Patents

Literature

43results about How to "Avoid launching" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

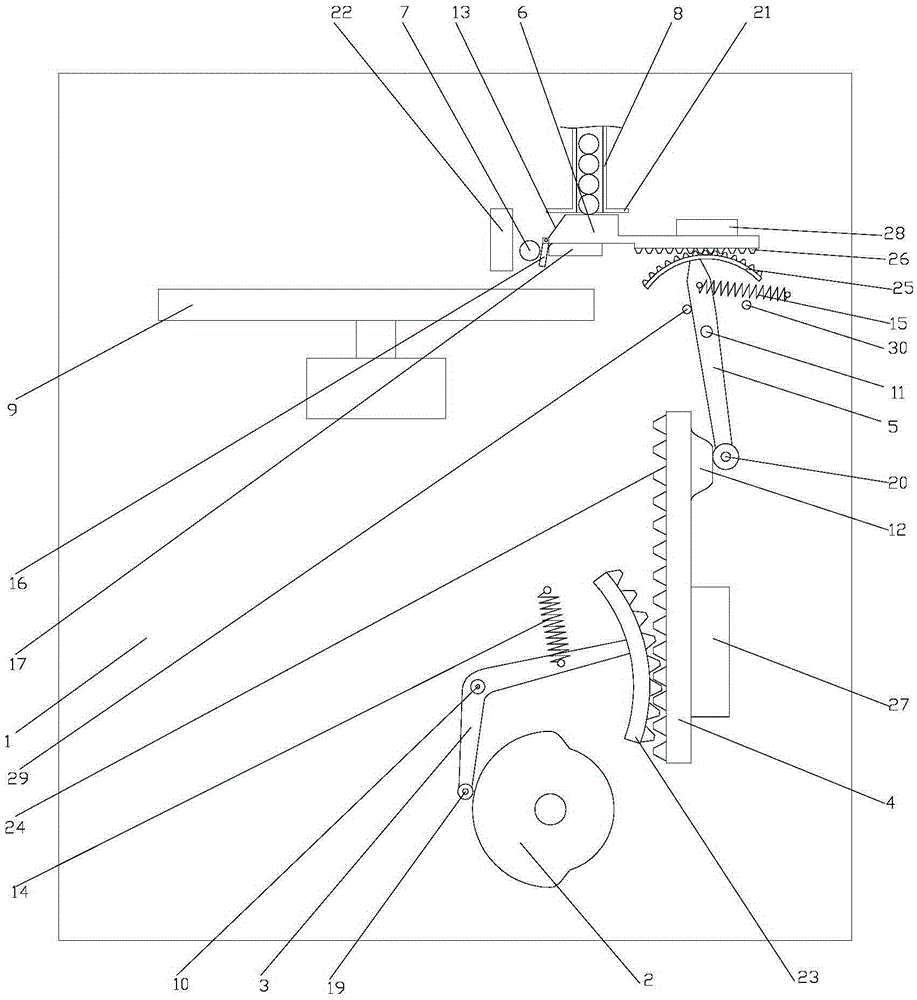

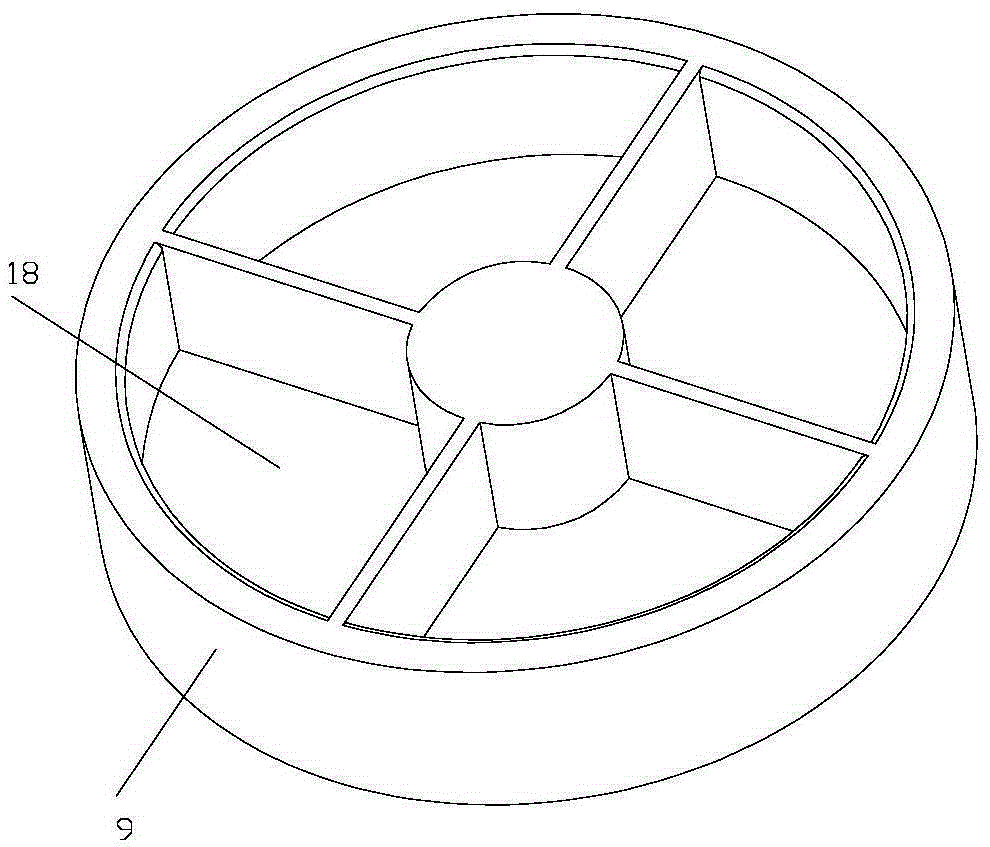

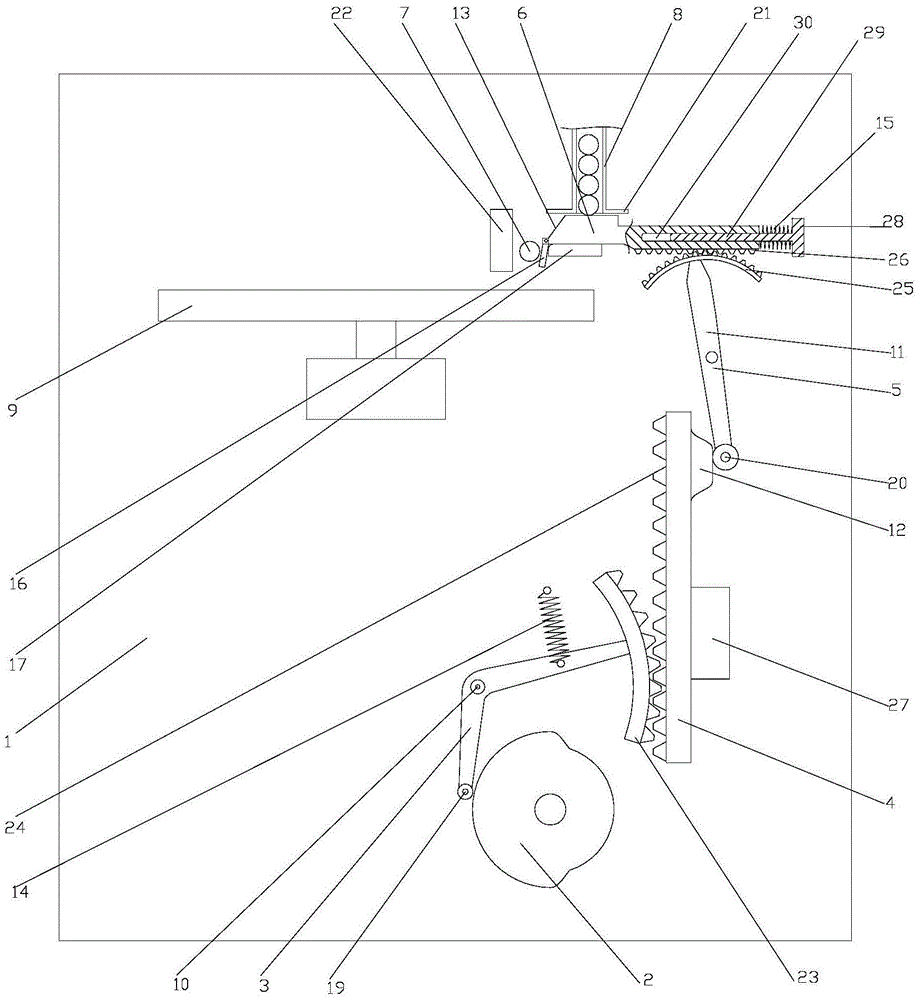

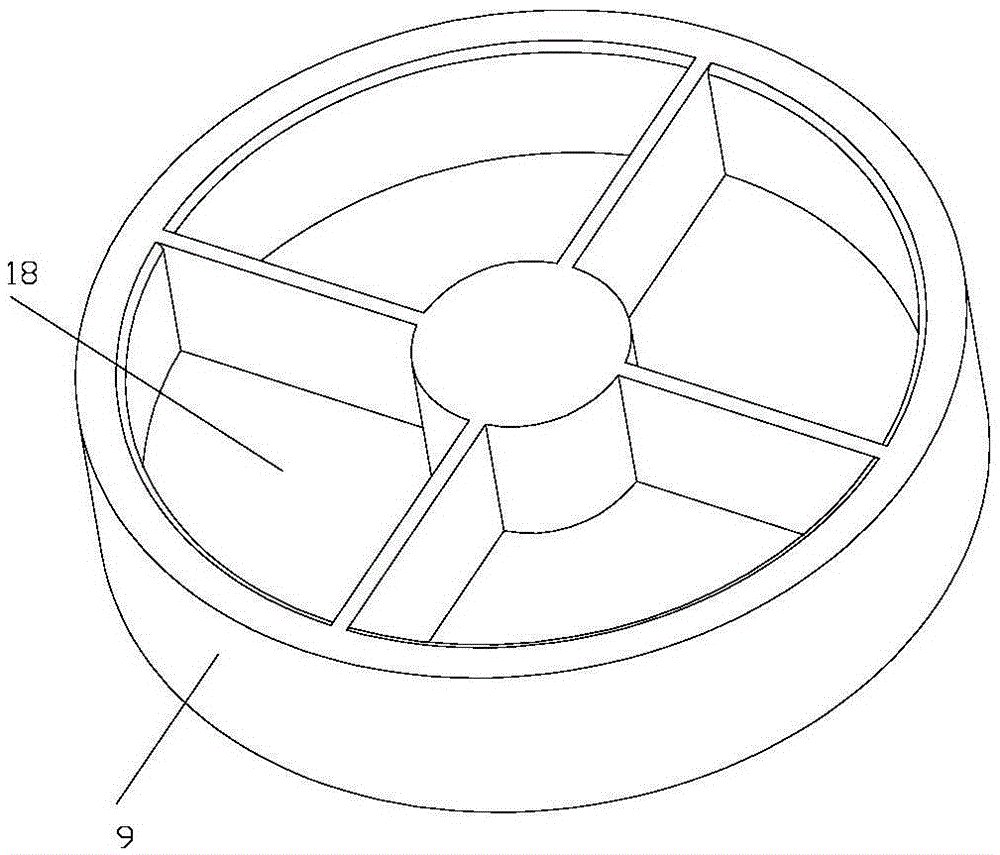

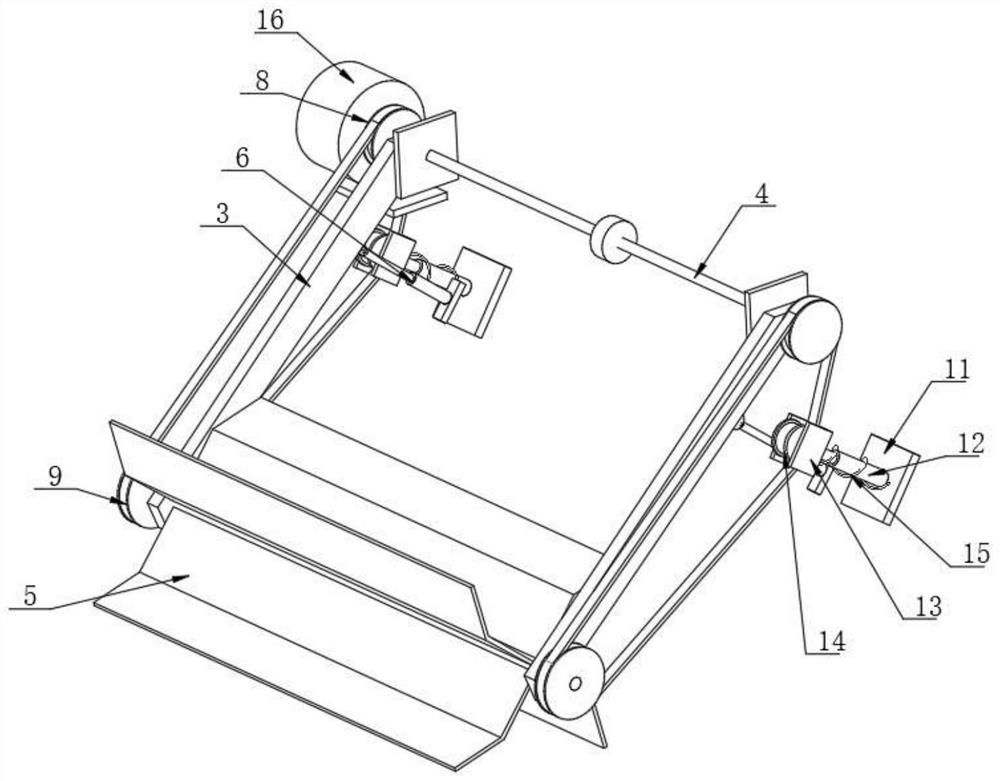

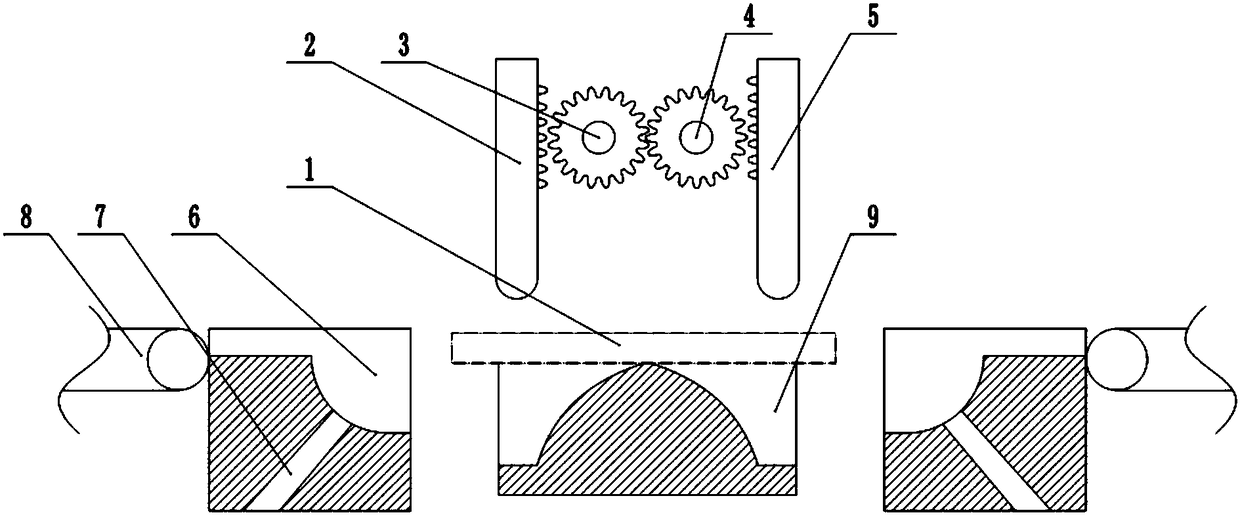

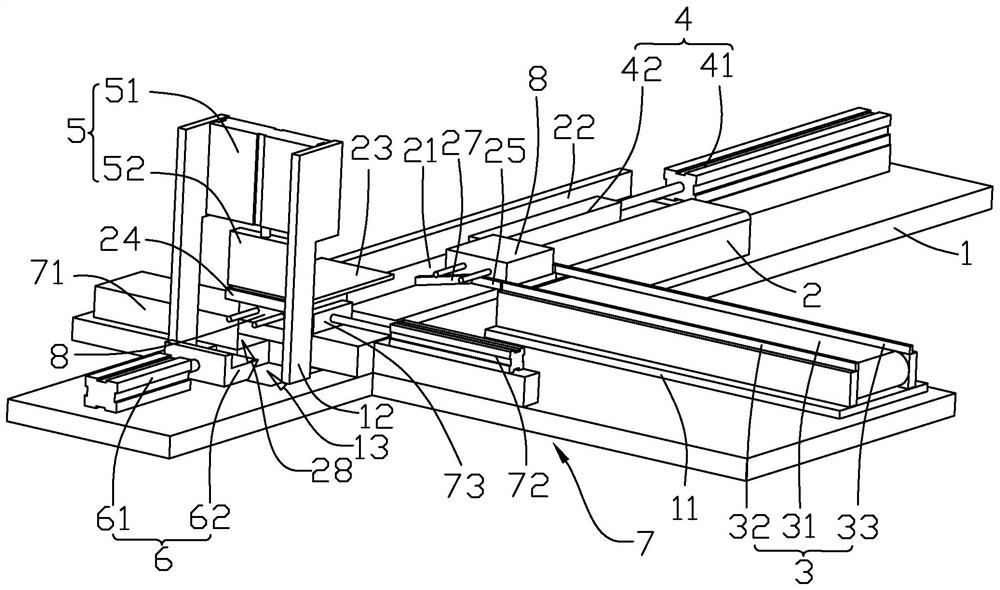

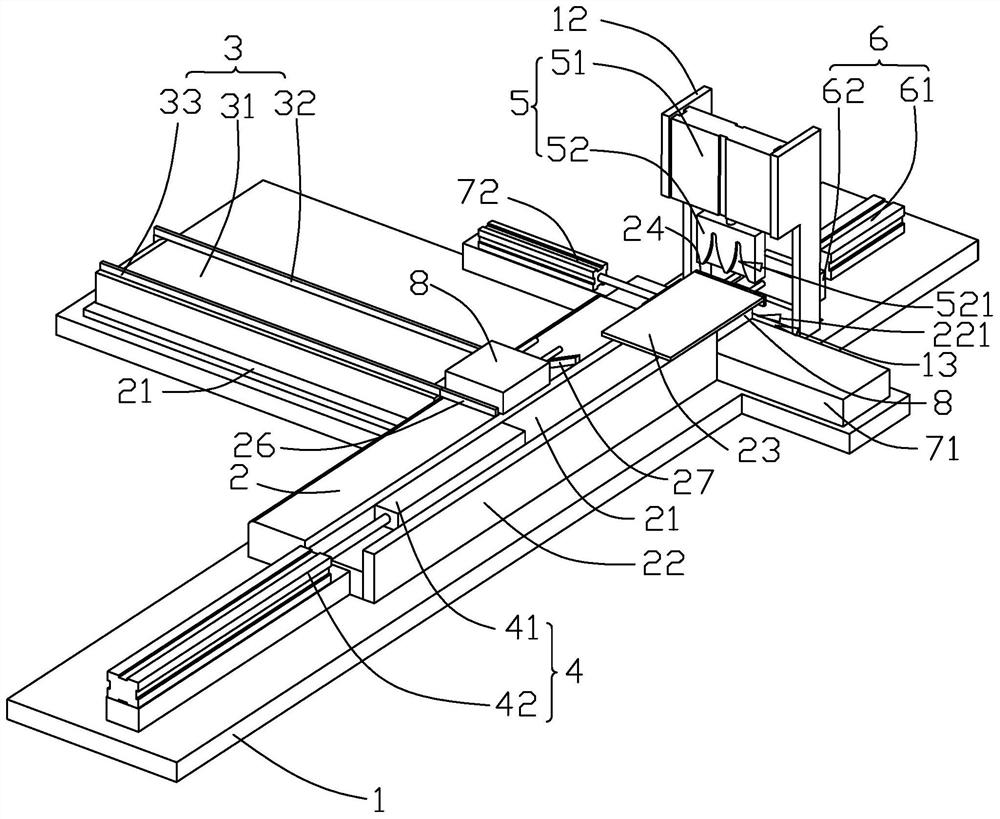

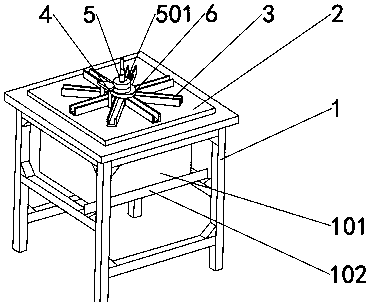

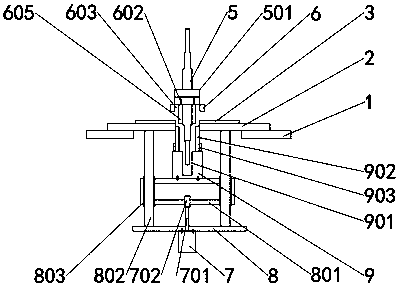

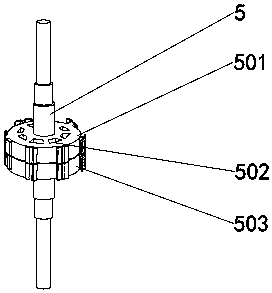

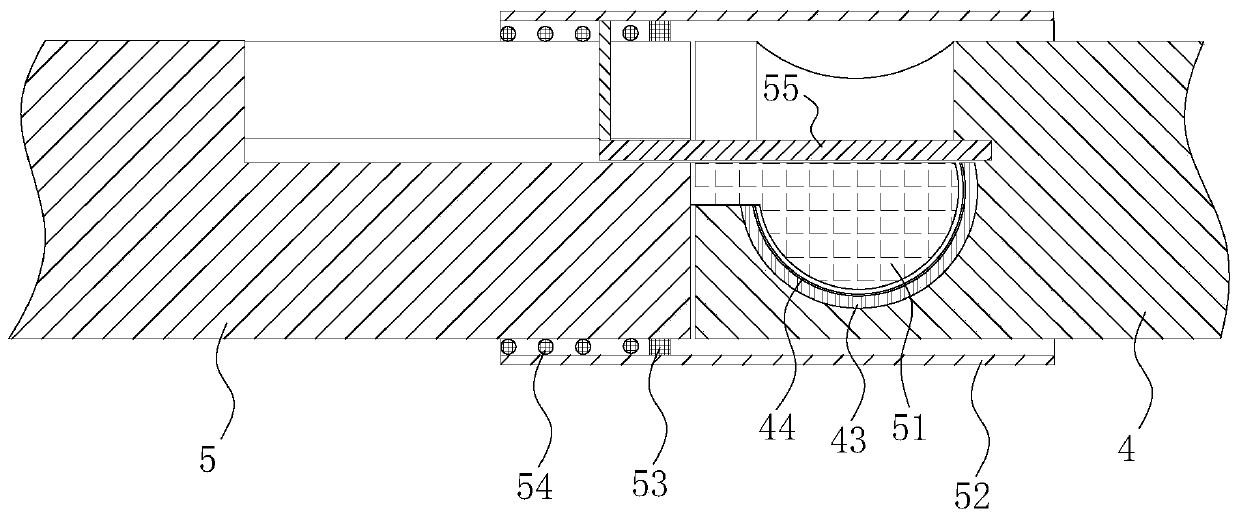

Automatic rolling ball grouping mechanism

InactiveCN105252248AReduce labor intensitySmooth slidingMetal working apparatusElectric machineryCam

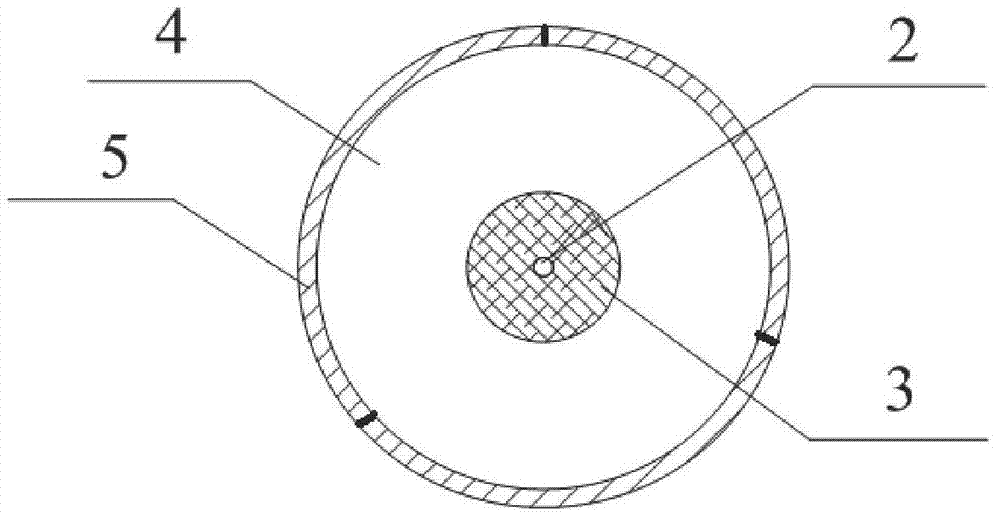

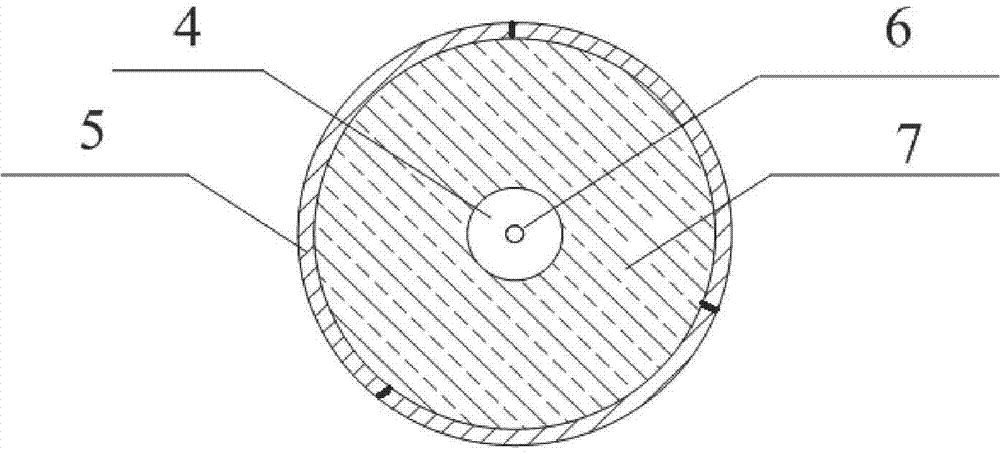

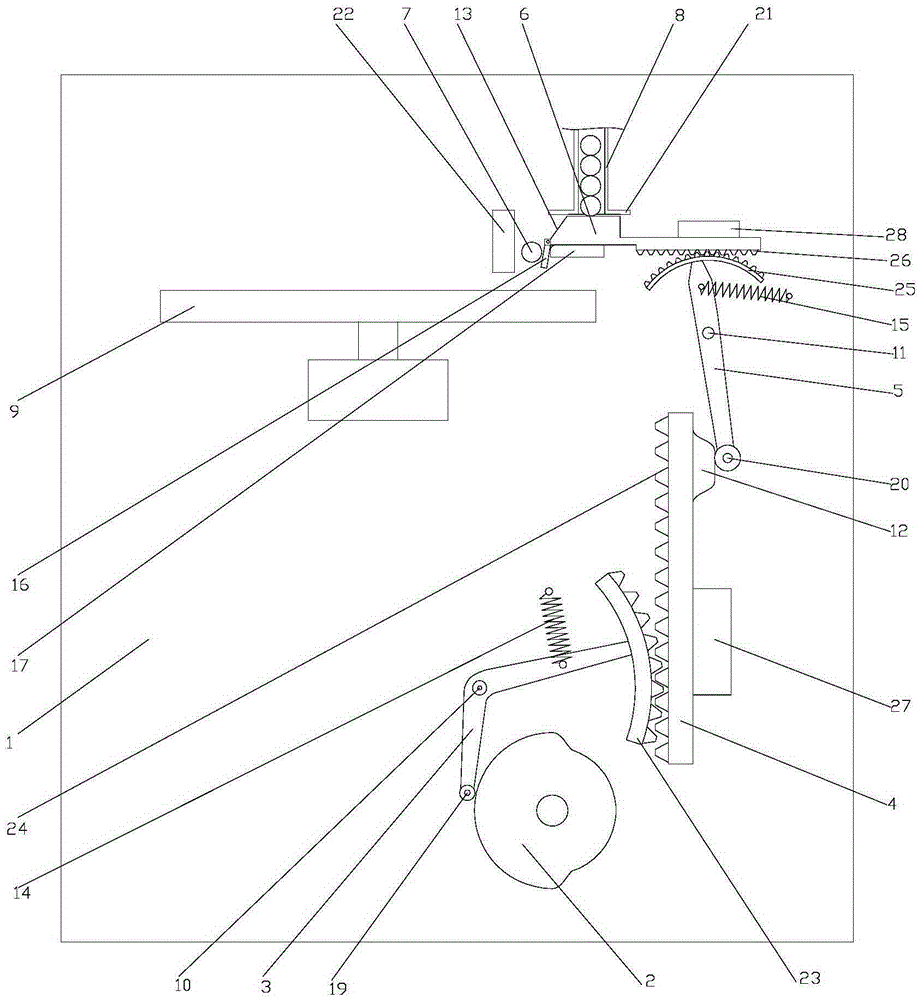

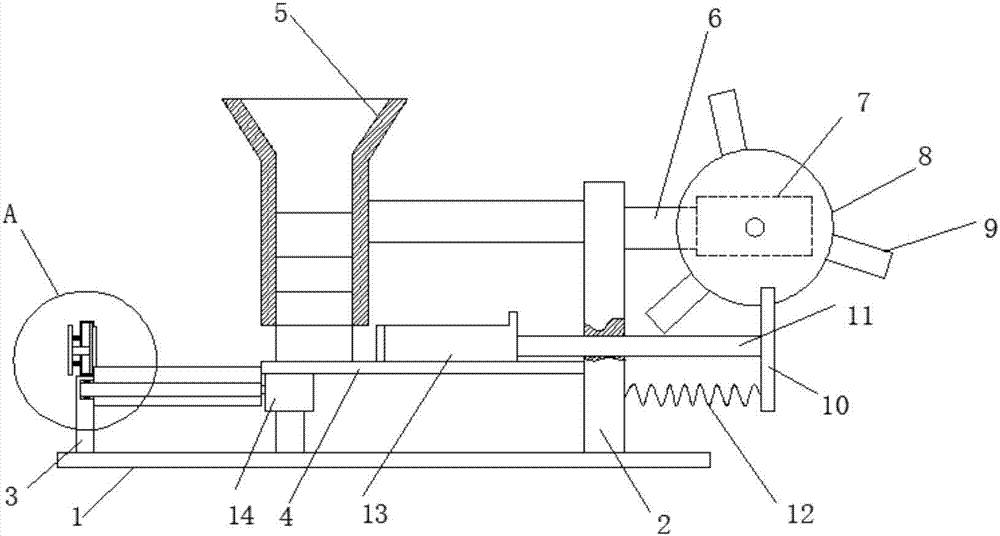

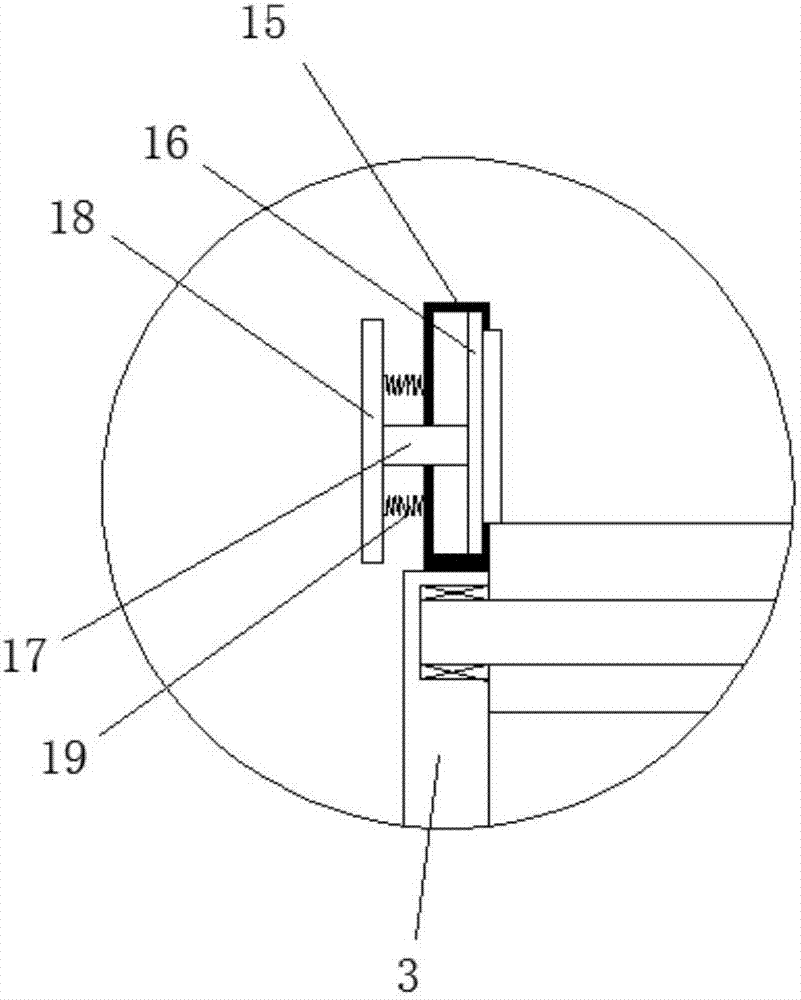

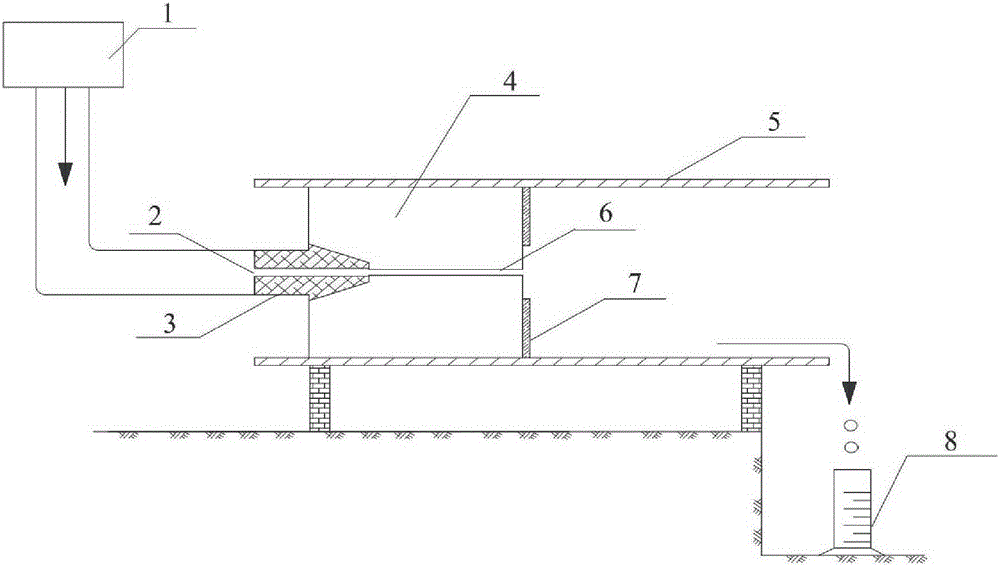

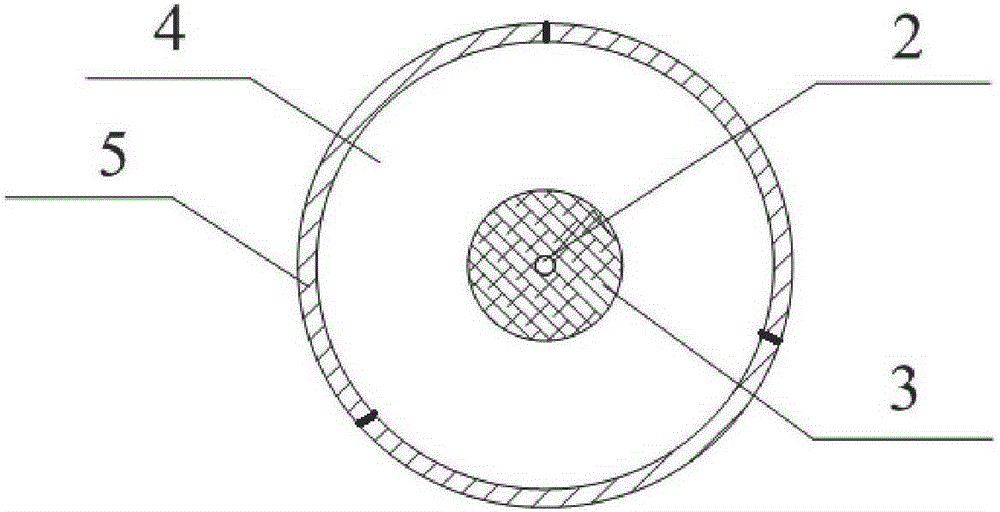

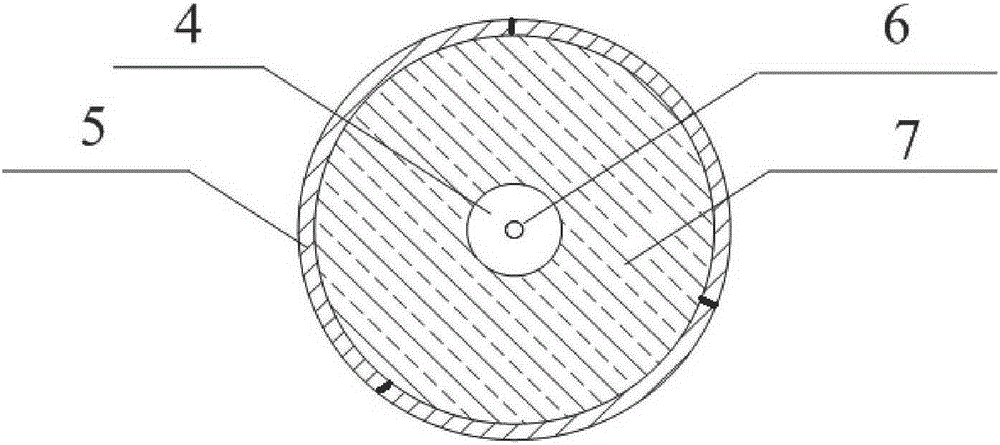

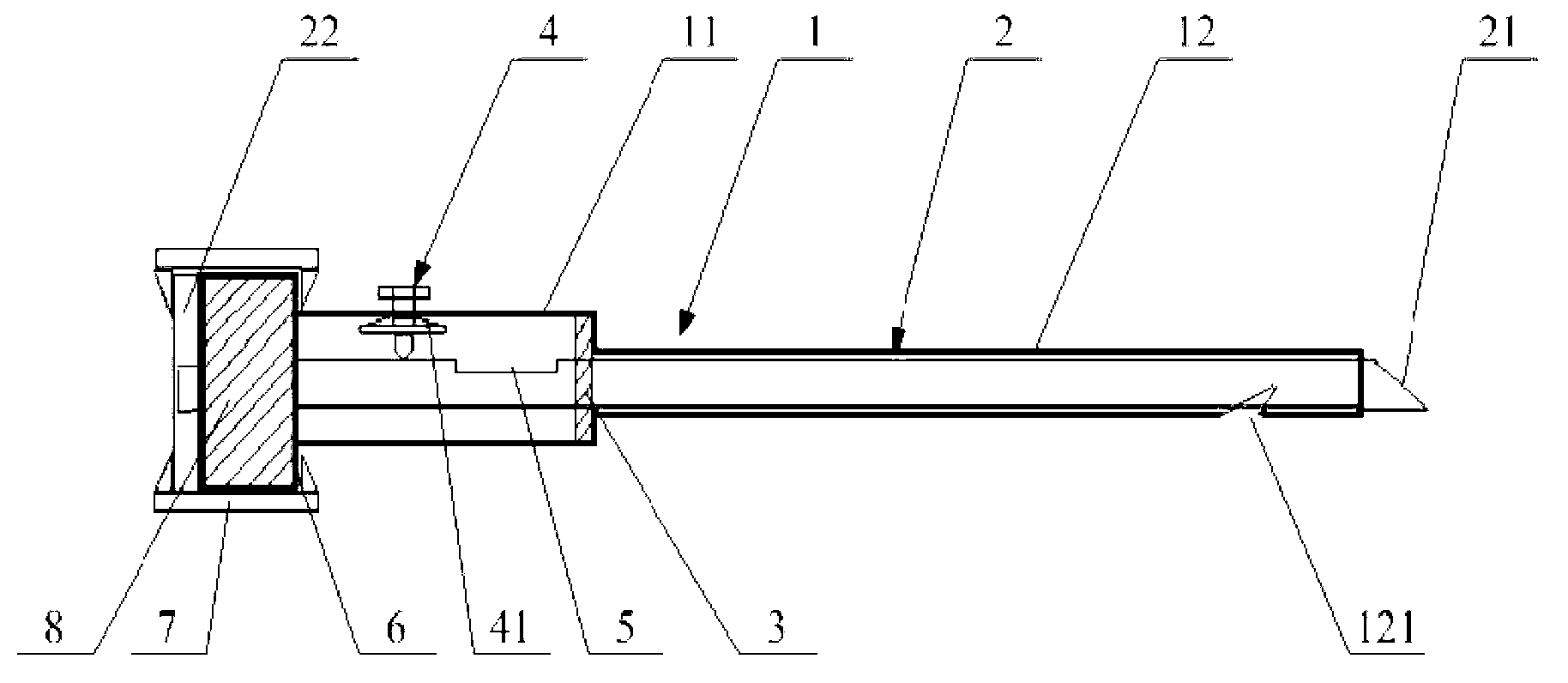

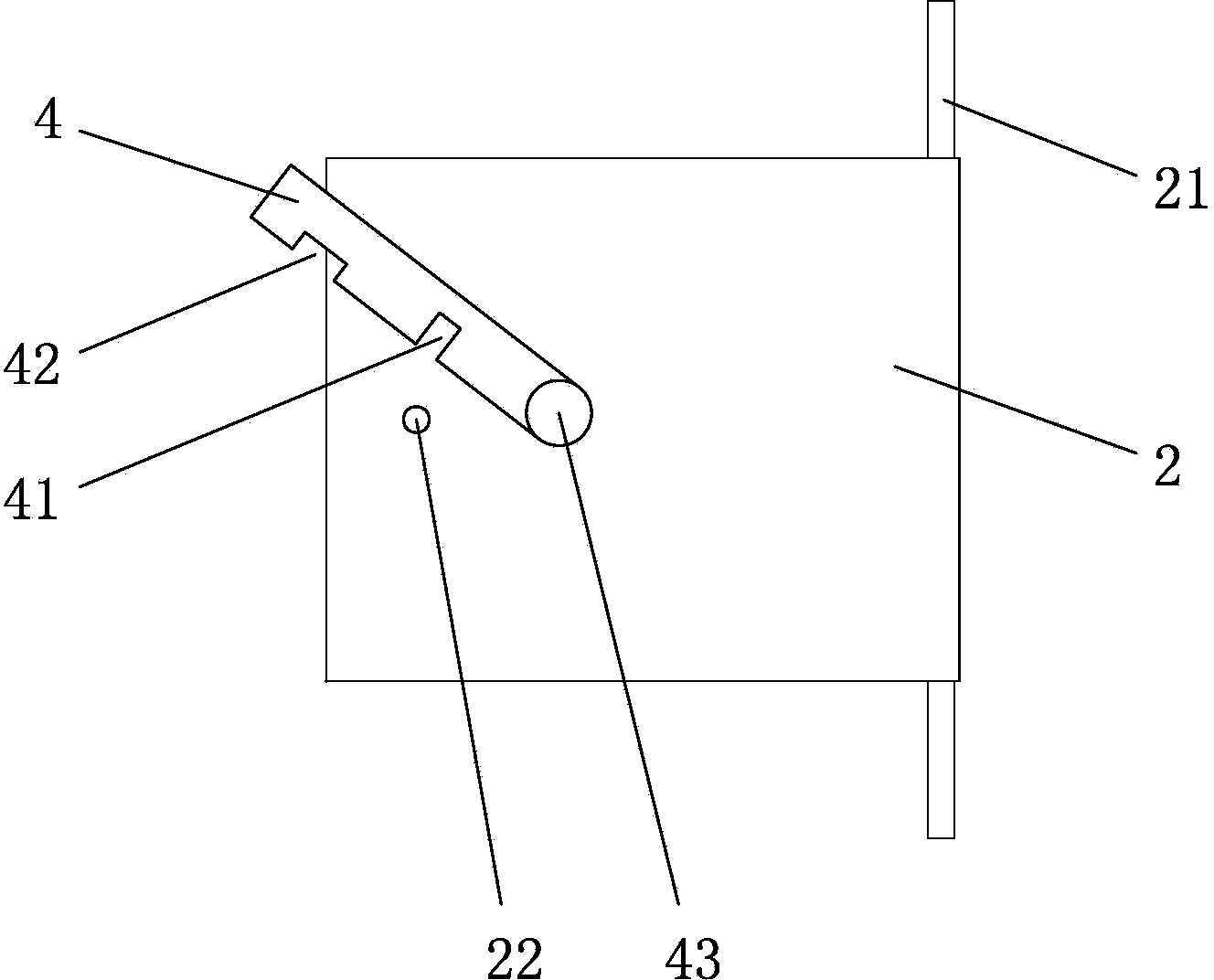

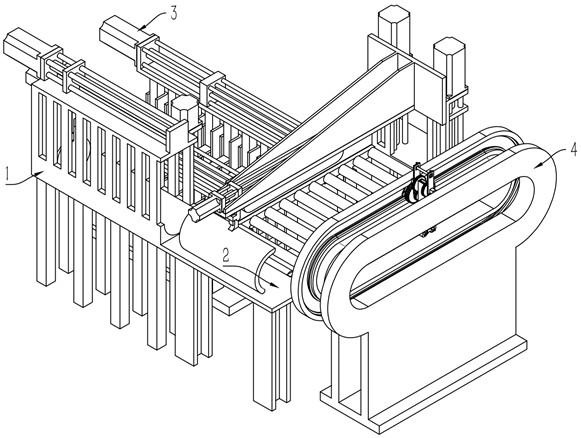

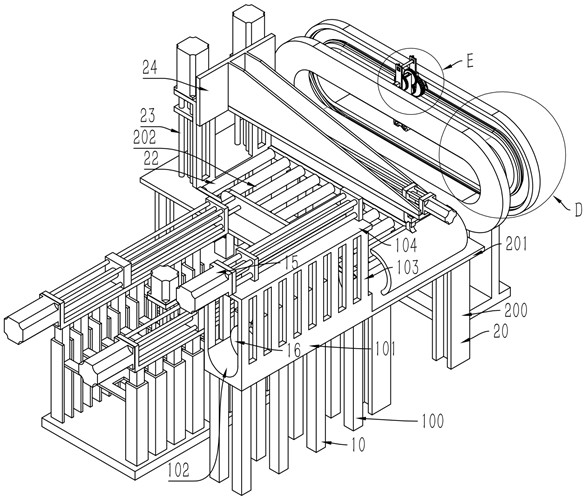

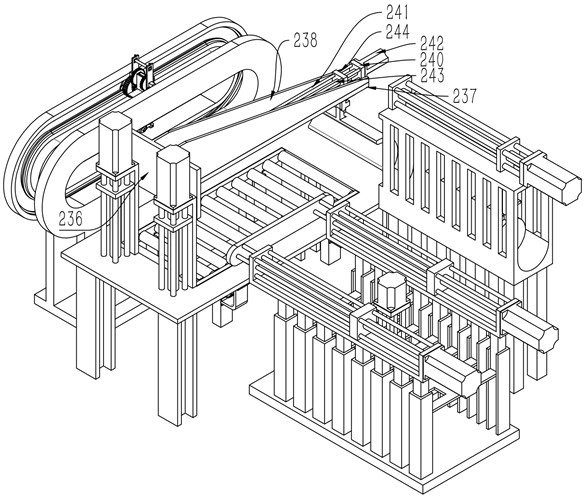

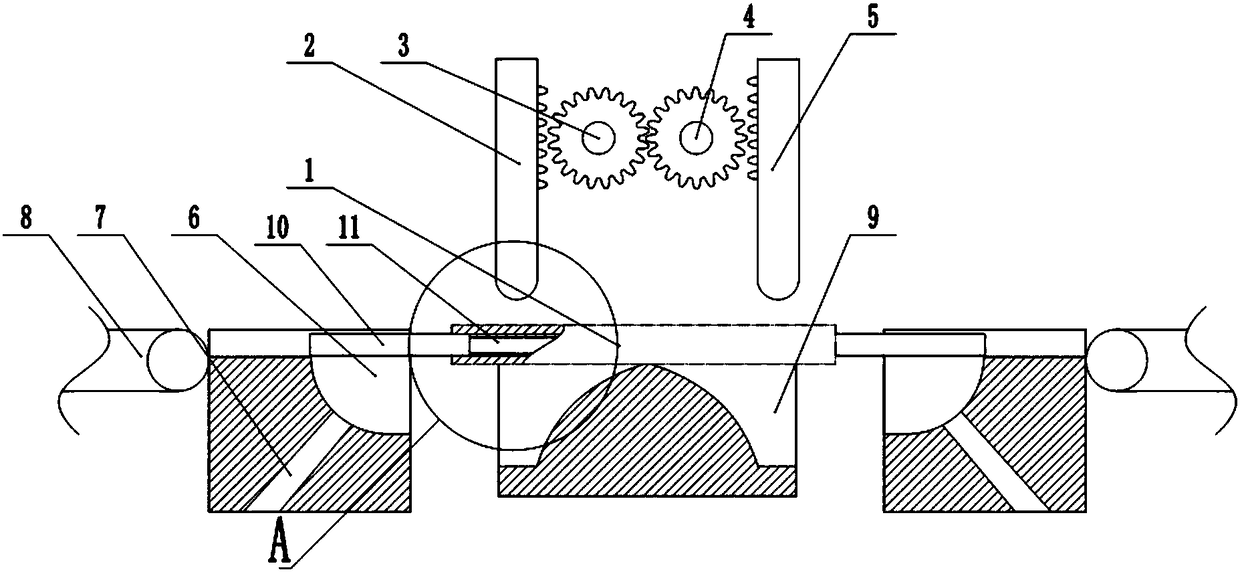

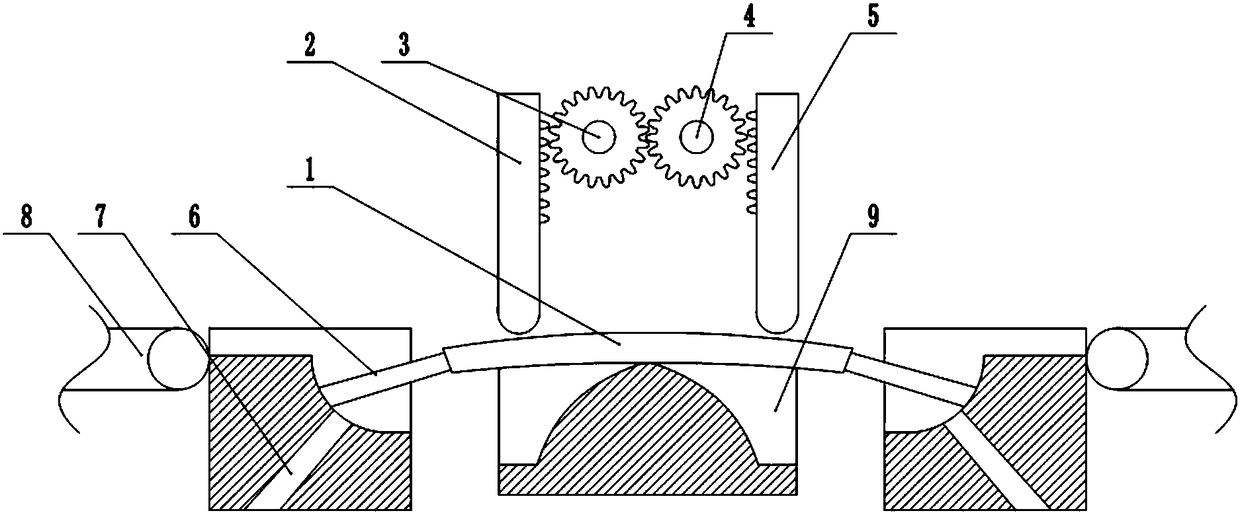

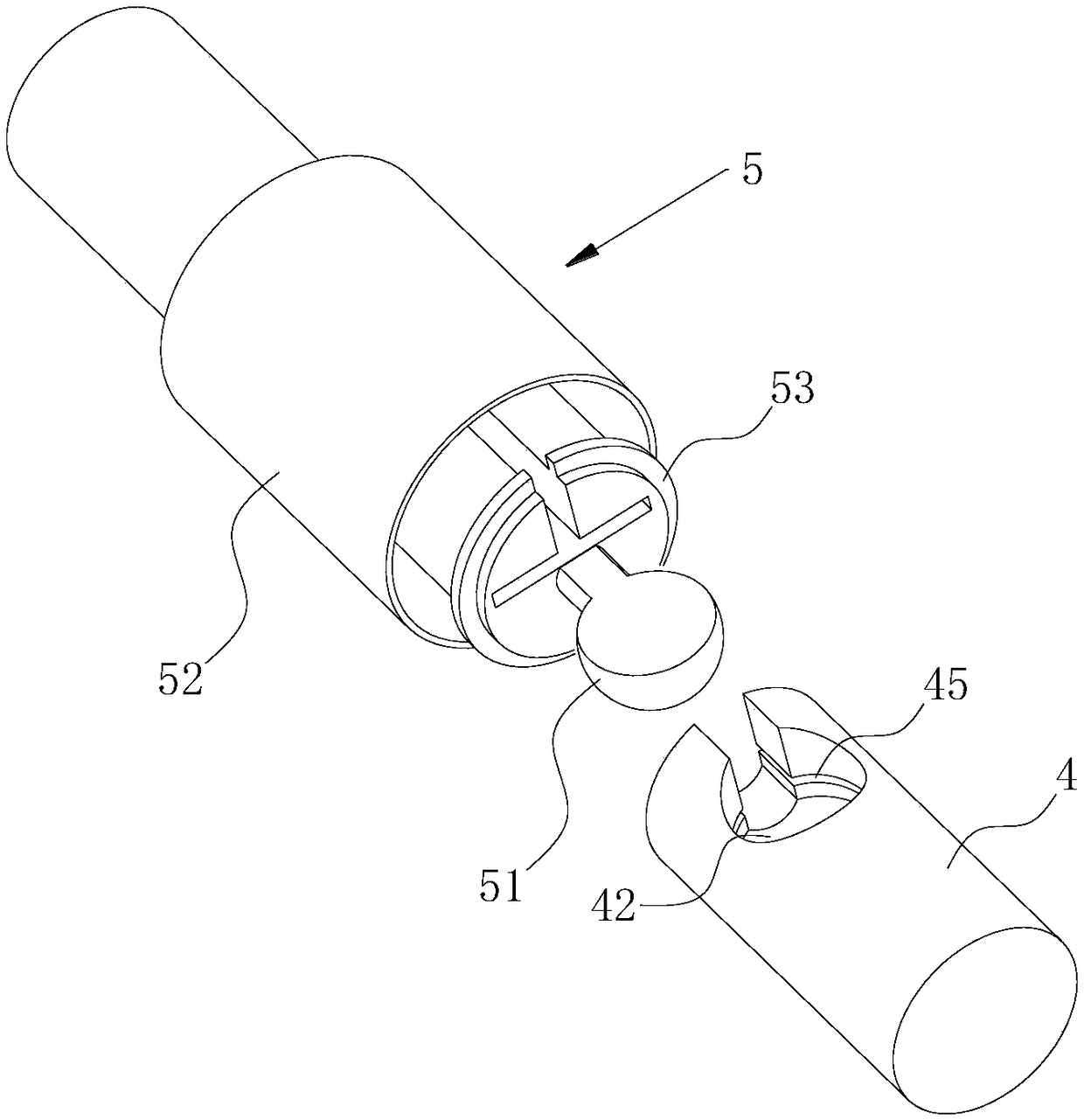

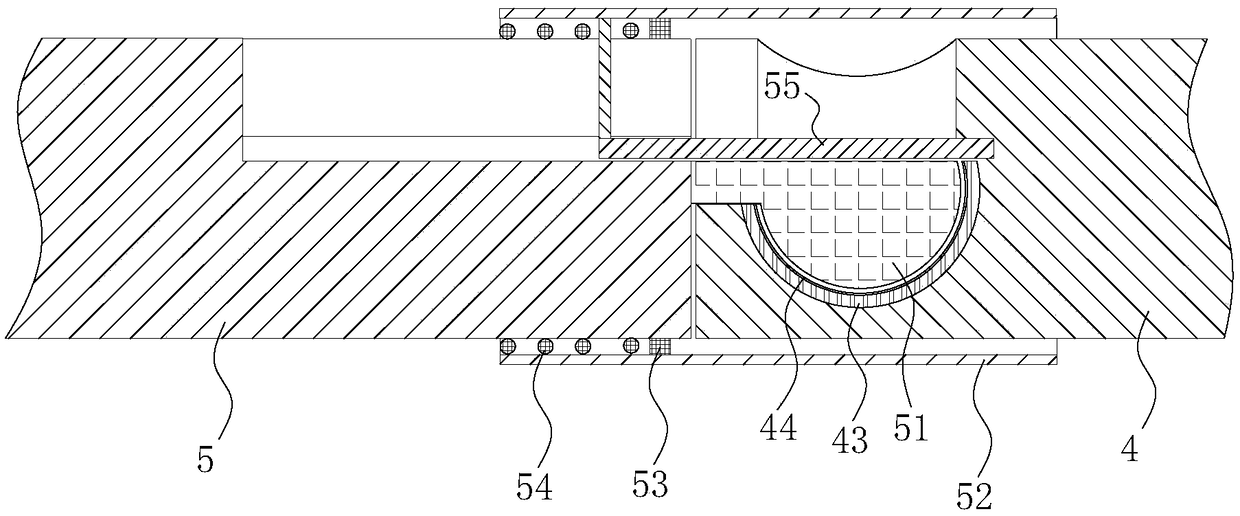

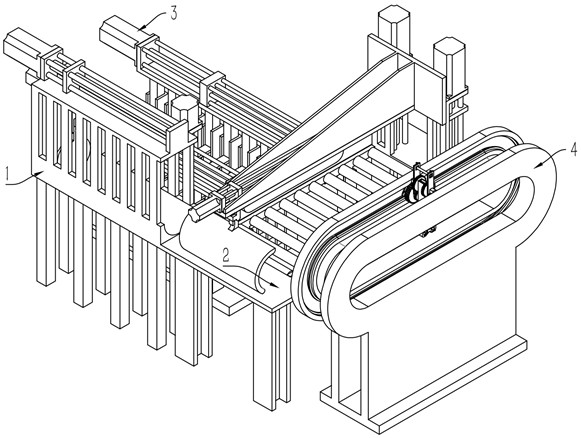

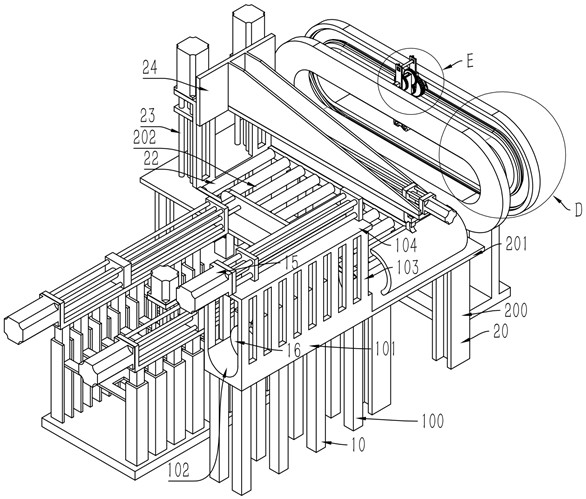

The invention discloses an automatic rolling ball grouping mechanism which comprises a base (1), a cam (2), a transmission rod (3), a vertical plate (4), a swing rod (5), a pushing block (6), a material barrel (8) and a rotary plate (9), wherein the cam (2) is rotatably connected on the base (1); a first motor for driving the cam (2) to rotate is arranged on the base (1); the middle part of the transmission rod (3) is rotatably connected on the base (1) through a first hinged point (10); one end of the transmission rod (3) abuts against the external contour of the cam (2); the other end of the transmission rod (3) is provided with a first arc-shaped rack (23); and a first tension spring (14), which is used for tensioning the transmission rod (3) to ensure that one end of the transmission rod (3) always abuts against the external contour of the cam (2), is arranged between the transmission rod (3) and the base (1). The invention provides the automatic rolling ball grouping mechanism, and the mechanism is accurate in checking rolling balls, and small in labor intensity of an operator.

Owner:NEWSUN NINGBO AUTO BEARING MFG

Roll ball grouping apparatus

The invention discloses a roll ball grouping apparatus, comprising a base (1), a cam (2), a driving rod (3), a vertical plate (4), an oscillating rod (5), a push block (6), a charging barrel (8) and a rotating disc (9); the cam (2) is rotatably connected to the base (1) and a first motor is arranged on the base (1); the middle of the driving rod (3) is rotatably connected to the base (1) through a first hinge point (10); one end of the driving rod (3) tightly abuts against an outer contour of the cam (2); a first cambered rack (23) is arranged on the other end of the driving rod (3); the vertical plate (4) is connected to the base (1) in a sliding manner in a vertical direction; and a lug (12) is arranged on the vertical plate (4). The roll ball grouping apparatus provided has the advantages of accurate roll ball counting and reduction of labor intensity of an operator.

Owner:NEWSUN NINGBO AUTO BEARING MFG

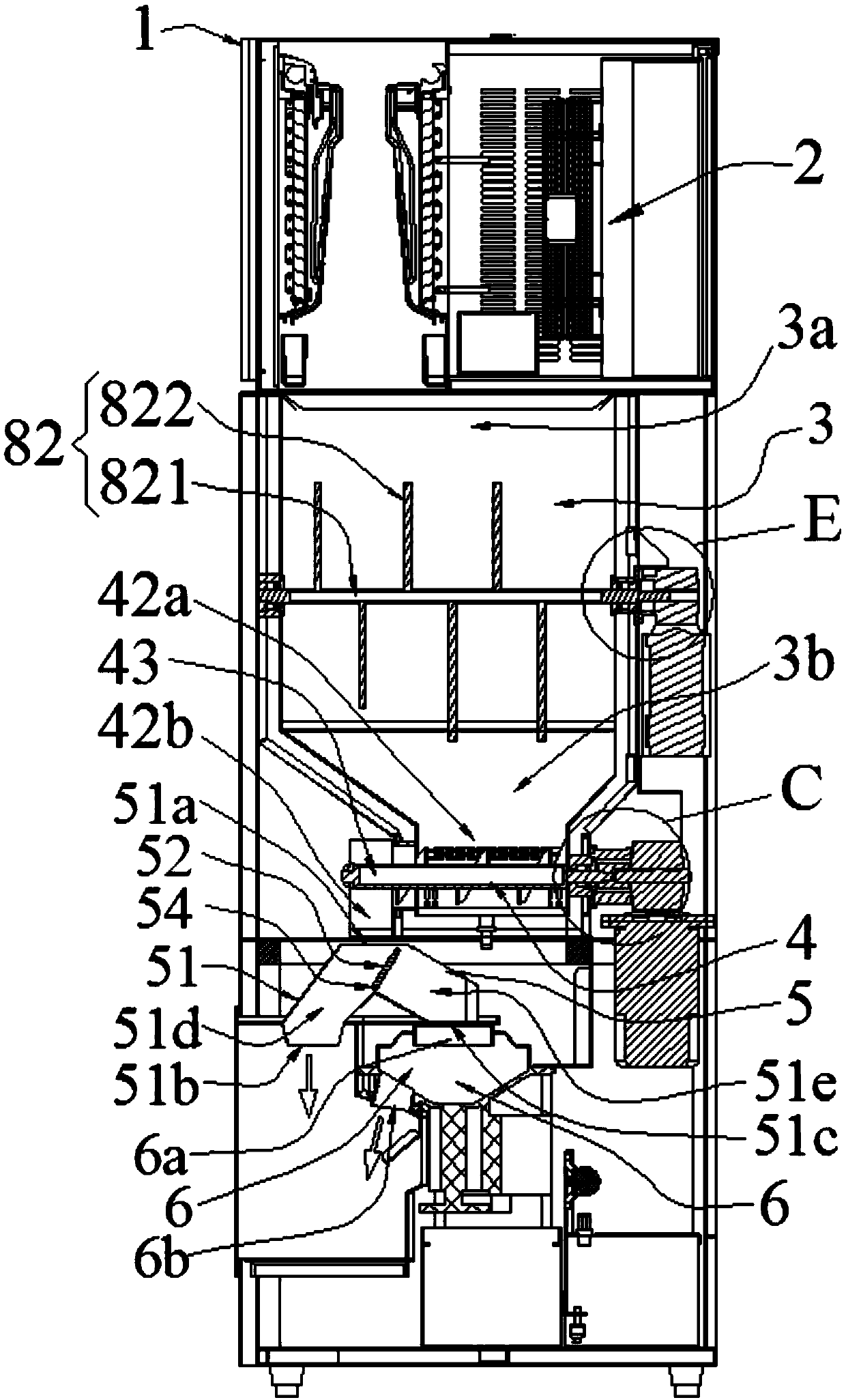

Ice maker capable of automatically outputting ice blocks and broken ice

ActiveCN107702397AFully automatedEnsure food hygiene and safetyLighting and heating apparatusIce storing/distributionThermodynamicsIce storage

The invention discloses an ice maker capable of automatically outputting ice blocks and broken ice. The ice maker is additionally equipped with an ice storage box, an automatic ice discharge device ofthe ice storage box, an ice block diverter valve, an ice breaking unit and an ice receiving platform, wherein an outlet of the ice block diverter valve is switched, so that ice blocks in the ice storage box are directly output from a first output of the ice block diverter valve or are crushed into broken ice for being output through the ice breaking unit; in an ice output process of the ice blocks or the broken ice, an operator only needs to put a container onto the ice receiving platform for receiving the ice blocks or the broken ice, and therefore, automation of the ice output process of the ice blocks and the broken ice is realized, labor intensity of taking ice by the operator is greatly reduced, and ice output time is reduced; and moreover, in the whole ice output process, the ice blocks and the broken ice at not in contact with the operator, so that hygiene and food safety of the ice blocks and the broken ice are guaranteed easier.

Owner:GUANGZHOU GUANGSHEN ELECTRIC PROD CO LTD

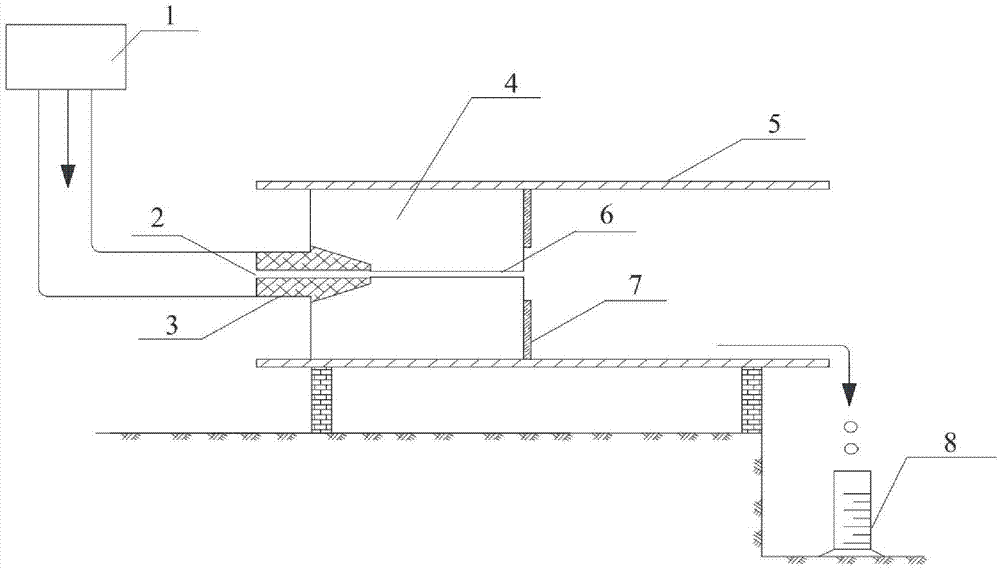

Clay dispersibility testing device and clay dispersibility testing method

InactiveCN103398931AEasy to openAvoid launchingPermeability/surface area analysisSoil scienceWater flow

The invention discloses a clay dispersibility testing device. The clay dispersibility testing device comprises a fixed water head water tank, a small cone and a soil sample tube, wherein a connecting column of the small cone is communicated with the water tank through a water pipe, the soil sample tube is formed by 2-5 tube sections which are fixed to form a cylinder through a tube hoop. The invention further discloses a clay dispersibility testing method. The clay dispersibility testing method comprises the following steps of: step 1. preparing a test specimen; step 2. pushing the cone part of the small cone into one side of the test specimen, keeping the superposition of the axis of the small cone and the axis of the test specimen; step 3. forming a test specimen through hole; step 4. painting a cementing material on the other side of the test specimen so as to form a protection layer; and step 5. performing a seepage test, and determining the diameter of the test specimen through hole. The device and the method have the beneficial effects that since the detachable soil sample tube is adopted, after the test is finished, the tube hoop is detached, the soil sample tube is easily opened, the test specimen is completely taken out, and the diameter of the test specimen through hole is accurately determined. In addition, the protection layer can prevent a free face of the test specimen from being eroded by water flow during the testing process.

Owner:NORTHWEST A & F UNIV

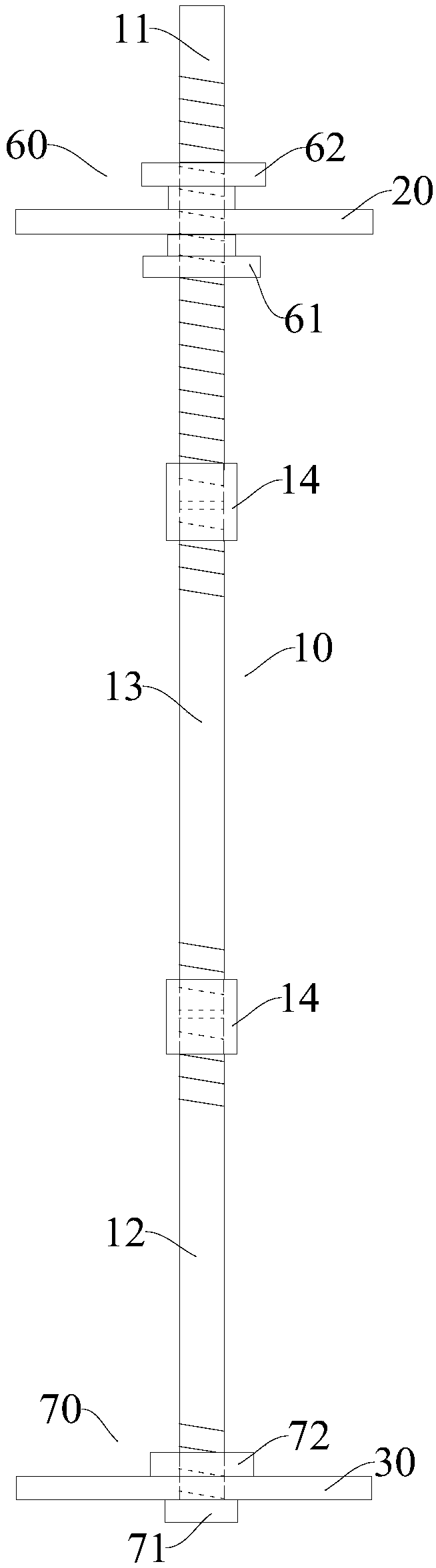

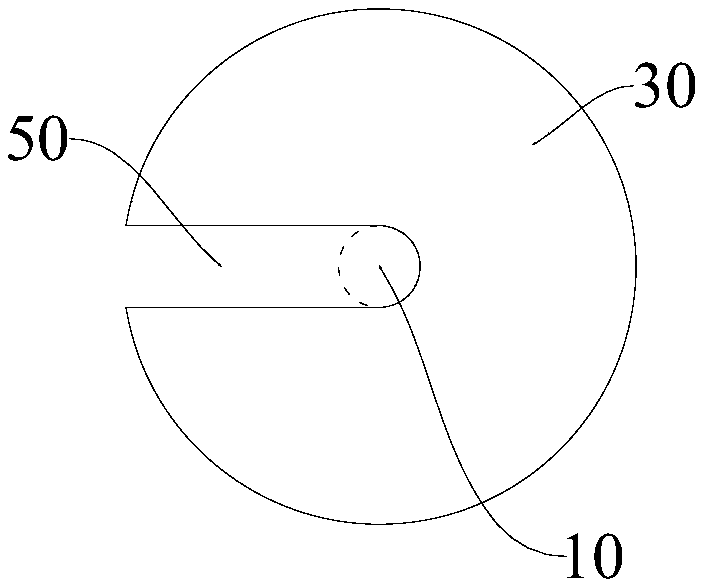

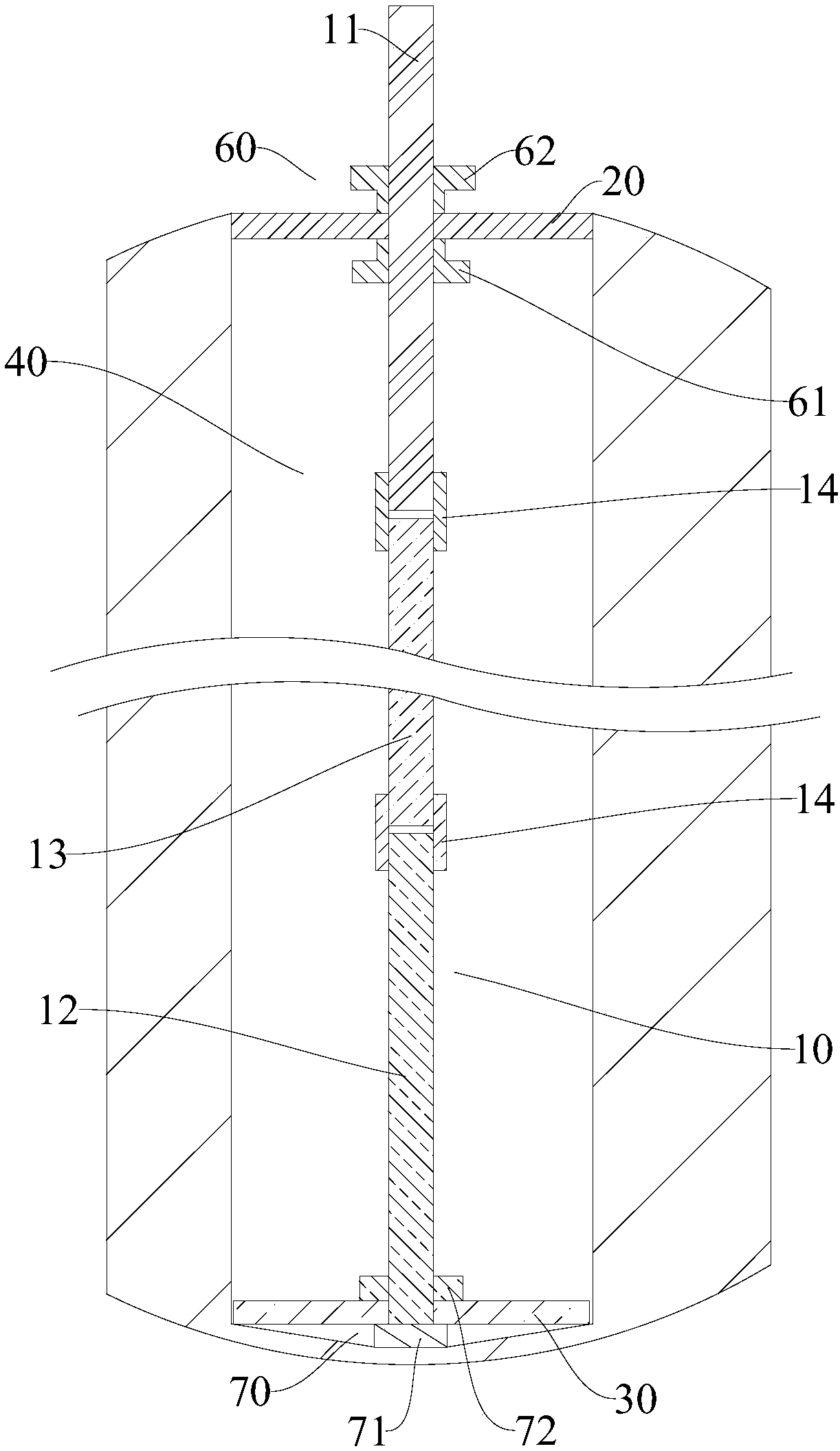

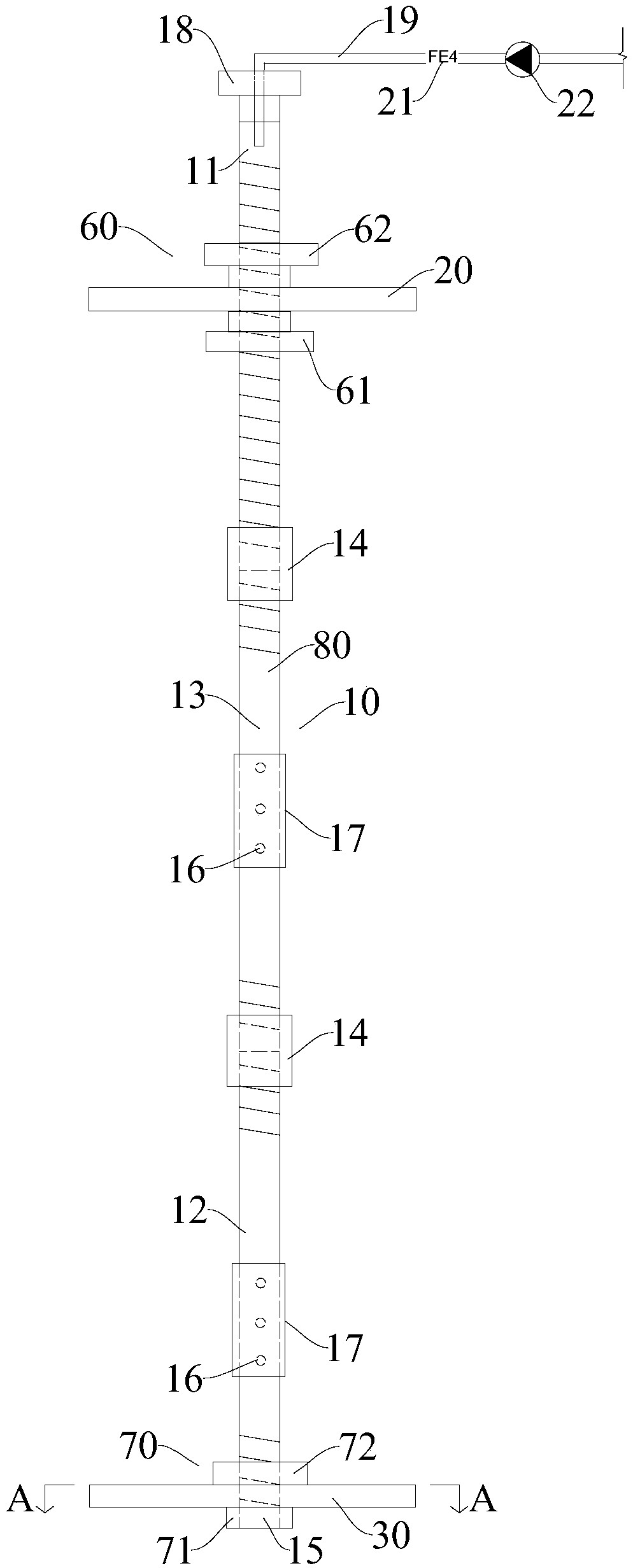

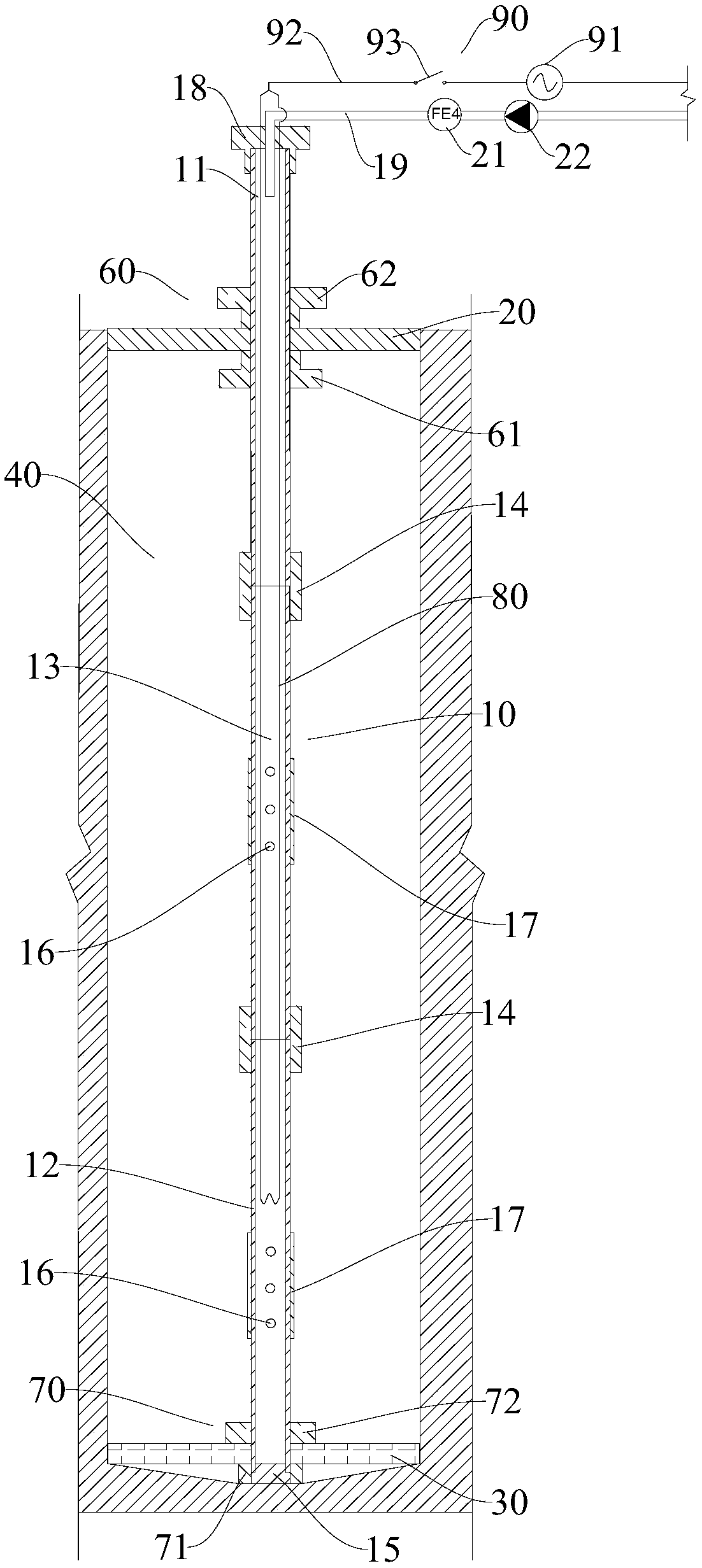

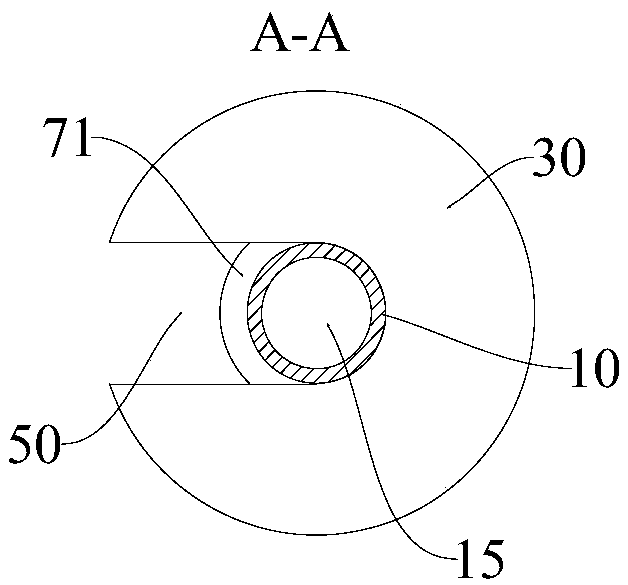

Static blasting anti-punching device and blasting method

The invention a static blasting anti-punching device and belongs to the technical field of engineering blasting. The static blasting anti-punching device comprises a connecting rod, an upper baffle and a lower baffle. The upper baffle sleeves the outer wall of the upper portion of the connecting rod and is detachably connected with the connecting rod and used for plugging a drilling opening. The lower baffle sleeves the outer wall of the bottom of the connecting rod. An anti-punching containing cavity for containing a static explosive is defined by the upper baffle, the side wall of a drilledhole and the lower baffle. A first fixing part for fixing the upper baffle is arranged on the connecting rod. The invention further provides a static blasting method. The static blasting anti-punchingdevice and the blasting method aim at solving the technical problem that a current market is in lack of a static blasting anti-punching device or blasting method which prevents punching, and is convenient to operate and good in blasting effect.

Owner:SHIJIAZHUANG TIEDAO UNIV +1

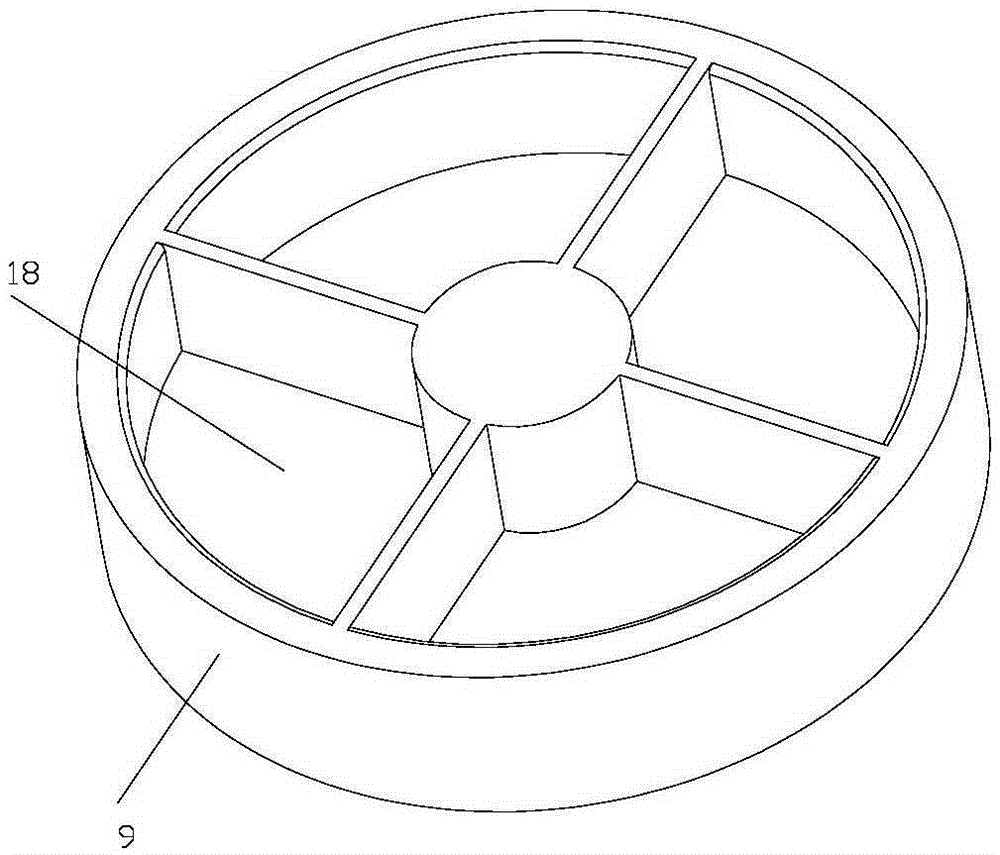

Ball grouping device

The invention discloses a ball grouping device which comprises a base (1), a cam (2), a transmission rod (3), a vertical plate (4), a swing rod (5), a push block (6), a barrel (8) used for accommodating balls (7) and a rotating disc (9) used for storing the balls (7) rolling out of the barrel (8). The cam (2) is rotatably connected to the base (1), and a first motor used for driving the cam (2) to rotate is arranged on the base (1). According to the ball grouping device, the balls can be accurately counted, and labor intensity of operators is low.

Owner:NEWSUN NINGBO AUTO BEARING MFG

Citrus picking device

InactiveCN105409450APicking achievedImprove the efficiency of fruit pickingPicking devicesFruit treeEngineering

Owner:CHONGQING PINGWEI CHAOYANG AGRI DEV CO LTD

Large-aperture static blasting anti-punching device and blasting method

The invention provides a large-aperture static blasting anti-punching device and belongs to the technical field of the engineering blasting. The device comprises a connecting pipe, a rubber sleeve, anupper baffle, and a lower baffle, wherein the bottom of the connecting pipe is provided with a baffle for blocking a bottom port of the connecting pipe, and the middle and lower side walls of the connecting pipe are provided with water injection holes for allowing an inner chamber of the connecting pipe to communicate with a drill hole; the rubber sleeve sleeves the outer side wall of the connecting pipe for blocking outlets of the water injection holes; the upper baffle sleeves the outer side wall of the upper portion of the connecting pipe and is detachably connected with the connecting pipe for blocking a mouth of the drill hole; the lower baffle sleeves the outer side wall of the bottom of the connecting pipe; and the upper baffle, the side walls of the drill hole, and the lower baffle define an anti-punching accommodating chamber for containing a static crushing agent. The invention also provides a large-aperture static blasting method. The large-aperture static blasting anti-punching device and the blasting method aim to solve the technical problem that the market is short of a static blasting device capable of preventing punching, adding water and heating at present.

Owner:SHIJIAZHUANG TIEDAO UNIV +1

Collision-proof loading device for bearing production

InactiveCN107458845AReduce the impactAvoid launchingPackagingConveyor partsElectric machineryEngineering

The invention discloses a collision-proof loading device for bearing production. The device comprises a base; a mounting plate and a support rod are vertically fixed at the top of the base; the mounting plate is positioned on one side of the support rod; a storage shell and a loading plate, arranged up and down, are fixed on one side, near the support rod, of the mounting plate; a fixed rod is fixed on the other side of the mounting plate; a first motor is fixed at one end, far from the mounting plate, of the fixed rod; a turntable is fixed on an output shaft of the first motor; and first contact blocks, arranged at equal intervals, are fixed in the peripheral direction of the turntable. Through matching use of such structures as the storage shell, the loading plate, the first motor, the turntable, the first contact blocks, second contact blocks, a connecting rod and a pushing plate, the device can periodically feed materials, can adjust the feeding time, and achieves the use flexibility; and compared with a traditional manual loading mode, the device saves more time and labors, and is high in loading efficiency.

Owner:成都捷科菲友信息技术有限公司

A kind of clay dispersibility testing device and clay dispersibility testing method

InactiveCN103398931BEasy to openAvoid launchingPermeability/surface area analysisSoil scienceWater flow

The invention discloses a clay dispersibility testing device. The clay dispersibility testing device comprises a fixed water head water tank, a small cone and a soil sample tube, wherein a connecting column of the small cone is communicated with the water tank through a water pipe, the soil sample tube is formed by 2-5 tube sections which are fixed to form a cylinder through a tube hoop. The invention further discloses a clay dispersibility testing method. The clay dispersibility testing method comprises the following steps of: step 1. preparing a test specimen; step 2. pushing the cone part of the small cone into one side of the test specimen, keeping the superposition of the axis of the small cone and the axis of the test specimen; step 3. forming a test specimen through hole; step 4. painting a cementing material on the other side of the test specimen so as to form a protection layer; and step 5. performing a seepage test, and determining the diameter of the test specimen through hole. The device and the method have the beneficial effects that since the detachable soil sample tube is adopted, after the test is finished, the tube hoop is detached, the soil sample tube is easily opened, the test specimen is completely taken out, and the diameter of the test specimen through hole is accurately determined. In addition, the protection layer can prevent a free face of the test specimen from being eroded by water flow during the testing process.

Owner:NORTHWEST A & F UNIV

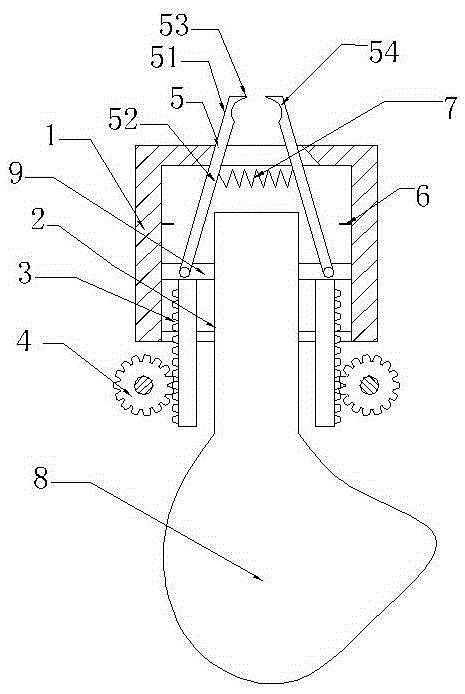

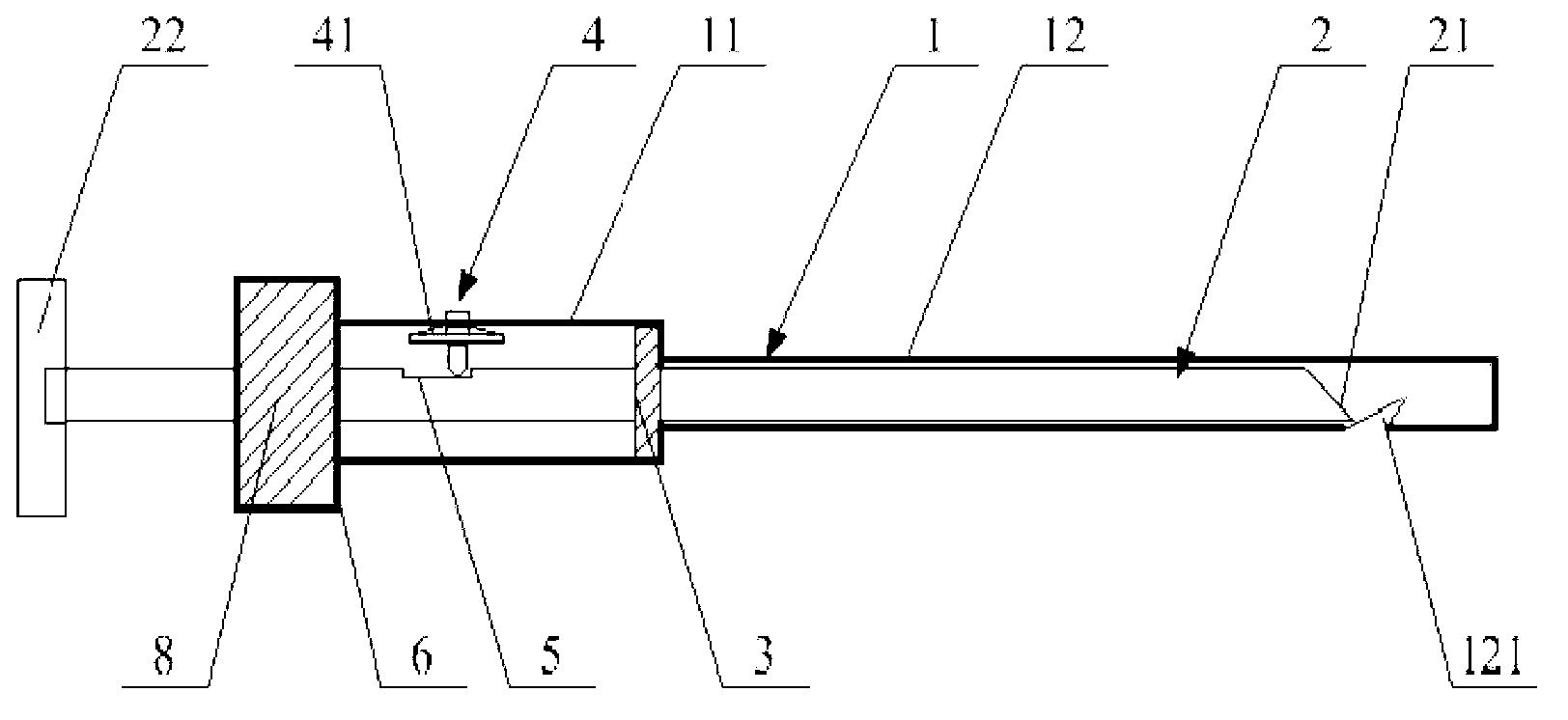

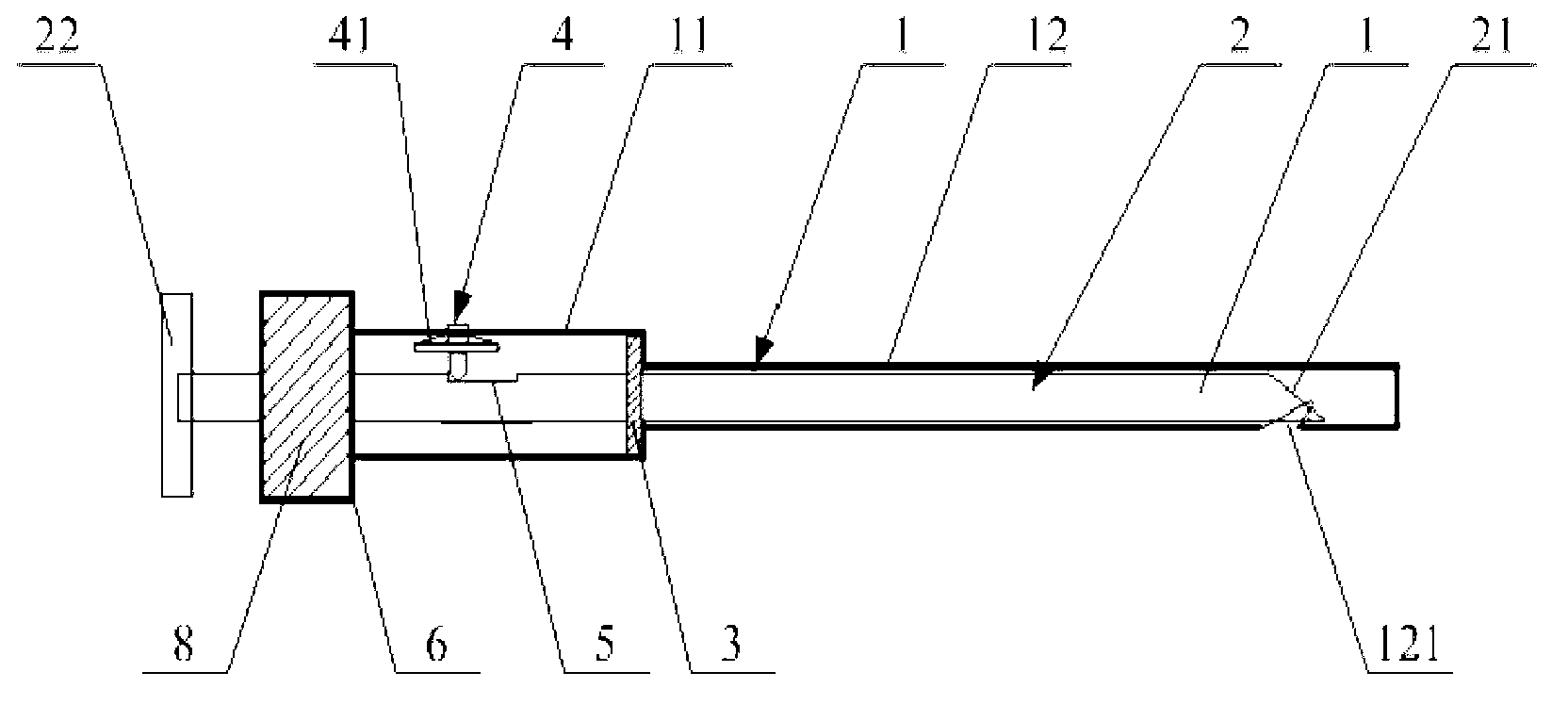

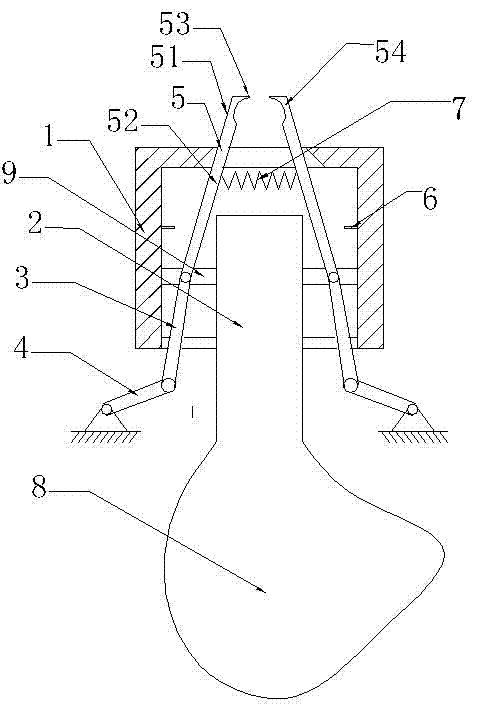

Pleura biopsy needle

The invention provides a pleura biopsy needle which comprises a needle sleeve and a needle core. The needle core is arranged in the needle sleeve. The needle sleeve comprises a sealed cylinder and a needle cylinder. The rear end of the needle cylinder is connected with the front end of the sealed cylinder. A slant groove is formed at the front end of the needle cylinder. The needle cylinder is sleeved on the outer wall of the needle core in a connected mode and matched with the needle core in a sliding mode. A first sealing ring is arranged in the sealed cylinder. The outer wall of the first sealing ring is fixedly connected with the inner wall of the sealed cylinder. The inner wall of the first sealing ring is sleeved on the outer wall of the needle core in a connected mode and matched with the needle core in a sliding mode. At first, the needle core and the needle sleeve pierce the pleural cavity, and then the pleural tissue is obtained by match of the needle core and the needle sleeve. A needle is not replaced in the whole process and the first sealing ring is used for sealing the needle sleeve so that the pleural cavity is not communicated with the outside and the rate of pneumothorax is reduced.

Owner:WEST CHINA HOSPITAL SICHUAN UNIV

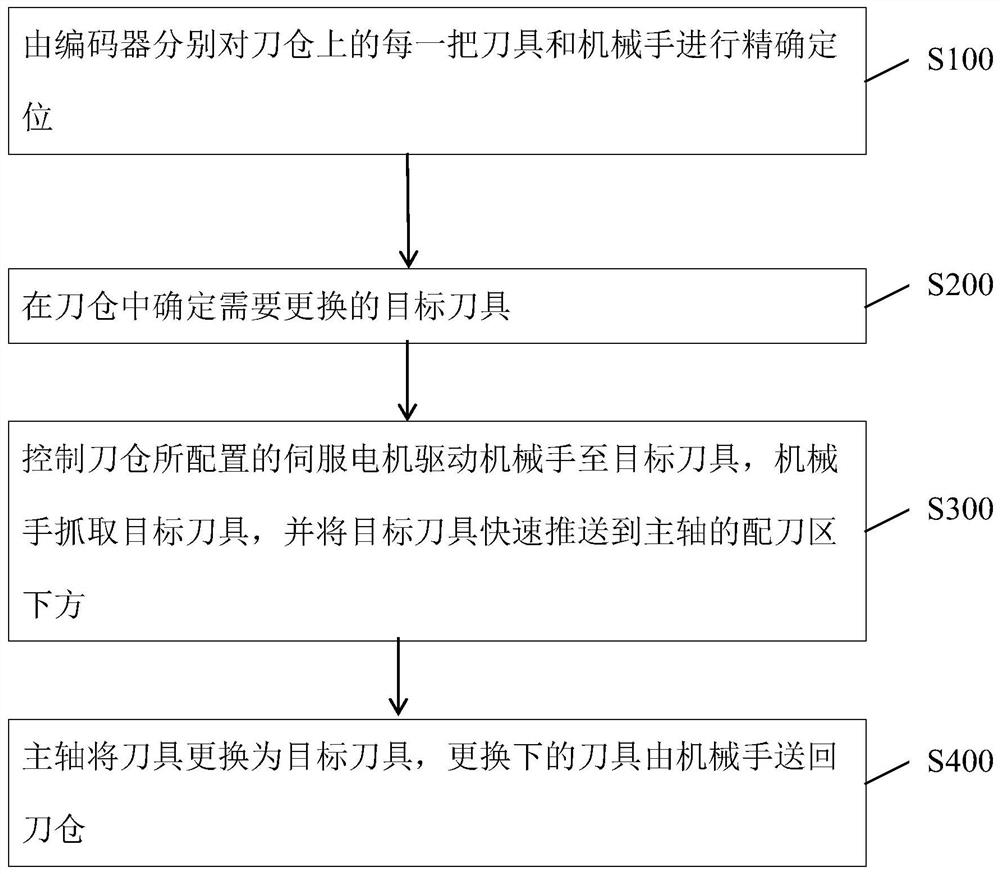

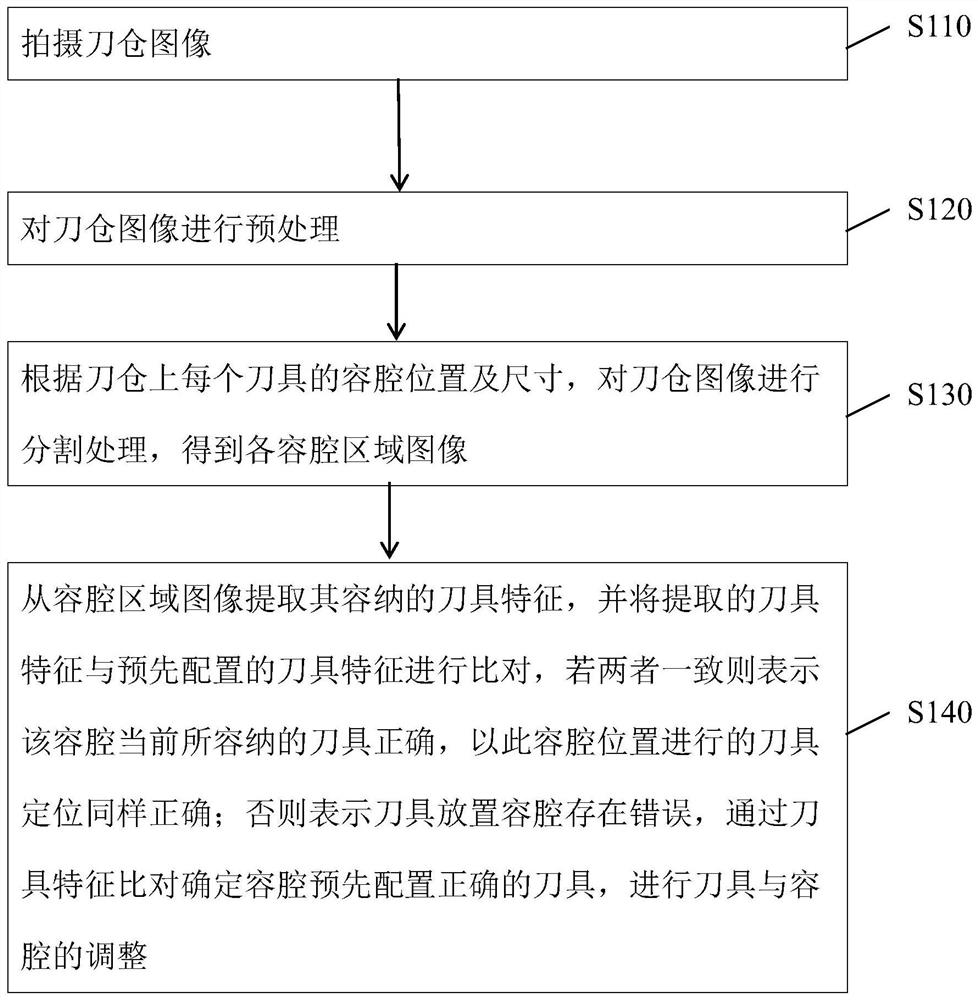

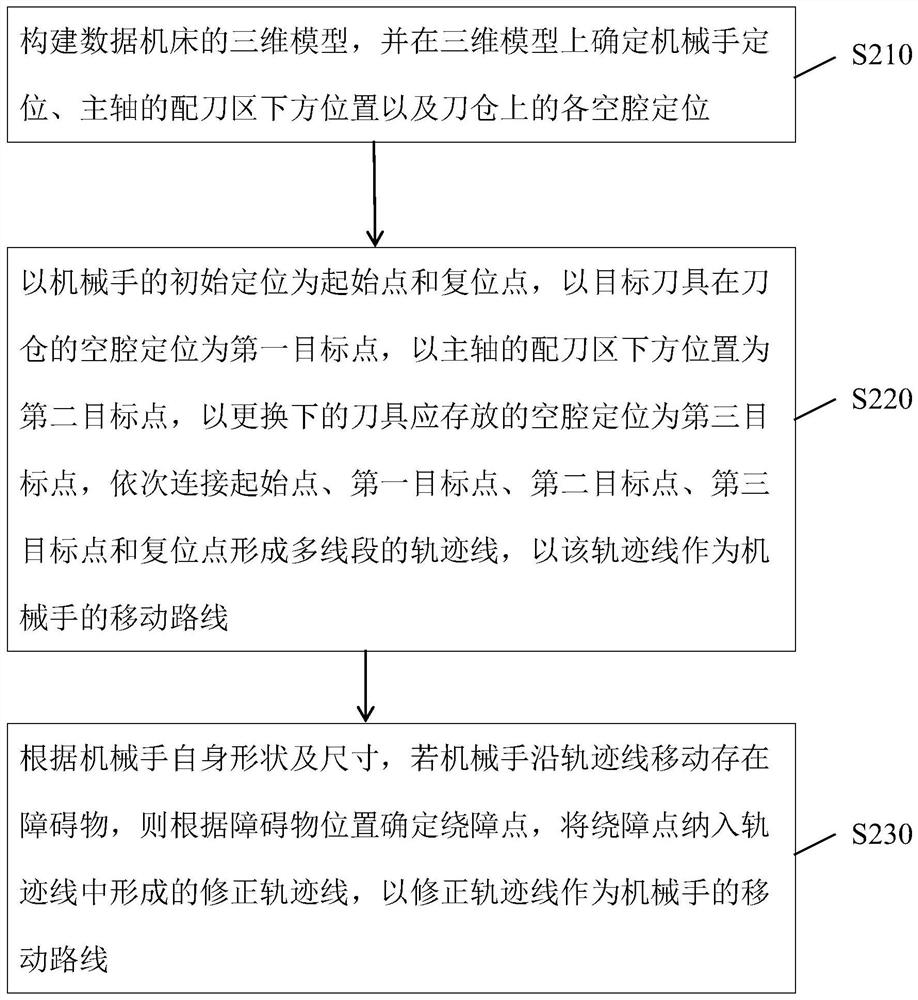

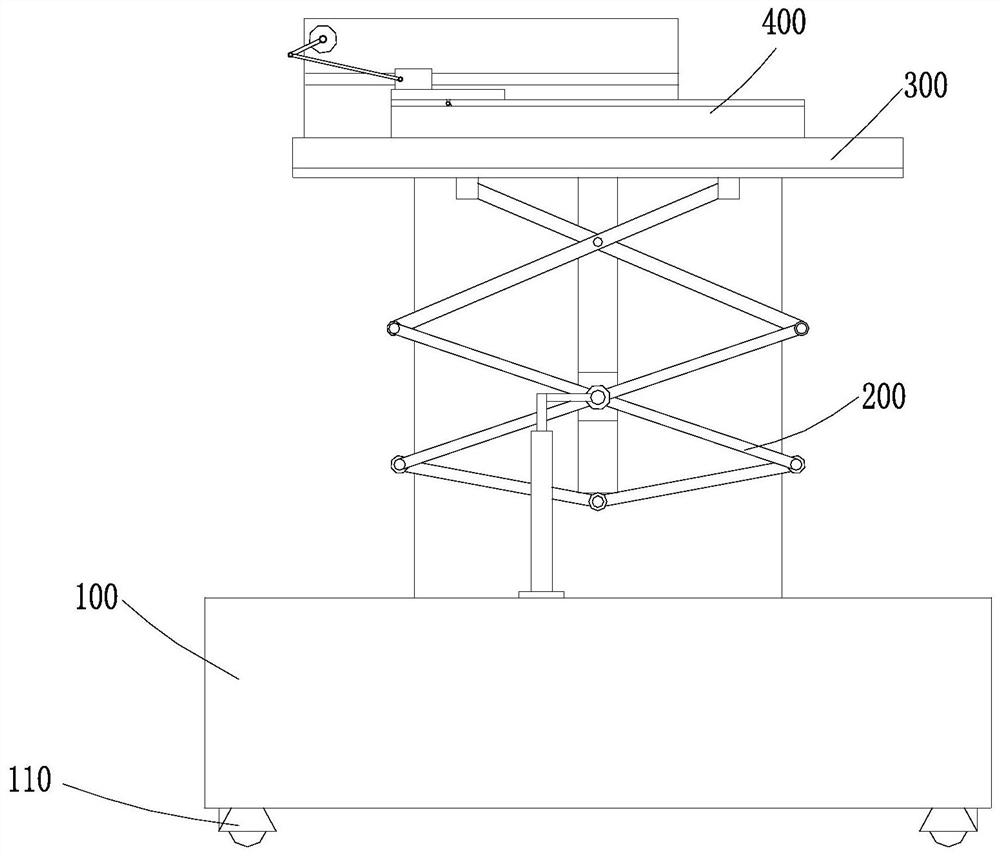

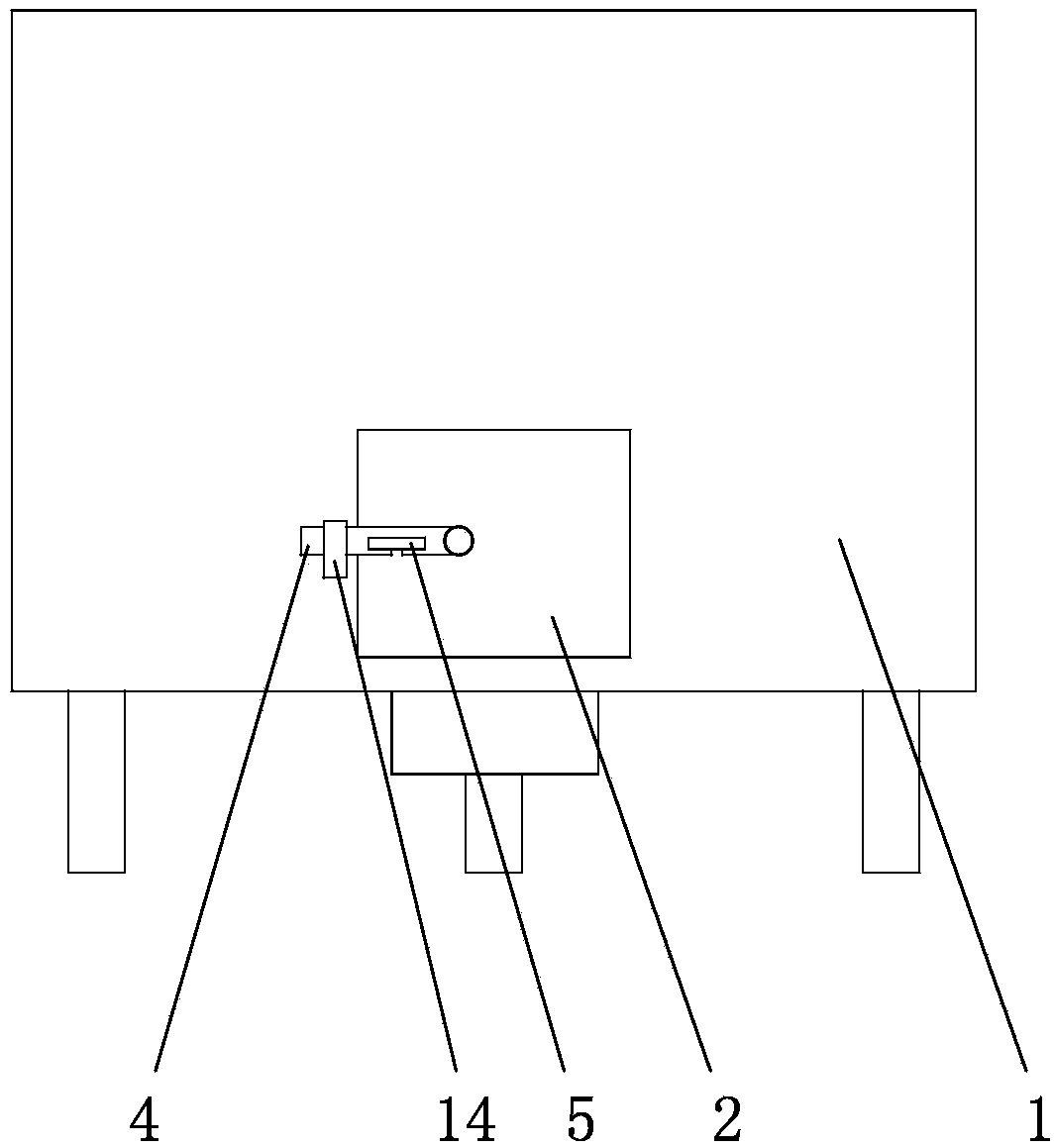

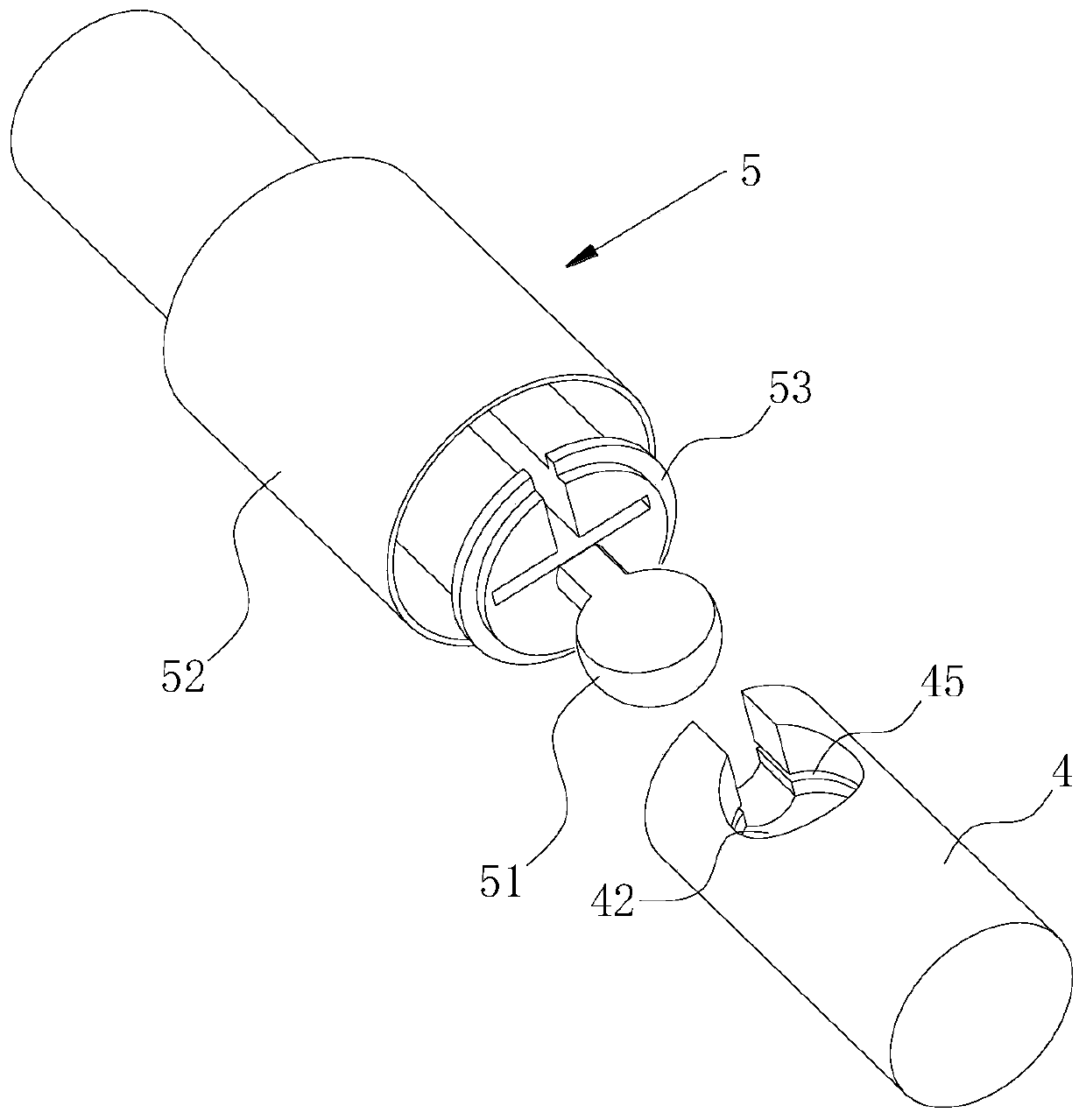

Method for rapidly replacing cutter capacity of numerical control machine tool

ActiveCN114749974AImprove processing efficiencyAvoid launchingPositioning apparatusMetal-working holdersNumerical controlMachine

The invention relates to the technical field of numerical control machine tools, in particular to a numerical control machine tool cutter capacity quick replacement method which comprises the steps that an encoder accurately positions each cutter on a cutter bin and a mechanical arm; a target tool needing to be replaced is determined in the tool bin; a servo motor arranged on the tool bin is controlled to drive a mechanical arm to the target tool, and the mechanical arm grabs the target tool and rapidly pushes the target tool to the position below a tool distribution area of the main shaft; and the main shaft replaces the cutter with the target cutter, and the replaced cutter is sent back to the cutter bin through the mechanical arm. The tool bin with the capacity larger than that of a traditional tool is adopted to contain more tools, and the requirements for technology upgrading and machining procedure increasing are met; a target cutter needing to be replaced is conveyed in a manipulator rapid pushing mode, the whole cutter bin is prevented from being pushed out, the cutter replacing speed and flexibility are improved, and the cutter replacing efficiency is improved; the machining efficiency of the numerical control machine tool can be improved, and the product machining capacity can be expanded.

Owner:东莞市炜度创新精密设备有限公司

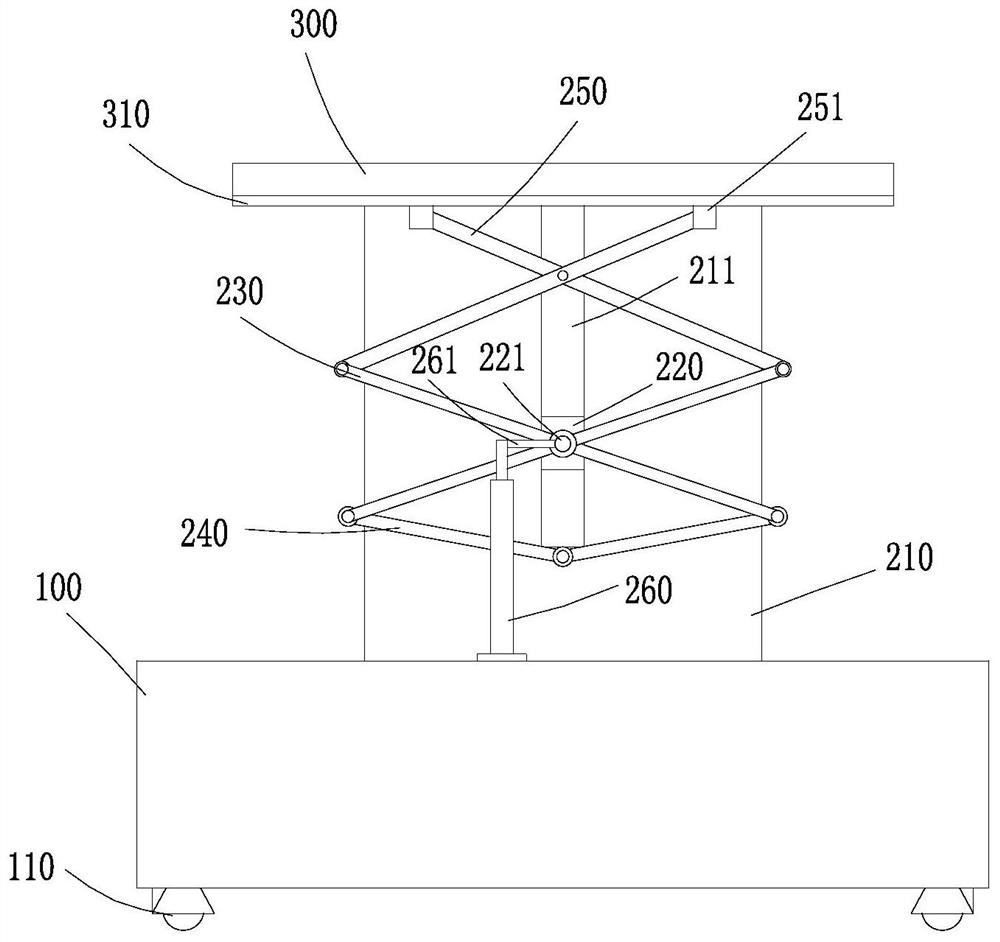

Adjustable power transmission cable installation device

PendingCN113555819AAvoid damagePlay the role of buffer protectionLifting framesApparatus for overhead lines/cablesStructural engineeringMechanical engineering

The invention discloses an adjustable power transmission cable mounting device, and the device comprises a supporting seat, wherein a moving wheel set is mounted at the bottom of the supporting seat, and the moving wheel set is a universal wheel; a movable plate which is arranged above the supporting seat, wherein the movable plate is provided with a clamping mechanism used for placing and clamping a cable, the clamping mechanism comprises a fixed plate arranged at the upper end of the movable plate, the upper end of the fixed plate is provided with an arc-shaped groove, one end of the arc-shaped groove is a threading opening, the other end of the arc-shaped groove is a cable outlet, the cable enters the arc-shaped groove from the threading opening and penetrates out of the cable outlet, the arc-shaped groove is provided with a cover plate on the upper side of the threading port, and the lower side of the cover plate is provided with an abutting block which abuts against the upper outer side face of the cable; and a lifting mechanism which is arranged in the middle of the upper end of the supporting seat and used for driving the movable plate to rise. The outer side face of the cable is tightly abutted, so that the cable is clamped on the movable plate to be kept stable, the lifting mechanism drives the movable plate to rise, and the cable is conveyed to the specific height position where the cable needs to be installed.

Owner:安徽永汇新材料科技有限公司

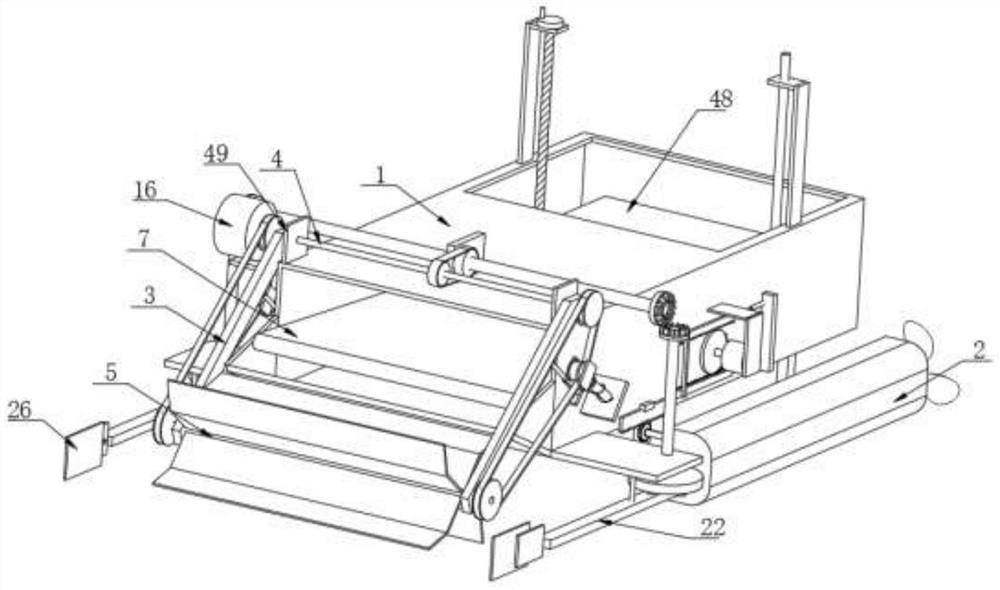

Movable spilled oil recovery ship for recovering marine oil floating objects

ActiveCN114319278AEasy to collect and salvageAvoid launchingWater cleaningWaterborne vesselsMarine engineeringPetroleum engineering

The invention provides a movable spilled oil recovery ship for recovering marine oil floating objects, and relates to the technical field of spilled oil recovery ships. The movable spilled oil recovery ship comprises a recovery ship body, driving devices are fixed to the two sides of the recovery ship body correspondingly, a collecting frame is arranged in the recovery ship body, a first rotating rod is arranged at the top of the recovery ship body, mounting plates are arranged at the two ends of the first rotating rod correspondingly, and the mounting plates are fixedly connected with the recovery ship body; according to the movable spilled oil recycling ship for recycling the marine oil floating objects, a first belt wheel is fixedly connected to the outer side of a first rotating rod, a second belt wheel and a third belt wheel are fixedly connected to the outer side of a salvage roller, and the first belt wheel, the salvage roller and the third belt wheel are in transmission through a belt, so that the salvage roller rotates; when the salvage roller rotates to throw garbage on the sea surface, the garbage on the outer side of the salvage roller is thrown into the recovery ship through centrifugal rotation, and the garbage is conveniently collected and salvaged.

Owner:青岛海洋工程水下设备检测有限公司

Automatic fruit picker

InactiveCN105432236APicking achievedImprove the efficiency of fruit pickingPicking devicesFruit treeEngineering

The invention relates to an automatic fruit picker which comprises a rack, a sleeve and two opposite clamping jaws. The top ends of the inner walls of the two clamping jaws protrude oppositely to form cutters. An arc-shaped holding end is arranged at the portion, close to the corresponding cutter, of the inner wall of each clamping jaw. A groove allowing the two clamping jaws to be inserted is formed in the top of the sleeve. The outer walls of the clamping jaws abut against the wall of the groove. A push plate is arranged in the sleeve in a sliding fit mode. A feed cylinder is in sliding connection with the push plate. A feed port of the feed cylinder is opposite to the groove. A spring is connected between the inner walls of the two clamping jaws. The bottom ends of the clamping jaws are hinged to the push plate. The automatic fruit picker further comprises connecting rods. Through grooves are formed in the bottom face of the sleeve. One ends of the connecting rods penetrate through the through grooves and are hinged to the push plate. The other ends of the connecting rods are hinged to cranks. The cranks are hinged to the rack. A fruit collecting bag is arranged under the feed cylinder. Compared with the prior art, a motor is used for driving the crank connecting rods to move, fruit in fruit trees can be picked automatically, and picking efficiency is improved.

Owner:CHONGQING PINGWEI CHAOYANG AGRI DEV CO LTD

Milling device of refractory mortar

InactiveCN104028354APrevent fallingAvoid launchingGrain treatmentsElectric machineryMaterials science

The invention relates to a milling device of refractory mortar, belongs to the field of refractory mortar crushing equipment, and prevents the dropping of the refractory mortar from a material port opened carelessly. In order to solve the problem, the invention adopts the following technical scheme: the milling device of the refractory mortar comprises a milling barrel, and a motor arranged on the milling barrel, wherein a milling groove is formed in the milling barrel; the material port is formed in the side wall of the milling groove; the milling barrel is provided with a baffle plate component corresponding to the material port; the baffle plate component comprises an outer baffle plate, an inner baffle plate and a rotating shaft; the inner baffle plate is provided with a rotating handle, and a rotating disc connected with the rotating handle; the rotating handle penetrates through the outer baffle plate to be clamped in a neck; a locking piece is arranged on the rotating disc; the side wall of the material port is provided with a locking groove fitted with the locking piece; a switch piece connected with the motor is arranged on the wall of the locking groove; and the locking piece controls the conduction or disconnection of a circuit of the motor through the switch piece.

Owner:浙江立鑫高温耐火材料有限公司

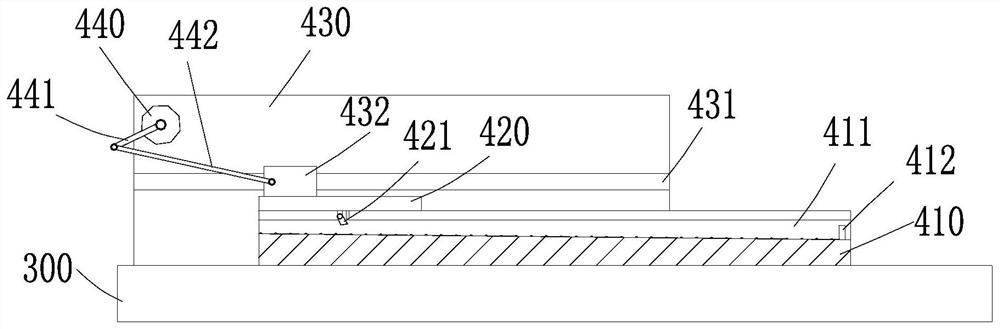

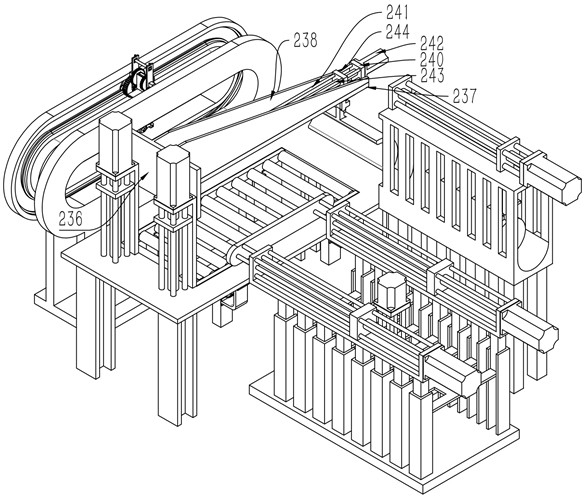

Bundling device for waterproof roll

ActiveCN112061469AReduce work intensityImprove bundling efficiencyBundling machine detailsAdhesive beltEngineering

The invention discloses a bundling device for a waterproof roll. The device comprises a forward pushing unit, a conveying unit, a backward pushing unit, a bundling unit and the like, wherein the conveying unit comprises a conveying fixing component arranged at one end of a forward pushing supporting component, the conveying fixing component is provided with a conveying lifting component, and a pressing component is arranged at one end of the conveying fixing component; the backward pushing unit comprises a backward pushing component and is used for lifting movement of the backward pushing component, and the backward pushing component is used for pushing one end of the waterproof roll located on the conveying unit; and the bundling unit comprises a guide component arranged on the other sideof the conveying unit, the guide component is provided with a driving component, and the driving assembly is used for driving the limiting component to move along the track of the guide component inorder to wind a waterproof roll bundling adhesive tape around the outer side of the waterproof roll. The bundling device is convenient for bundling operation of a plurality of waterproof rolls, the working intensity of operators is reduced, the conveying efficiency of the waterproof rolls is improved, the subsequent transportation of the waterproof rolls is facilitated, the cost investment of enterprises is reduced, and the practicability is higher.

Owner:北新防水(四川)有限公司

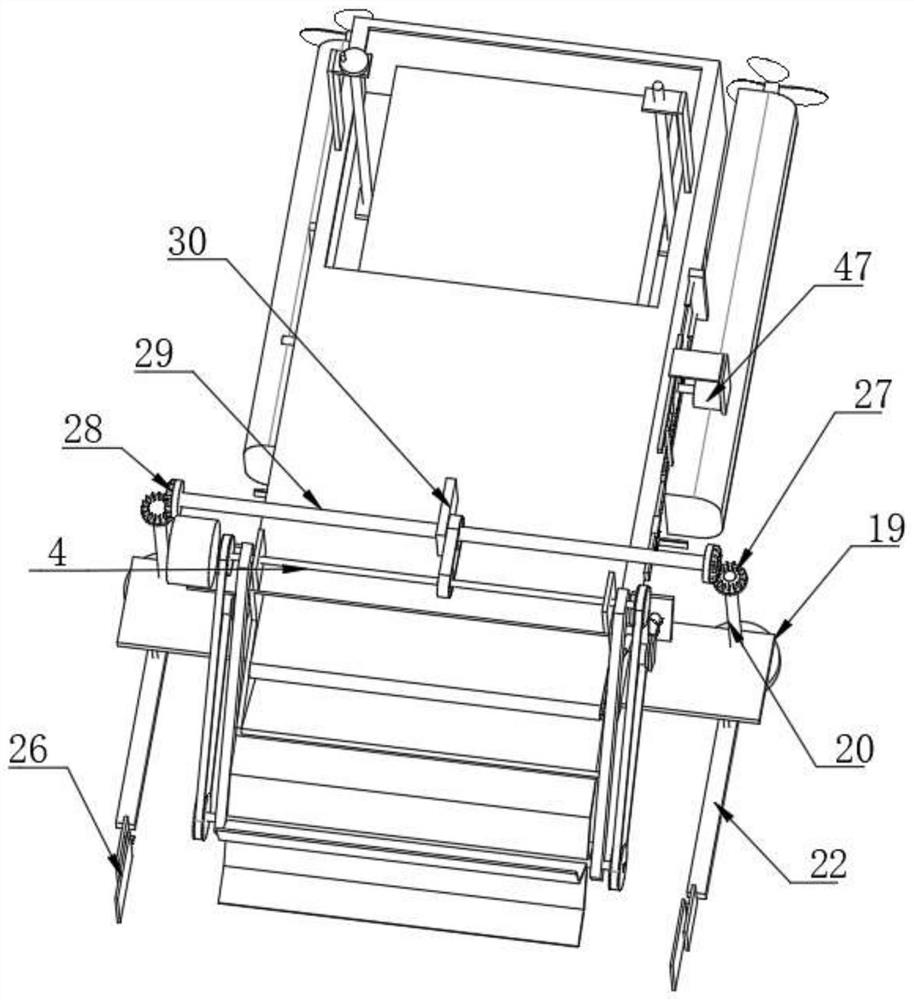

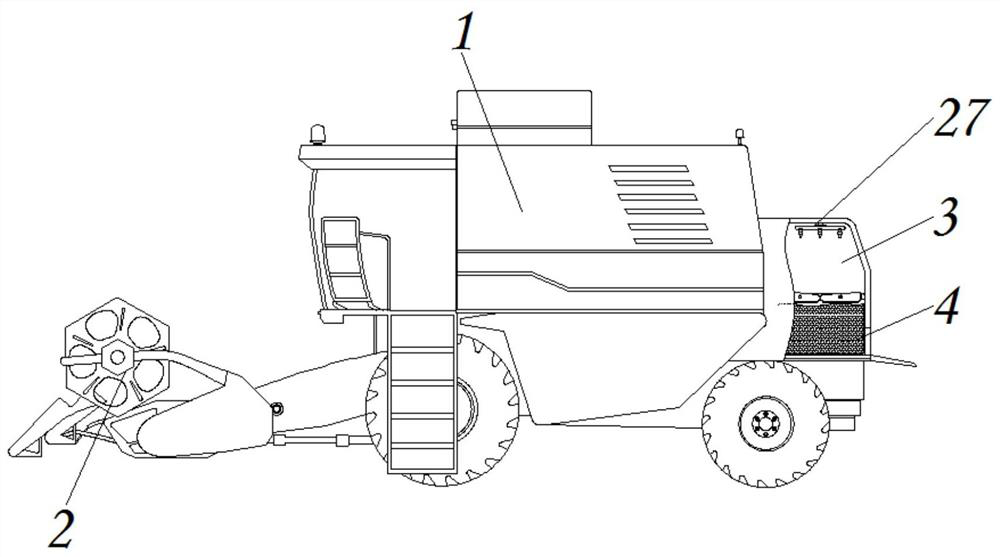

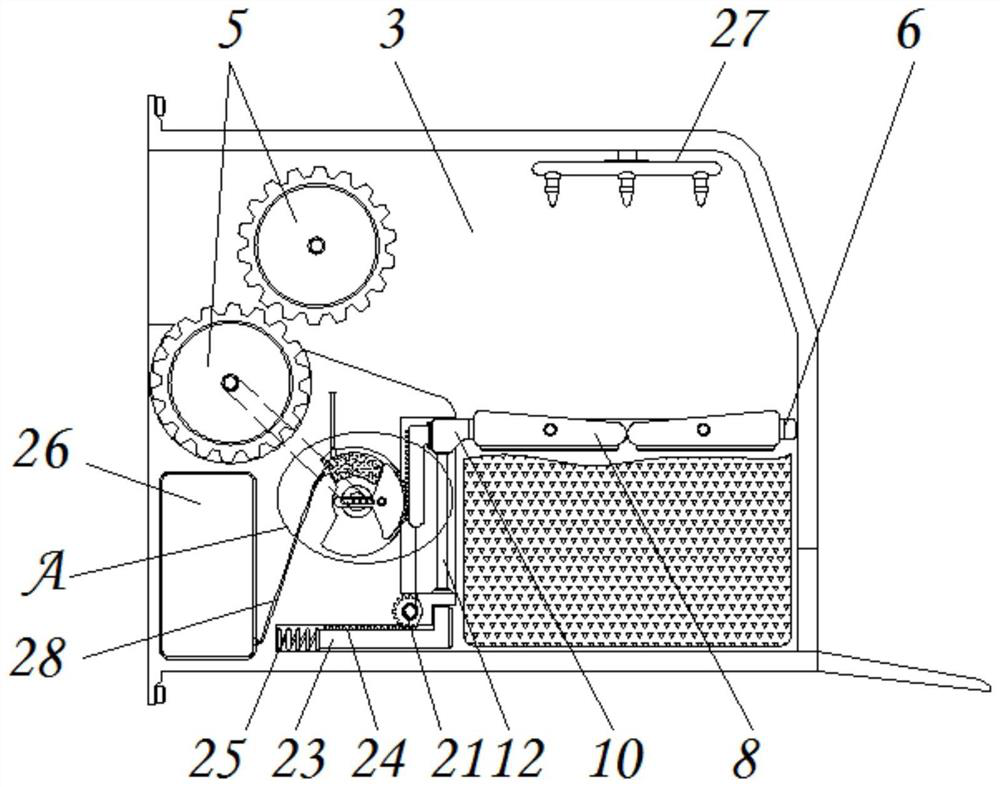

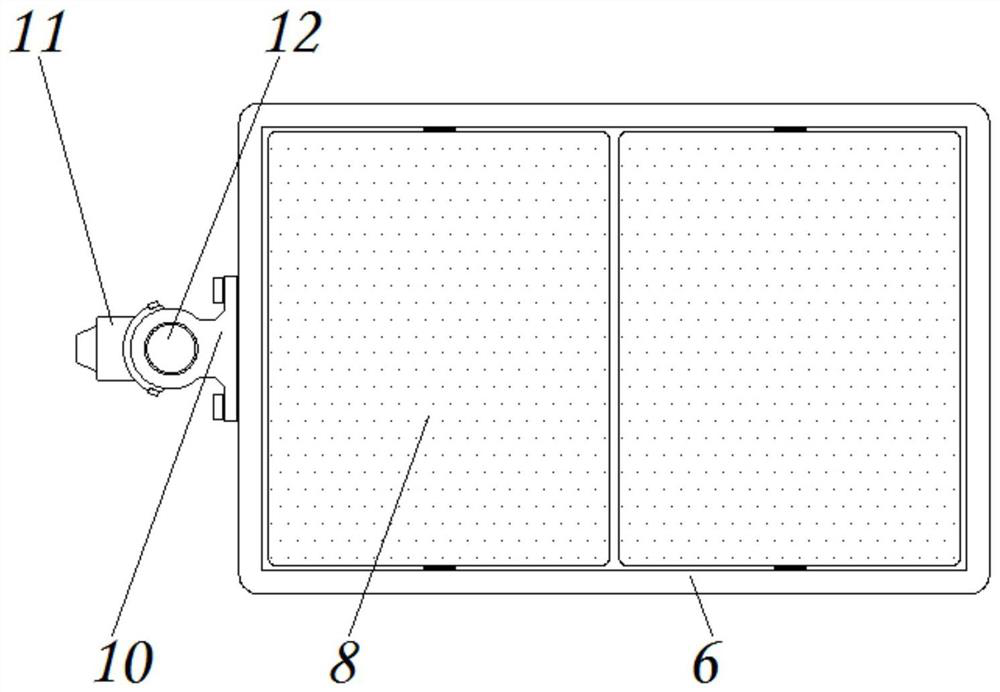

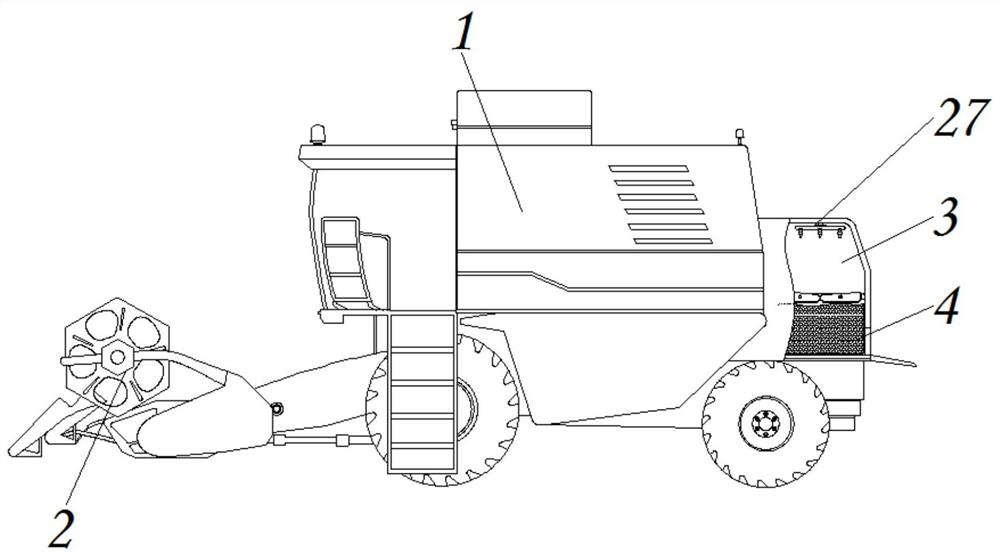

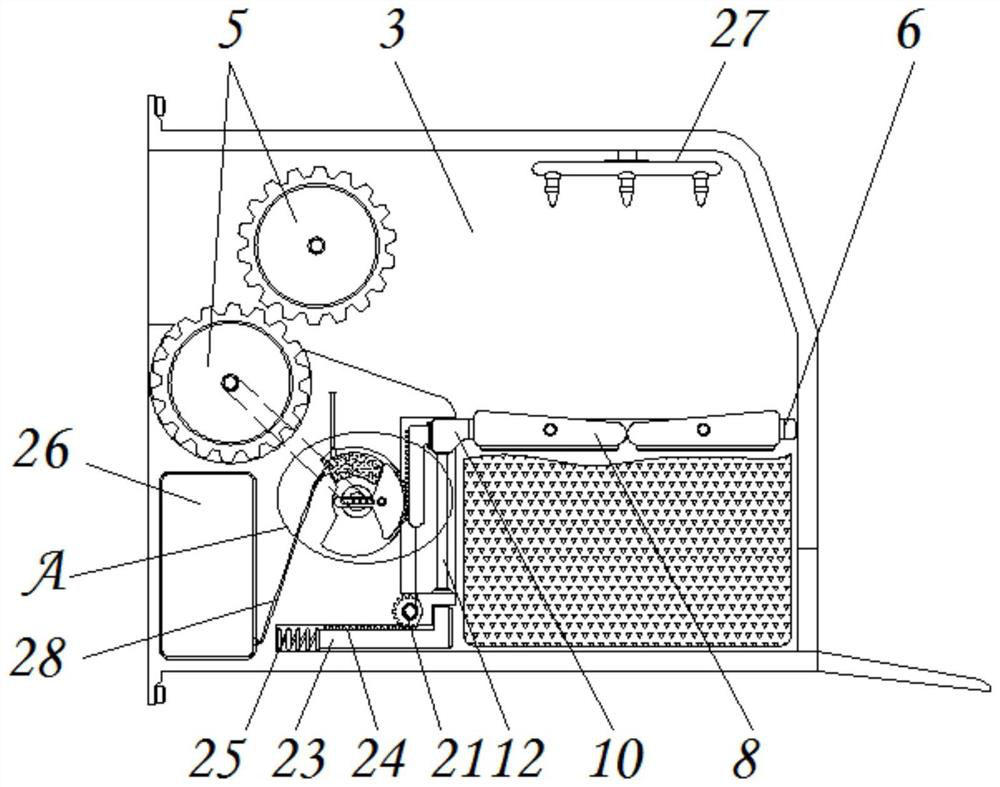

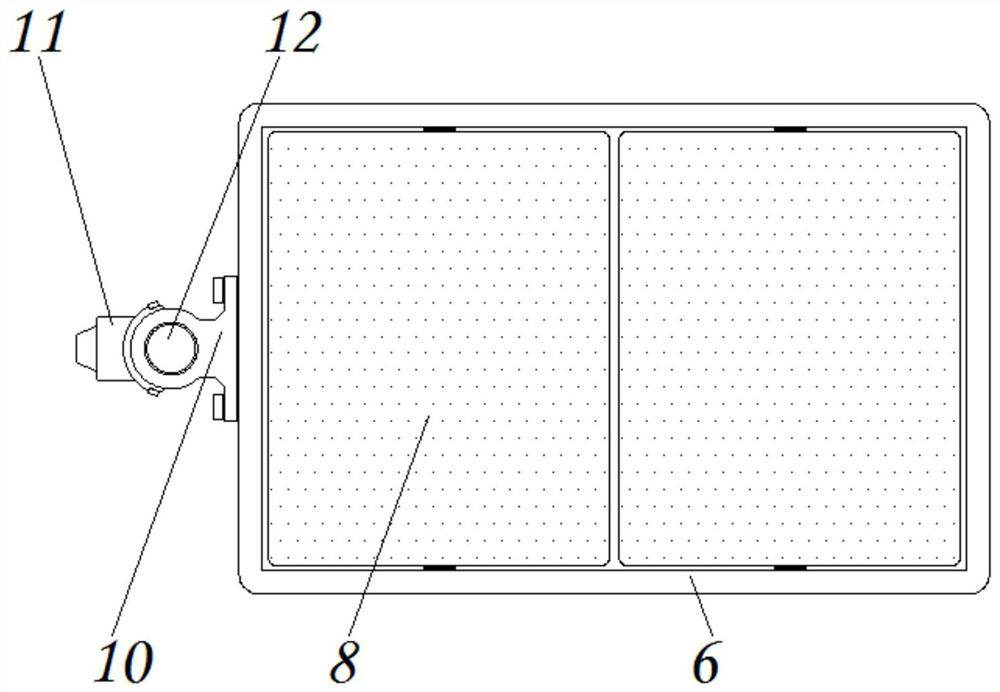

Straw harvester with compression mechanism for agricultural machinery

ActiveCN112913457ASave spaceEasy to collectUsing liquid separation agentMowersAgricultural scienceGear wheel

The invention discloses a straw harvester with a compression mechanism for agricultural machinery. The straw harvester comprises a harvester body, a compression cabin, breaking rollers, extrusion plates, a linkage block, a water bag and a pushing rod, wherein the outer side of the harvester body is provided with a cutting table; the inner side of an extrusion cabin is provided with a movable frame; the inner side of the movable frame is connected with the extrusion plates through a shaft rod; the side surface of a fixing block is fixedly provided with a rack; a guiding column is arranged in the compression cabin; the inner side of the compression cabin is in shaft connection with a fan-shaped gear; the pushing rod is arranged below the fan-shaped gear; the inner side of the compression cabin is provided with a water tank; and one side, which is near the extrusion cabin, of the inner side of the compression cabin is provided with a shower nozzle. The straw harvester with the compression mechanism for the agricultural machinery can break and compress harvested straws, a straw placement space can be effectively reduced so as to be convenient to subsequently collect the straws, meanwhile, in a utilization process, automatic dust fall can be carried out, and practicality is high.

Owner:李明刚

Exhaust pipe machining device

The invention belongs to the field of automobile part machining, and particularly discloses an exhaust pipe machining device. The device comprises a machine frame, wherein a workbench is arranged on the machine frame, a placing groove is formed in the upper surface of the workbench, and the bottom of the containing groove is arc-shaped; bent parts are symmetrically arranged on the two sides of thecontaining groove in the machine frame, the bending parts comprise sliding grooves arranged on the machine frame, the sliding grooves comprise horizontal sections and arc sections, and through holesare formed in the arc section; bending rods are slidably connected in the sliding grooves, the bending rods comprise flexible sections and rigid sections, storage cavities are formed in the flexible sections, and hydrochloric acid and sodium carbonate are correspondingly arranged in the storage cavities of the two flexible sections; discharging openings are formed in the flexible section; the lower pressing unit comprises a first gear and a second gear, the first gear is rotationally connected to the machine frame, and the second gear is meshed with the first gear; and the lower pressing unitfurther comprises a first rack and a second rack which are connected to the machine frame in a sliding mode, and stamping heads are arranged at the lower ends of the first rack and the second rack. Bythe adoption of the scheme of the exhaust pipe machining device, the problem that cross section shape distortion is easily caused when the exhaust pipe is bent is solved.

Owner:宁波高新区新柯保汽车科技有限公司

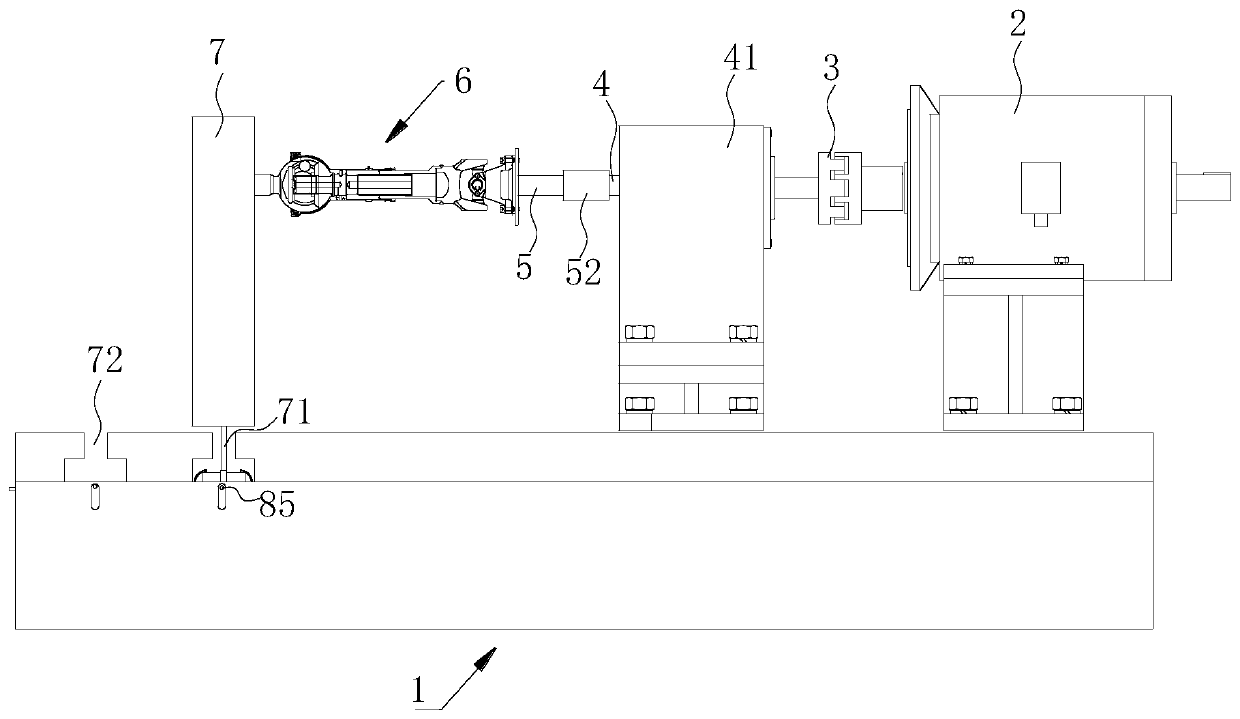

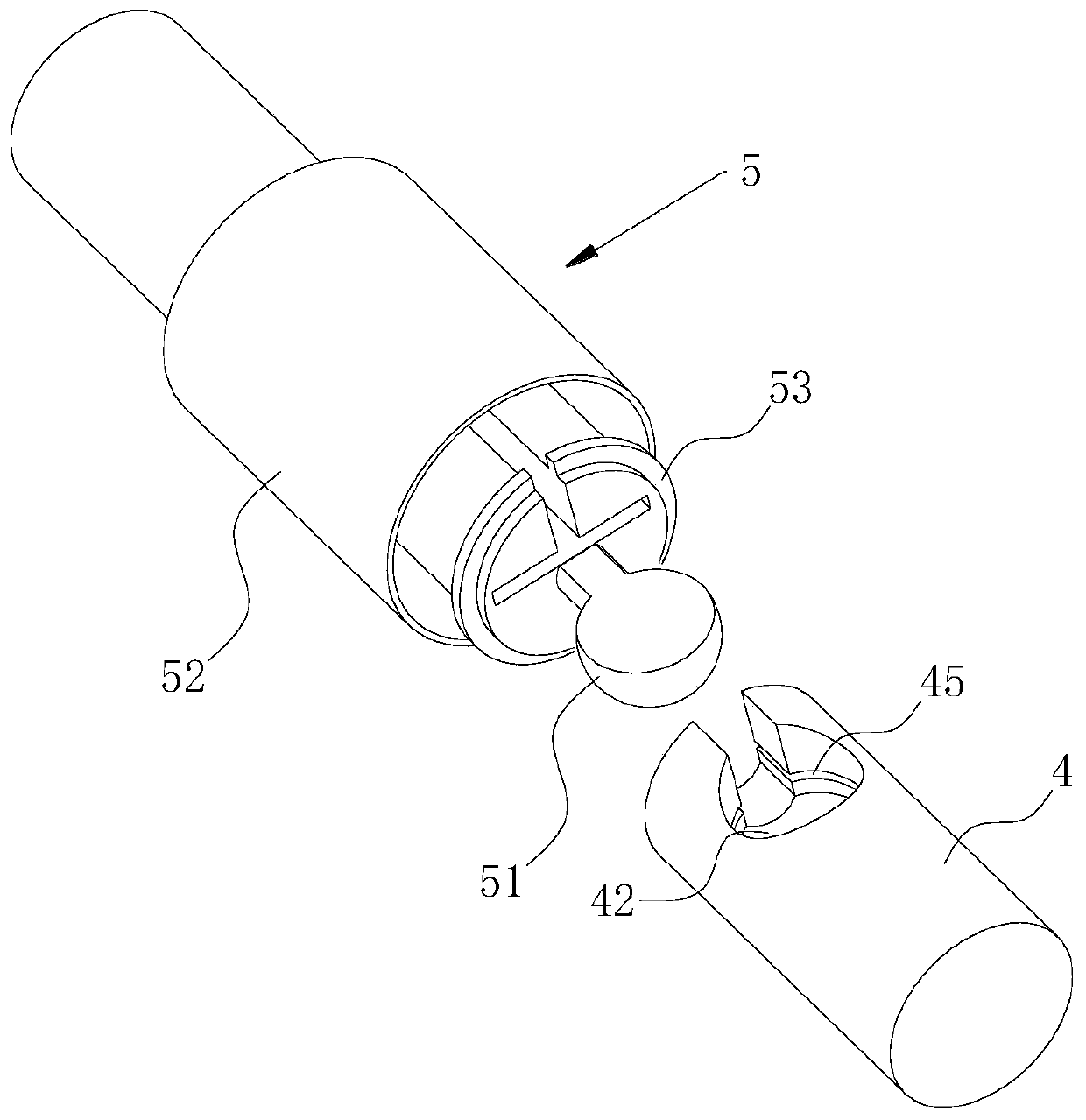

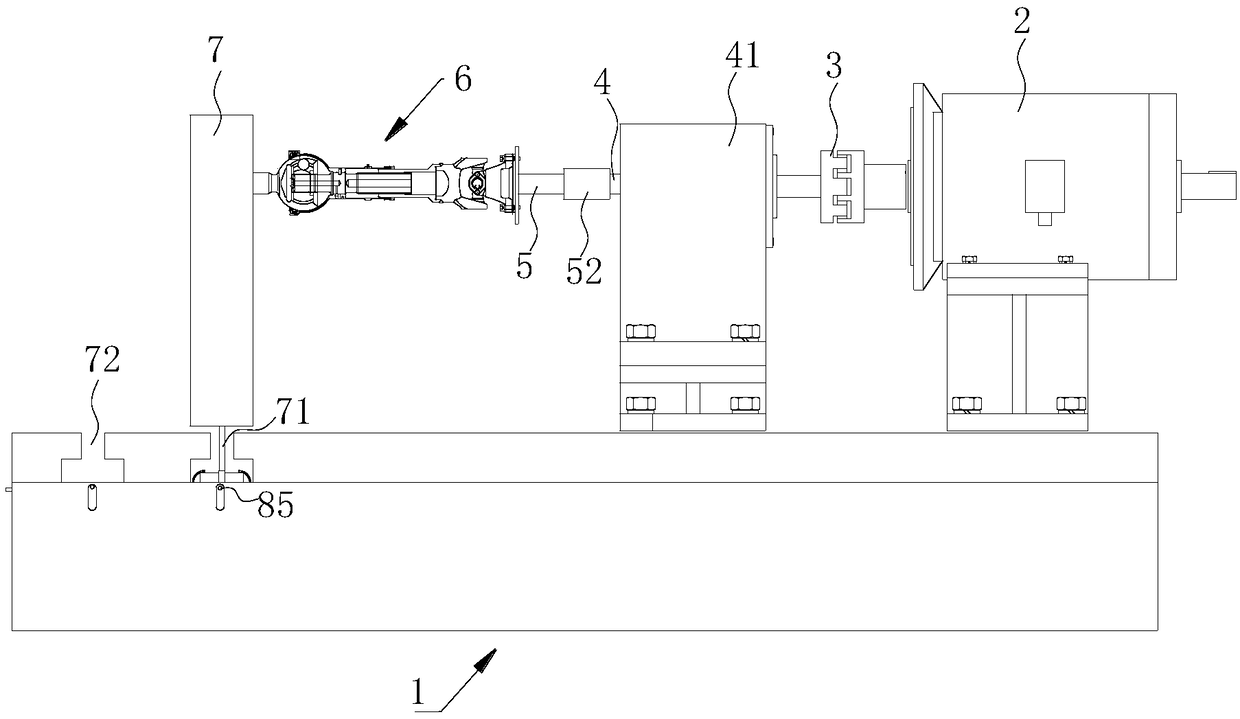

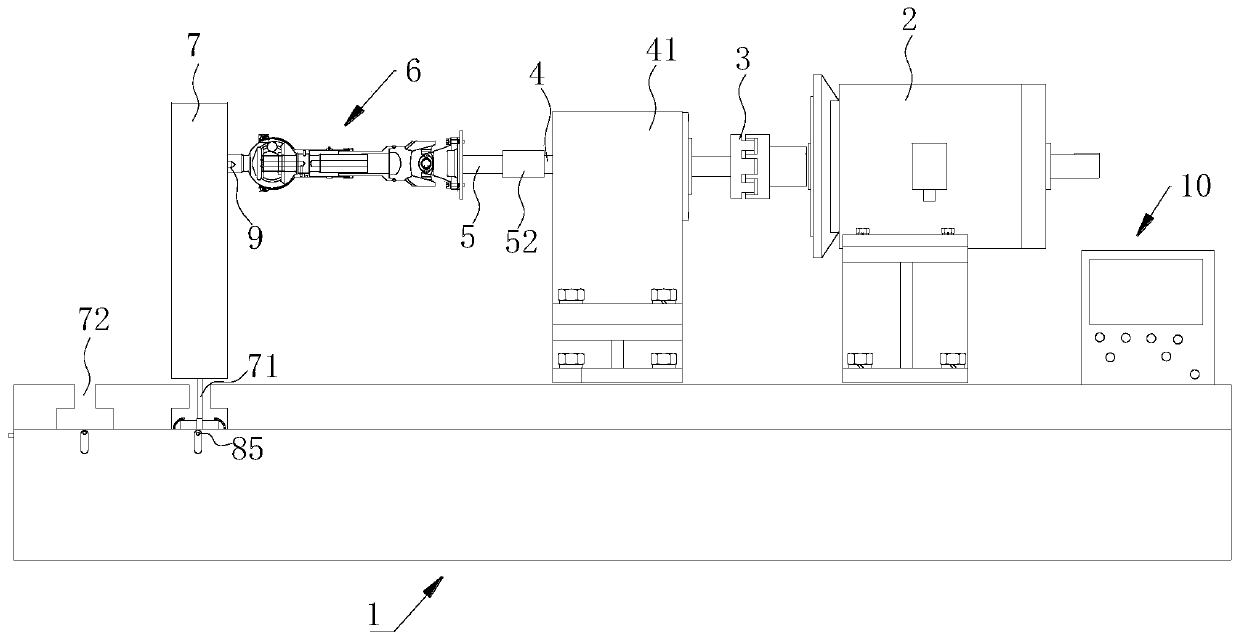

A coupling no-load running-in equipment

The invention relates to zero-load run-in equipment of a shaft coupling, belongs to the technical field of bearing processing, and the equipment can be used to effectively reduce vibration of a detection motor when the detection motor drives the shaft coupling to rotate and prevent the detection motor from damage. The equipment is characterized by comprising the detection motor, the shaft couplingto be tested is positioned in the output end of the detection motor, one end of the shaft coupling to be tested is connected with the output end of the detection motor via a universal drive shaft, the other end of the shaft coupling to be tested is rotationally connected with a tail fixed plate, the universal drive shaft is connected with the shaft coupling to be tested via a connecting shaft, the connecting shaft is rotationally arranged in a shoe plate, and the connecting shaft is arranged coaxial with an output shaft of the detection motor and can rotate along the axial direction of the connecting shaft itself. During detection, the shaft coupling to be tested vibrates, the vibration is transferred to the connecting shaft and weakened for the first time, and then transmitted to universal drive shaft and weakened again, and vibration transmitted to the detection motor finally is very low, and the detection motor is protected to largest extent.

Owner:XIANGYANG YUQING TRANSMISSION TECH

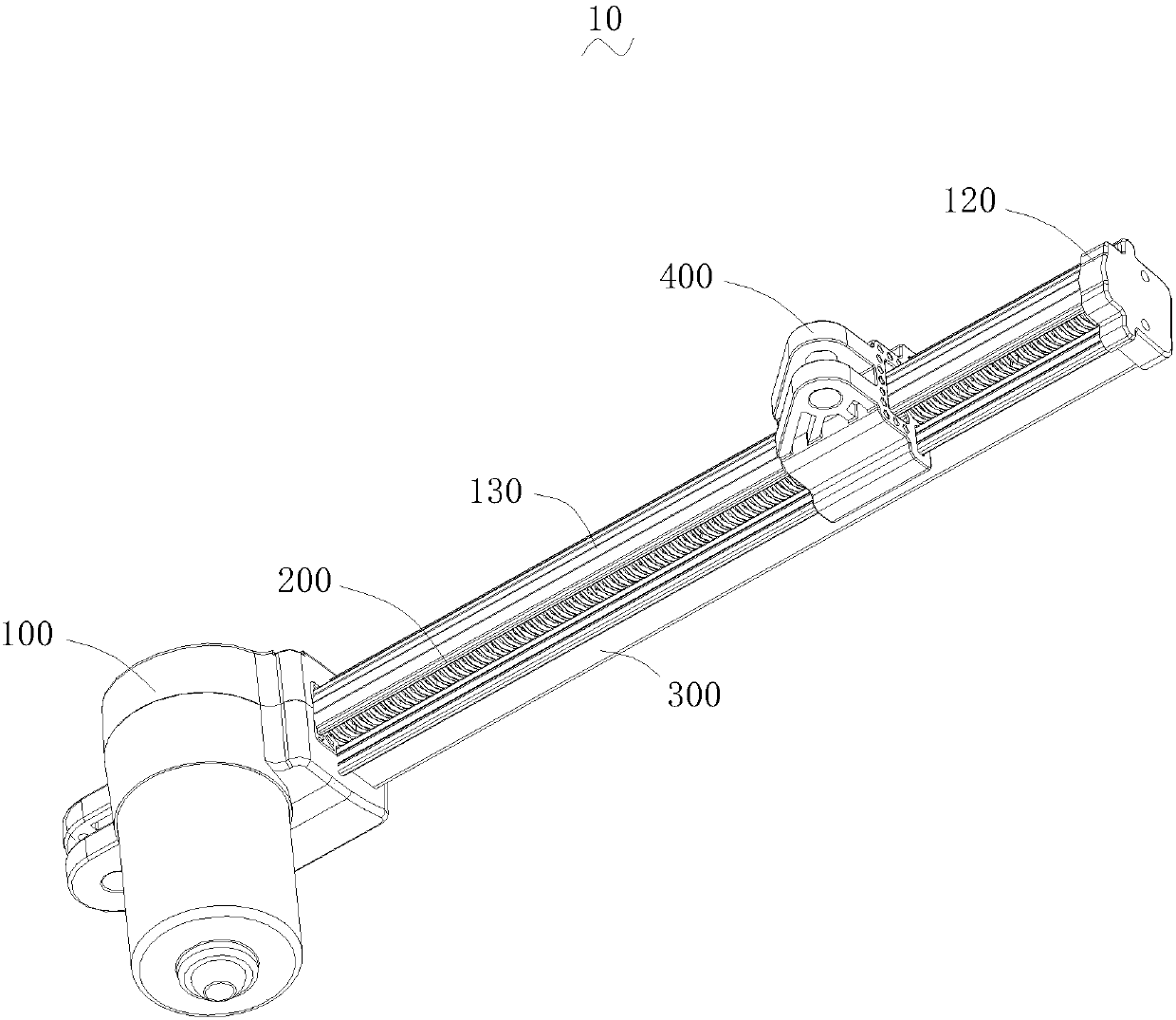

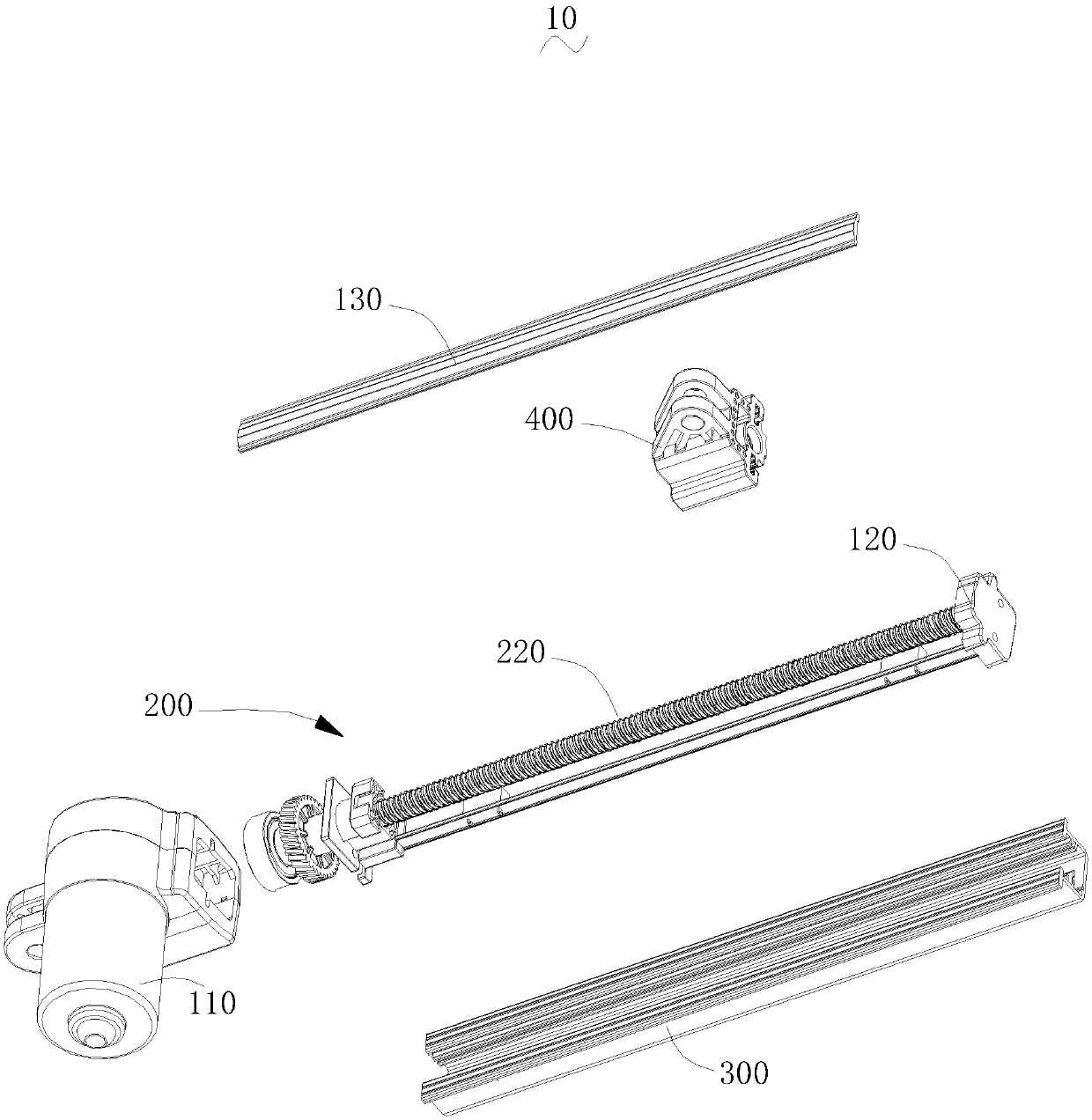

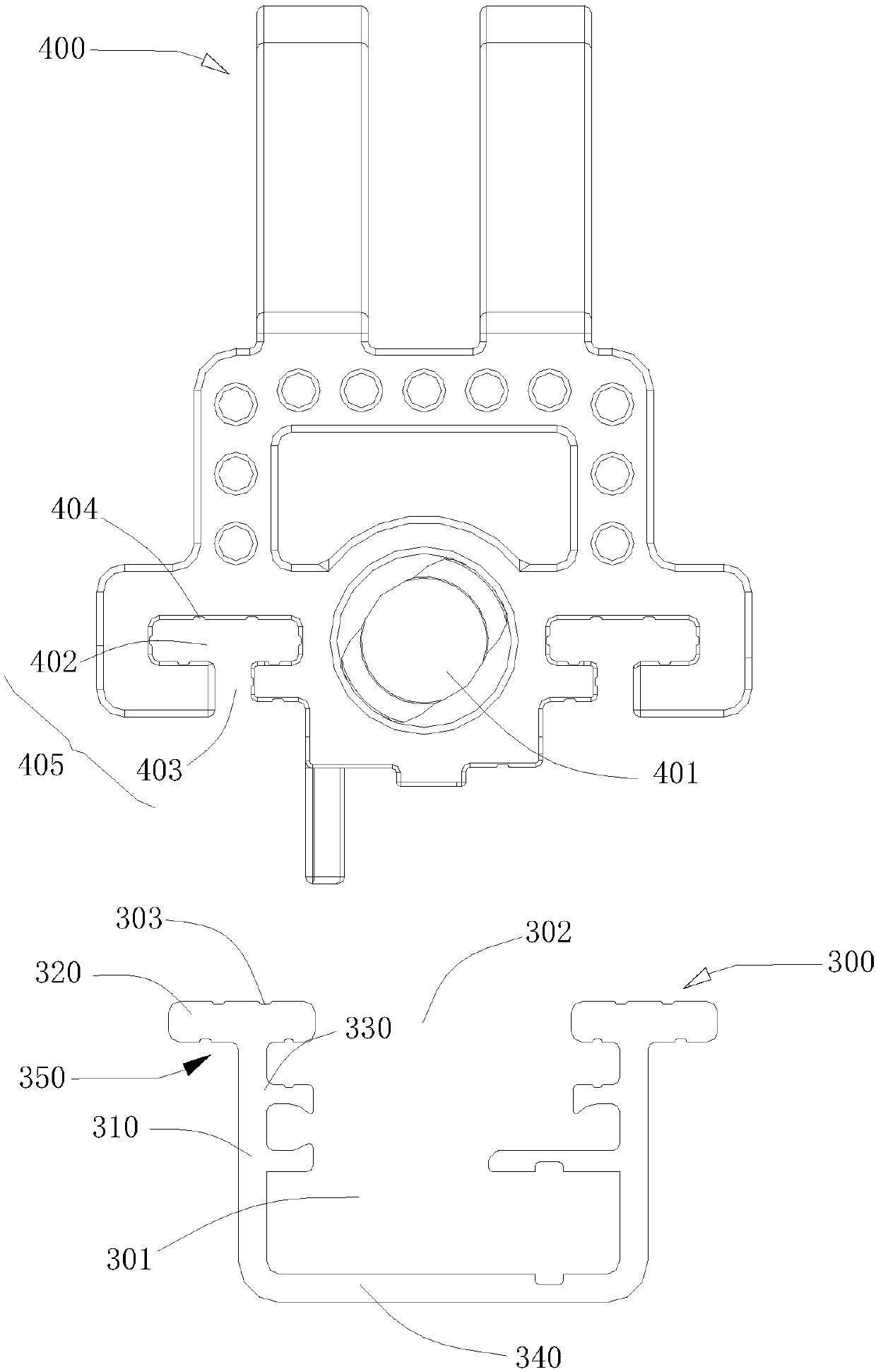

Guide rail, sliding block and driving device

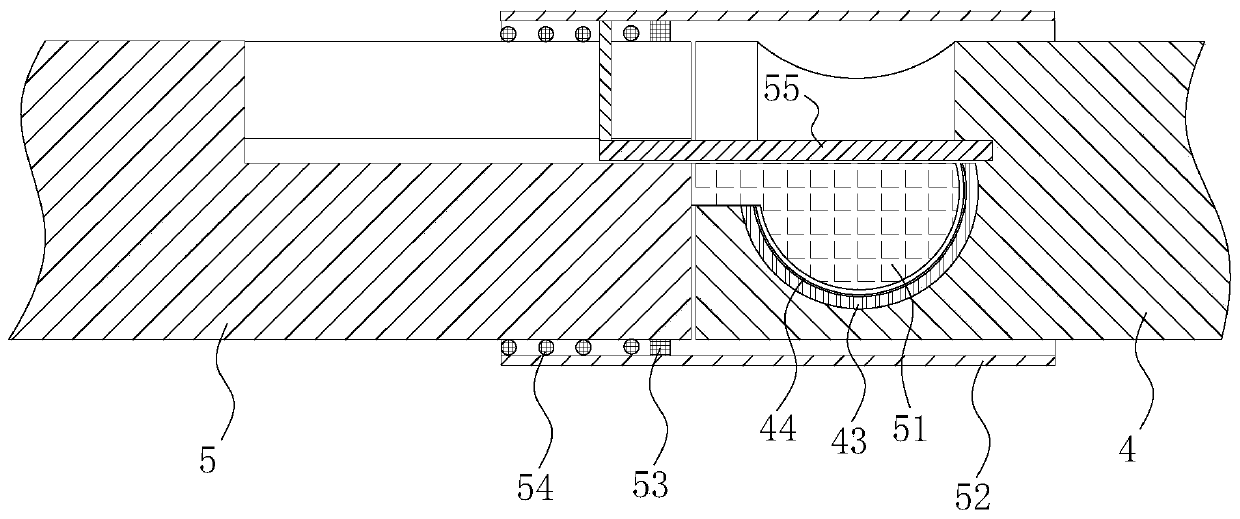

PendingCN107664190ALow sliding resistanceAvoid launchingGearingGear lubrication/coolingEngineeringLubrication

The invention relates to a guide rail, a sliding block and a driving device. The driving device comprises a motor assembly, a worm assembly, the guide rail and the sliding block; the motor assembly isin driving connection with the worm assembly; the guide rail is connected with the motor assembly; a screw joint hole is formed in the middle of the sliding block, the outside of the worm assembly ismovably sleeved with the sliding block by the screw joint hole, and the side wall of the screw joint hole is in screw joint with the worm assembly; the sliding block is arranged on the guide rail, and at least one groove is formed in at least one of the mutual abutting surfaces of the sliding block and the guide rail in the sliding direction of the sliding block. The groove is formed in the guiderail or the sliding block so that the lubricating grease between the guide rail and the sliding block can be accommodated in the groove, the lubricating grease can be prevented from being pushed outof the sliding block by the sliding block, the lubricating grease can provide a lubricating function for the sliding of the sliding block effectively, the sliding resistance of the sliding block is effectively reduced, and the driving efficiency is effectively improved.

Owner:MAN WAH FURNITURE MFG HUIZHOU

Capacitor pin bending and cutting device

ActiveCN113477846AIncrease productivityReduce the chance of being pinchedCapacitor manufactureStructural engineeringCapacitor

The invention discloses a capacitor pin bending and cutting device. The capacitor pin bending and cutting device comprises a workbench and a material table installed on the top face of the workbench, wherein a guide chute is formed in the top face of the material table; a capacitor is arranged in the guide chute; the capacitor is in sliding connection with the material table through the guide chute ; the guide chute is communicated with the side face of one side of the material table; a baffle is fixedly connected to the side face of one side of the material table and located on the side face of the side, communicated with the material table, of the guide chute; a top plate is fixedly connected to the top end face of the baffle; a limiting strip is fixedly connected to the end face of one end of the top plate; a lead of the capacitor extends out of the material table; a conveying mechanism used for conveying the capacitor to the material table and a pushing mechanism used for pushing the capacitor to the limiting strip are installed on the material table; a bending mechanism used for bending a capacitor lead and a cutting-off mechanism used for cutting off the capacitor lead are installed at one end of the material table; and a receiving mechanism used for conveying the processed capacitor away from the material table is installed on the material table. The capacitor pin bending and cutting device has the effect of solving the problem of low equipment safety.

Owner:SHENZHEN SINCERITY TECH

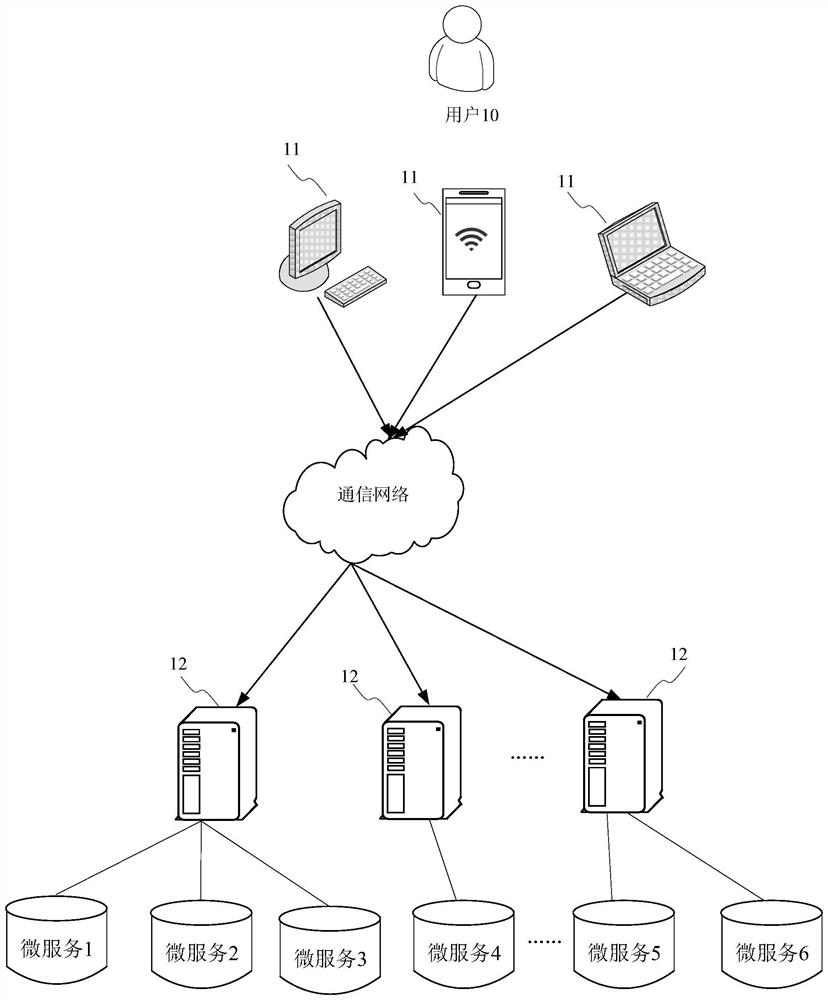

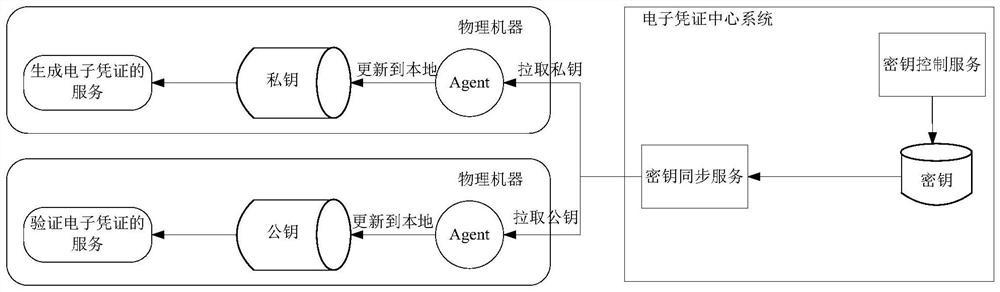

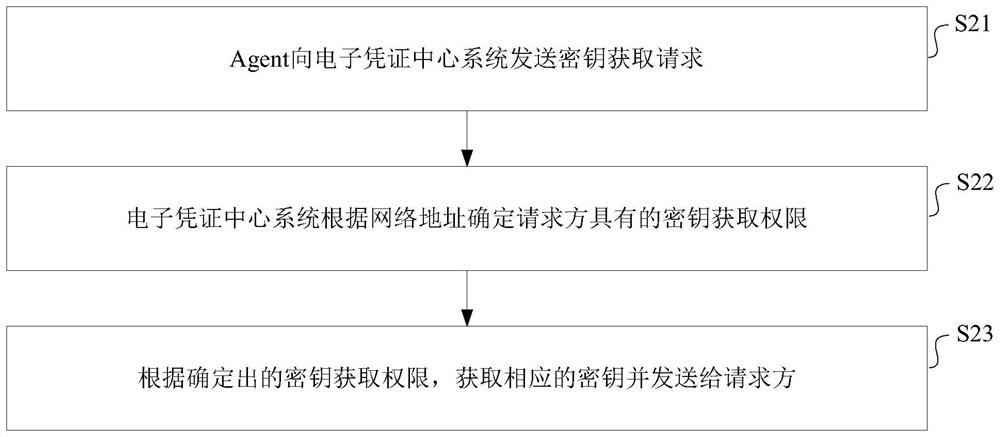

A service authentication method, device and medium

The invention discloses a service authentication method, device and medium, which are used to improve the security of service data processing in a microservice architecture system. The business authentication method includes: receiving a business processing request, the business processing request carrying a first electronic credential and a first authentication factor required for this business processing, and the first electronic credential carrying this At least one second authentication factor required for secondary business processing, the second authentication factor is an authentication factor that has been authenticated; the first authentication factor is authenticated; and the stored public key is used to authenticate the Verify the first electronic certificate, wherein the public key is obtained from the electronic certificate center system; if it is determined that the authentication of the first authentication factor is passed and the verification of the first electronic certificate is passed, it is determined that this business processing Request authentication passed.

Owner:TENCENT TECH (SHENZHEN) CO LTD

Straw harvester with compression mechanism for agricultural machinery

ActiveCN112913457BSave spaceEasy to collectUsing liquid separation agentMowersAgricultural scienceAgricultural engineering

Owner:李明刚

Cash register with printer capable of being rapidly disassembled and assembled

PendingCN111489508AAchieve fixationEliminate the steps of removing and installing screwsCash registersOther printing apparatusComputer printingMechanical engineering

Owner:北京亚博高腾科技有限公司

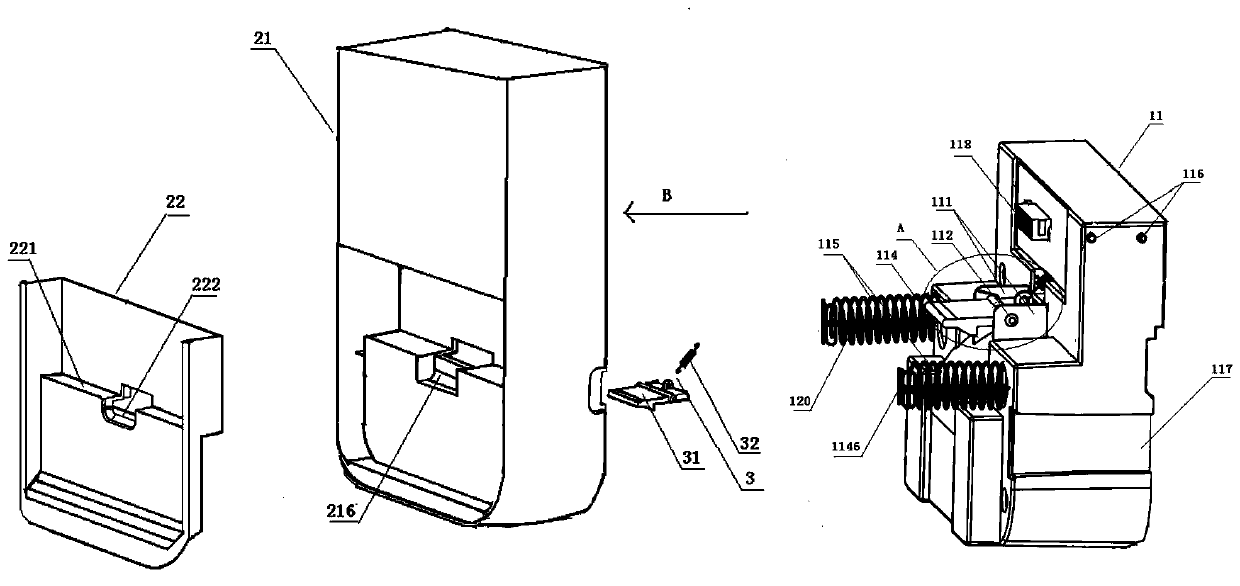

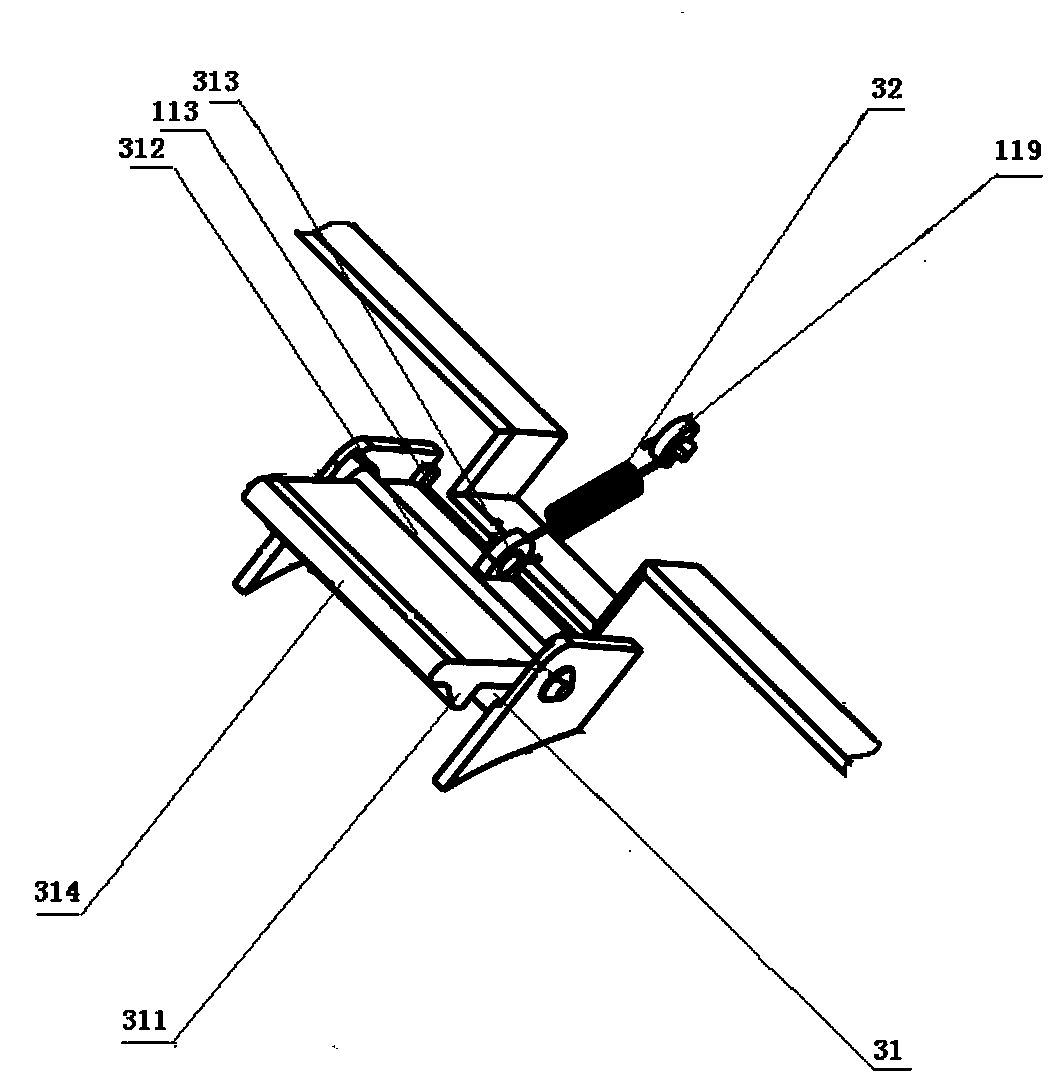

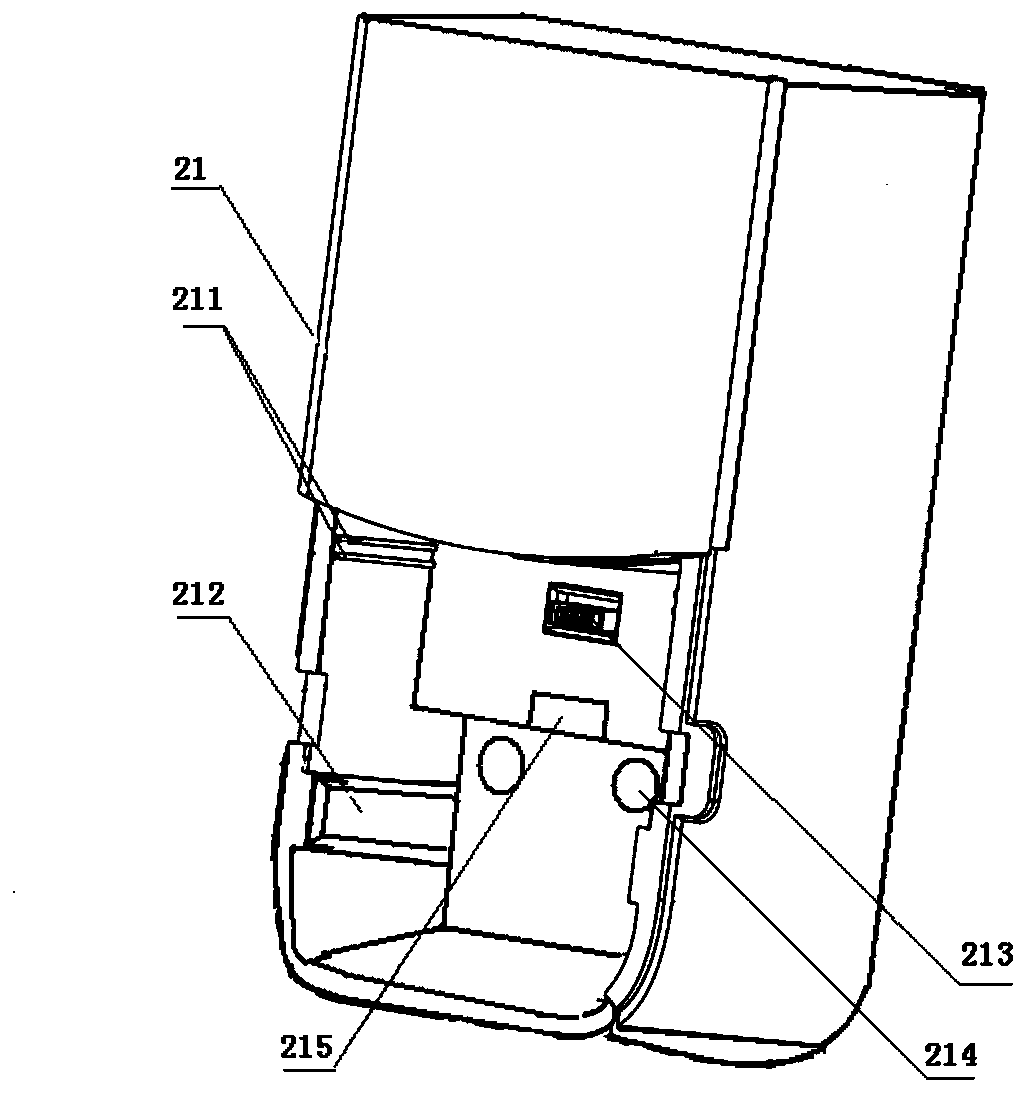

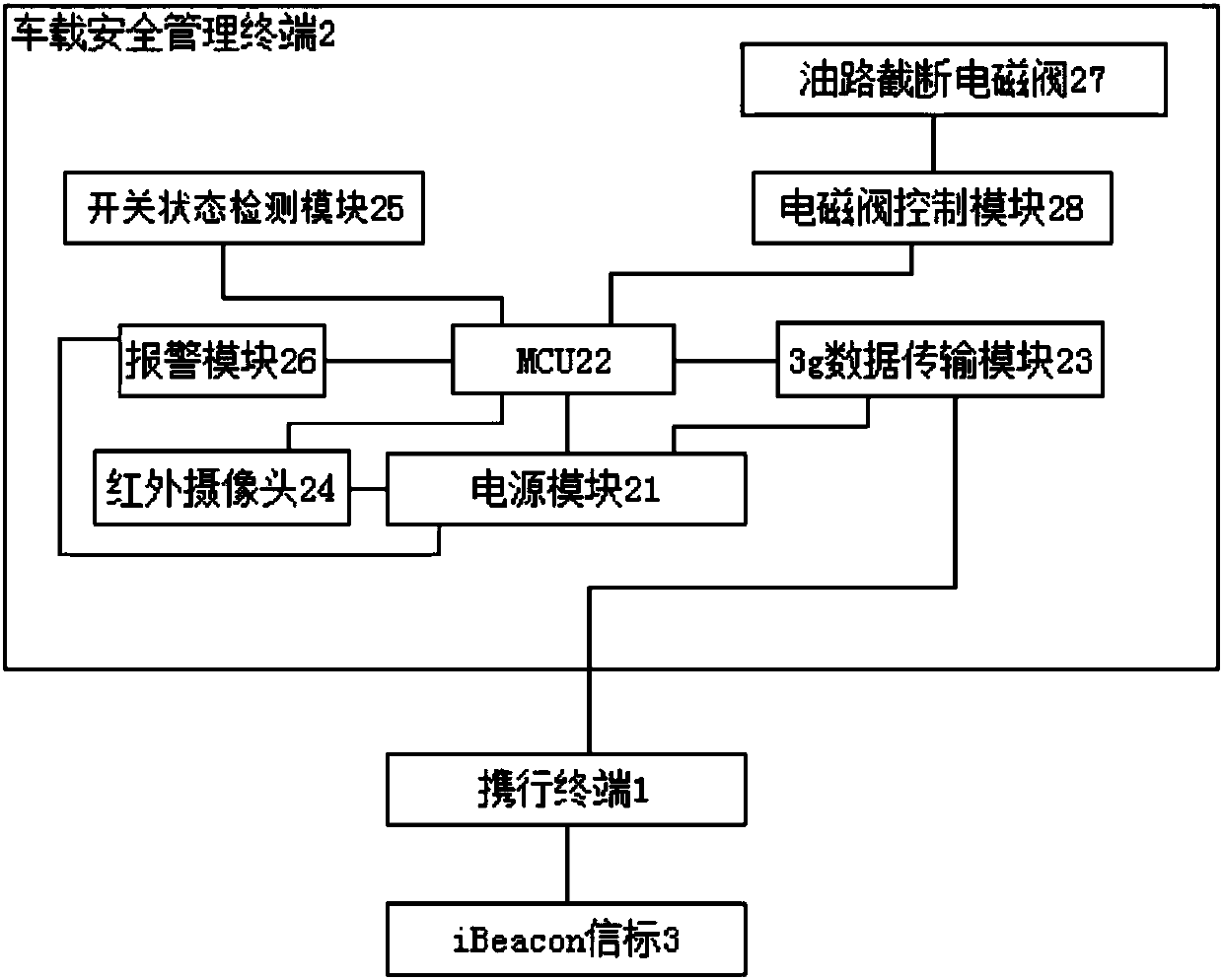

Intelligent automobile safety management system and control method based on iBeacon

The iBeacon-based smart car safety management system and control method are composed of an iBeacon installed in the car, a car safety management terminal and a smart phone as a portable terminal; when the iBeacon is connected to the Bluetooth module, it indicates the relationship between the car and the owner The distance is relatively close and under the control of the car owner. At this time, the vehicle-mounted alarm module is in a dormant state. When the distance between the Bluetooth module of the vehicle-mounted alarm module and the iBeacon exceeds the set value, the vehicle-mounted alarm module is in an alarm state. At this time, the opening of the door touch switch is detected. , it means that the car door has been opened illegally. At this time, the MCU activates the infrared camera and the alarm module, and the alarm module dials the preset phone number to call the police, and uses the infrared camera to take images of illegal entrants and transmits them to the cloud server through the 3G network.

Owner:TIANJIN ENORTH NEW MEDIA GRP CO LTD

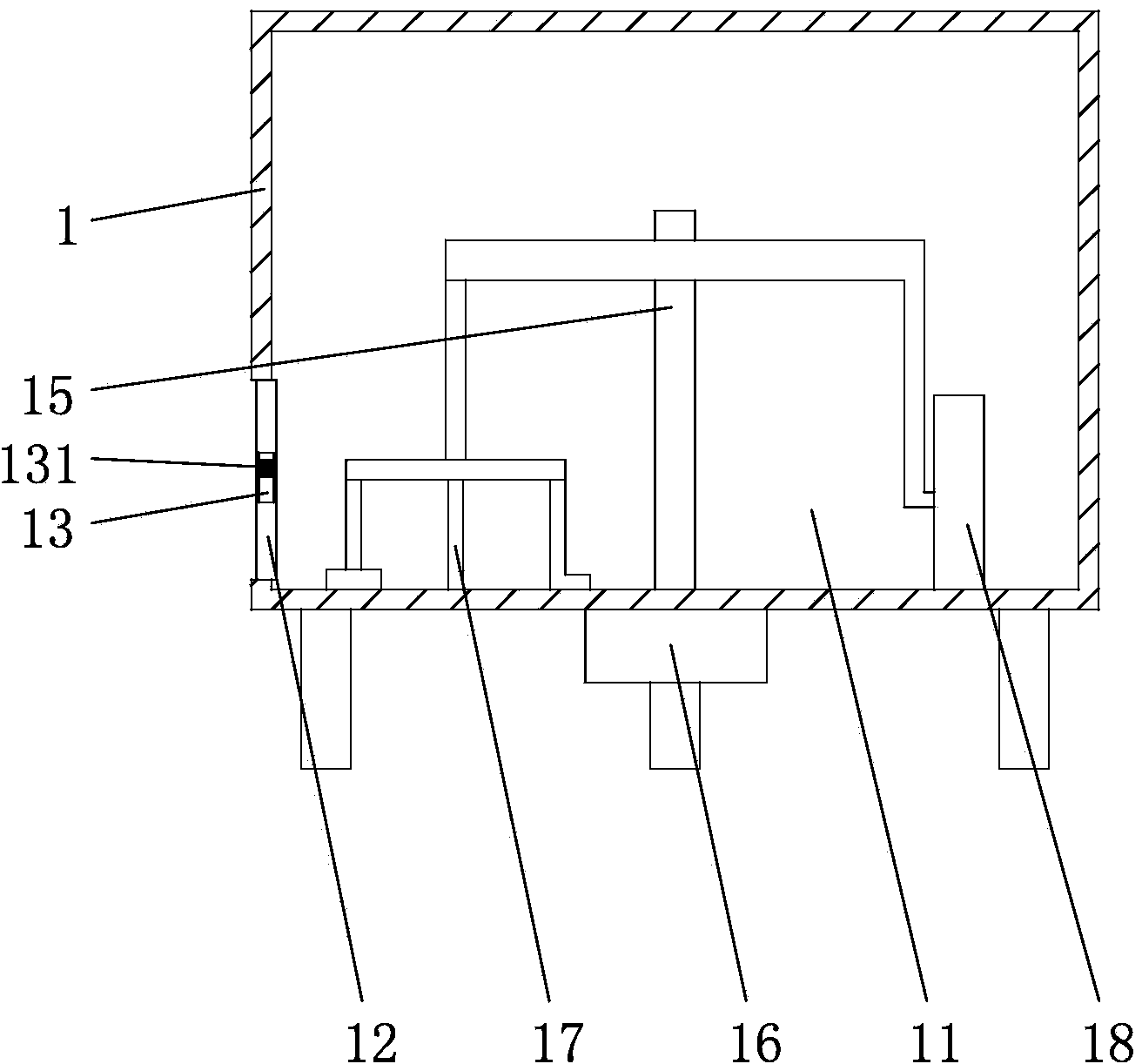

Magnet steel sticking device for permanent magnet motor rotor

PendingCN110417209AInsert automaticallyTo achieve the effect of pushing the push pinManufacturing stator/rotor bodiesEngineeringPermanent magnet motor

The invention belongs to the technical field of motors and particularly relates to a magnet steel sticking device for a permanent magnet motor rotor. The device comprises a device body, an upper end surface of the device body is fixedly connected with an operation table, an operation box is set in the device body, a cylinder is arranged inside the operation box, an output end of the cylinder is equipped with a telescopic rod, an upper end of the telescopic rod is fixedly connected to a cylinder connecting head, an outer side wall of the cylinder connecting head is fixedly connected to a pushing block, an upper end surface of the pushing block is fixedly connected to a pushing pin fixing block, an upper end surface of the pushing pin fixing block is provided with a core groove, and the upper end surface of the pushing pin fixing block is fixedly connected to a plurality of pushing pins matched with magnetic steel holes. Magnetic steels are pushed to a lower side of an upper guide blockthrough magnetic steel grooves, then the cylinder is operated to drive the telescopic rod to move upwards, thus, the pushing pin fixing block and the pushing pins are driven to move upward when the pushing block is allowed to move upwards, then the pushing pins push the magnetic steels to pass through the magnetic steel holes upwards to be inserted into the magnetic steel grooves, and therefore, the magnetic steels can be automatically inserted into the magnetic steel grooves by the device.

Owner:浙江佳雪微特电机有限公司

Zero-load run-in equipment of shaft coupling

ActiveCN108827629ALow powerQuick connectionMachine gearing/transmission testingMotor driveDrive shaft

The invention relates to zero-load run-in equipment of a shaft coupling, belongs to the technical field of bearing processing, and the equipment can be used to effectively reduce vibration of a detection motor when the detection motor drives the shaft coupling to rotate and prevent the detection motor from damage. The equipment is characterized by comprising the detection motor, the shaft couplingto be tested is positioned in the output end of the detection motor, one end of the shaft coupling to be tested is connected with the output end of the detection motor via a universal drive shaft, the other end of the shaft coupling to be tested is rotationally connected with a tail fixed plate, the universal drive shaft is connected with the shaft coupling to be tested via a connecting shaft, the connecting shaft is rotationally arranged in a shoe plate, and the connecting shaft is arranged coaxial with an output shaft of the detection motor and can rotate along the axial direction of the connecting shaft itself. During detection, the shaft coupling to be tested vibrates, the vibration is transferred to the connecting shaft and weakened for the first time, and then transmitted to universal drive shaft and weakened again, and vibration transmitted to the detection motor finally is very low, and the detection motor is protected to largest extent.

Owner:XIANGYANG YUQING TRANSMISSION TECH

A tying device for waterproofing membrane

ActiveCN112061469BReduce work intensityImprove bundling efficiencyBundling machine detailsAdhesive beltEngineering

A binding device for waterproof coiled materials, comprising: a forward pushing unit, a conveying unit, a backward pushing unit, a binding unit and the like. The conveying unit includes a conveying fixing assembly arranged at one end of the forward push support assembly, the conveying fixing assembly is provided with a conveying lifting assembly, and one end of the conveying fixing assembly is provided with a pressing assembly; the pushback unit includes a pushback assembly for pushing back the assembly Lifting movement, the push-back component is used to push one end of the waterproof membrane located in the conveying unit; the binding unit includes a guide component arranged on the other side of the conveying unit, the guide component is provided with a driving component, and the driving component is used to drive the limit component Move along the track of the guide assembly so that the waterproof membrane bundling tape is wrapped around the outside of the waterproof membrane. It is convenient to carry out the bundling operation of multi-volume waterproof membranes, reduces the work intensity of operators, improves the transportation efficiency of waterproof membranes, facilitates the subsequent transportation of waterproof membranes, and reduces the cost input of enterprises. It has strong practicability.

Owner:北新防水(四川)有限公司

A coupling factory run-in equipment

The invention relates to the technical field of bearing machining, in particular to coupler pre-delivery bench running-in equipment, which is capable of well weakening detection motor vibration in rotation of a to-be-tested coupler driven by a detection motor to further avoid damages of the detection motor. The equipment is technically characterized by comprising the detection motor and the to-be-tested coupler positioned at an output end of the detection motor, one end of the to-be-tested coupler is connected with the output end of the detection motor through a universal shaft while the otherend is in rotational connection with a tail fixing plate, the universal shaft is connected with the to-be-tested coupler through a connection shaft which is rotationally arranged in a supporting plate, and the connection shaft is coaxial with the output shaft of the detection motor and rotates around own axis. In detection, vibration of the to-be-tested coupler is transmitted to the connection shaft to be weakened for the first time and then transmitted to the universal shaft, deflection of the universal shaft weakens vibration transmitted to the detection motor, and accordingly vibration finally transmitted to the detection motor is quite weak, and the detection motor is protected to the maximum extent.

Owner:XIANGYANG YUQING TRANSMISSION TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com