Intelligent horseshoe bending device

A bending device and horseshoe technology, applied in the field of forging machinery, can solve the problems of complex structure, inability to detect bending degree, unstable bending, etc., and achieve the effect of accurate bending angle and improving equipment practicability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

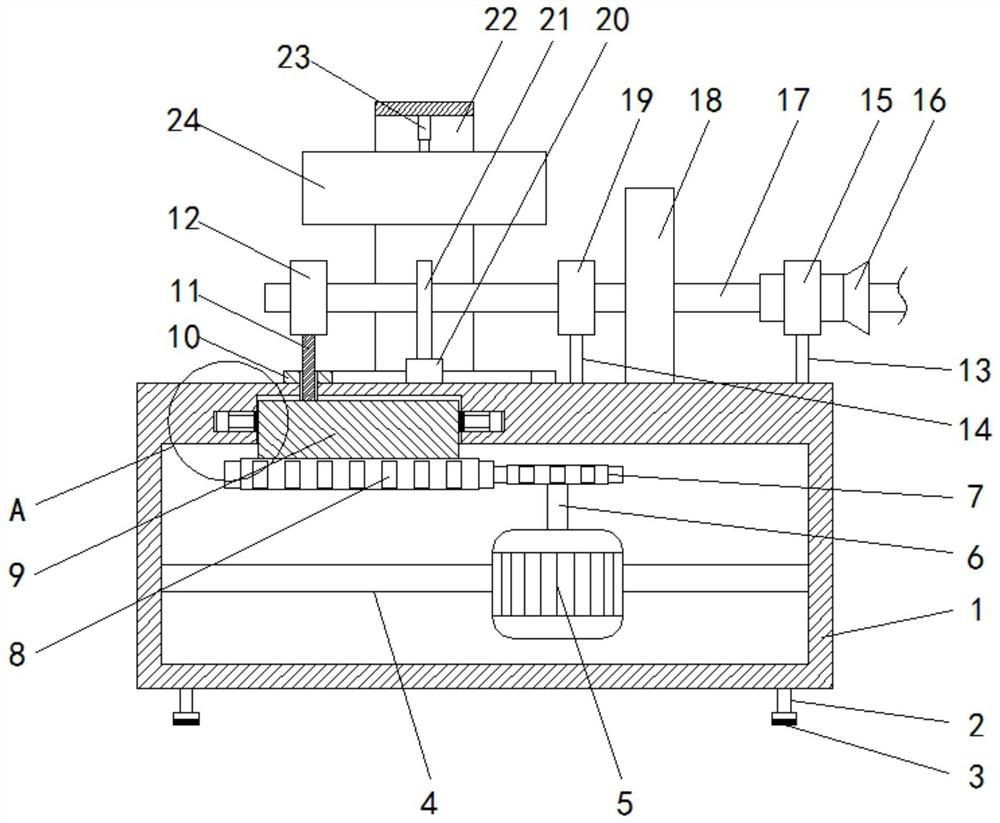

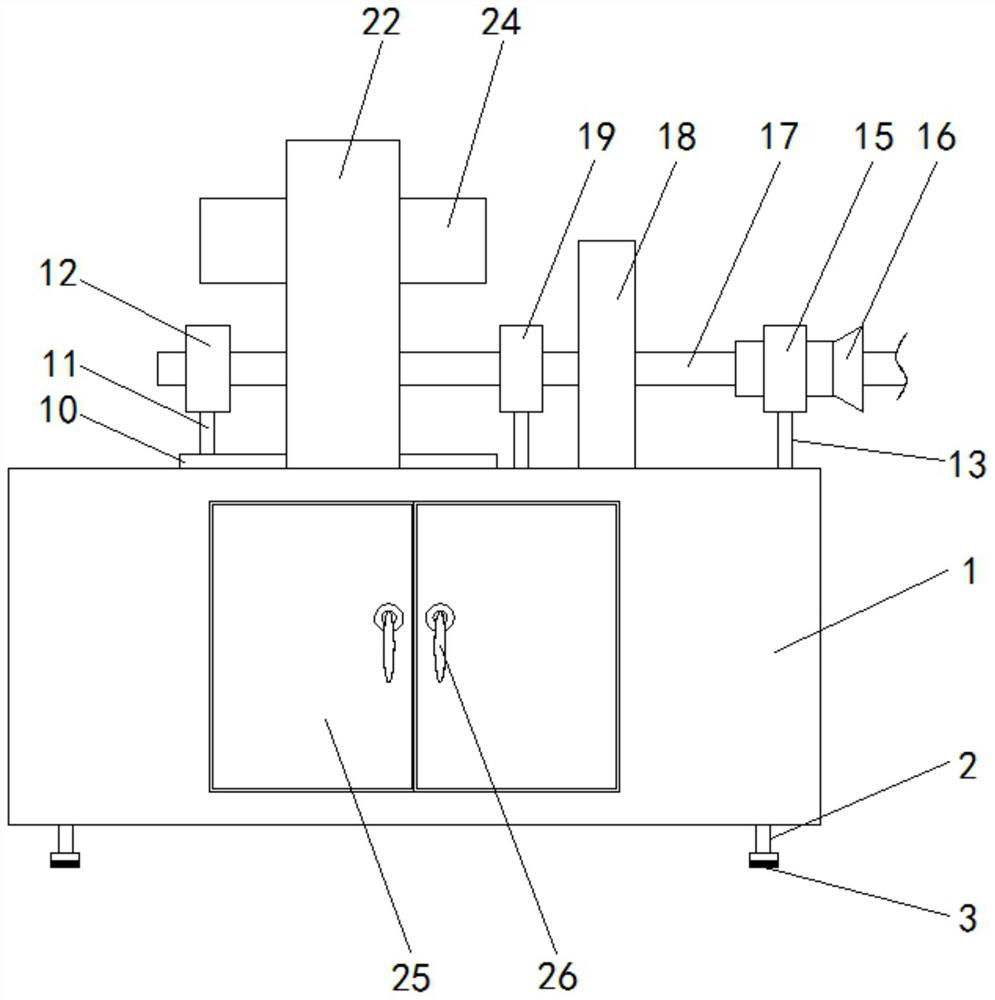

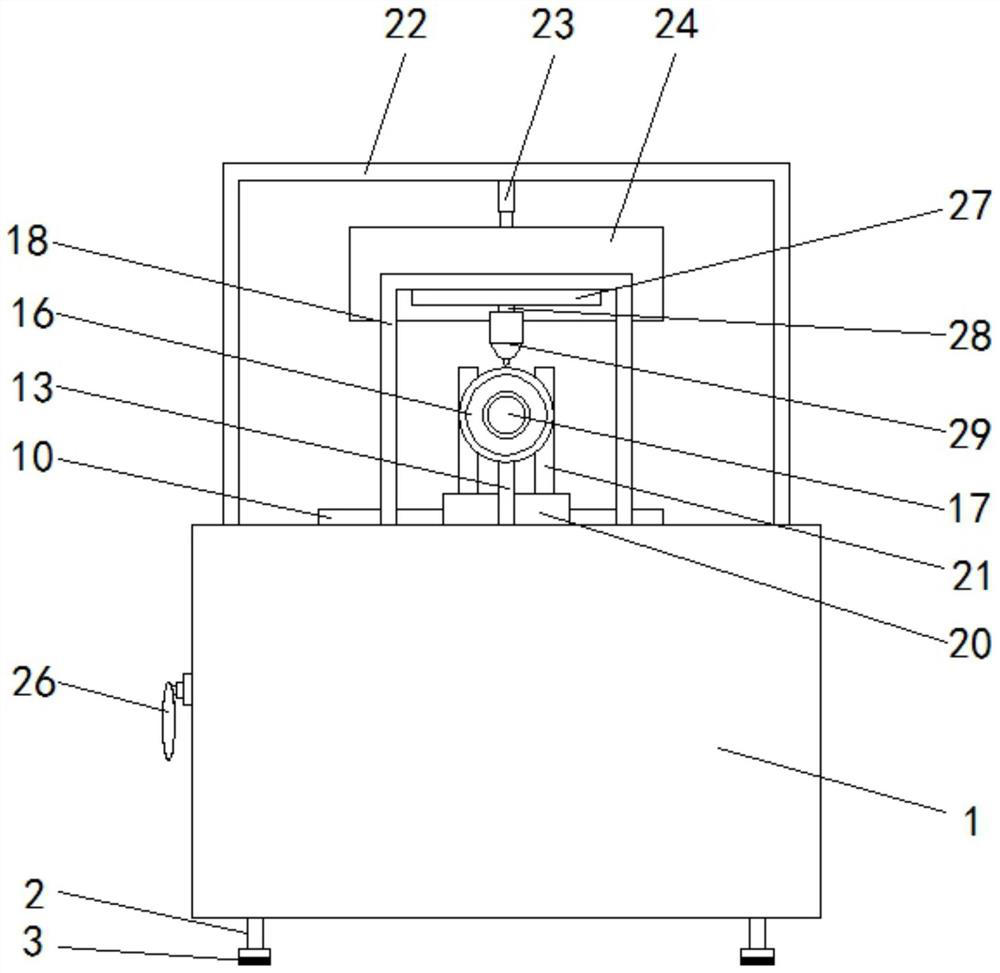

[0028] as attached figure 1 to attach Image 6 Shown:

[0029] The invention provides an intelligent bending device for horseshoes, which includes a housing 1, a fixing part 4 is fixedly installed inside the housing 1, a motor 5 is fixedly installed on the fixing part 4, and a motor 5 is movably installed on the upper side of the motor 5. The rotating shaft 6, the upper end of the rotating shaft 6 is fixedly equipped with a driving gear 7, the driving gear 7 is connected with a driven gear 8 through meshing, the upper side of the driven gear 8 is fixedly installed with a fixed block 9, and the inside of the housing 1 is provided with a mounting part 31, the end of the mounting part 31 opposite to the fixed block 9 is fixedly installed with a brake pad 32, and the side of the brake pad 32 away from the mounting part 31 is connected with a fixed block 9. When the equipment is bent to a certain degree, the emergency stop mechanism will be driven The gear 8 brakes to make the wo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com