Hand-hydraulic pipe bender

A pipe bending machine and hydraulic technology, which is applied in the field of hydraulic equipment, can solve the problems that the bending angle cannot be accurately controlled, is not suitable for pipes, and is expensive to process, and achieves accurate angle processing, simple and convenient operation, and reasonable structural design. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

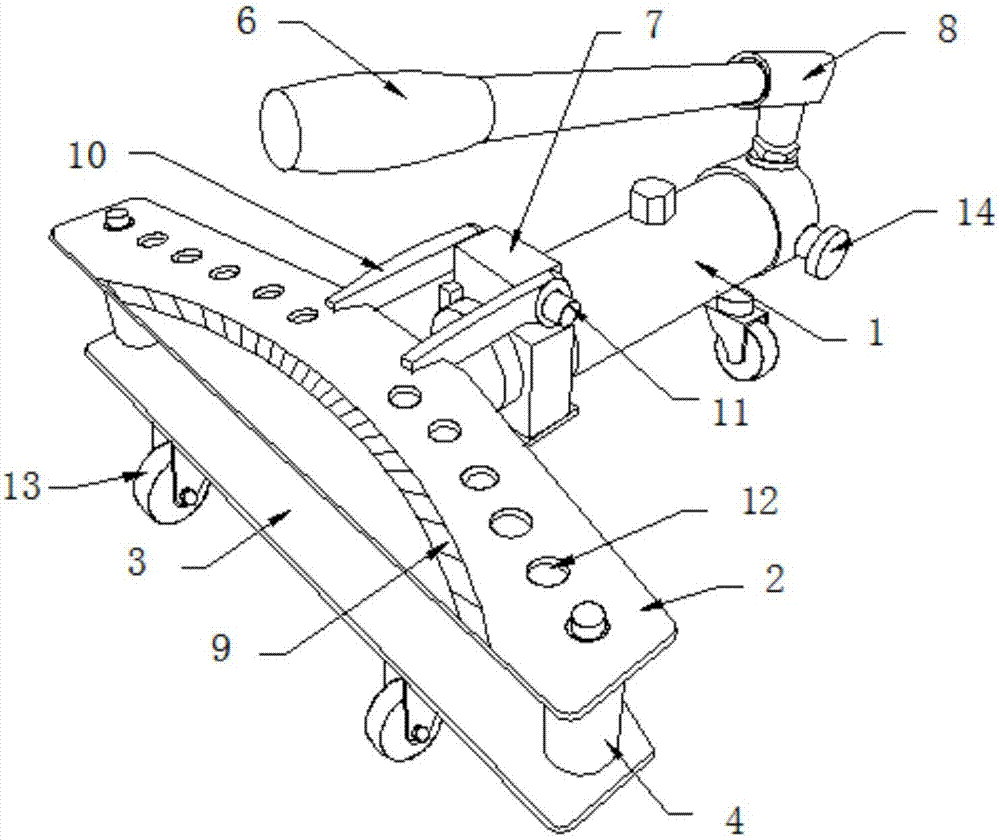

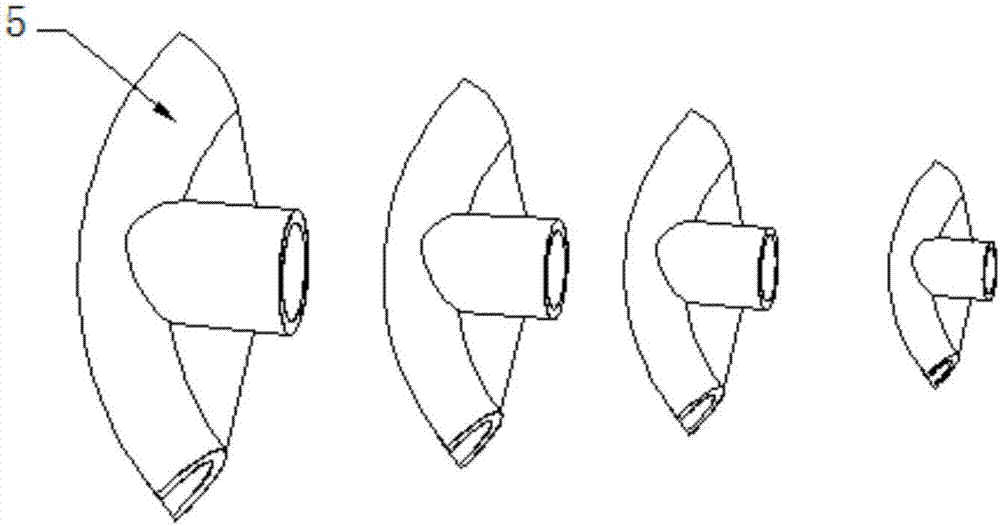

[0018] Such as Figure 1-2 As shown, a manual hydraulic pipe bending machine includes a hydraulic cylinder 1, an upper clamping plate 2, a lower clamping plate 3, a movable limiter 4, a pipe bending die 5 and a handle 6, and one end of the hydraulic cylinder 1 is provided with The upper clamping plate mounting seat 7, the other end of the hydraulic cylinder 1 is provided with a handle mounting base 8, the lower clamping plate 3 is connected with the hydraulic cylinder 1 under one end of the upper clamping plate mounting base 7 through bolts Side connection, the upper surface of the upper clamping plate 2 is provided with an angle ruler 9, and one side of the upper clamping plate 2 is provided with a pair of connecting arms 10, and the connecting arms 10 are provided with a connecting shaft 11, and the connecting arms 10 pass through The connecting shaft 11 is connected with the upper clamp mounting base 7, the movable limiter 4 is set to two, and the two ends of the two movabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com