Ice maker capable of automatically outputting ice blocks and broken ice

A technology for ice making machines and ice cubes, which is applied in ice making, ice storage/distribution, lighting and heating equipment, etc. It can solve the problems that ice cubes are difficult to push out through the storage refrigerator, it is difficult to meet market demand, and the volume of ice cubes is large. Achieve the effects of ensuring food hygiene and safety, saving ice making time, and high work reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

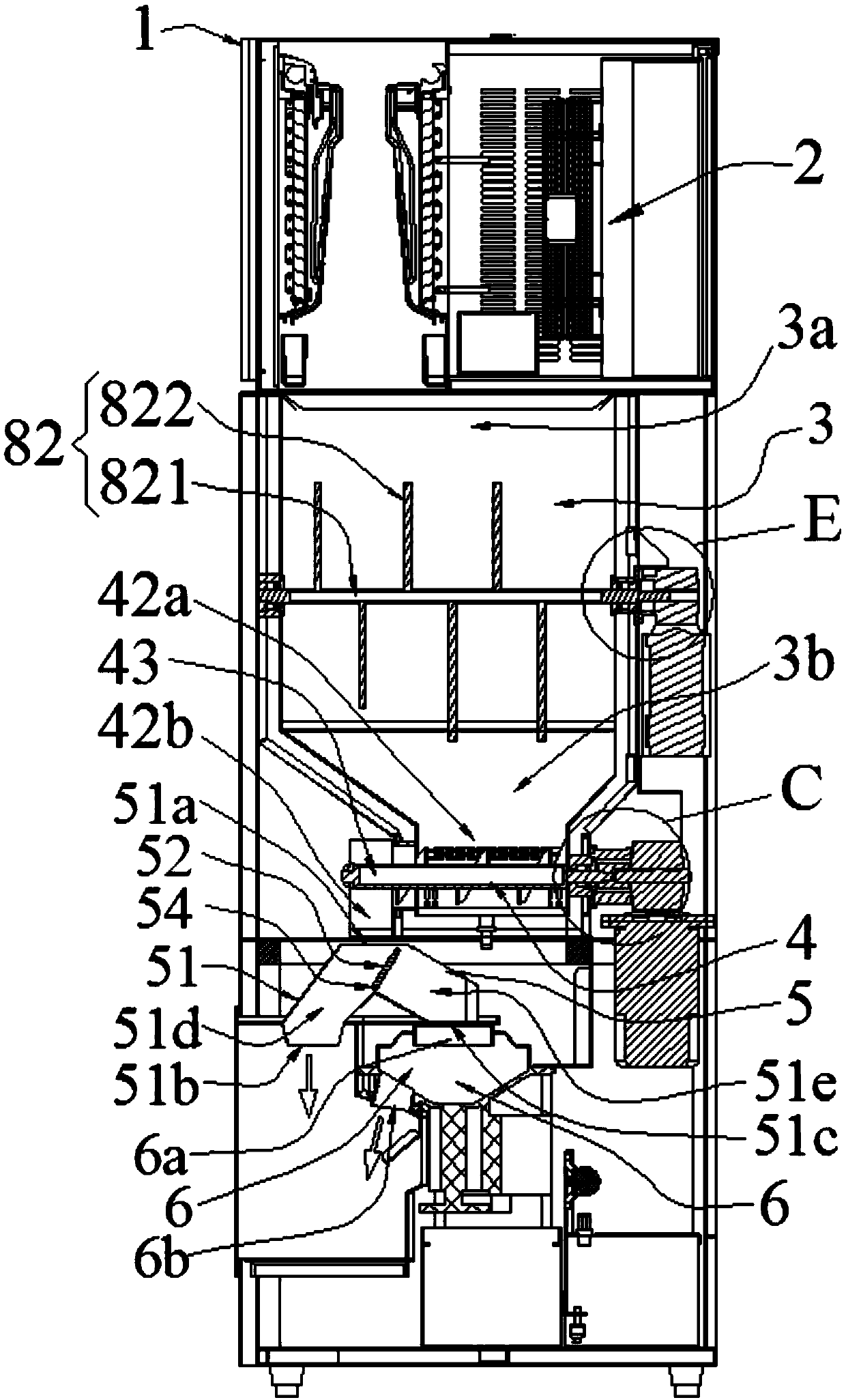

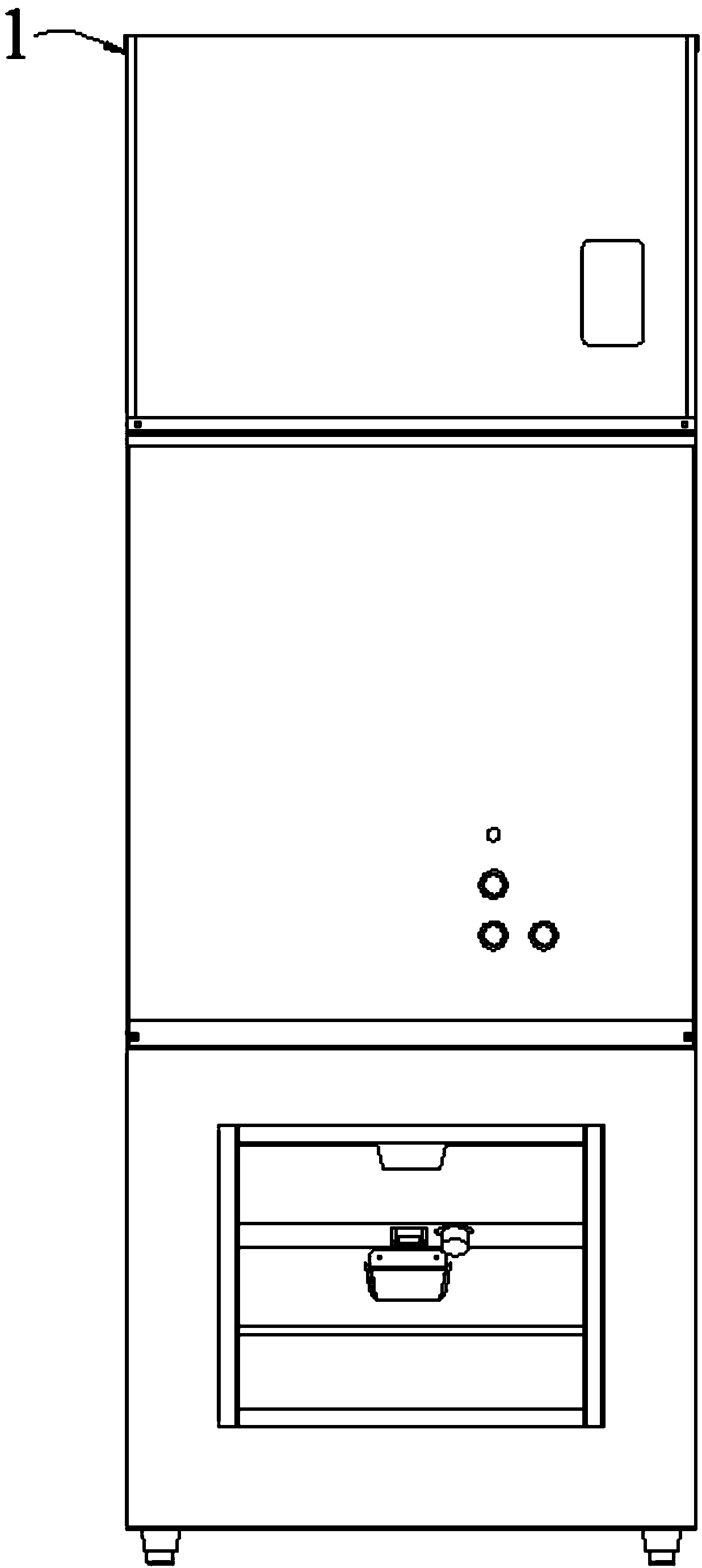

[0057] Such as Figure 1 to Figure 15 As shown, the present invention discloses an automatic ice-discharging crushed ice machine, which is provided with a fuselage 1 and an ice-making unit 2 installed in the fuselage 1. The ice machine is also equipped with a storage bin 3 installed in the fuselage 1, an automatic ice discharge device 4 for the storage bin, an ice diversion valve 5, an ice crushing unit 6 and an ice receiving platform 7; an ice making unit 2, a storage bin 3, The automatic ice discharge device 4 of the storage bin, the ice diversion valve 5 and the ice crushing unit 6 are arranged sequentially from top to bottom. The ice cubes made by the ice making unit 2 fall into the storage bin 3 for airtight storage, and the storage bin automatically discharges ice. The device 4 can output the ice cubes stored in the storage bin 3 to the inlet of the ice cube diversion valve 5, the ice cube diversion valve 5 is provided with a first outlet and a second outlet, and the ice...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com