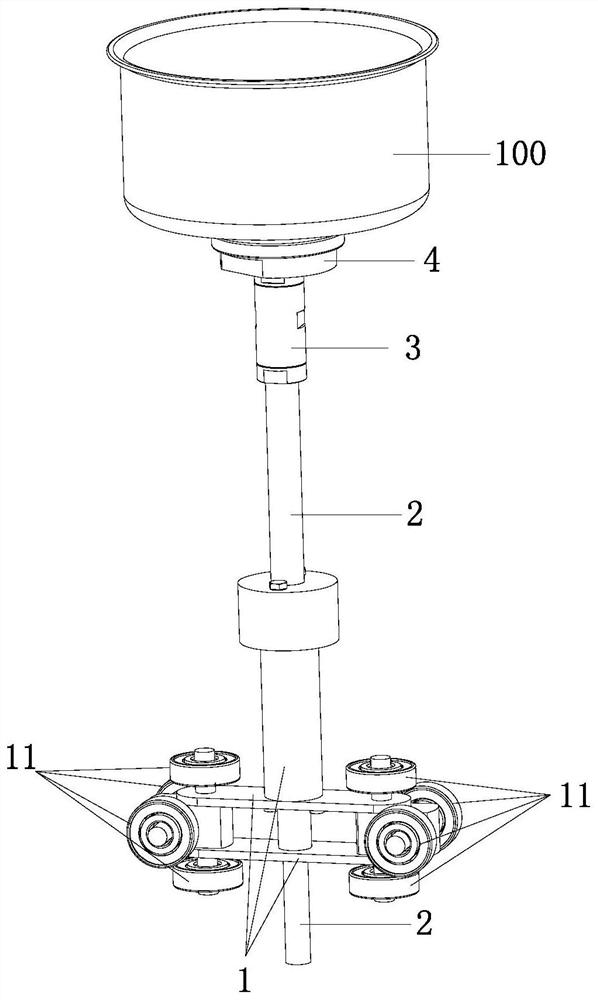

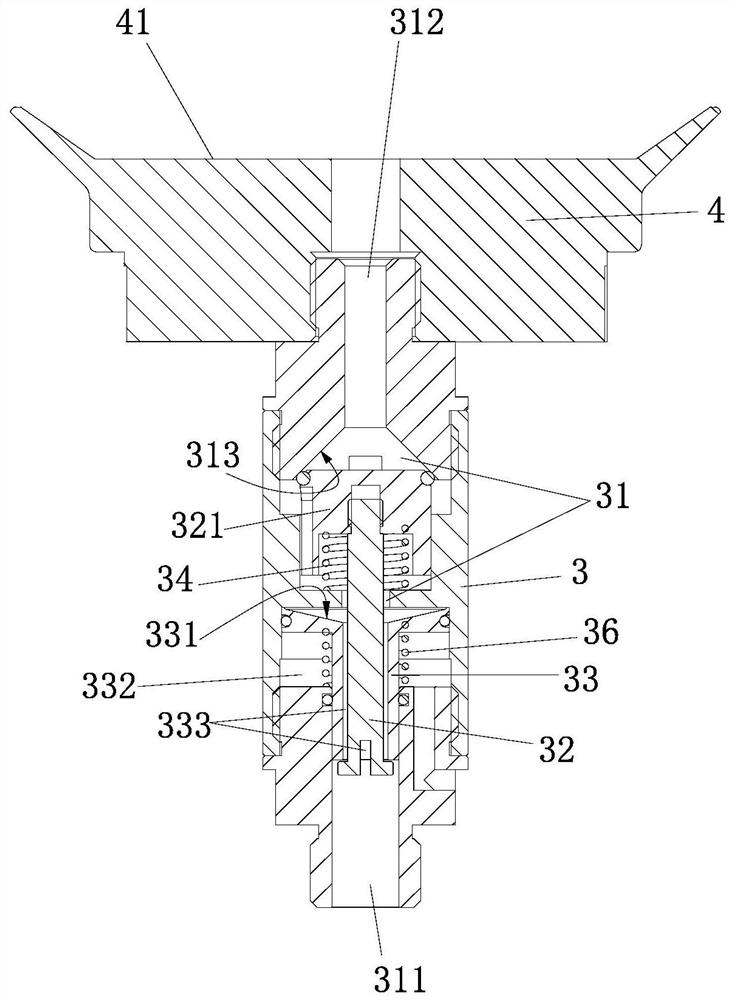

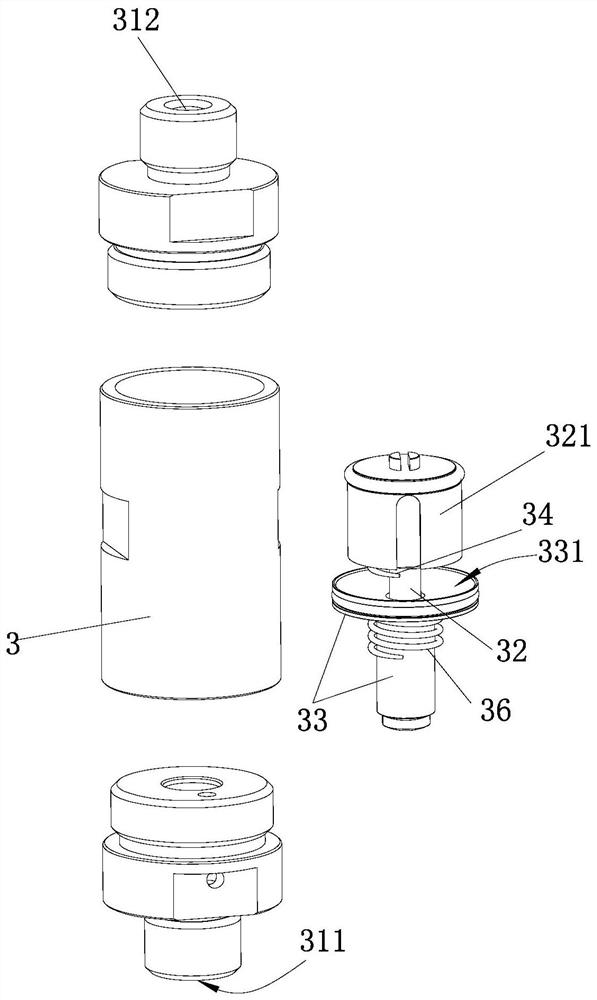

[0025] Such as Figure 1 to Figure 3 As shown, a device for moving workpieces includes a moving base 1, on which a vertical pipe 2 capable of rotating around a vertical axis is connected, and the upper end of the vertical pipe 2 is connected with a suction valve 3 through a connecting valve 3. The suction cup 4 that holds the workpiece 100, the upper end of the connection valve 3 communicates with the adsorption surface / adsorption chamber 41 of the suction cup 4, and the connection valve (3) is provided with an automatic sealing and suction device for automatically closing the suction cup (4) after being vacuumized. A valve assembly that opens automatically when the air supply breaks the vacuum.

[0026] As mentioned above, when specifically vacuuming, the external vacuum de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com