Design of bending region structure of flexible printed circuit board

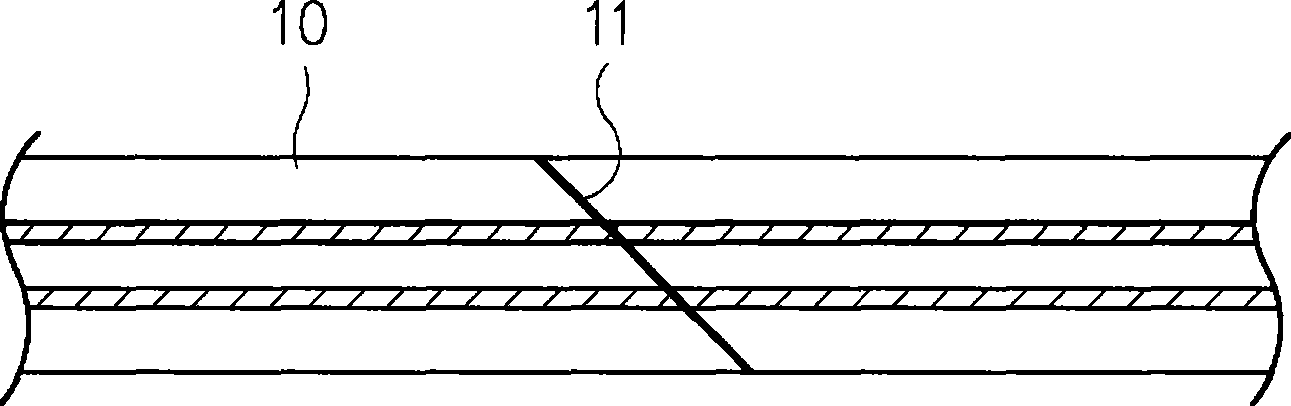

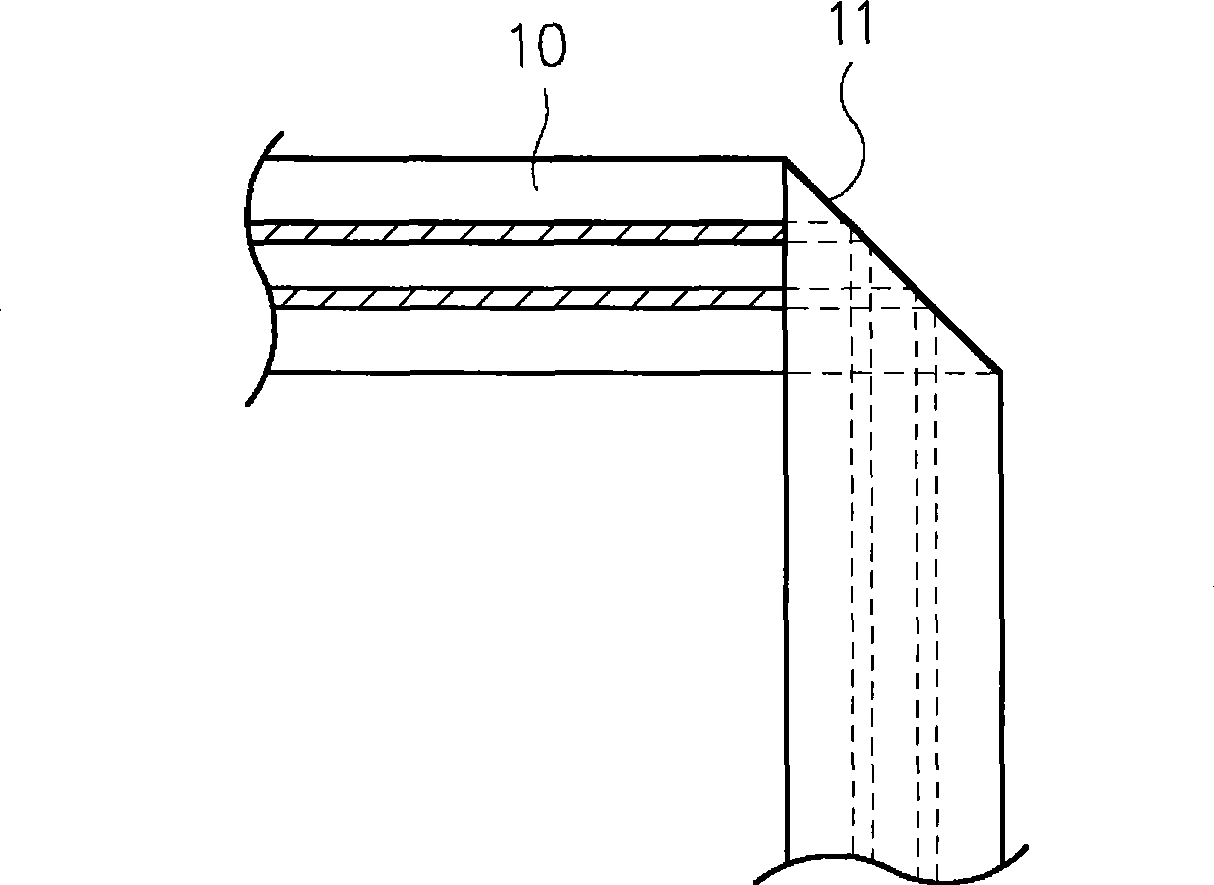

A flexible printed circuit, printed circuit technology, applied in the direction of printed circuit components, etc., can solve the problem of flexible printed circuit board fracture, bending accuracy is difficult to control, and the flexible printed circuit board 10 cannot achieve a complete bending angle. precision etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

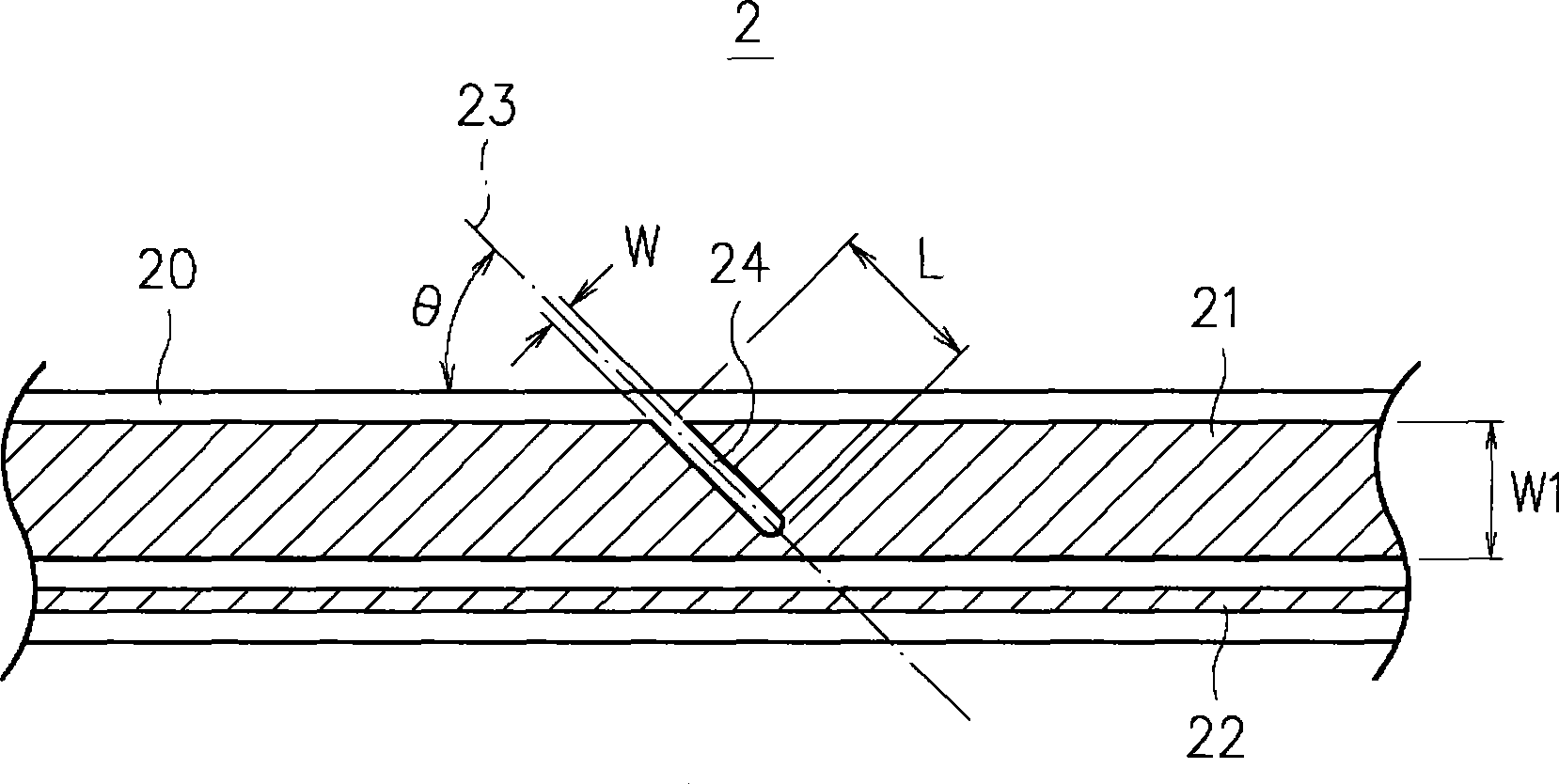

[0032] The technical means and effects used by the present invention to achieve the purpose will be described below with reference to the attached drawings, and the embodiments listed in the following drawings are only for auxiliary explanation, to facilitate understanding, but the technical means of the present invention are not limited The diagrams listed.

[0033] see image 3 As shown, a specific embodiment of the structural design of the flexible printed circuit board bending area provided by the present invention, the flexible printed circuit board 2 has a substrate 20, at least one printed circuit and a bending area 23, as shown in the figure There are two printed circuits 21 and 22, and the bending area 23 intersects with the printed circuits 21 and 22. Usually, the bending area 23 and the substrate 20 form a bending angle θ of 45 degrees; through etching and other processing methods, A groove 24 is formed at the bending area 23 of the printed circuit 21 .

[0034] S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com