V-shaped workpiece bending-forming mold and forming method

A technology for bending and forming workpieces, which is applied in the direction of forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of high waste rate of processing technology and affect economic benefits, etc., to increase economic benefits, improve forming pass rate, and improve forming efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

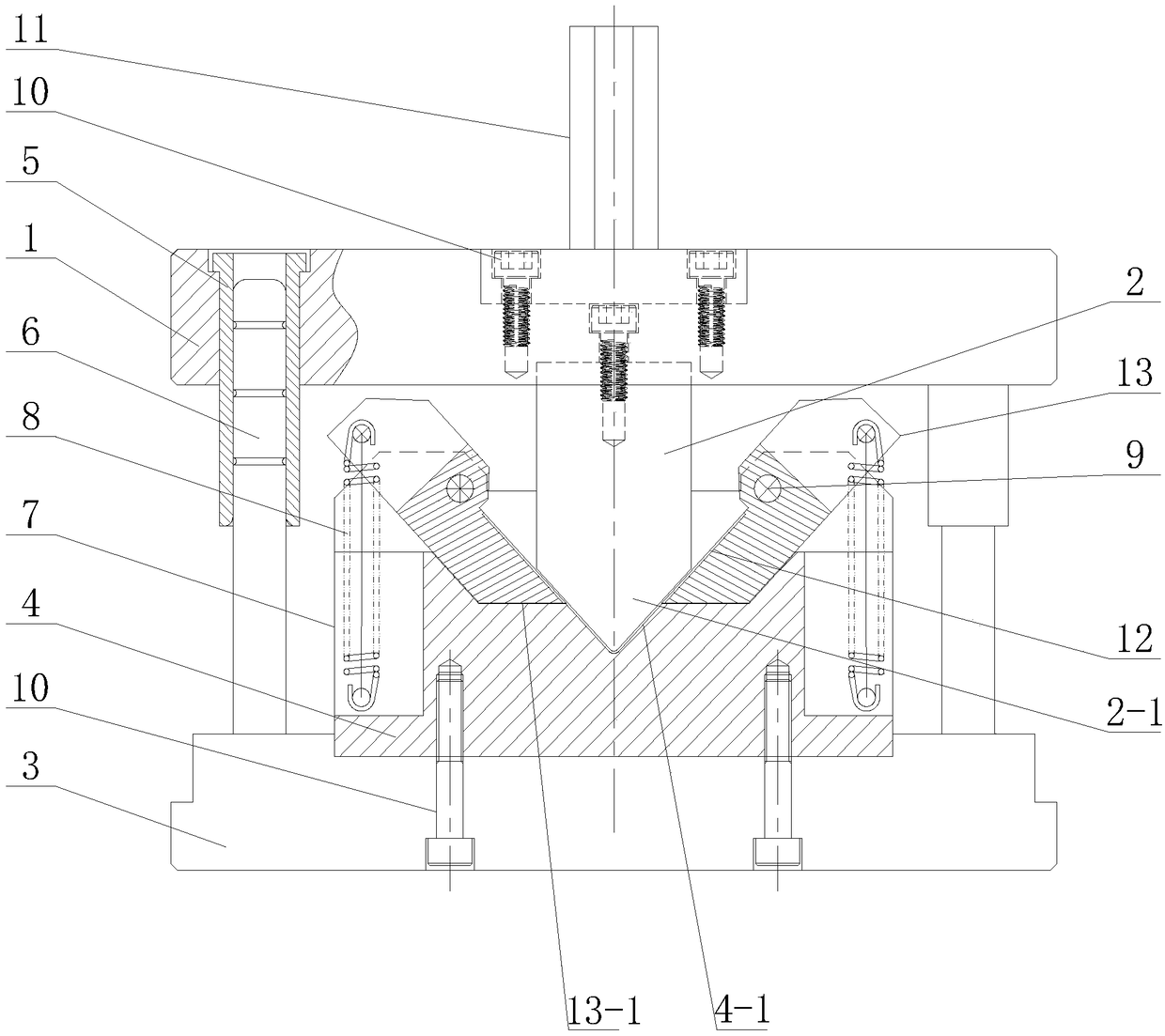

[0023] Specific implementation mode one: combine figure 1 Describe this embodiment, a V-shaped workpiece bending forming mold described in this embodiment includes an upper mold base 1, a punch 2, a lower mold base 3 and a die 4, and the upper mold base 1 and the lower mold base 3 are arranged from top to bottom Arranged sequentially, the upper end of the punch 2 is connected with the upper die base 1, the lower surface of the die 4 is connected with the upper surface of the lower die base 3, the lower end of the punch 2 is provided with a downwardly convex V-shaped protrusion 2-1, and the concave The upper surface of the mold 4 is provided with a V-shaped groove 4-1 matched with the V-shaped protrusion 2-1, and the V-shaped groove 4-1 is located directly below the V-shaped protrusion 2-1.

specific Embodiment approach 2

[0024] Specific implementation mode two: combination figure 1 To illustrate this embodiment, a V-shaped workpiece bending molding die described in this embodiment also includes two guide sleeves 5 and two guide posts 6, and the two guide sleeves 5 are symmetrically arranged on both sides of the punch 2, and the guide sleeves The upper end of 5 is inserted in the lower surface of the upper die base 1, two guide posts 6 are symmetrically arranged on both sides of the die 4, and the lower ends of the guide posts 6 are fixedly connected with the upper surface of the lower die base 3, each guide The upper end of the column 6 is inserted into the lower end of a corresponding guide sleeve 5 , and the guide column 6 can move linearly up and down along the inner wall of the guide sleeve 5 . Such arrangement can make the punch 2 move up and down in a straight line in the vertical direction without deviation, thereby ensuring the molding quality of the workpiece. Other components and co...

specific Embodiment approach 3

[0025] Specific implementation mode three: combination figure 1 To illustrate this embodiment, a V-shaped workpiece bending molding die described in this embodiment also includes two flaps 13 and two support assemblies, the two support assemblies are symmetrically arranged on both sides of the die 4, and the two flaps The boards 13 are respectively installed on the two support assemblies, and the turning plate 13 is rotatably connected with the support assemblies. With such arrangement, the turnover plate 13 can take out the formed V-shaped workpiece from the V-shaped groove 4-1, thereby improving the forming efficiency. Other components and connections are the same as those in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com