Automatic fruit picker

A technology for automatic fruit picking, applied in the direction of picking machines, harvesters, agricultural machinery and implements, etc., can solve problems such as physical damage, shorten storage time, troubles, etc., and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below by means of specific embodiments:

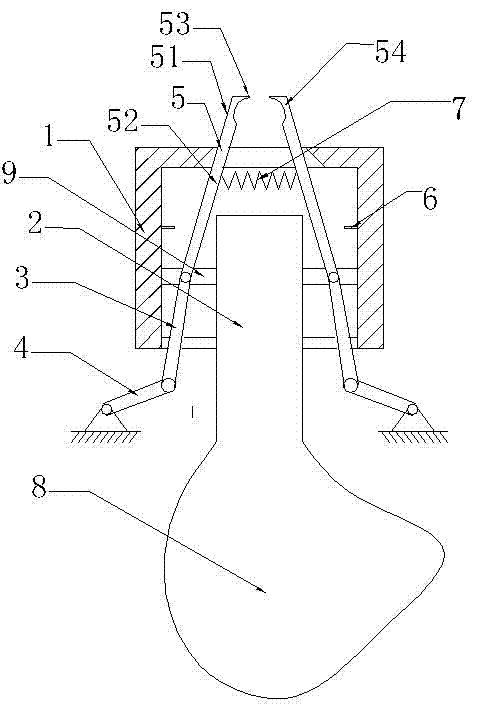

[0016] The reference signs in the drawings of the description include: sleeve 1, feeding cylinder 2, connecting rod 3, crank 4, jaw 5, jaw outer wall 51, jaw inner wall 52, cutter 53, arc-shaped clamping end 54, Limiting block 6, spring 7, fruit collection bag 8, push plate 9,.

[0017] Example basic reference figure 1 Shown:

[0018] An automatic fruit picking machine in this solution includes a frame, a sleeve 1 and two opposite jaws 5, the tops of the inner walls of the two jaws 5 protrude relatively to form a cutter 53, and the inner wall 52 of the jaws is close to the cutter 53 The part is provided with an arc-shaped clamping end 54; the top of the sleeve 1 has a groove for the insertion of two jaws 5, and the outer wall 51 of each jaw is against the groove wall of the groove, and the sleeve 1 is provided with a limit Block 6, a push plate 9 is slidably fitted in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com