Automatic pipe bending machine

A pipe bending machine, fully automatic technology, applied in the direction of feeding device, manufacturing tool, positioning device, etc., can solve the problem of inability to bend continuously, and achieve the effect of avoiding bending and protecting the bending angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings.

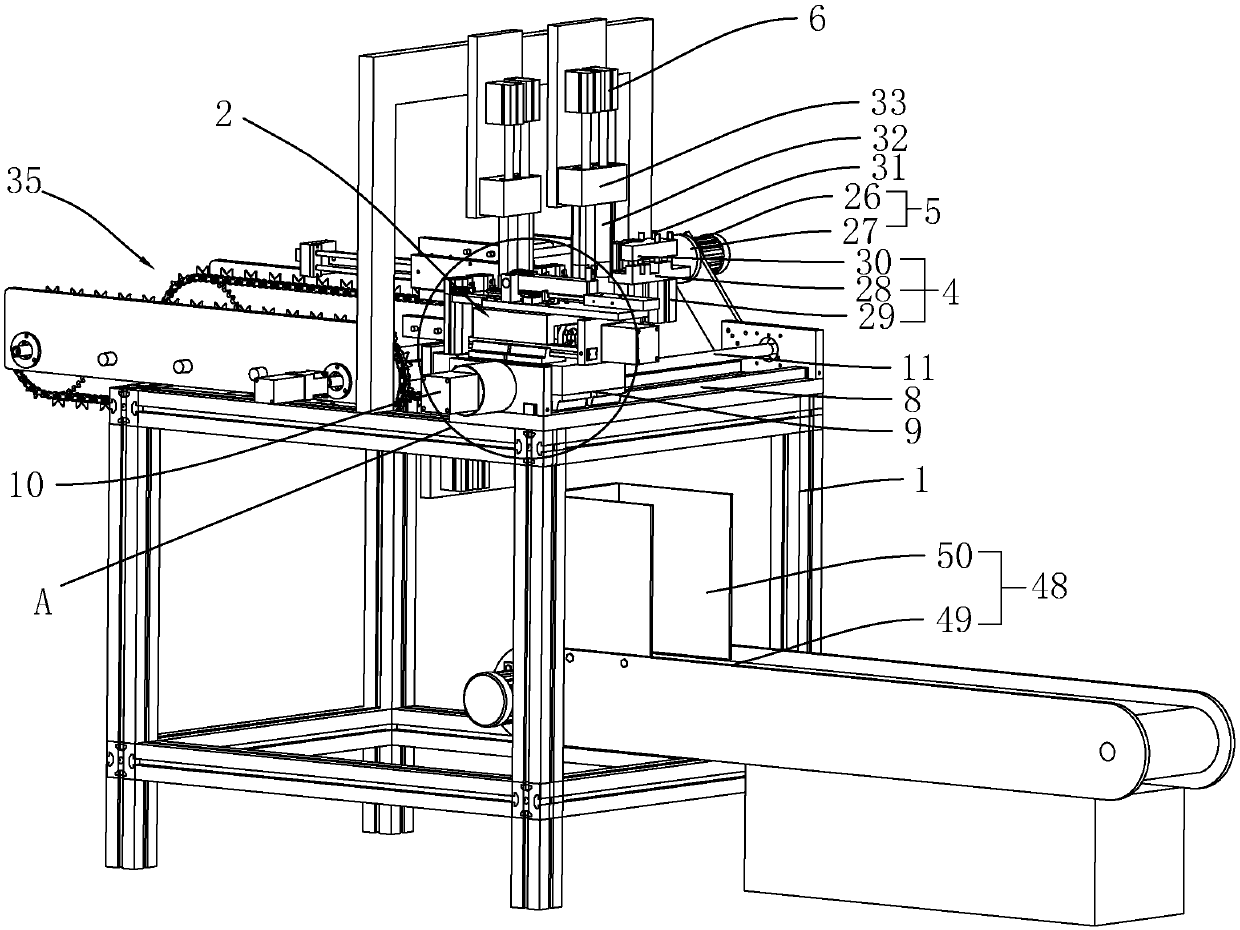

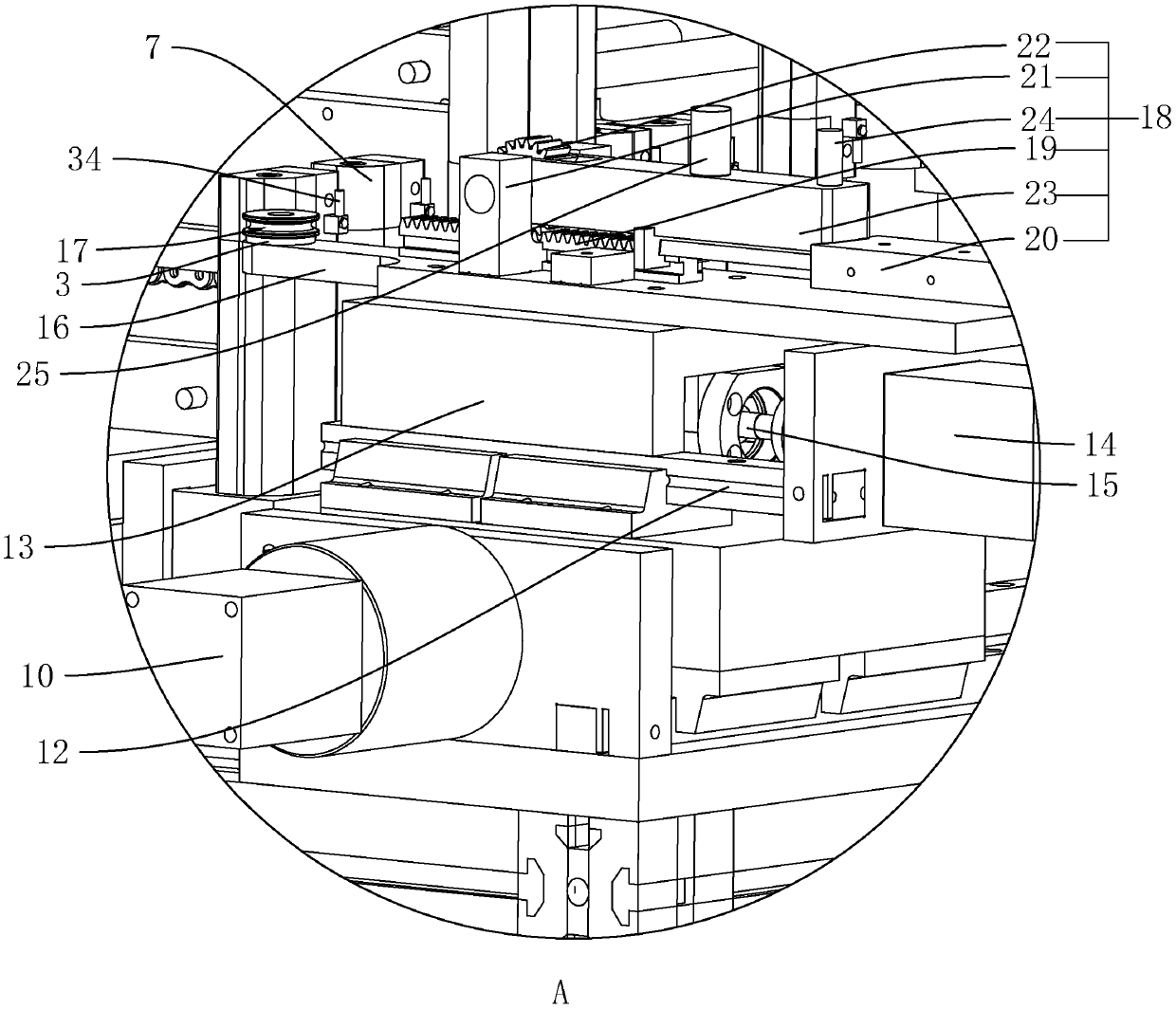

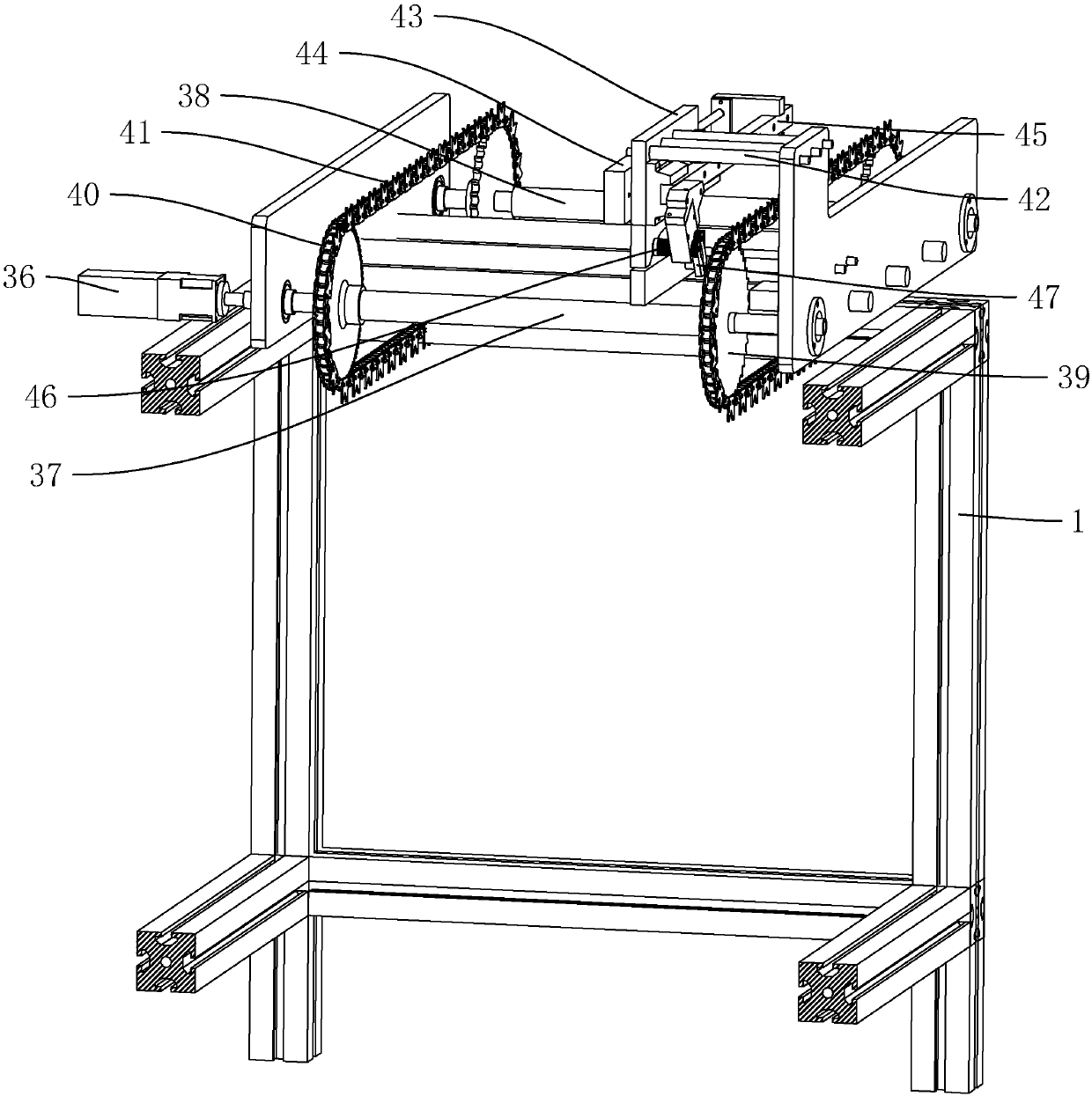

[0032] combine figure 1 and figure 2 As shown, a fully automatic pipe bending machine includes a frame 1. According to the moving sequence of the pipe material, a feeding device 35, a clamping device 4, a rotating device 5, a straightening mechanism 18, Elbow 3 and forming block 7, drive mechanism 2 and discharge device 48.

[0033] The pipe material is sent to the clamping device 4 by the feeding device 35 for clamping, and then the rotating device 5 controls the rotation of the clamping device 4 so that the clamped pipe material rotates automatically, and at the same time, the straightening mechanism 18 straightens the pipe. The material is straightened, and then the driving mechanism 2 drives the pipe bending part 3 to move to match the arc angle on the forming block 7 that abuts on the pipe material to bend the pipe material, so that the pipe material ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com