Centrifugal integral cast metal mould for dual-tray flange straight pipes

A metal mold and integral casting technology, which is applied in the field of metal mold manufacturing, can solve the problems that cannot be completely eliminated, it is difficult to ensure the parallelism of the concentricity of the two flange holes, and the welding quality cannot be evaluated by the user, so as to achieve the completeness of the overall metallographic structure. Consistent and effective control of the wall thickness of the pipe body, which is conducive to the effect of protecting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

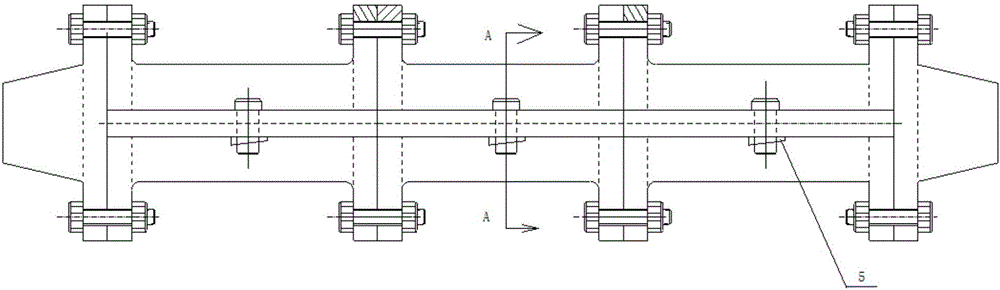

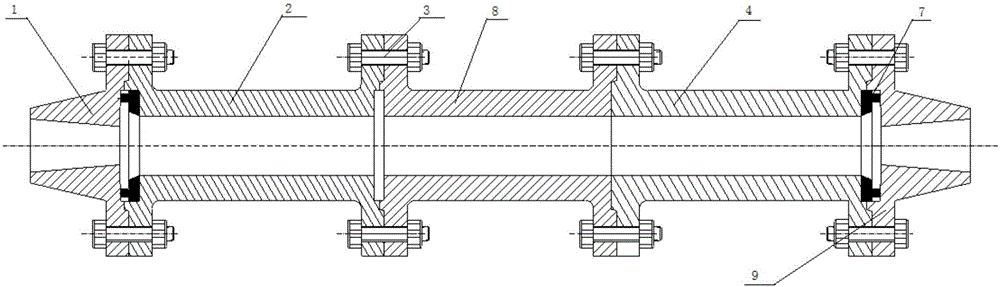

[0054] Cast PN16 with a centrifuge, the length is 5.8 meters, and the method of DN1000 double-disc flange straight pipe is:

[0055] (1) Mold preparation

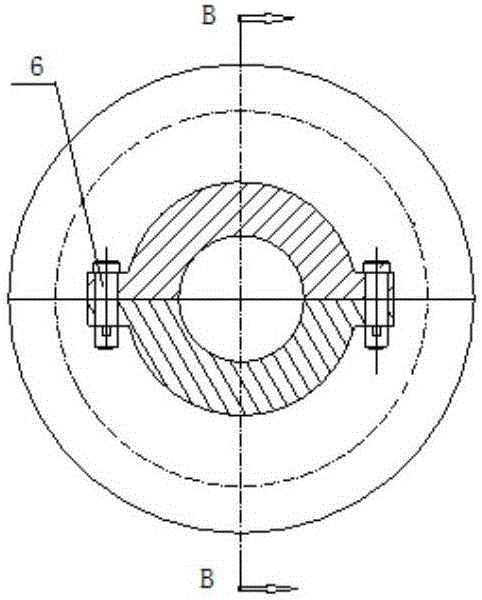

[0056] A. According to the user's needs, prepare 1 set of PN16 tapered inserts at both ends of the DN1000 pipe mold, one set at each end, change the tapered inserts at both ends of the pipe mold, and the pipe fitting flange can be replaced with PN10, PN16, PN25, and the PN value is different ( pressure level), the thickness of the flange, the diameter of the bolt hole, and the number of holes are also different. At the same time prepare 3 sections of DN1000 transition pipe mold, the lengths are 5 meters, 0.5 meters and 0.2 meters respectively. The flange thickness of DN1000 and PN16 is 50 mm, and the total length is 5.8 meters, which meets the needs of customers;

[0057] B. Assemble and connect the segmented pipe molds, pay attention to the positioning pins, and the positioning table is intact;

[0058]C. The pipe mold ...

Embodiment 2

[0071] Use a centrifuge to cast PN10, DN200 single disc through-wall flange straight pipe, the length is 4.02 meters, and the length between the wall-through flange and the flange sealing surface is 2.01 meters. The method is:

[0072] (1) Mold preparation

[0073] A. According to the user's needs, prepare 1 set of DN200 pipe mold PN10 tapered inserts with flange and without flange, change the tapered inserts at both ends of the pipe mold, and the pipe flange can be replaced with PN10, PN16, PN25 , The PN value is different (pressure level), the thickness of the flange, the diameter of the bolt hole, and the number of holes are also different. At the same time, prepare DN200, 1 section of pipe mold with a length of 1 meter and a wall-through flange, 1 section of pipe mold with a length of 2 meters, and 1 section of pipe mold with a length of 1 meter and a socket. The position of the through-wall flange is accomplished by adjusting the length of the transition pipe mold. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com