Punching mold for preventing rebound of bent piece

A stamping die and anti-springback technology, which is applied in the field of stamping dies, can solve problems such as poor product quality and large bending angle deviation, and achieve the effect of ensuring the bending angle and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

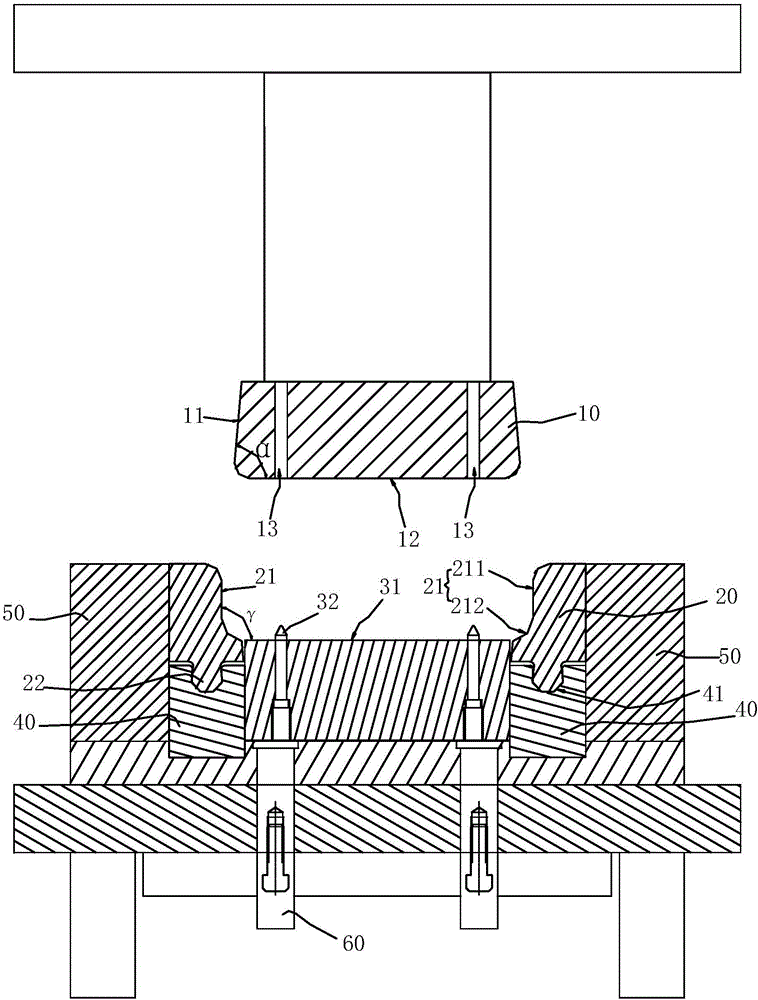

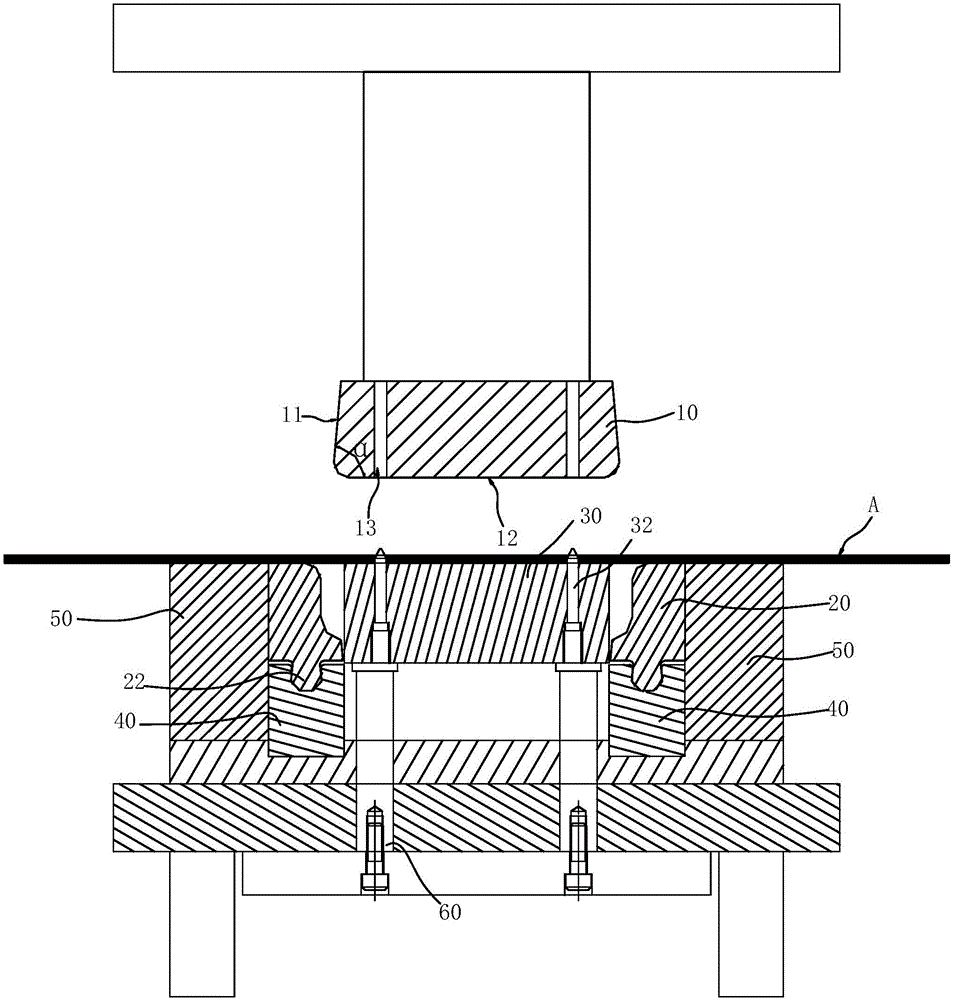

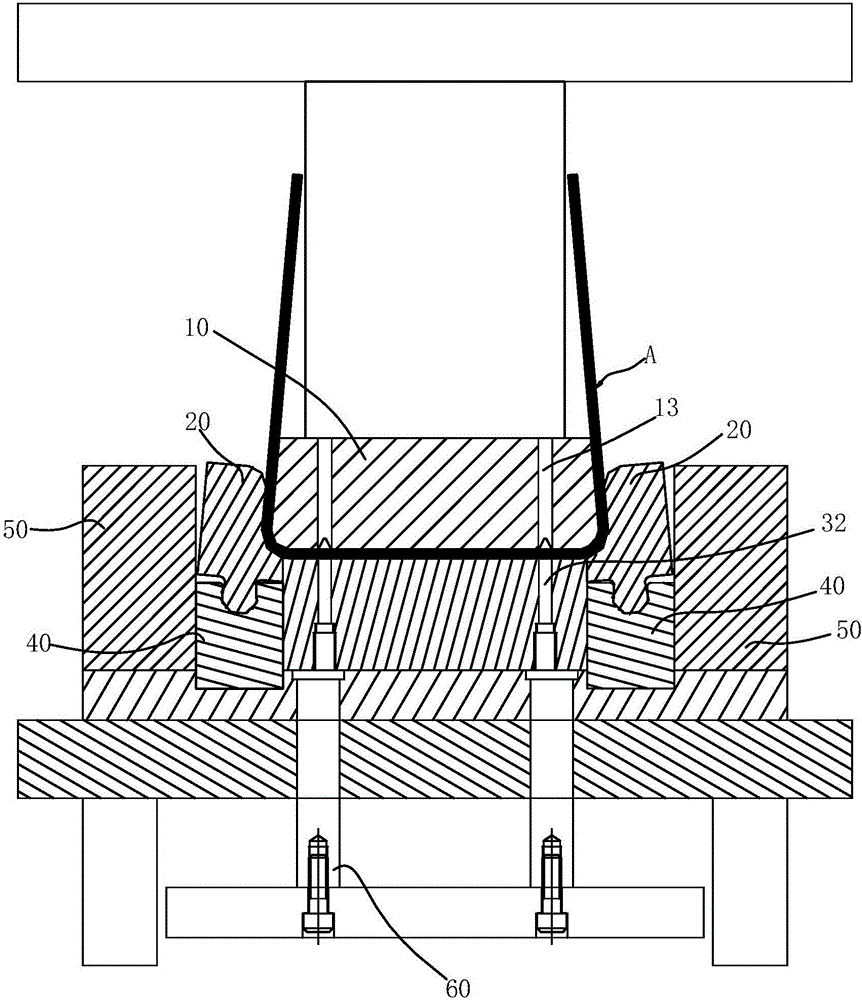

[0008] A stamping die for preventing springback of a bent part, comprising a punch 10, the angle between the side forming surface 11 and the bottom forming surface 12 of the punch 10 constitutes an anti-rebound angle α; The mold comprises a side mold 20 and a bottom mold 30. The outside of the side mold 20 is hinged to the side mold support 40 by a hinge shaft. The included angle constitutes the bending angle γ, and the bending angle γ is located between the anti-rebound angle α and the demolding angle β.

[0009] The bottom mold 30 and the side mold 20 form a mold cavity for accommodating the upper mold 10. The material of the part A to be bent is fixed, and the springback angle △α is constant when the parameters of the stamping mold are fixed. can be calculated or obtained through experiments. In this application, the anti-springback angle α=the theoretical bending angle of the part A to be bent-the springback angle △α, and the demoulding angle β in this application is to e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com