Pressing device and method of full-automatic magnetic powder molding press

A magnetic powder, fully automatic technology, applied in the field of the pressing device of the automatic magnetic powder molding press, can solve the problems of low qualified rate of magnet blank molding, narrow particle diameter distribution, and lack of precise and rigorous elaboration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

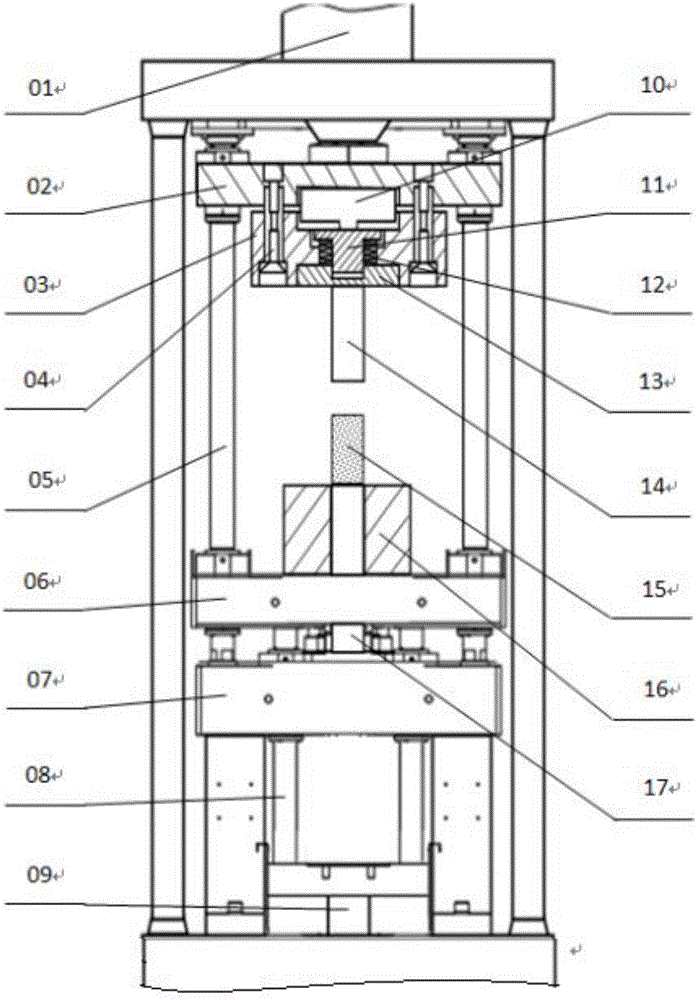

[0041] see figure 1 , the invention discloses a pressing device of a fully automatic magnetic powder powder molding press, which includes a press frame, the two ends of which are respectively the top plate of the frame and the table top of the frame, and an upper mold that releases and maintains pressure in a small amount device, lower mold device and guide post frame transmission mechanism;

[0042] The micro-release pressure holding device of the upper mold includes an upper template 02 and a pressure-holding installation module 03; the upper template 02 is provided with an upper template cavity with an opening downward, and a sensor 10 is arranged in the upper template cavity; The press installation module 03 has a stepped cavity that penetrates up and down. The lower part of the stepped cavity is packaged with a mounting plate 13, and a guide push rod 11 and a spring are slidably embedded inside it; the spring 12 is sleeved on the guide push rod 11, the upper end of the g...

Embodiment 2

[0059] see Figure 2 to Figure 5 , a method for manufacturing a magnet blank capable of controlling pressure holding and pressure release in a small amount, which includes the step of manufacturing a magnet blank by using the above-mentioned pressing device of a full-automatic magnetic powder powder molding press.

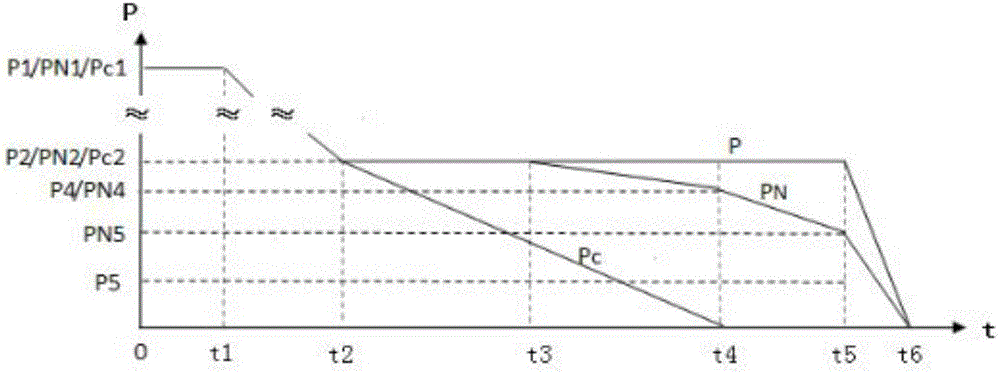

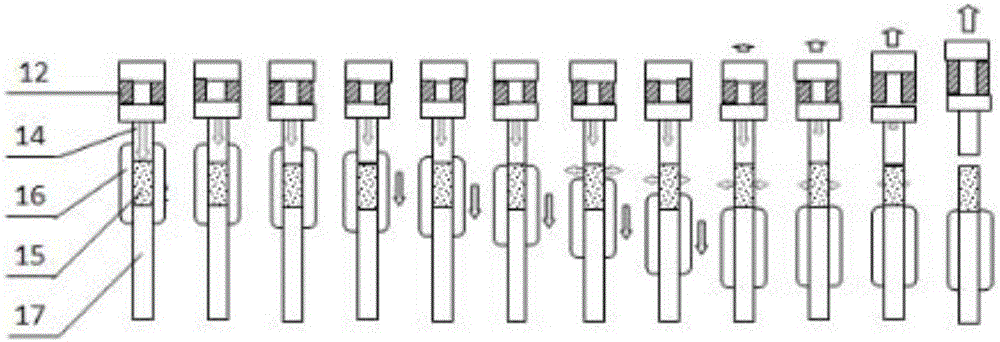

[0060] Further, it includes the steps of secondary pressure maintaining and three small releases of pressure; specifically, firstly, under the control of the automatic PCL program, the switch button of the control box is activated, and under the action of the power source of the lower cylinder 09, the lower template 06 carries the lower Yin The mold 16 rises, and the mandrel 17 of the lower mold comes out to form the required mold cavity depth; secondly, a certain amount of magnetic powder is added to the mold cavity of the lower female mold 16 through the automatic feeding device, and the polarity of the magnetic powder is arranged under the radiation of the set ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com