Ship exhaust gas treatment system

A waste gas treatment and ship technology, which is applied in the field of ship waste gas treatment system, can solve the problems of bag opening, rigid collision, corrosion of buildings, etc., and achieve the effect of increasing tension, facilitating deformation, and improving cushioning and shock absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

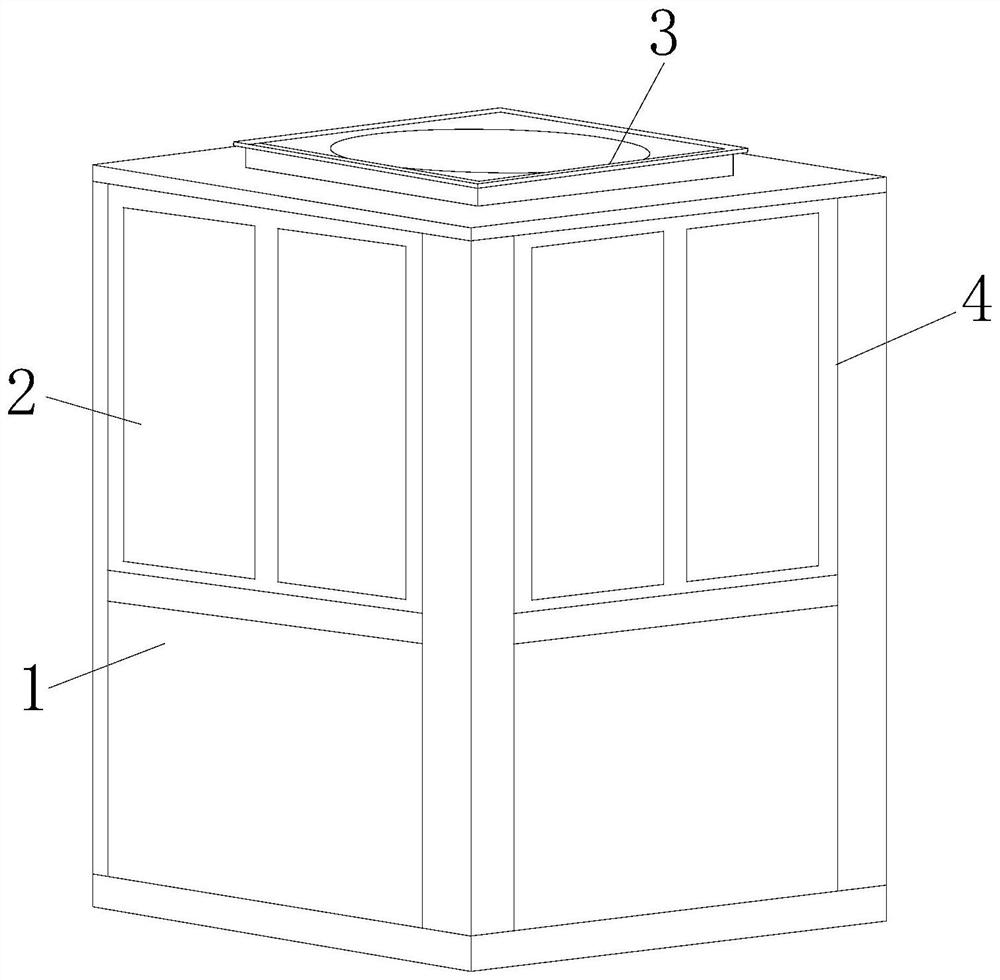

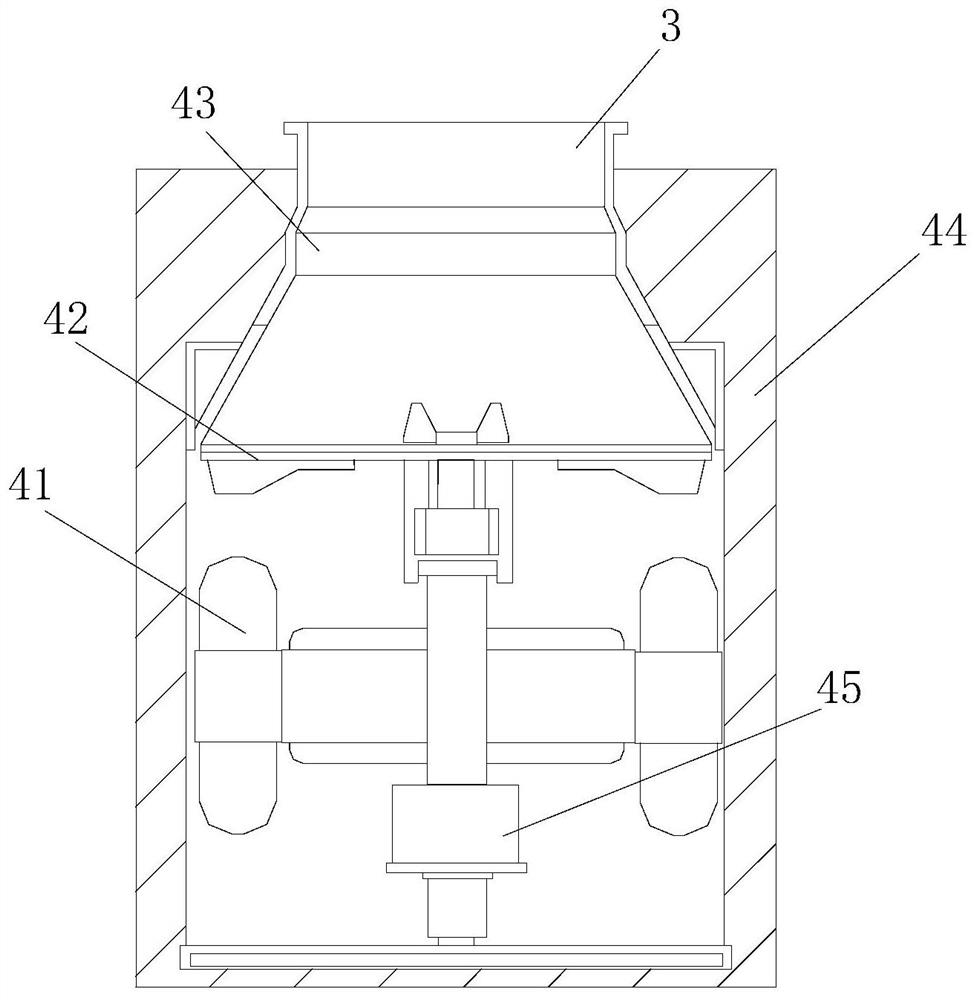

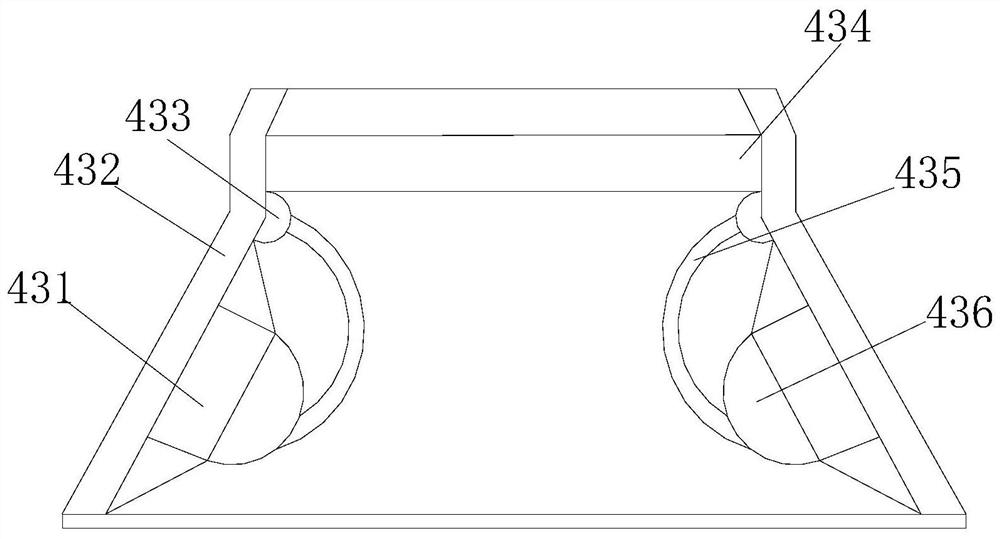

[0028] Such as Figure 1-Figure 4 As shown, the present invention provides a ship exhaust gas treatment system, the structure of which includes a base 1, an exhaust port 2, a top cover 3, and a main body 4. The base 1 and the exhaust port 2 are fixedly connected to the bottom and surroundings of the main body 4, respectively. The top of the main body 4 is welded with a top cover 3, and the main body 4 includes a processing machine 41, an equalizer 42, a feed channel 43, a housing 44, and a driving body 45. Between the processing machine 41 and the driving body 45 Cooperate in an electrically connected manner, the equalizing channel 42 is fixedly connected to the bottom of the feed channel 43, the feed channel 43 is installed inside the housing 44, and the top is welded to the bottom of the top cover 3, and the feed channel 43 is connected to the bottom of the top cover 3 by welding. The material channel 43 includes a supporting plate 431, an inner channel 432, a rotating shaft...

Embodiment 2

[0030] Such as Figure 5-Figure 8As shown, on the basis of Embodiment 1, the present invention combines the mutual cooperation of the following structural components. The buffer frame 362 includes a touch pad 621, a push plate 622, an elastic member 623, a moving rod 624, and a bucket 625. The tip of the contact pad 621 is embedded and connected inside the inner support part 361, and its arc surface is fixedly connected with a moving rod 624 and a push plate 622. There are two moving rods 624, which are respectively welded and connected to the elastic member 623. On both sides, one side of the push plate 622 is inserted and connected with a spreading bucket 625, and the elastic member 623 is in the shape of an inverted arch bridge, the middle part of which will sink and bend to indirect contact with the middle part of the inner support part 361, and the creases at both ends will Transition fit with the spreading bucket 625, so that the corrugated structure on the other side of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com