Pliers facilitating bending of rebars

A technology for bending steel bars and pliers, which is applied in the field of pliers that are convenient for bending steel bars, can solve the problems of high bending difficulty, influence on aesthetics, different bending angles, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

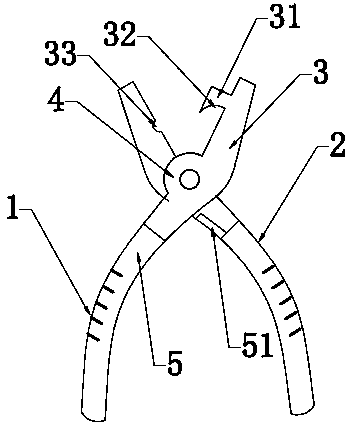

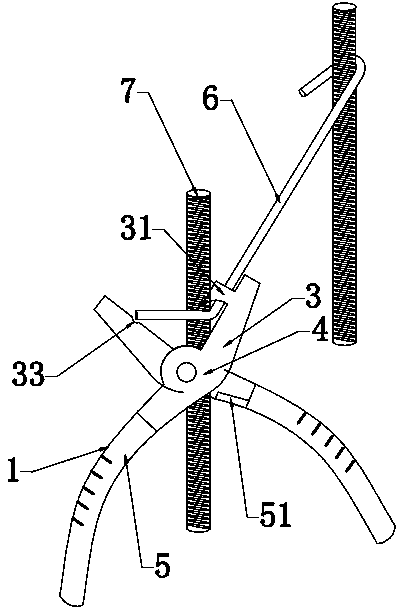

[0021] The pliers that are convenient to bend the reinforcing bar that present embodiment provides, as figure 1 , figure 2 As shown, it includes two main tongs 1 and auxiliary tongs 2 that are arranged across each other and are rotatably fixed together. The main tongs 1 and auxiliary tongs 2 are both composed of a tong head 3, a connecting part 4 and a grip handle 5 ; Inside the jaw 3 of the main tongs 1 is provided with a fastening portion 31 for holding the longitudinal rib tightly, and at the upper end of the gripping handle 5 of the auxiliary tongs 2 is provided with a gripping handle 5 upper end higher than the main tongs 1 and The limit projection 51 of the connection part 2 has a gap between the end of the limit projection 51 adjacent to the connection part 4 and the connection part when the grip handle 5 is not pulled, and the vertical distance of the gap is not Less than 2.696L (L is the distance between the main tongs 1 and the auxiliary tongs 2 adjacent to the con...

Embodiment 2

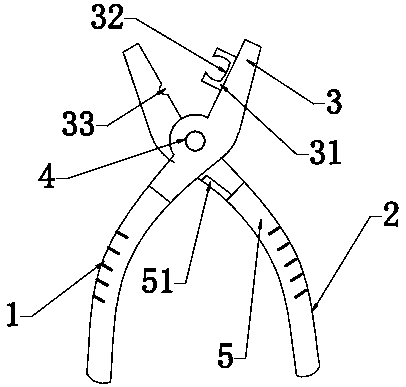

[0025] A pair of pliers for bending steel bars, such as image 3 As shown, it includes two main tongs 1 and auxiliary tongs 2 that are arranged across each other and are rotatably fixed together. The main tongs 1 and auxiliary tongs 2 are both composed of a tong head 3, a connecting part 4 and a grip handle 5 ; Inside the jaw 3 of the main tongs 1 is provided with a fastening portion 31 for holding the longitudinal rib tightly, and at the upper end of the gripping handle 5 of the auxiliary tongs 2 is provided with a gripping handle 5 upper end higher than the main tongs 1 and The limit projection 51 of the connection part 2 has a gap between the end of the limit projection 51 adjacent to the connection part 4 and the connection part when the grip handle 5 is not pulled, and the vertical distance of the gap is not Less than 2.696L (L is the distance between the main tongs 1 and the auxiliary tongs 2 adjacent to the connection part 4 when the tongs are in a closed state).

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com