Exhaust pipe machining device

A processing device and exhaust pipe technology, which is applied in the field of auto parts processing, can solve problems such as the distortion of the cross-sectional shape of the exhaust pipe, and achieve the effect of easy deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following is further described in detail through specific implementation methods:

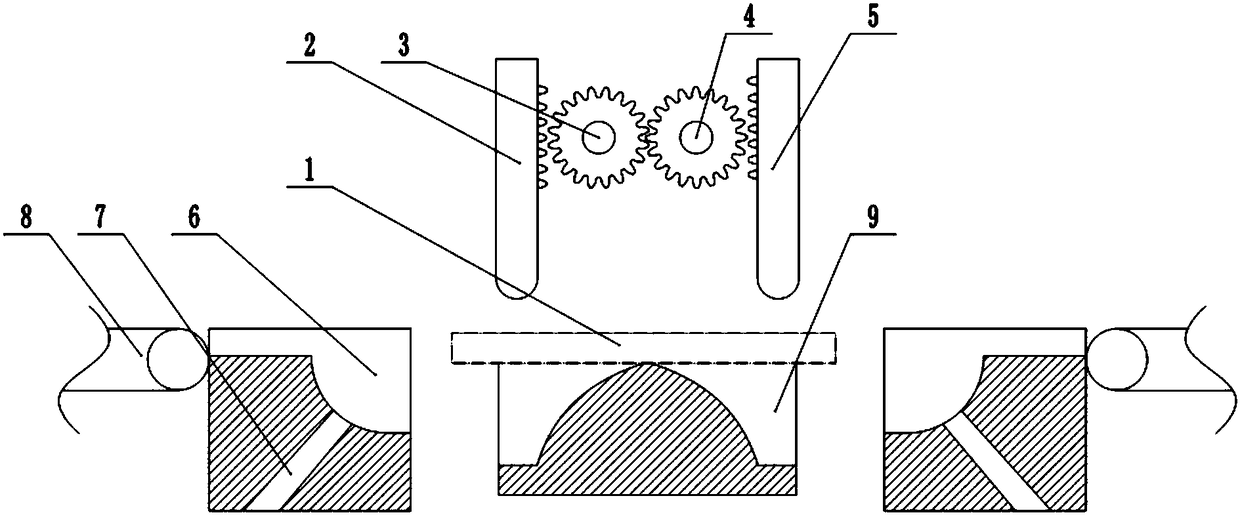

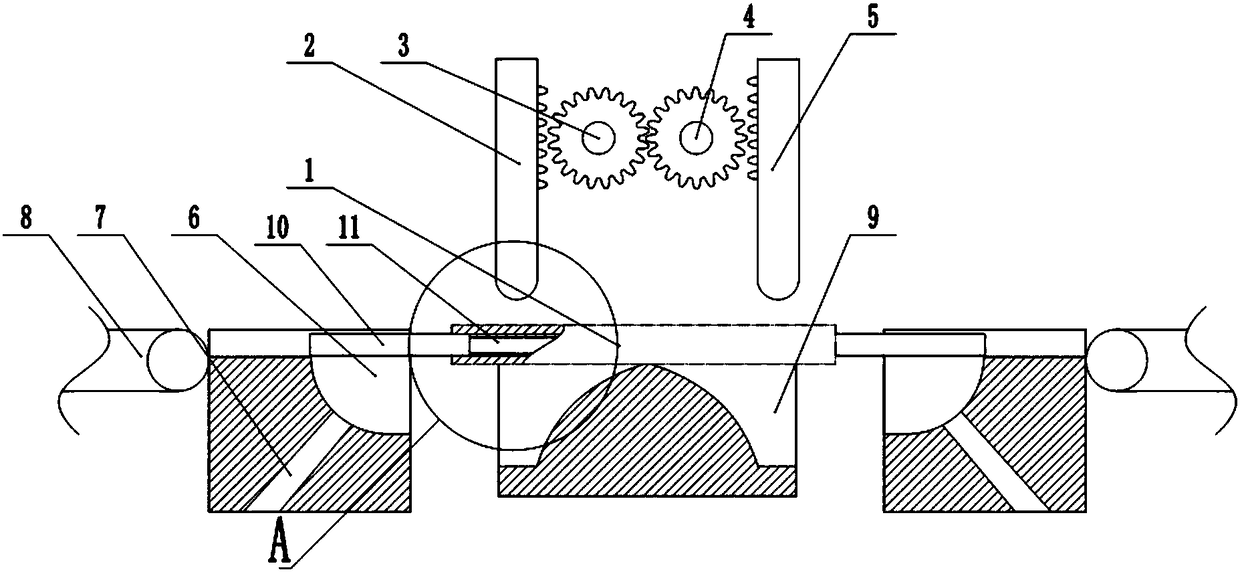

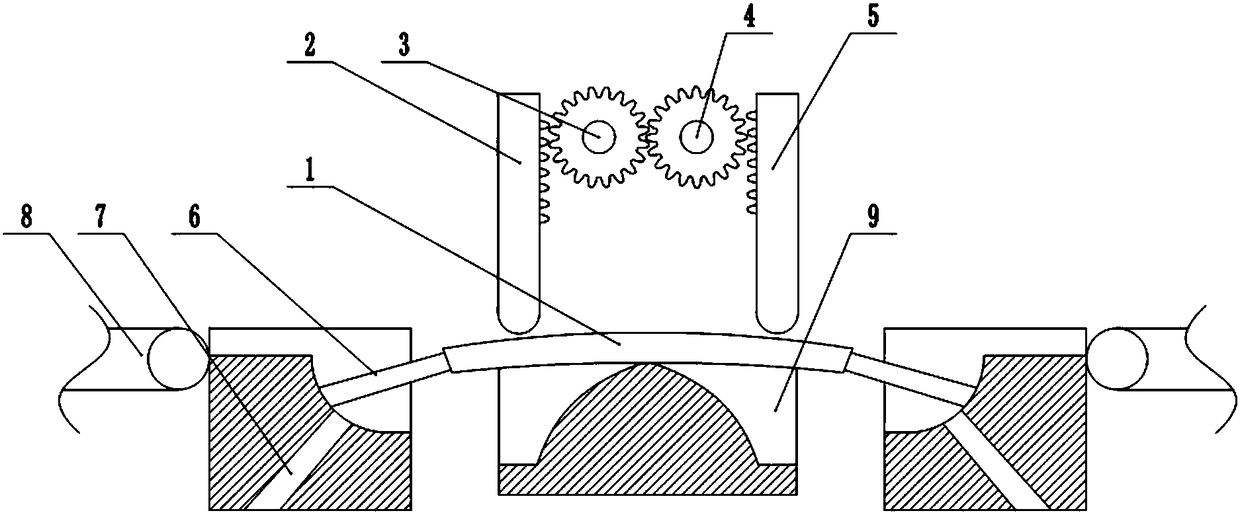

[0027] The reference signs in the accompanying drawings include: exhaust pipe 1, first rack 2, first gear 3, second gear 4, second rack 5, chute 6, through hole 7, conveyor belt 8, placement slot 9. Rigid segment 10, flexible segment 11, bump 12, reed 13.

[0028] like figure 1 As shown, the exhaust pipe 1 processing device includes a frame, and a workbench is fixed on the frame. The upper surface of the workbench is provided with a placement groove 9, and the bottom of the placement groove 9 is arc-shaped with two ends bent downward, and the exhaust pipe 1 is placed in the placement groove 9, when the exhaust pipe 1 is bent, the bottom of the placement groove 9 will not hinder the downward movement of both ends of the exhaust pipe 1. An electric heater is provided at the center of the bottom of the placement groove 9. When the exhaust pipe 1 is bent, the electric heater can be use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com