Method for preparing inorganic nano-tube by employing porous templates

A technology of inorganic nanotubes and porous templates, applied in the direction of nanotechnology, nanotechnology, nanostructure manufacturing, etc., can solve problems such as limitations, complicated post-processing operations, and limited applications, so as to achieve simple and easy experimental operations and avoid complicated operations. , the effect of broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

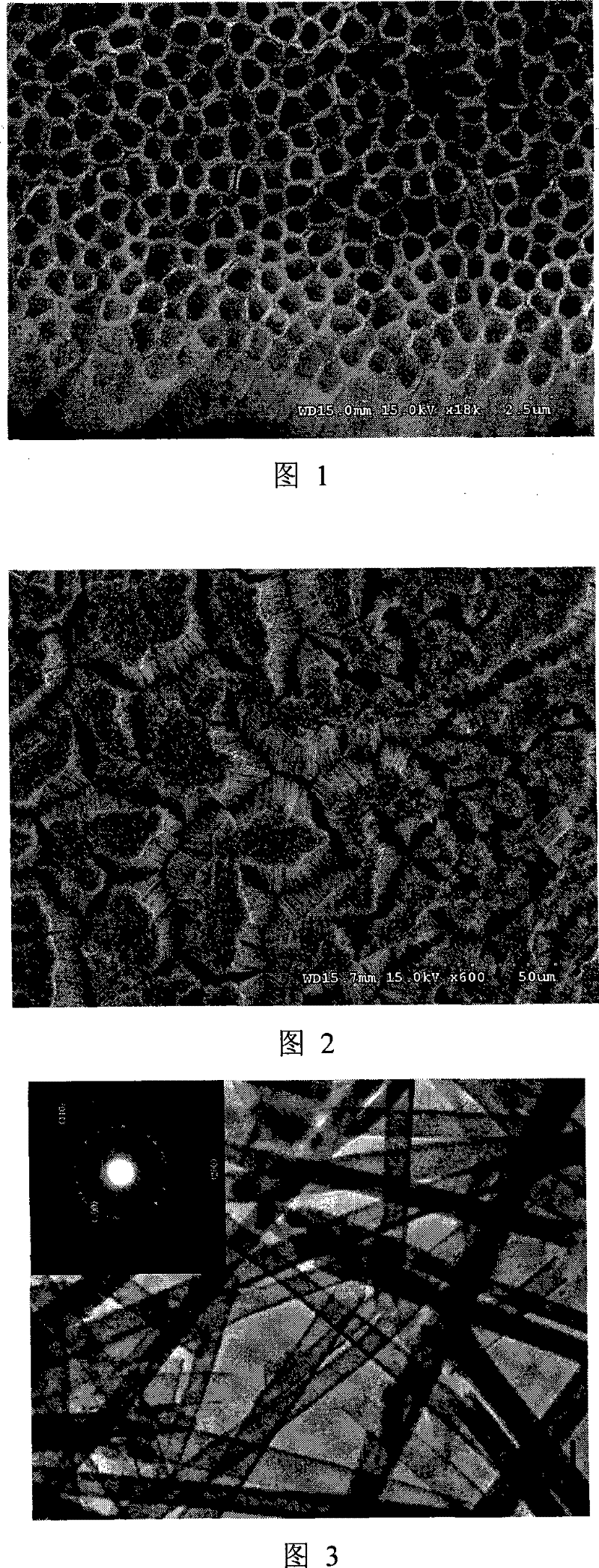

[0036] Embodiment 1, preparation ZnS inorganic nanotube

[0037] Using zinc diethyldithiocarbamate as raw material, its mass is 0.5g. The raw material was placed upstream of a tube furnace, and an alumina template with a pore size of 200 nm was vertically placed in the center of the furnace. With high purity N 2 As the carrier gas, the mass flow meter is used to control the gas flow, and the valve is used to control the pumping speed of the vacuum pump to control the pressure of the furnace. During the reaction, the carrier gas flow rate is controlled at 20SCCM, the furnace pressure is controlled at 20Pa, and the temperature of the tube furnace is raised to the reaction temperature of 420°C. At this time, the temperature of the raw material is 150°C. When the furnace temperature reaches the required temperature, the furnace temperature is controlled at the reaction temperature for 240min. . After slowly cooling down to room temperature, the template loaded with ZnS was take...

Embodiment 2

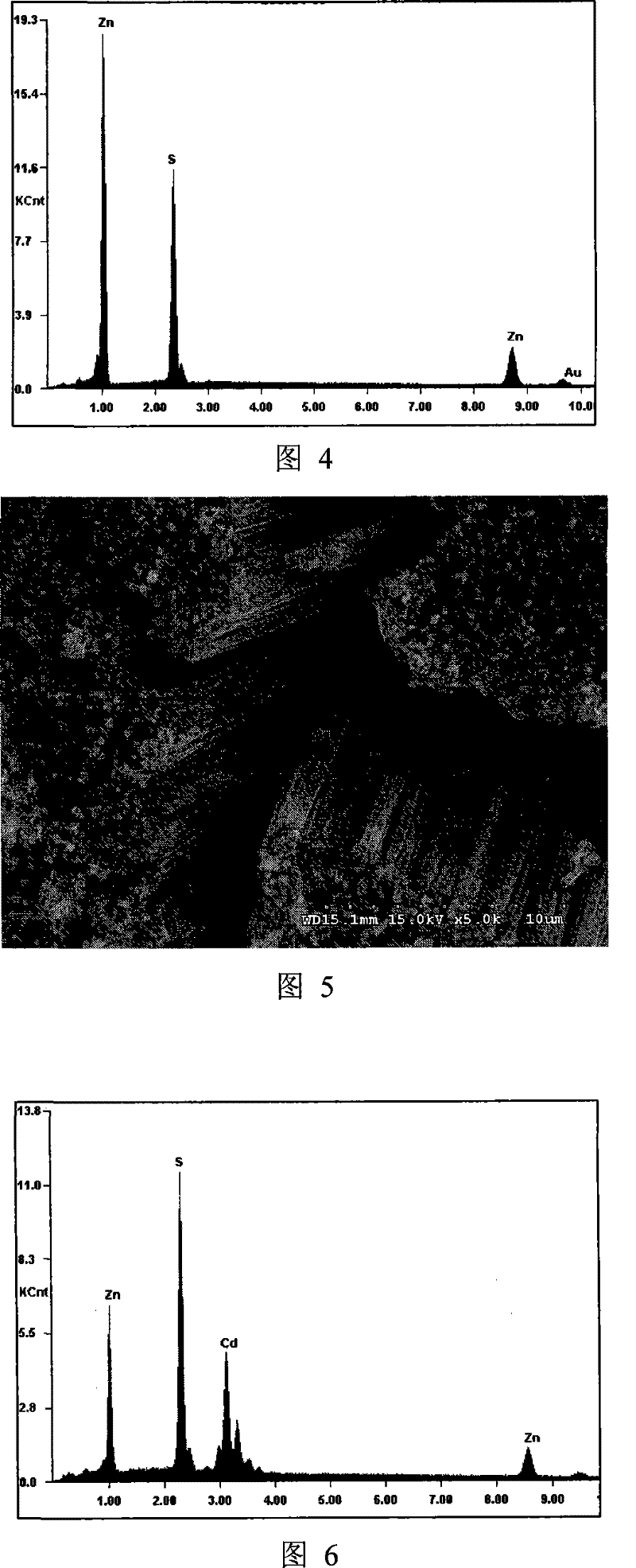

[0039] Embodiment 2, preparation Zn 0.5 Cd 0.5 S Inorganic Nanotubes

[0040] A mixture of zinc diethyldithiocarbamate and cadmium diethyldithiocarbamate with a molar ratio of 1:1 is used as a raw material, and its mass is 4 g. The raw material was placed upstream of a tube furnace, and an alumina template with a pore size of 200 nm was vertically placed in the center of the furnace. With high purity N 2 As the carrier gas, the mass flow meter is used to control the gas flow, and the valve is used to control the pumping speed of the vacuum pump to control the pressure of the furnace. During the reaction, the carrier gas flow rate is controlled at 90SCCM, the furnace pressure is controlled at 90Pa, and the temperature of the tube furnace is raised to the reaction temperature of 430°C. At this time, the temperature of the raw material is 150°C. When the furnace temperature reaches the required temperature, the furnace temperature is controlled at the reaction temperature for ...

Embodiment 3

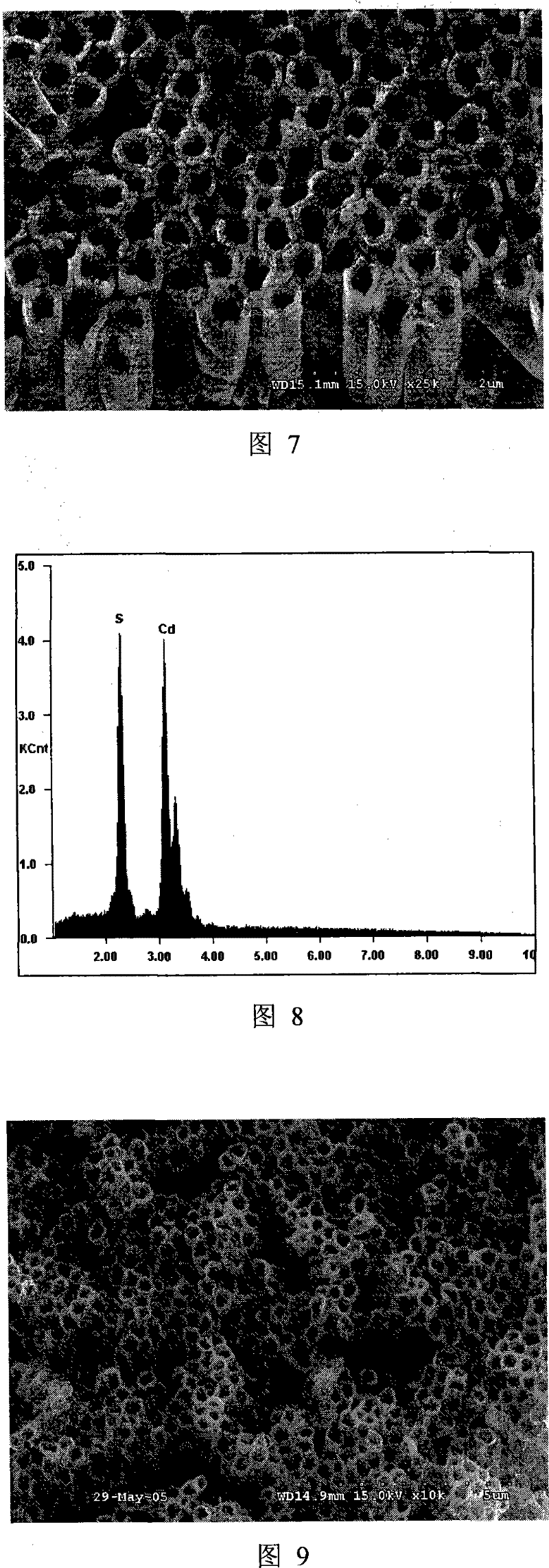

[0042] Embodiment 3, preparation CdS inorganic nanotube

[0043] Using zinc cadmium diethyldithiocarbamate as raw material, its mass is 2g. The raw material was placed upstream of a tube furnace, and an alumina template with a pore size of 200 nm was vertically placed in the center of the furnace. With high purity N 2 As the carrier gas, the mass flow meter is used to control the gas flow, and the valve is used to control the pumping speed of the vacuum pump to control the pressure of the furnace. During the reaction, the carrier gas flow rate is controlled at 80SCCM, the furnace pressure is controlled at 80Pa, and the temperature of the tube furnace is raised to the reaction temperature of 420°C. At this time, the temperature of the raw material is 150°C. When the furnace temperature reaches the required temperature, the furnace temperature is controlled at the reaction temperature for 20 minutes. . After slowly cooling down to room temperature, the template loaded with cadm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com