Automatic pipe bending machine

A pipe bending machine, automatic technology, applied in metal processing equipment, safety equipment, manufacturing tools, etc., can solve the problems of insufficient bending angle, waste of materials, low work efficiency, etc., and achieve accurate bending angle, convenient use and structure. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

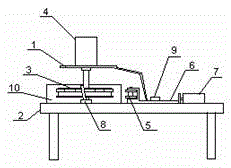

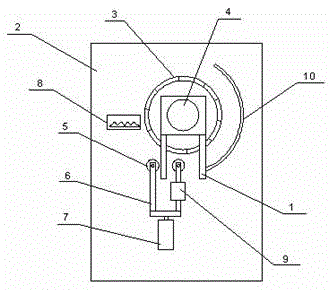

[0018] Such as Figure 1-4 As shown, an automatic pipe bending machine includes an electrical system, a frame, a turntable 3, a motor 4, a chuck 5, a slide rail 6, a cylinder 7, and a rotating shaft 11, and the frame includes a support 1 and a base 2. The rotating shaft 11 passes through the center of the rotating disk 3, one end of which is fixed on the base 2, the motor 4 is arranged on the support 1 above the rotating disk 3, the other end of the rotating shaft 11 is connected with the motor 4, Two chucks 5 are arranged on the right side of the turntable 3, and the slide rail 6 is in a "U" shape. The chucks 5 are respectively fixed on two free ends of the slide rail 6, and the cylinder 7 and the The right end of the slide rail 6 is fixedly connected, the slide rail 6 is provided with a limit slider 9, and the front of the turntable 3 is provided with a stopper device 8, and the stopper device 8 is fixed on the base 2. An arc-shaped baffle 10 is arranged behind the turntabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com