Stamping die for left bent seat lining board of bulldozer

A stamping die and bulldozer technology, applied in the field of stamping die, can solve the problems of difficult to ensure accurate angle, can not meet production, poor quality of lining plate, etc., and achieve the effects of accurate forming position, simple structure and fast stamping speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

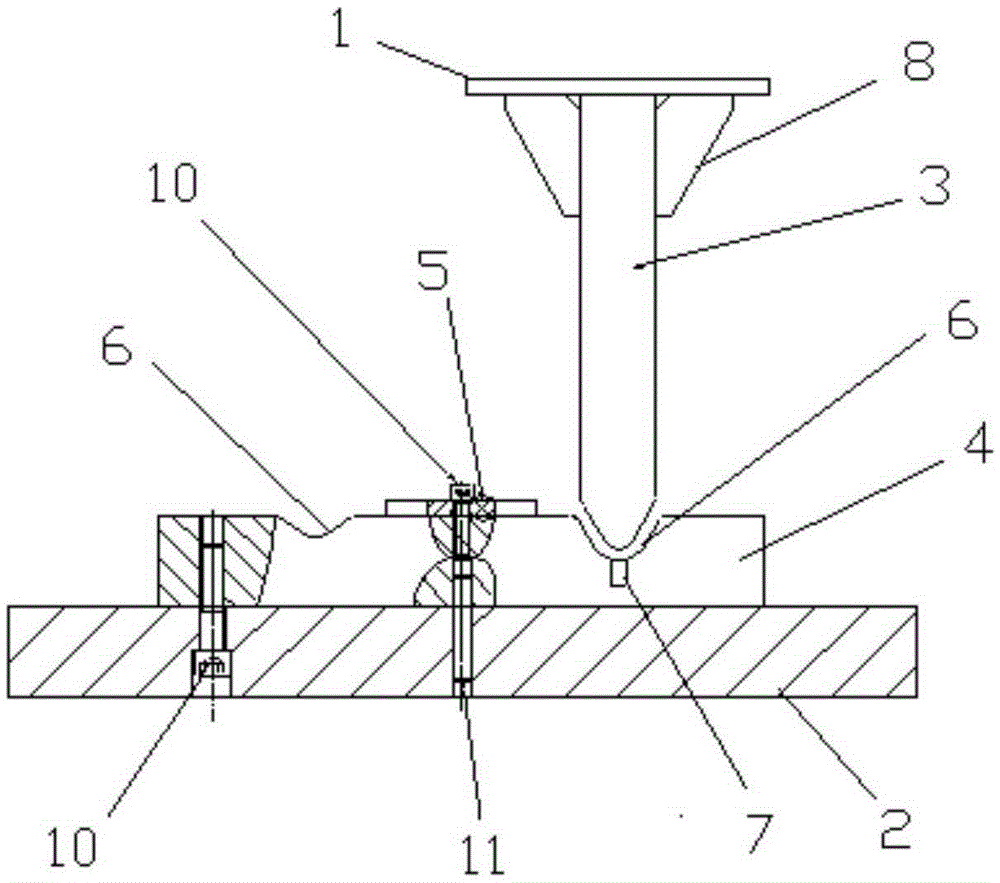

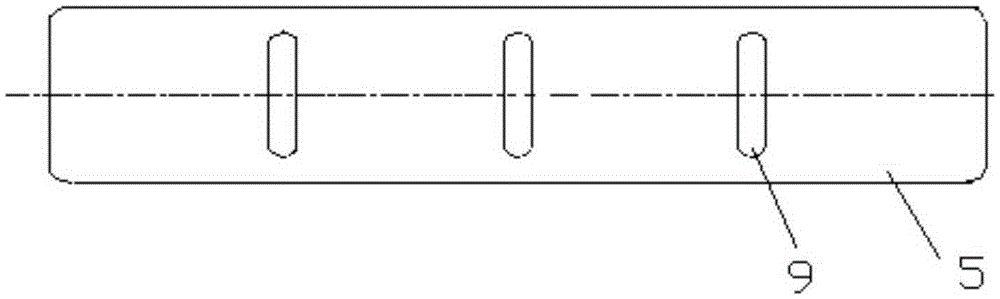

[0015] The present invention is made up of upper formwork 1, lower formwork 2, punch 3, die 4, positioning plate 5, rib plate 8, bolt 10, cylindrical pin 11.

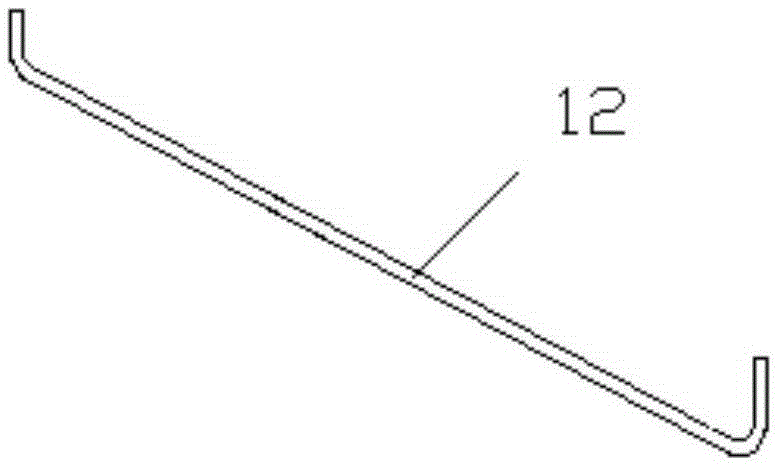

[0016] image 3 It is shown that both sides of the liner 12 are bent respectively, the left side is bent at an obtuse angle with an angle of 116°, and the right side is bent at an acute angle with an angle of 64°.

[0017] figure 1 It is shown that the upper template 1, the punch 3 and the rib plate 8 form the punch assembly. The upper template 1 is connected under the punch of the stamping equipment, the punch 3 is fixedly connected to the lower surface of the upper template 1, and the rib plate 8 is connected to the upper part of the upper template 1 and the punch 3, so that the upper template 1 and the punch 3 are firmly connected .

[0018] figure 1 It is shown that the lower template 2 is fixedly connected on the workbench of the stamping equipment, the die 4 is located on the upper surface of the lower templat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com